Interferon spray for lung administration and its prepn process

A technology for pulmonary drug delivery and interferon, which can be used in pharmaceutical formulations, aerosol delivery, medical preparations containing active ingredients, etc. To achieve the effect of convenient medication, large dosage, high chemical stability and microbial stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] This example describes a method for preparing highly active interferon spray-dried powder by adding lecithin as an active protective agent.

[0053] Used as the liquid phase for spray drying, its composition is: citric acid 0.38mg / ml, disodium hydrogen phosphate 3.8mg / ml, soybean lecithin 1.34mg / ml, lactose 66.7mg / ml, and each milliliter emulsion contains interferon α-2b is about 40,000 international units, and the measured pH value of the solution is 7.05. Gained emulsion is spray-dried with Buchi minispray dryer B-191 (the same below, no longer mentioned), and the spray conditions are as follows:

[0054] Solution temperature 6°C-8°C

[0055] Inlet temperature 110℃

[0056] Outlet temperature 70°C-80°C

[0057] Nozzle air flow rate 500l / h

[0058] Spray speed 1.8ml / min

[0059] Once the solution is sprayed, reduce the inlet temperature to maintain the outlet temperature at about 60°C-70°C for about 10 minutes, and perform secondary drying on the interferon spray-...

Embodiment 2

[0063] This example describes a method for preparing highly active interferon spray-dried powder by adding HPCD as an active protective agent.

[0064] Used as the liquid phase for spray drying, its composition is: citric acid 0.076mg / ml, sodium citrate 1.8mg / ml, disodium hydrogen phosphate 0.76mg / ml, HPCD 0.67mg / ml, lactose 66.7mg / ml, Each milliliter of the solution contains about 200,000 international units of interferon alpha-2a, and the measured pH value of the solution is 6.92.

[0065] The spray conditions are as follows:

[0066] Solution temperature 4°C-6°C

[0067] Inlet temperature 110℃

[0068] Outlet temperature 60°C-70°C

[0069] Nozzle nitrogen flow rate 570l / h

[0070] Spray speed 2.1ml / min

[0071] Spray Gun Condensation System On

[0072] Once the solution is sprayed, reduce the inlet temperature to maintain the outlet temperature at about 60°C-70°C for about 10 minutes, and perform secondary drying on the interferon spray-dried powder to further reduce ...

Embodiment 3

[0076] This example describes a method for preparing highly active interferon spray-dried powder using lysine as a stabilizer.

[0077] Used as the liquid phase for spray drying, its composition is: 0.38mg / ml citric acid, 3.8mg / ml disodium hydrogen phosphate, 0.67mg / ml lysine, 66.7mg / ml lactose, and interferon per milliliter emulsion α-2a is about 40,000 international units, and the measured pH value of the solution is 6.81.

[0078] The spray conditions are as follows:

[0079] Solution temperature 7℃-9℃

[0080] Inlet temperature 110℃

[0081] Outlet temperature 60°C-70°C

[0082] Nozzle air flow rate 500l / h

[0083] Spray speed 1.8ml / min

[0084] Once the solution is sprayed, reduce the inlet temperature to maintain the outlet temperature at about 60°C-70°C for about 10 minutes, and perform secondary drying on the interferon spray-dried powder to further reduce the water content.

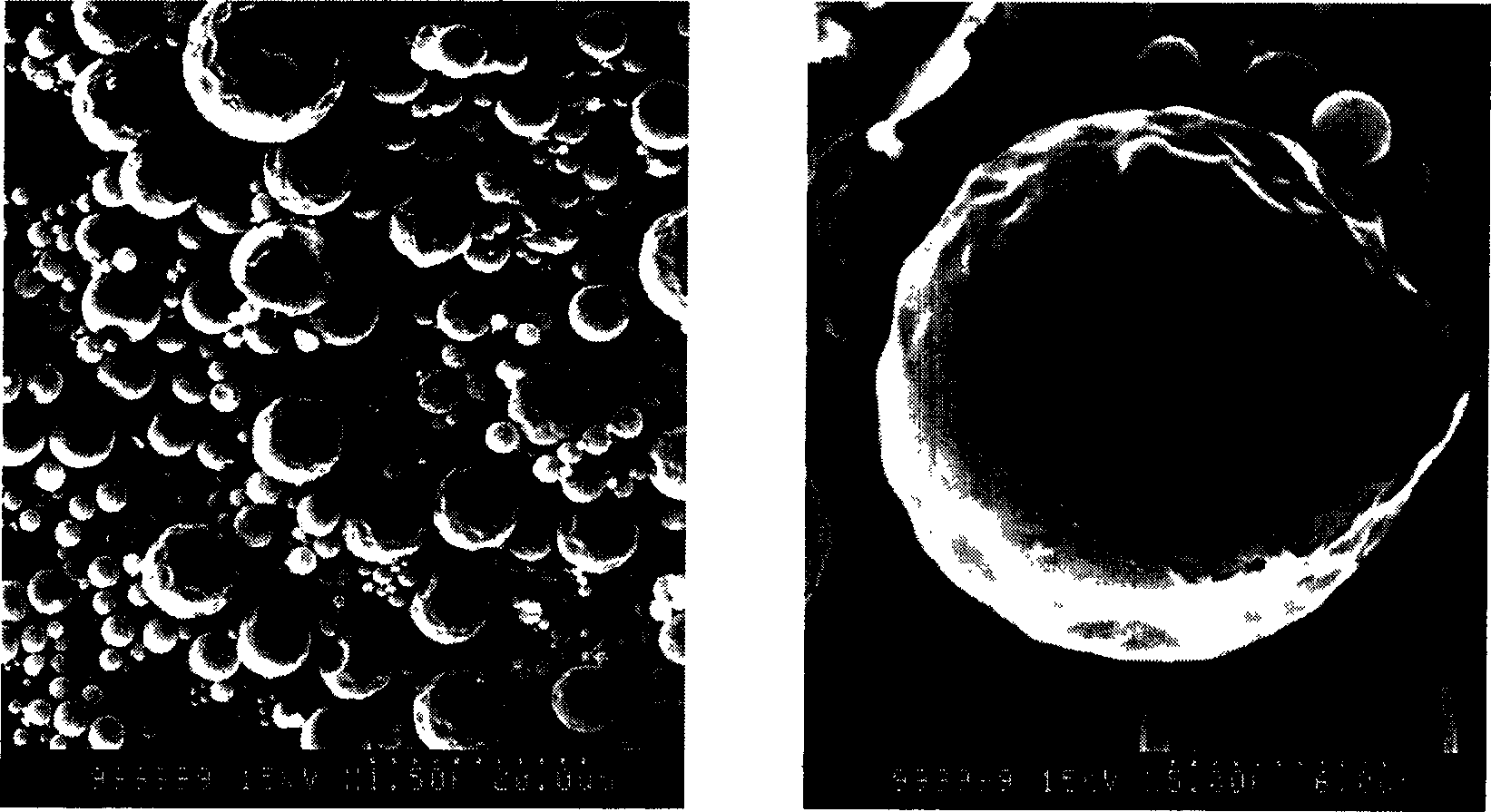

[0085] Spray-dried powder form: see image 3 . It can be seen from the figure that th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com