Use of a non-corrosive, martensitically hardening steel

A martensite and purpose technology, applied in the application field of corrosion-resistant maraging steel, can solve problems such as easy cracking, and achieve the effect of high ductility and good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

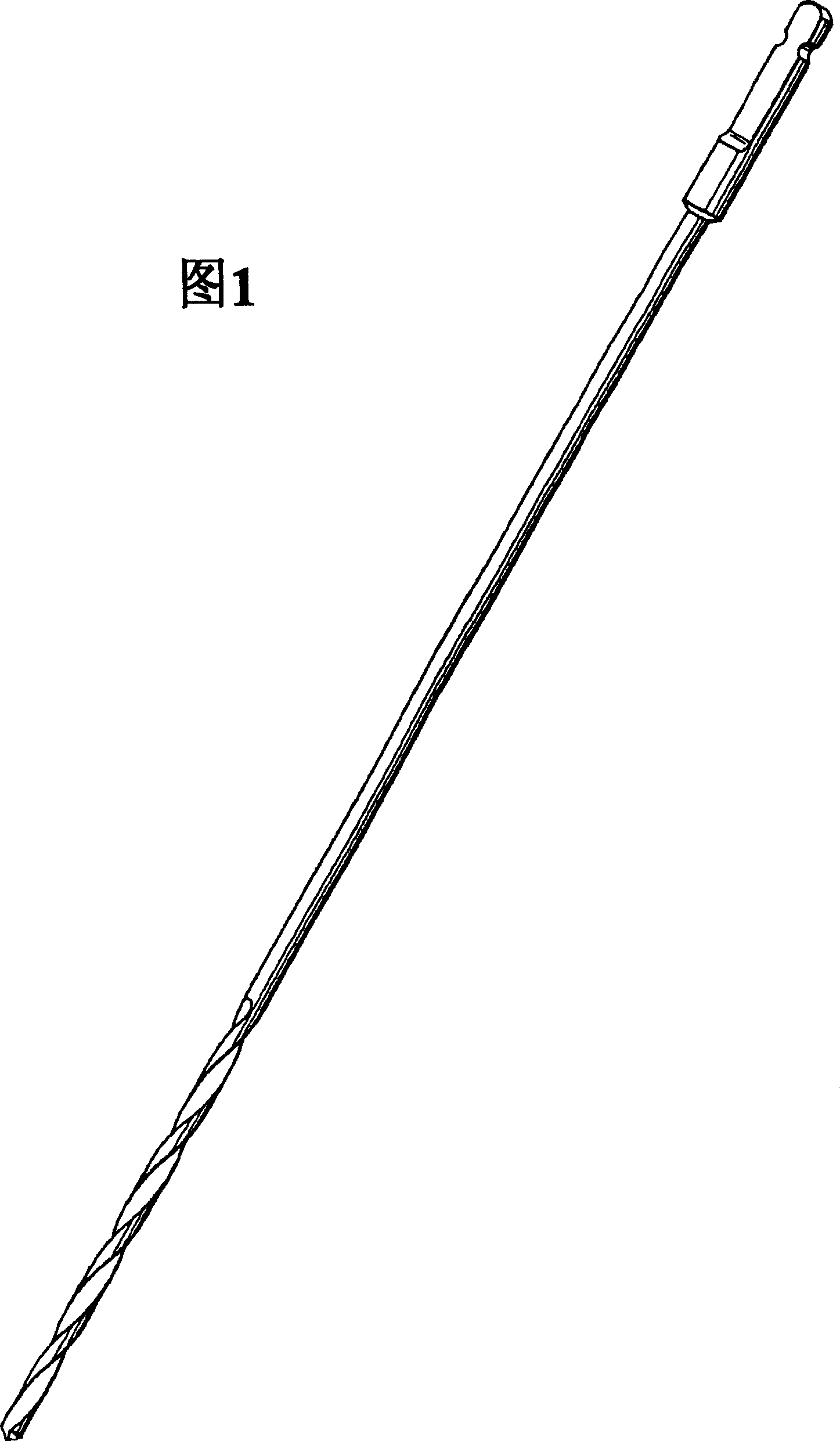

Image

Examples

Embodiment Construction

[0034] In accordance with the requirements of the present invention, fracture and hardness resistance tests were carried out on fully hardened solid material workpieces of the same geometric shape manufactured using the steel grade described in the present invention and two other steel grades currently used to make rotary tools. Tensile strength and elongation test.

[0035] According to the invention, the steel grade tested was a material with the 766685 material composition given in Table 2. For other details, see Table 2.

[0036] Material

[0037] 769228

[0038] The chemical compositions of steel grades 1.4112 and 1.4108 are given in Table 1, and they were used as comparative steel grades. The test specimens were rods of solid material with a circular cross-section and a diameter of 4.5 mm. All test specimens were precipitation hardened. According to the invention, hardening of the steel takes place at 475° C. for 4 hours. According to the harden...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com