Method for preparing solvent-free low-viscosity UV-cured polyurethane acrylate leather coating agent

A polyurethane acrylate, leather finishing agent technology, applied in polyurea/polyurethane coatings, devices for coating liquid on surfaces, coatings, etc., can solve problems such as affecting the use of coatings, danger, and gel time reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

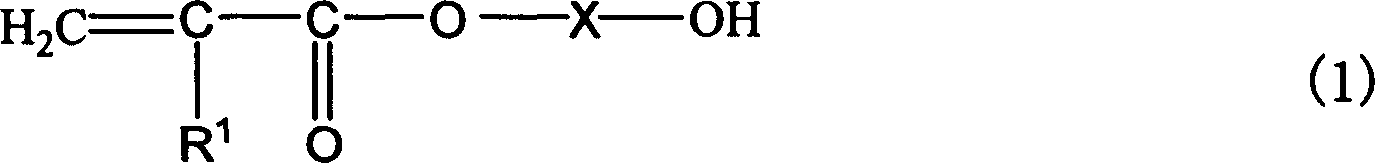

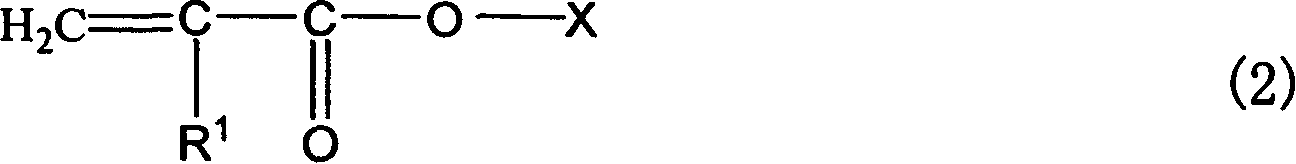

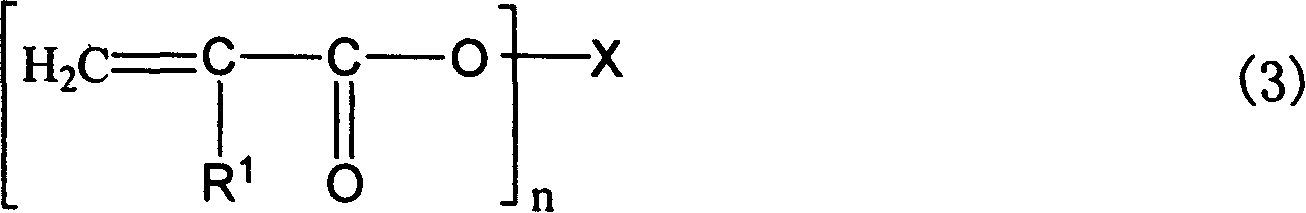

Method used

Image

Examples

Embodiment 1

[0042] Add 46.5 grams of hydroxyethyl acrylate (accounting for 10.03% of the total mass), 0.3 grams of 2,6-di-tert-butyl -4-Methylphenol (0.065% of the total mass) was used as a polymerization inhibitor, stirred and heated to 50°C, and then 70 grams of toluene diisocyanate (15.09% of the total mass) was added to the system, and the reaction started. Measure the content of isocyanate in the system by the di-n-butylamine method, after the hydroxyl and isocyanate in the system reacted for 2 hours, add 200 grams of polyethylene glycol (average molecular weight 1000) (accounting for 43.12% of the total mass) , continue stirring. Within 2 hours, add 3 grams of catalyst triethylamine (accounting for 0.647% of the total mass) in 4 times on average, each time you will find that the temperature of the system rises by 1 to 2°C in 5 minutes, and after 5 to 10 minutes , the temperature slowly dropped back to 50°C. After the second step reaction was carried out for 6 to 7 hours, the react...

Embodiment 2

[0047] Add 57.6 grams of hydroxypropyl methacrylate (accounting for 16.27% of the total mass), 1.5 grams of nitrobenzene (accounting for total mass) 0.424% of the mass) as a polymerization inhibitor, stirred and heated to 50°C, then added 100 grams of 4,4'-diphenylmethane diisocyanate (accounting for 28.24% of the total mass) to the system, and the reaction started. The content of isocyanate in the system was measured by the di-n-butylamine method. After the reaction of hydroxyl groups and isocyanate in the system for 2 hours, 25 grams of ethylene glycol (accounting for 7.06% of the total mass) were added, and the stirring was continued. Within 2 hours, add 4 grams of catalyst triethylamine (accounting for 1.13% of the total mass) in 4 times on average, each time you will find that the temperature of the system increases by 2 to 3°C in 5 minutes, and after 5 to 10 minutes , the temperature slowly dropped back to 50°C. After the second step reaction was carried out for 6 to 7 ...

Embodiment 3

[0052] Add 52 grams of hydroxypropyl acrylate (9.49% of the total mass), 0.07 grams of 2,6-di-tert-butyl in the polymerization reactor equipped with nitrogen inlet, thermometer socket, stirrer socket, sampling port and condenser socket - 4-methylphenol (0.0128% of the total mass) was used as a polymerization inhibitor, stirred and heated to 30°C, and then 89 grams of isophorone diisocyanate (16.24% of the total mass) was added to the system to start the reaction. Measure the content of isocyanate in the system by the di-n-butylamine method. After the hydroxyl group in the system reacted for 2 hours with the isocyanate all reacted, add 300 grams of polypropylene glycol (average molecular weight 1500) (accounting for 54.74% of the total mass), continue Stir. The temperature was raised to 50° C., and within 2 hours, 4 grams of catalyst triethylamine (accounting for 0.730% of the total mass) was continuously added, and the temperature of the system was kept at 50° C. throughout. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com