Acrylic fiber-crosslinking plant protein composite fiber and method for manufacturing the same

A composite fiber and plant protein technology, applied in the direction of cellulose/protein conjugated artificial filament, fiber treatment, conjugated synthetic polymer artificial filament, etc., can solve the problems affecting the affinity between fiber and skin, hygroscopicity, fiber Problems such as not being resistant to washing, poor hydrophilicity, etc., to overcome static electricity and poor human affinity, solve the effects of not being resistant to washing, and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Soybean cake was mixed with 10 times its weight of water, soaked at 30°C for 8 hours, and insoluble polysaccharide residues were separated, and these residues were mixed with water at a weight ratio of 1:12, soaked for 1 hour, and the supernatant was taken. The two parts of the solution were combined and the pH value of the solution was adjusted to 4.4 with acetic acid and allowed to stand for 2 hours for acid precipitation. The obtained protein was centrifuged and dehydrated so that its water content was 30% (by weight).

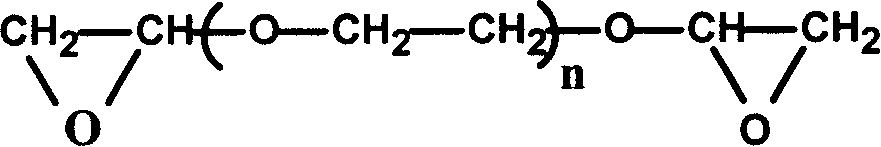

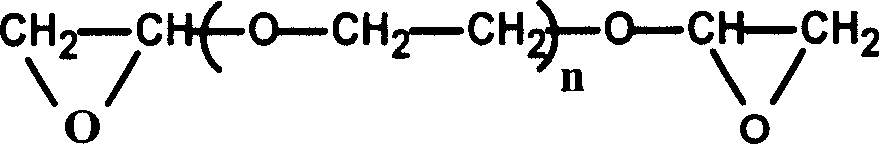

[0030] The above protein is dissolved in a sodium thiocyanate solution with a weight concentration of 30%, so that the protein weight concentration is 10%, and then compounded with the acrylic fiber slurry and the protein solution in a weight ratio of 1:4, and the crosslinking agent is double-shrunk. Glycerin glycol ether is added by 0.5% of solvent weight, and the spinning slurry prepared is left to stand for 12h for defoaming;

[0031] The spinnin...

Embodiment 2

[0033] Sunflower meal and sodium hydroxide solution with a pH value of 8.8 were mixed at a weight ratio of 1:8, soaked at room temperature for 2 hours, and the insoluble polysaccharide residue was separated. The sodium hydroxide solution was mixed in a weight ratio of 1:9, soaked for 1 hour to get the supernatant. The two parts of the solution were combined and the pH value of the solution was adjusted to 4.6 with hydrochloric acid and allowed to stand for 2 hours for acid precipitation. The obtained protein was centrifuged and dehydrated so that its water content was 25%.

[0034] This albumen is dissolved in the zinc chloride solution that weight concentration is 17%, and its protein weight concentration is 10%, and fiber grade polyacrylonitrile is dissolved in the zinc chloride solution that weight concentration is 16%, and protein solution and poly The acrylonitrile slurry is compounded according to the weight ratio of 1:5, and the crosslinking agent glycidyl ether is add...

Embodiment 3

[0037] Peanut cake and hydrochloric acid solution with a pH value of 6.8 are mixed in a weight ratio of 1:9, kept at 50°C for 30 minutes, the insoluble residue is separated, and the residue and water are mixed in a weight ratio of 1:10, soaked at 50°C for 30 minutes minutes, the supernatant was separated. The two parts of the solution were combined and the pH of the solution was adjusted to 4.3 with acetic acid and allowed to stand for 1.5 hours for acid precipitation. The obtained protein was centrifuged and dehydrated so that its water content was 20%.

[0038] Dissolve the above protein in dimethylformamide, adjust the protein weight concentration to be 10%, dissolve fiber-grade polyacrylonitrile in dimethylformamide, and mix the protein solution and polyacrylonitrile solution in a weight ratio of 1:4.5. Prepared, the cross-linking agent diglycidyl butanediol ether is added according to 0.4% of the weight of the solvent, and the spinning slurry is left to stand for defoami...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com