Electron beam welding method of adding transition layer into compound between metals of titanium aluminium alloy

An intermetallic compound, electron beam welding technology, applied in electron beam welding equipment, welding equipment, metal processing equipment and other directions, can solve the problems of low mechanical strength of welded joints and easy cracking of joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

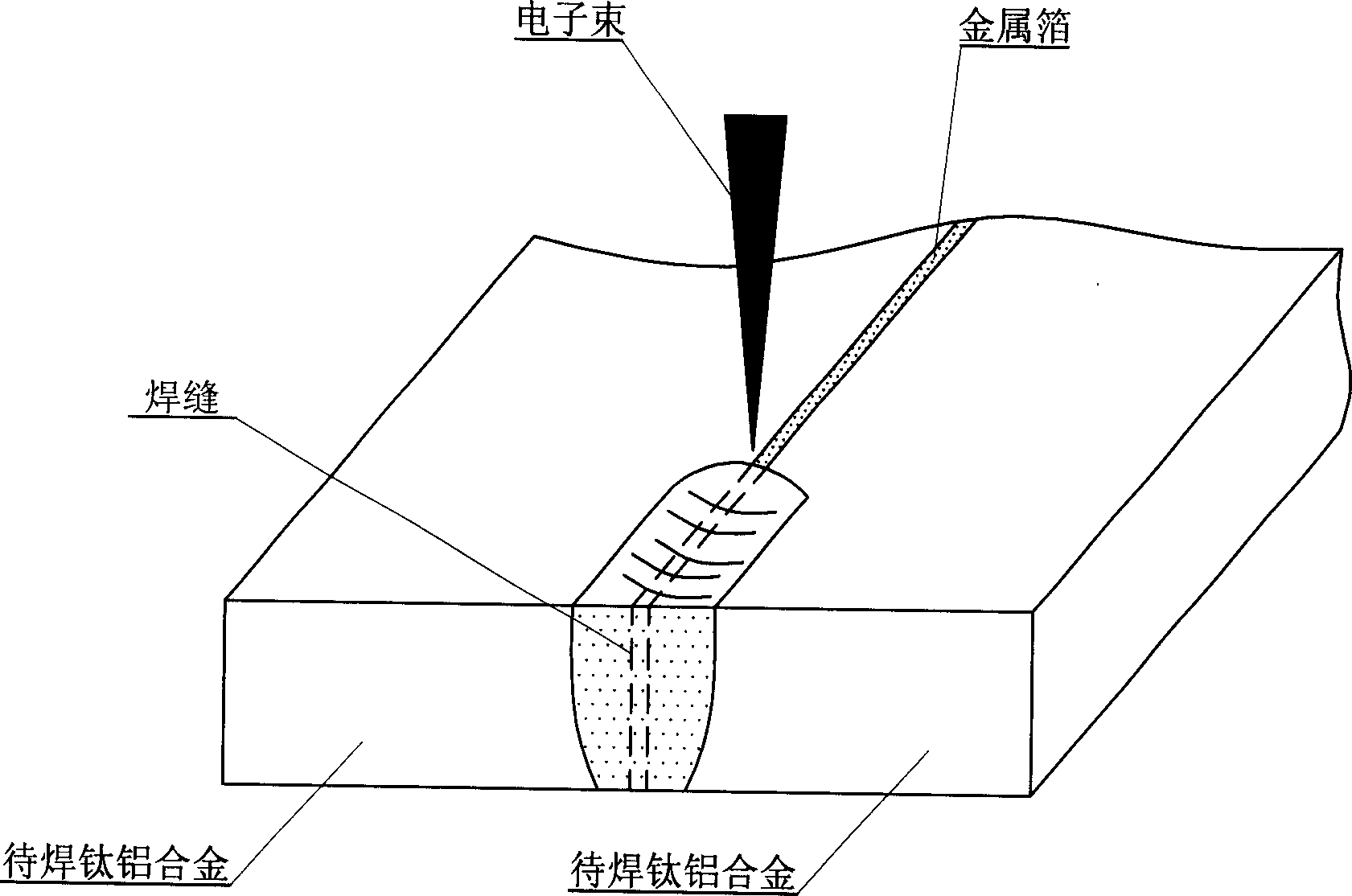

[0005] Specific implementation mode one: combine figure 1 To illustrate this embodiment, the steps of its welding method are as follows: a. Perform stress-relieving heat treatment on the titanium-aluminum alloy to be welded before welding. Physical cleaning and chemical cleaning are carried out on the surface of the welded part of the titanium-aluminum alloy and the surface of the metal foil. The thickness of the metal foil is 30 μm to 1000 μm; c. Set the metal foil between the welds and clamp it; d. 5×10 -2 Pa~5×10 -4 Under the condition of Pa, use the electron beam to scan and preheat the weld seam or defocus the preheating, the number of preheating times is 1 to 4 times; e, the vacuum degree is 5×10 -2 Pa~5×10 -4 Under the condition of Pa, the welding seam is micro-alloyed with an electron beam with a focusing current of 2500mA-2700mA, an accelerating voltage of 40kV-60kV, and an accelerating current of 10mA-30mA; f, natural cooling in situ to room temperature. The phys...

specific Embodiment approach 2

[0006] Embodiment 2: In the step b of the welding method described in Embodiment 1, the chemical composition of the metal foil is composed of one or more of titanium and β-phase stabilizing elements; the above-mentioned β-phase stabilizing elements include molybdenum, molybdenum, Chromium, vanadium, niobium or manganese.

specific Embodiment approach 3

[0007] Embodiment 3: In step d of the welding method described in Embodiment 1, the scanning waveform of the electron beam scanning preheating is a symmetrical waveform. The scanning waveform of electron beam scanning preheating can be selected as square wave or sine wave.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com