Process for preparing biological antibacterial agent

A biological antibacterial agent and seed technology, applied in the field of bioengineering, can solve the problems of ecological environment system damage, chemical control of fungal diseases and other problems, achieve the effects of crop and environmental safety, increase the yield of antipeptide, and simple nutritional requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

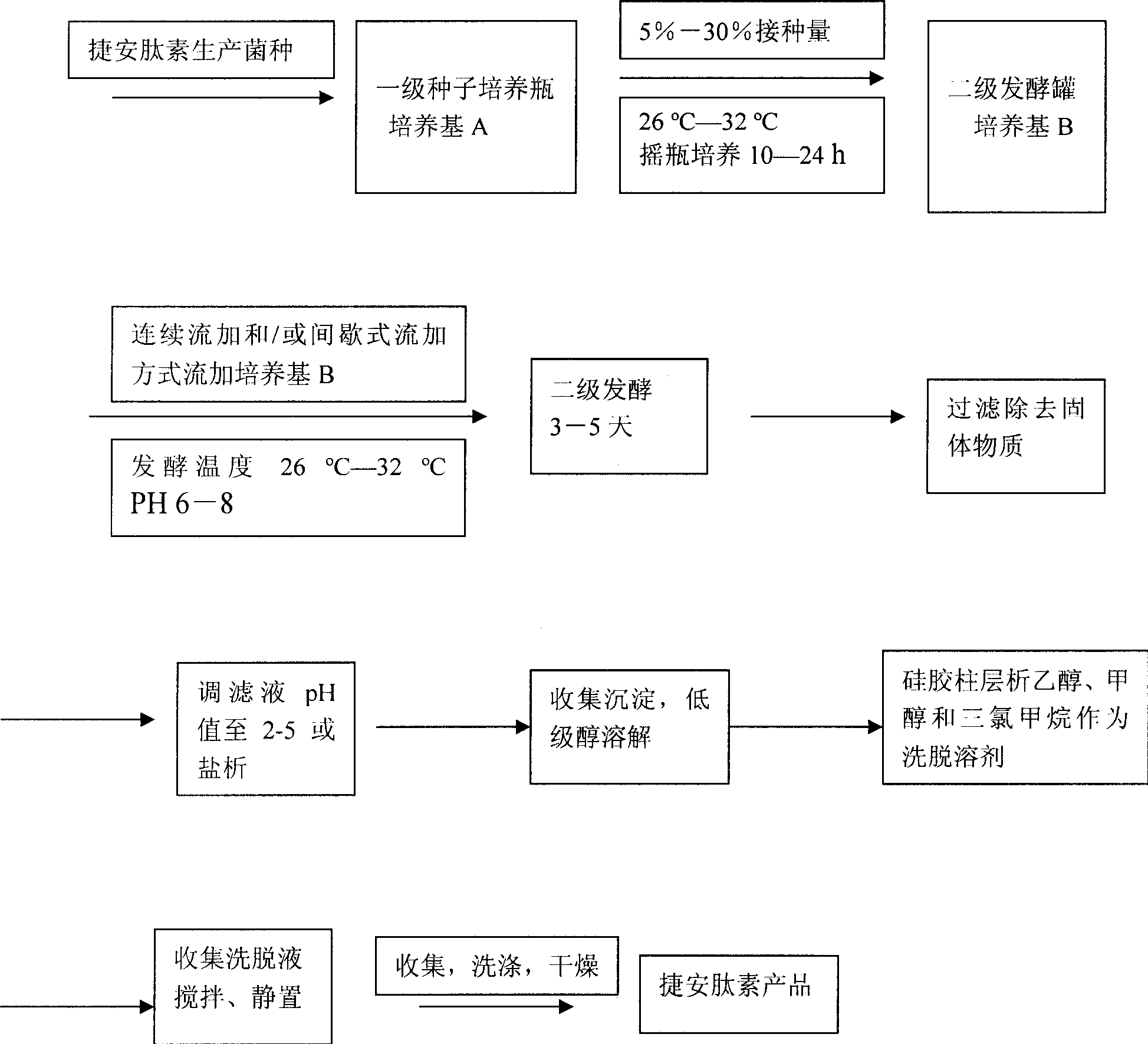

Method used

Image

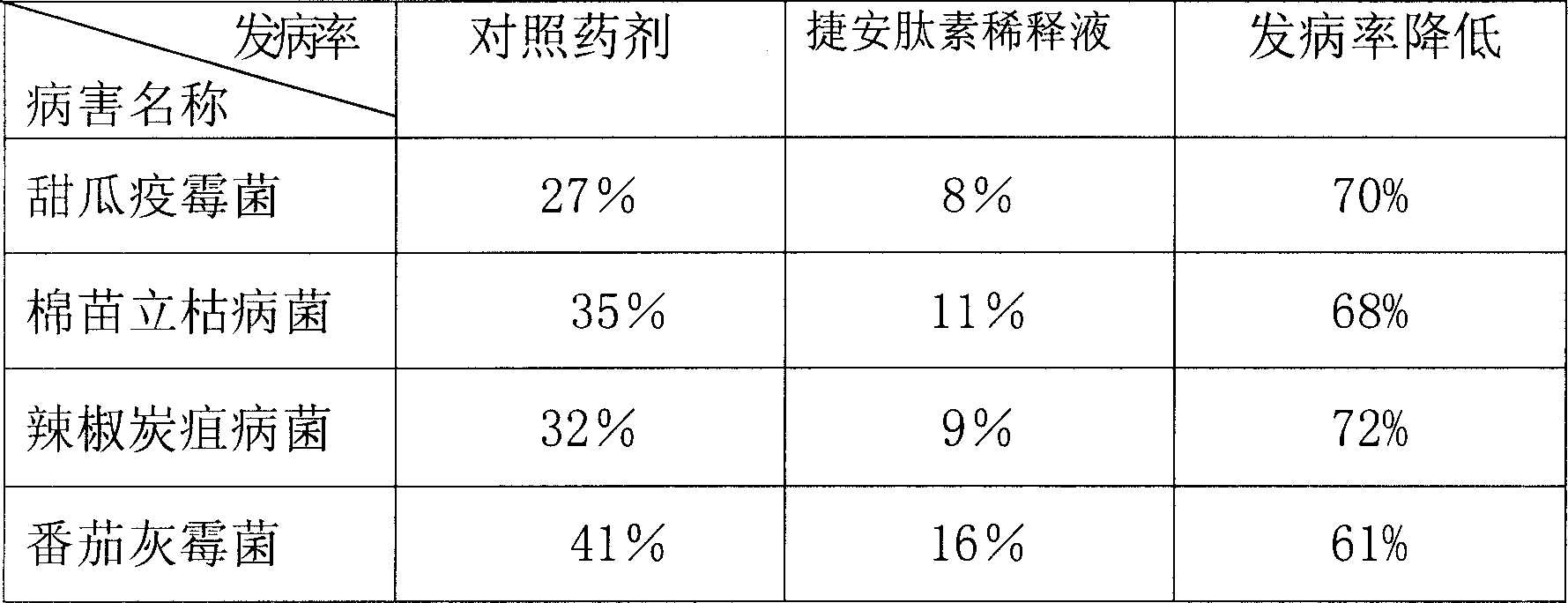

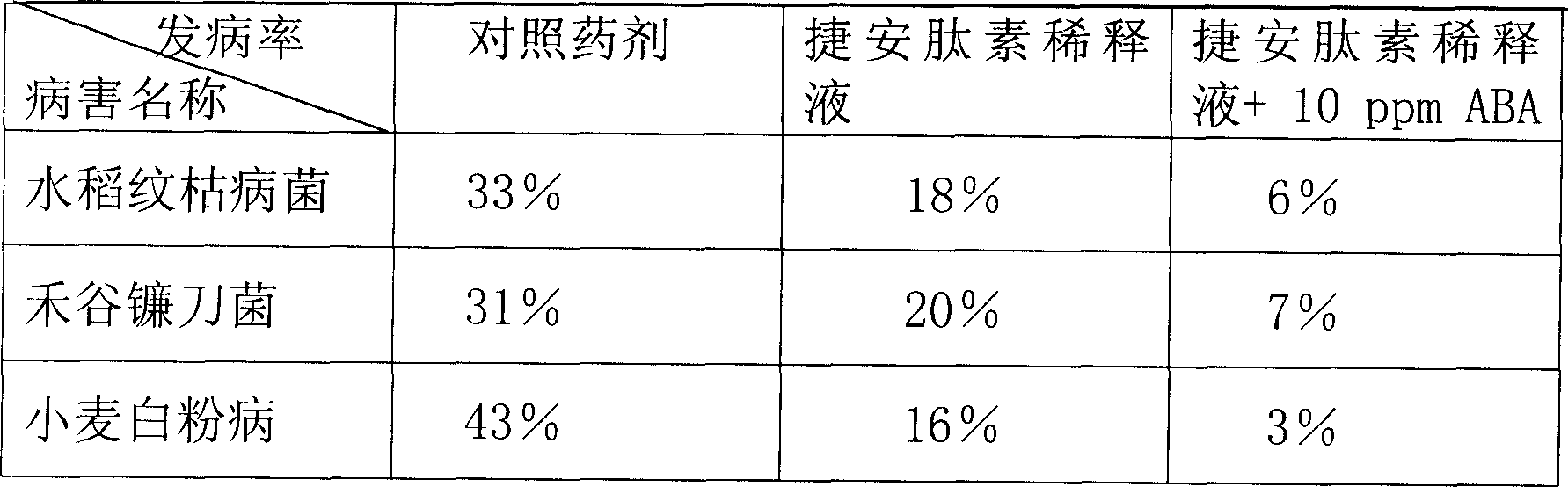

Examples

Embodiment 1

[0050] Use 10 1000mL Erlenmeyer flasks, each with 300mL medium A (glucose 2.0% peptone 3.0% beef extract 0.5% magnesium sulfate 0.1% potassium dihydrogen phosphate 0.2%), sterilize at 120°C, cool and inoculate with activated Jie’an The copeptin-producing bacterium Bacillus firmus bacterium liquid was placed at a temperature of 30° C. and shaken for 18 hours. Inoculate the cultivated seed liquid into 50L sterile medium B (1.0% starch, 2.0% dextrin, 1.0% lactose, 2.0% sucrose, 0.5% glycerin, 1.0% corn flour, waste molasses, 3.0% glucose, etc.) 2.0% peptone 5.0% ammonium nitrate 1.0% ammonium sulfate 0.5% peanut cake powder 2.0% soybean cake powder 0.5% biological nitrogen 1.0% potassium dihydrogen phosphate 0.5% zinc sulfate 0.5% sodium chloride 0.5% iron sulfate 0.1%.) In a 100L fermenter, at a temperature of 28°C-30°C, after 8-15 hours of aerated and stirred fermentation, medium B is continuously fed at a rate of 0.1-1.0L / h until about 12 hours before the fermentation is stopp...

Embodiment 2

[0054] Use 100 1000mL Erlenmeyer flasks, each bottle filled with 300mL medium A (glucose 3.0%, peptone 2.0%, beef extract 0.8%, magnesium sulfate 0.1%, potassium dihydrogen phosphate 0.5%.) Sterilize at 120°C, cool and inoculate the activated Jiean The copeptin-producing bacterium Bacillus firmus bacterium liquid was placed at a temperature of 30° C. and shaken for 18 hours. Inoculate the cultivated seed liquid into 250L sterile medium B (2.0% starch, 2.0% dextrin, 1.0% lactose, 1.0% sucrose, 0.5% glycerol, 0.5% corn flour, 3.0% glucose 1.0% peptone 1.0% ammonium nitrate 3.0% ammonium sulfate 2.0% peanut cake powder 5.0% soybean cake powder 2.0% biological nitrogen 3.0% potassium dihydrogen phosphate 0.1% zinc sulfate 0.1% sodium chloride 0.5% iron sulfate 0.5%.) In a 500L fermenter, at a temperature of 28°C-30°C, after fermentation with aeration and stirring for 10-15 hours, add medium B continuously at a rate of 0.5-2.0L / h until about 12 hours before stopping fermentation (l...

Embodiment 3

[0057] Embodiment 3: use 100 of 1000mL Erlenmeyer flasks, every bottle packs 300mL medium A (glucose 4.0% peptone 3.0% beef extract 0.8% 8 magnesium sulfate 0.3% potassium dihydrogen phosphate 0.4%.) Sterilize at 120 ℃, inoculate after cooling The activated Jieanpeptide-producing bacterium Bacillus firmus was cultured at 30°C for 18 hours in a shaker flask. Inoculate the cultivated seed solution into 250L sterile medium B (starch 2.0%, dextrin 1.0%, lactose 1.0%, sucrose 2.0%, glycerin 0.5%, corn flour 0.5, waste molasses 0.5%, glucose 3.0) according to the inoculation amount of 10%-15%. % peptone 5.0%, ammonium nitrate 0.5%, ammonium sulfate 0.5%, peanut cake powder 1.0%, soybean cake powder 2.0%, biological nitrogen 5.0%, potassium dihydrogen phosphate 1.0%, zinc sulfate 0.1%, sodium chloride 0.1%, iron sulfate 0.5%.) 500L In the fermenter, at a temperature of 28°C-30°C, after aeration and stirring for 10-15 hours, medium B is intermittently fed, and the intermittent time is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com