Tilmicosin enteric-coated pellets and preparation method thereof

A technology of tilmicosin and enteric-coated pellets, which is applied in the field of tilmicosin enteric-coated pellets and its preparation, can solve problems such as the taste-masking problem not involved in tilmicosin, and achieve good drug efficacy and high biological efficacy. Utilization, effects of avoiding impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

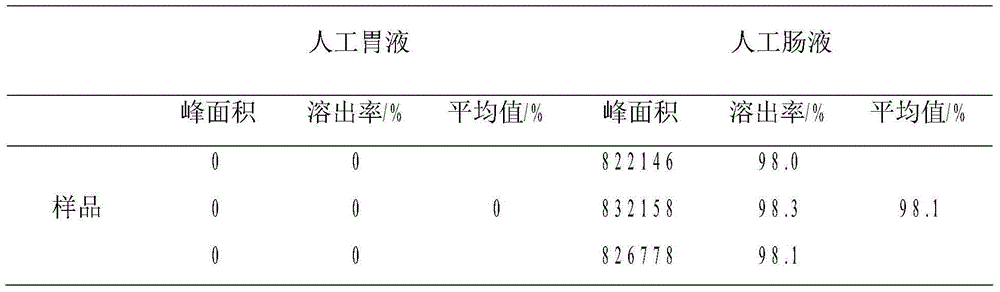

[0034] The preparation method of tilmicosin enteric-coated pellets of the present invention comprises:

[0035] The first step is to mix tilmicosin, poloxamer 188 and microcrystalline cellulose evenly, and then mix them with purified water at a solid-liquid weight ratio of 0.9-1.1:1 to obtain a soft material; The material is extruded and spheronized by a spherical extruder and a spheronizer, and then dried to obtain a pellet core; the pellet core is composed of the following components by weight percentage: tilmicosin 20-60%, poloxane Mu 1885-35%, microcrystalline cellulose 20-75%;

[0036] The second step is to sieve the pellet core, take the pellet core whose size is between the sieve aperture of 24 mesh sieve and the aperture of 28 mesh sieve, and set aside; make the coating liquid with the coating material and purified water ,stand-by;

[0037] The third step is to put the micropill core to be used in the fluidized bed, and to coat it with the coating liquid to form a co...

Embodiment 1

[0041] The pellet core of tilmicosin enteric-coated pellets consists of the following components by weight percentage:

[0042] Tilmicosin 30%

[0043] Poloxamer 18835%

[0044] Microcrystalline cellulose 35%;

[0045] The coating layer of tilmicosin enteric-coated pellets consists of the following components by weight percentage:

[0046] Polyacrylic resin 60%

[0047] Triethyl Citrate 10%

[0049] The weight of the coating layer accounts for 15-18% of the total weight of the tilmicosin enteric-coated pellets.

[0050] During preparation, firstly mix tilmicosin, poloxamer 188 and microcrystalline cellulose evenly, and then mix them evenly with purified water at a solid-to-liquid weight ratio of 0.9:1 to obtain a soft material; The extruder and spheronizer carry out extrusion and spheronization, and then dry to obtain the pellet core; the pellet core is sieved, and the pellets whose size is between the sieve aperture of 24 mesh sieve and the ape...

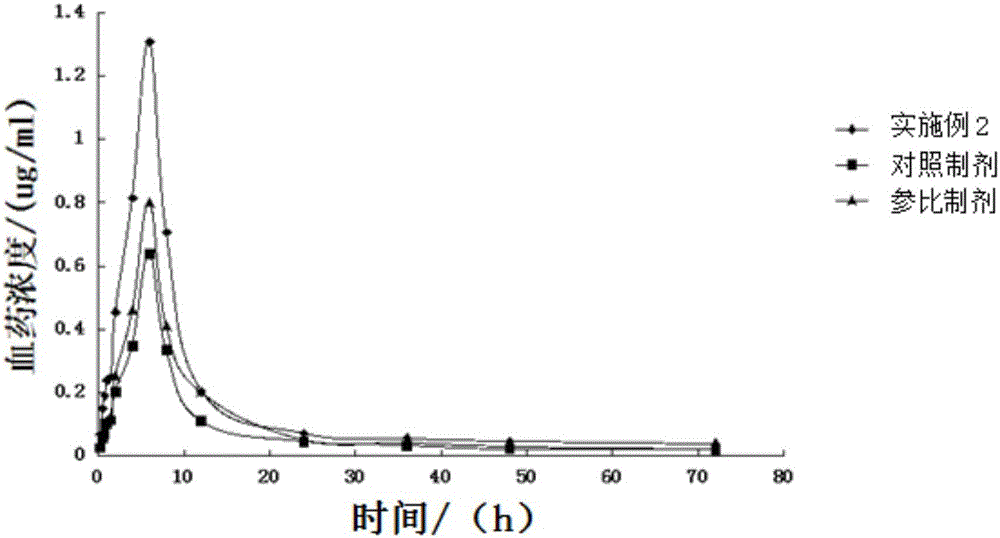

Embodiment 2

[0052] Basically the same as Example 1, the difference is:

[0053] The pellet core of tilmicosin enteric-coated pellets consists of the following components by weight percentage:

[0054] Tilmicosin 40%

[0055] Poloxamer 18815%

[0056] Microcrystalline Cellulose 45%;

[0057] The coating layer of tilmicosin enteric-coated pellets consists of the following components by weight percentage:

[0058] Hydroxypropyl Methyl Cellulose 50%

[0059] Triethyl Citrate 15%

[0060] Talc 35%;

[0061] The weight of the coating layer accounts for 18-20% of the total weight of the tilmicosin enteric-coated pellets.

[0062] During preparation, the solid-to-liquid weight ratio when making soft materials is 1:1; set the inlet air temperature of the fluidized bed to 70°C, the outlet air temperature to 50°C, and the fan frequency to 40HZ; After the bed is started, when the temperature of the pellet cores to be used reaches 50°C, spray the coating solution, and maintain the temperature o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com