Process for producing crystalline nucleus and method of screening crystallization conditions

A manufacturing method and screening method technology, applied in solution crystallization, chemical instruments and methods, single crystal growth, etc., can solve problems such as insufficient crystallization, difficult protein crystallization, etc., and achieve rapid and definite results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

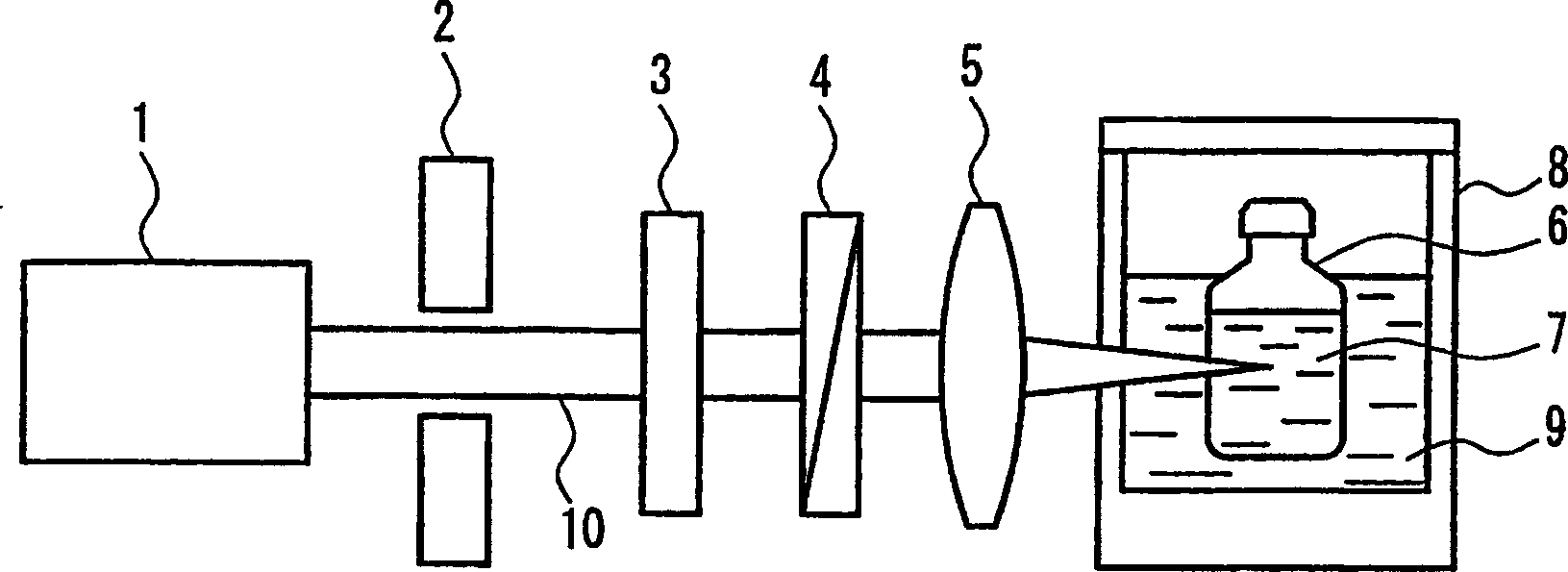

[0070]Put DAST (4-dimethylamino-N-methyl-4'-N-styrylpyridinium tosylate) 3.5g and methanol 200ml together with the rotor into a polytetrafluoroethylene container 6 with a volume of 200ml, It was heated to 55.0° C. in the constant temperature water tank 8 with an initial temperature of 27.0° C. over 2 hours, and dissolved while stirring it. After about 5 hours, it was confirmed that DAST was dissolved, and the solution 7 was divided into 3 parts, and used as a culture solution. At this point, remove the rotor. After the solution was prepared for 16 hours, it was heated at 55°C for 10 hours, followed by a 3°C drop per hour to bring the temperature down to 23°C. And drop 0.1°C per hour, bringing the temperature down to 21.4°C. In this state, the pulse energy is 250μJ / pulse (2×10 9 watts) and a repetition rate of 1 kHz to irradiate the femtosecond laser for 2 minutes. Thereafter, no crystallization was confirmed for 1 hour, and 10 hours later, crystallization was observed with...

Embodiment 2

[0072] Egg white lysozyme was used as a target for crystal nucleation. This solution was adjusted to pH 4.5 by adding 0.467 g of sodium acetate trihydrate to 50 ml of distilled water, adding acetic acid thereto, and then adding 1.25 g of sodium chloride and 1.25 g of egg white lysozyme. The aforementioned sample solution 7 adjusted to room temperature was placed in a 100 ml polytetrafluoroethylene container 6, and kept in a constant temperature water bath 8 at 40° C. for 24 hours to completely dissolve it. After that, it was cooled to 25° C. over 5 hours, and impurities were removed with a membrane filter. 2 ml of this solution and 3 ml of perfluorocarbon (Florinate) were respectively added to ten glass bottles 6 with screw caps having a diameter of 18 mm. These glass bottles 6 were kept at 25°C and left still in a constant temperature water tank 8, and the temperature of the solution was lowered to 15°C over 20 hours. The saturation point of this sample solution (lysozyme s...

reference example 1

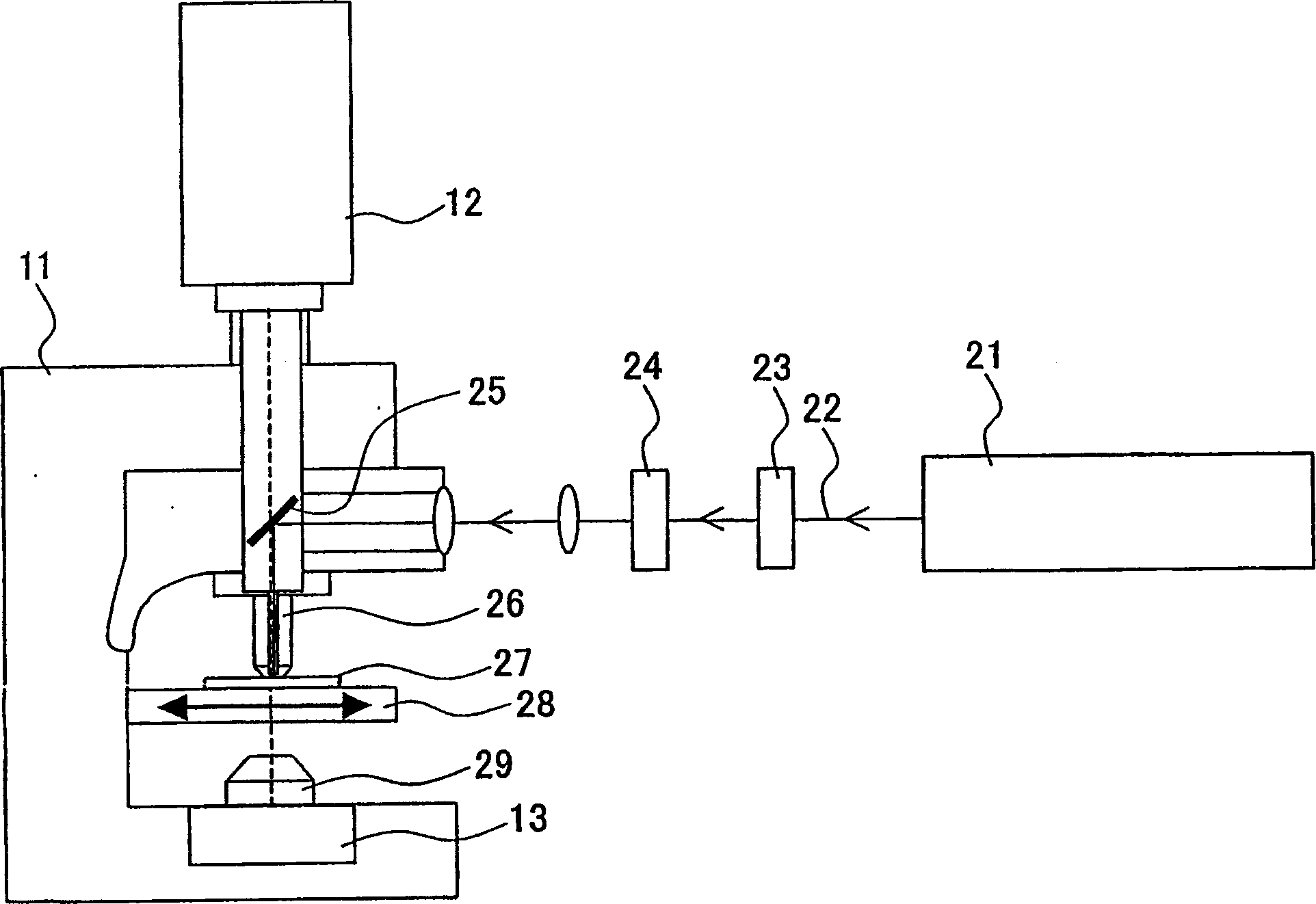

[0076] use figure 2 The shown setup investigates the shock wave generated by the explosive phenomenon using a pulsed laser. In this device, a pulsed laser irradiation device is mounted on an erecting microscope. As shown in the figure, the erect microscope 11 is provided with a stage 28 on which an object to be observed is placed, a condenser lens 29 and an objective lens (100 times, aperture number 1.25) 26, and a microchip 27 is placed on the stage 28. In addition, a light source lamp 13 is disposed below the condenser lens 29 at the lower portion of the erect microscope 11 , and a CCD camera 12 for detecting the light is disposed above the microscope 11 . In addition, a pulsed laser irradiation device 21 is arranged outside the erect microscope 11, and the laser light 22 is irradiated in the erect microscope 11 through the 1 / 2 wavelength plate 23 and the polarizer 24, and the optical path is bent at a right angle by the dichromatic mirror 25, and irradiated on the object....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com