Biology method for synthesizing beta alanine

A technology of biosynthesis and alanine, applied in the field of biosynthesis of β-alanine, can solve the problems of high cost and environmental pollution, and achieve the effect of low cost, high product purity and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Example 1: Biosynthesis of β-alanine

[0041] Seed medium: corn steep liquor 1.1 g, MgSO 4 .7H 2 O 0.02g, KH 2 PO 4 0.1g, sodium chloride 0.145g, beef extract 0.5g, water 100mL, sterilized at 121°C for 20min, acrylic acid 0.8g, sodium hydroxide adjusted to pH 7.0;

[0042] Fermentation medium: corn steep liquor 1.1g, MgSO 4 .7H 2 O 0.02g, KH 2 PO 4 0.1g, sodium chloride 0.145g, water 100mL, sterilized at 121°C for 20min, acrylic acid 0.8g, sodium hydroxide adjusted to pH 7.0;

[0043] Conversion solution: acrylic acid 15g, MgSO 4 .7H 2 O 0.11g, ammonia water to adjust pH to 7.5, and 0.2M phosphate buffer to make up to 500mL.

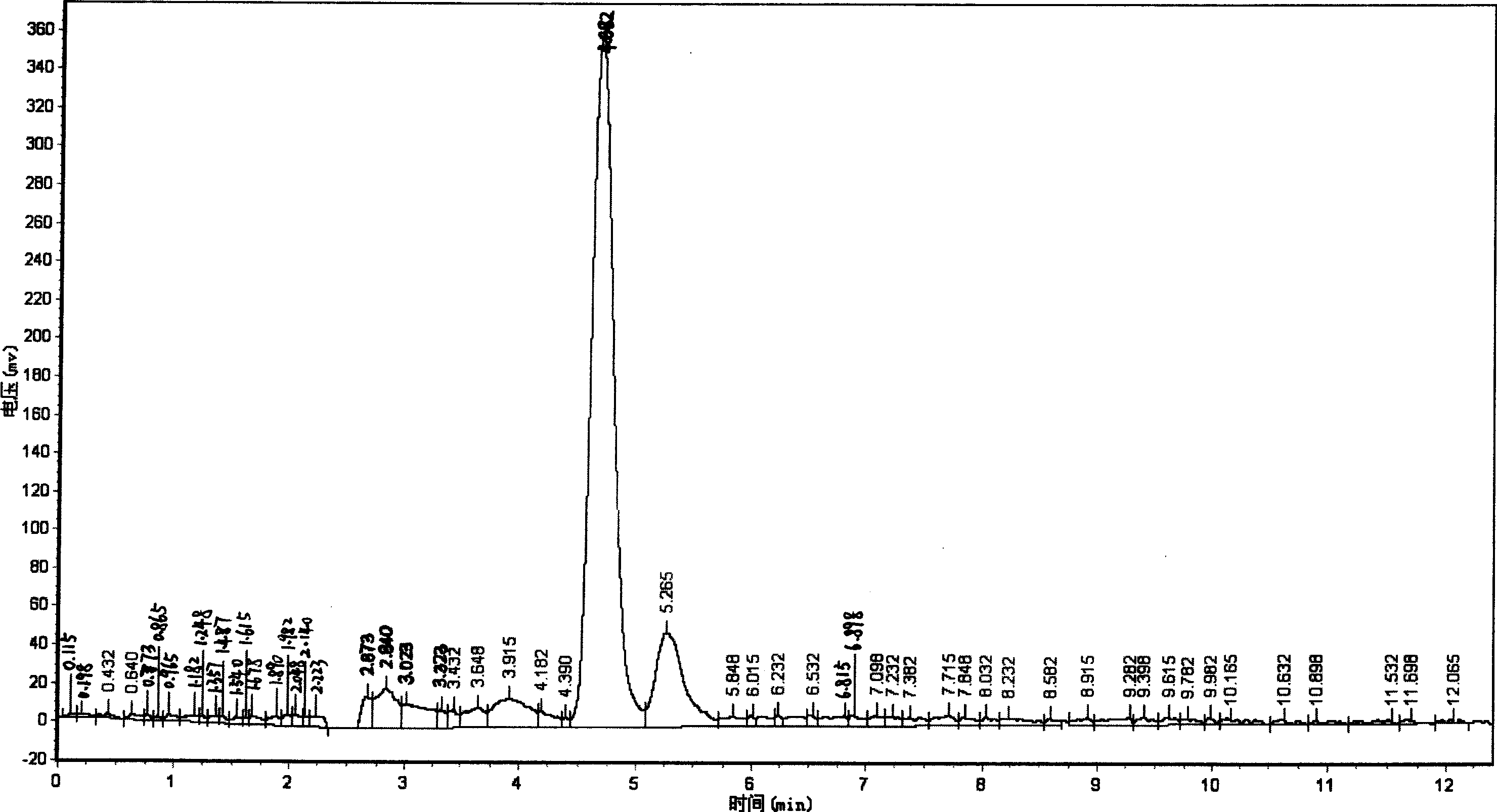

[0044] S. luteus slant strain was inserted into the seed medium, 200r / min, 30 ℃ shaking for 24h. 20% of the inoculum was transferred to the fermentation medium, and cultured at 30° C., 200 r / min on a shaker for 18 hours to obtain a fermentation broth. The fermentation broth is added to the transformation solution at a rate of 50%. Th...

Embodiment 2

[0045] Example 2: Biosynthesis of β-alanine

[0046] Seed medium: corn steep liquor 0.5g, MgSO 4 .7H 2 O 0.02g, KH 2 PO 4 0.05g, sodium chloride 0.10g, beef extract 0.8g, water 100mL, sterilized at 121°C for 20min, acrylic acid 0.08g, hydrochloric acid to adjust pH to 6.5;

[0047] Fermentation medium: corn steep liquor 0.5g, MgSO 4 .7H 2 O 0.02g, KH 2 PO 4 0.05g, sodium chloride 0.10g, water 100mL, sterilized at 121°C for 20min, acrylic acid 0.08g, adjusted to pH 6.5 with hydrochloric acid; transformation solution: acrylic acid 10g, MgSO 4 .7H 2 O 0.10g, ammonia water to adjust pH to 4.8, and 0.2M acetate buffer to make up to 500mL.

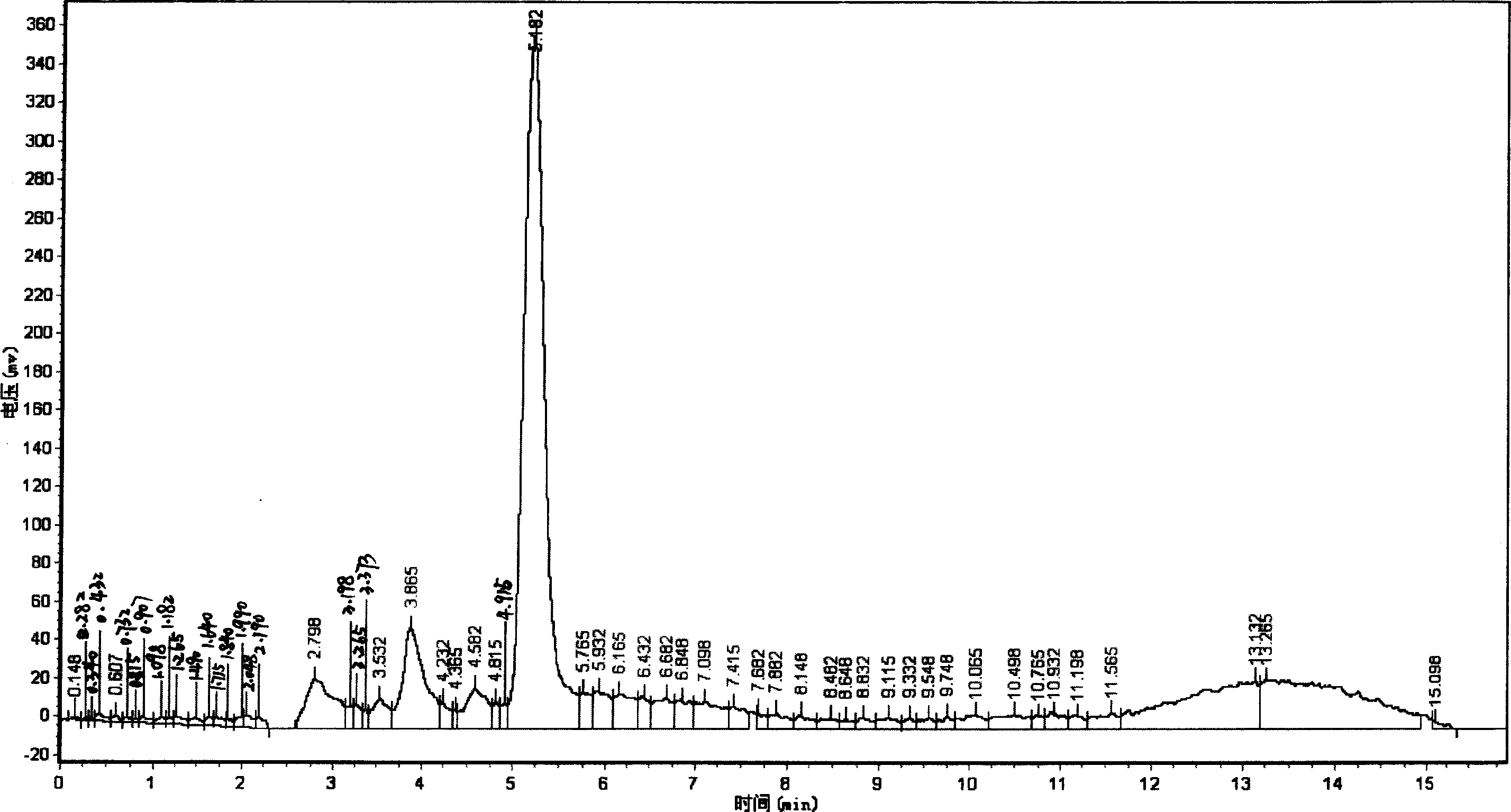

[0048] S. luteus slant strains were inserted into the seed medium, 100 r / min, and cultured on a shaker at 25°C for 20 h. 15% of the inoculum was transferred to the fermentation medium, and cultured at 25°C with a shaker at 100 r / min for 16 hours. The fermentation broth was added to the transformation solution at a ratio of 40%, the ...

Embodiment 3

[0049] Example 3: Biosynthesis of β-alanine

[0050] Seed medium: corn steep liquor 1.8g, MgSO 4 .7H 2 O 0.02g, KH 2 PO 4 0.05g, sodium chloride 0.45g, beef extract 6.5g, water 100mL, sterilized at 121°C for 20min, acrylic acid 7.5g, hydrochloric acid to adjust pH to 5.5;

[0051] Fermentation medium: corn steep liquor 1.8g, MgSO 4 .7H 2 O 0.02g, KH 2 PO 4 0.05g, sodium chloride 0.45g, water 100mL, sterilized at 121°C for 20min, acrylic acid 7.5g, and hydrochloric acid adjusted to pH 5.5;

[0052] Conversion solution: acrylic acid 200g, MgSO 4 .7H 2 O 0.12g, ammonia water to adjust pH6.0, 0.1M citric acid buffer solution to 500mL.

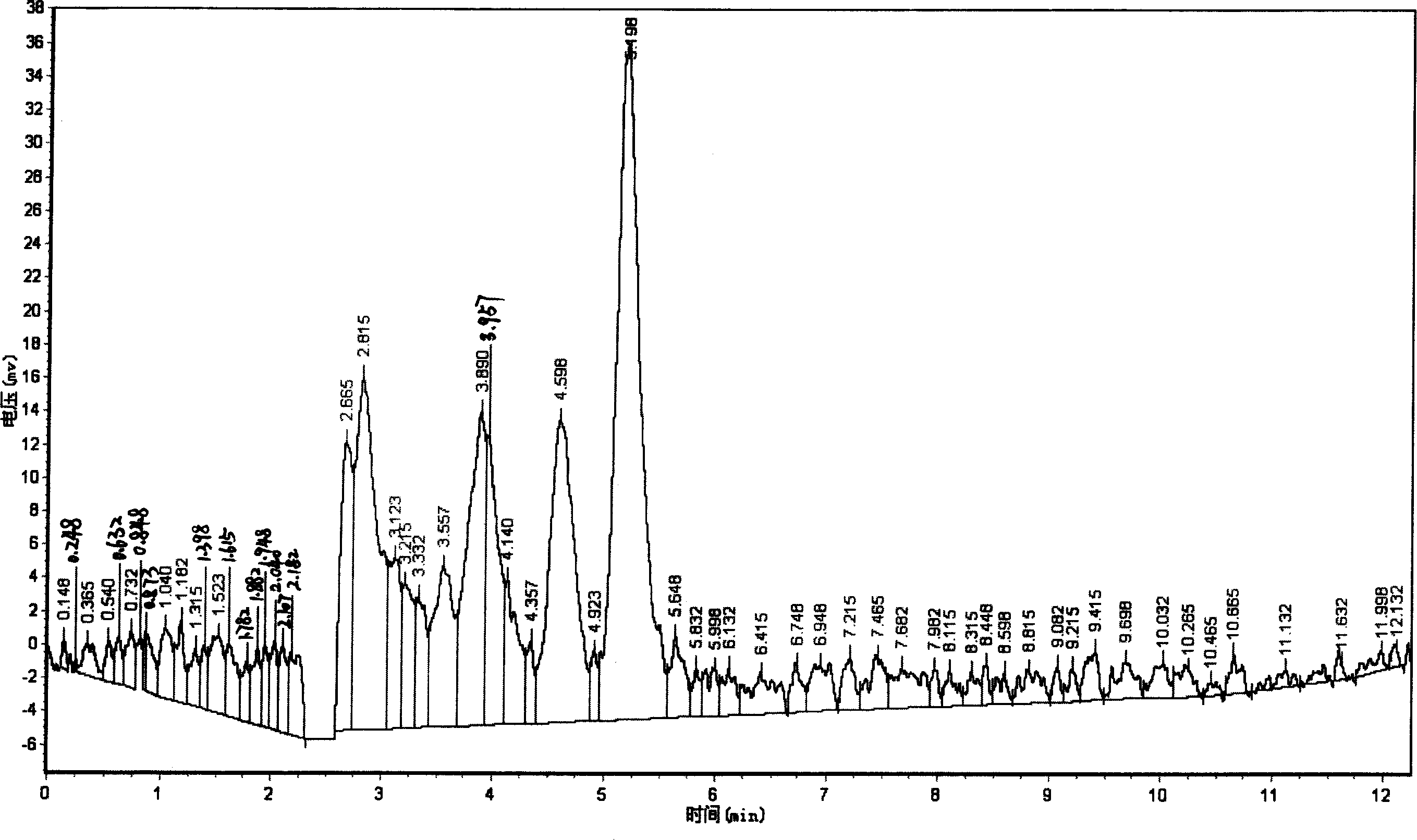

[0053] Escherichia coli slant strains were inserted into the seed medium, and incubated at 300 r / min at 55 °C for 18 h on a shaker. 15% of the inoculum was transferred to the fermentation medium, and cultured at 55° C., 300 r / min on a shaker for 16 hours. The fermentation broth was added to the transformation solution at a rate of 50%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com