Preparation method of organic-inorganic composite photochromic film material

A photochromic, inorganic composite technology, used in optics, optical components, nonlinear optics, etc., can solve the problems of poor flexibility, high temperature resistance, poor chemical stability, etc., to achieve good wear resistance, high mechanical strength, good The effect of thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

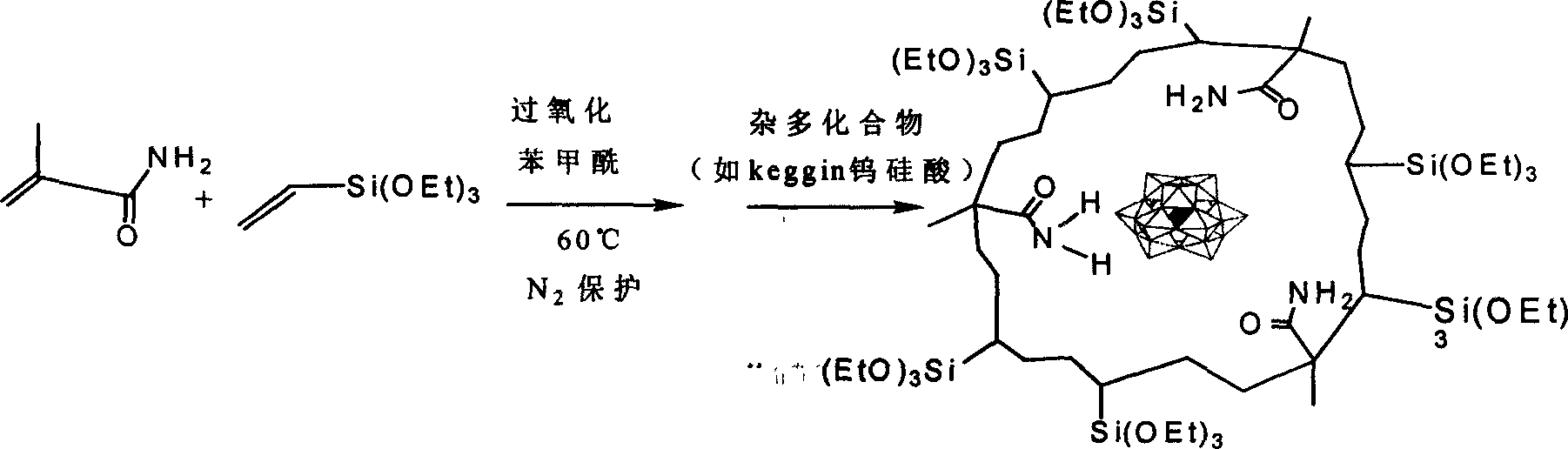

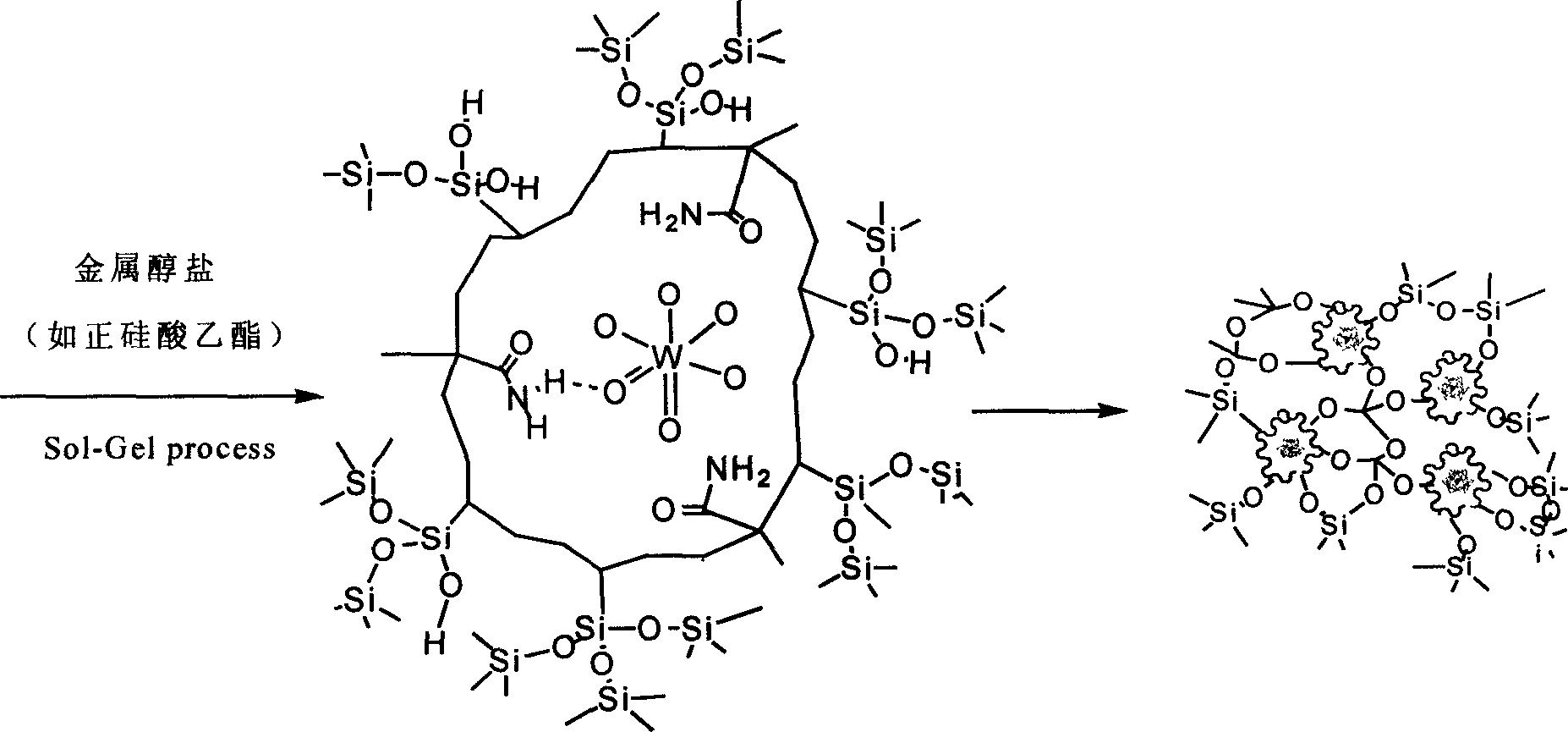

Method used

Image

Examples

Embodiment 1

[0019] Dissolve commercial or self-made keggin structure tungstosilicic acid in absolute ethanol to a concentration of 0.5mol L -1 The solution. Dissolve methacrylamide in a mixed solution of toluene and chloroform with a volume ratio of 2:1, and then add vinyltriethoxysilane. Put this mixed solution under the protection of nitrogen, heat the oil bath at a constant temperature of 70°C, then add 0.5% benzoyl peroxide, keep stirring at a high speed, and then add the above-mentioned ethanol solution of tungstosilicate; after the reaction reaches a certain level, add Ethyl orthosilicate, heated in a water bath at 50°C, stirred evenly, then added a mixed solution of water and ethanol drop by drop, keeping H 2 O:Si=4:1, constant temperature for 2 hours. Fix the substrate of quartz glass (or other materials) on the spin coater, drop the colorless and transparent sol on the substrate, control the speed of 1500rpm, rotate for 30 seconds, so that the sol is evenly coated on the substr...

Embodiment 2

[0021] Dissolve commercial or self-made keggin-structure phosphotungstic acid in absolute ethanol to a concentration of 0.5mol L -1 The solution. Dissolve methacrylamide in a mixed solution of toluene and chloroform with a volume ratio of 2:1, and then add vinyltriethoxysilane. Put this mixed solution under the protection of nitrogen, heat it in an oil bath at 70°C, add 0.5% benzoyl peroxide, keep stirring at a high speed, then add the above-mentioned ethanol solution of phosphotungstic acid; Heat in a water bath and stir evenly, then gradually add a mixed solution of water and ethanol dropwise to keep the H 2 O:Si=4:1, stirring at constant temperature for 30 minutes; then adding butyl titanate, in order to prevent the rapid hydrolysis of butyl titanate, add diethanolamine for complexation. Control H at the beginning 2 O:Ti=2:1, gradually reaching 4:1. According to the content of Ti, the obtained sol changes from colorless to orange-red. Fix the substrate of quartz glass ...

Embodiment 3

[0023] Dissolve commercial or self-made keggin structure phosphomolybdic acid in absolute ethanol to a concentration of 0.5mol L -1 The solution. Dissolve methacrylamide in a mixed solution of toluene and chloroform with a volume ratio of 2:1, and then add vinyltriethoxysilane. Put this mixed solution under the protection of nitrogen, heat the oil bath at a constant temperature of 70°C, then add 0.5% benzoyl peroxide, and keep stirring at a high speed, then add the above-mentioned ethanol solution of phosphomolybdic acid; Heat in a water bath at 50°C and stir evenly, then gradually add a mixed solution of water and ethanol dropwise to keep the H 2 O:Si=4:1, stirred at constant temperature for 30 minutes. Then add isopropyl zirconate, in order to prevent rapid hydrolysis of isopropyl zirconate, add ethyl acetoacetate for complexation. Control H at the beginning 2 O:Zr=2:1, gradually reaching 4:1. Fix the substrate of quartz glass (or other materials) on the spin coater, dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com