Preparation method of polymerized aluminium chloride having high aluminium content

A polyaluminum chloride, high content technology, applied in the direction of aluminum chloride, aluminum halide, flocculation/precipitation water/sewage treatment, etc., can solve the problems of long production process, poor dispersion performance, output limitation, etc., achieve short reaction cycle, The effect of low impurity content and high utilization rate of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

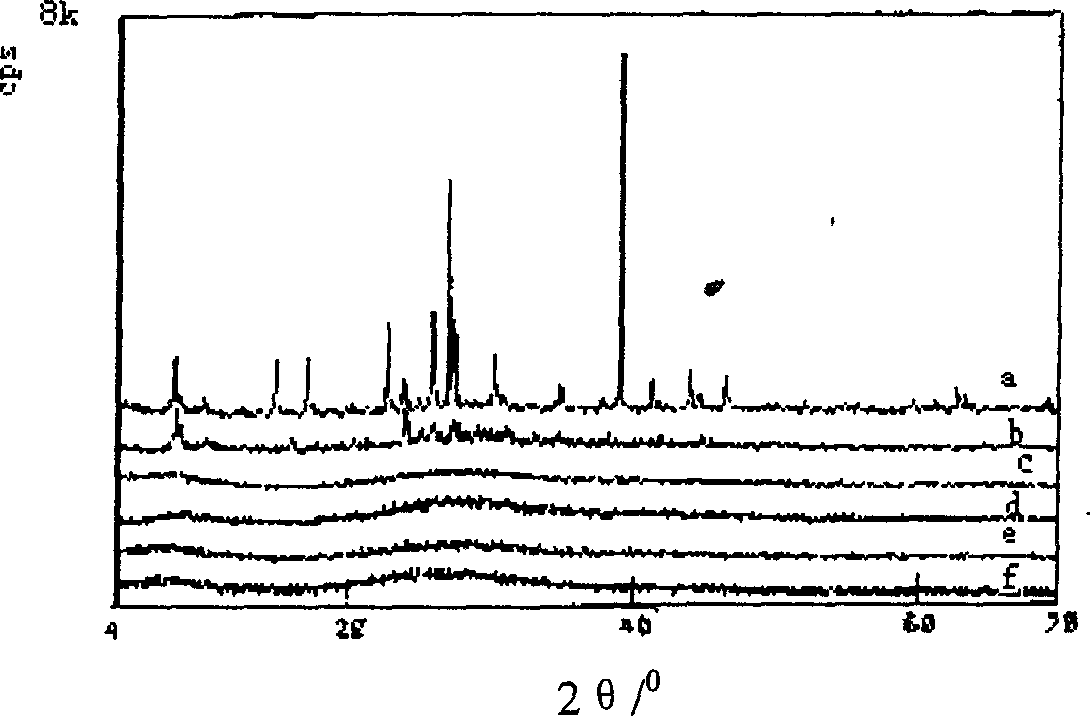

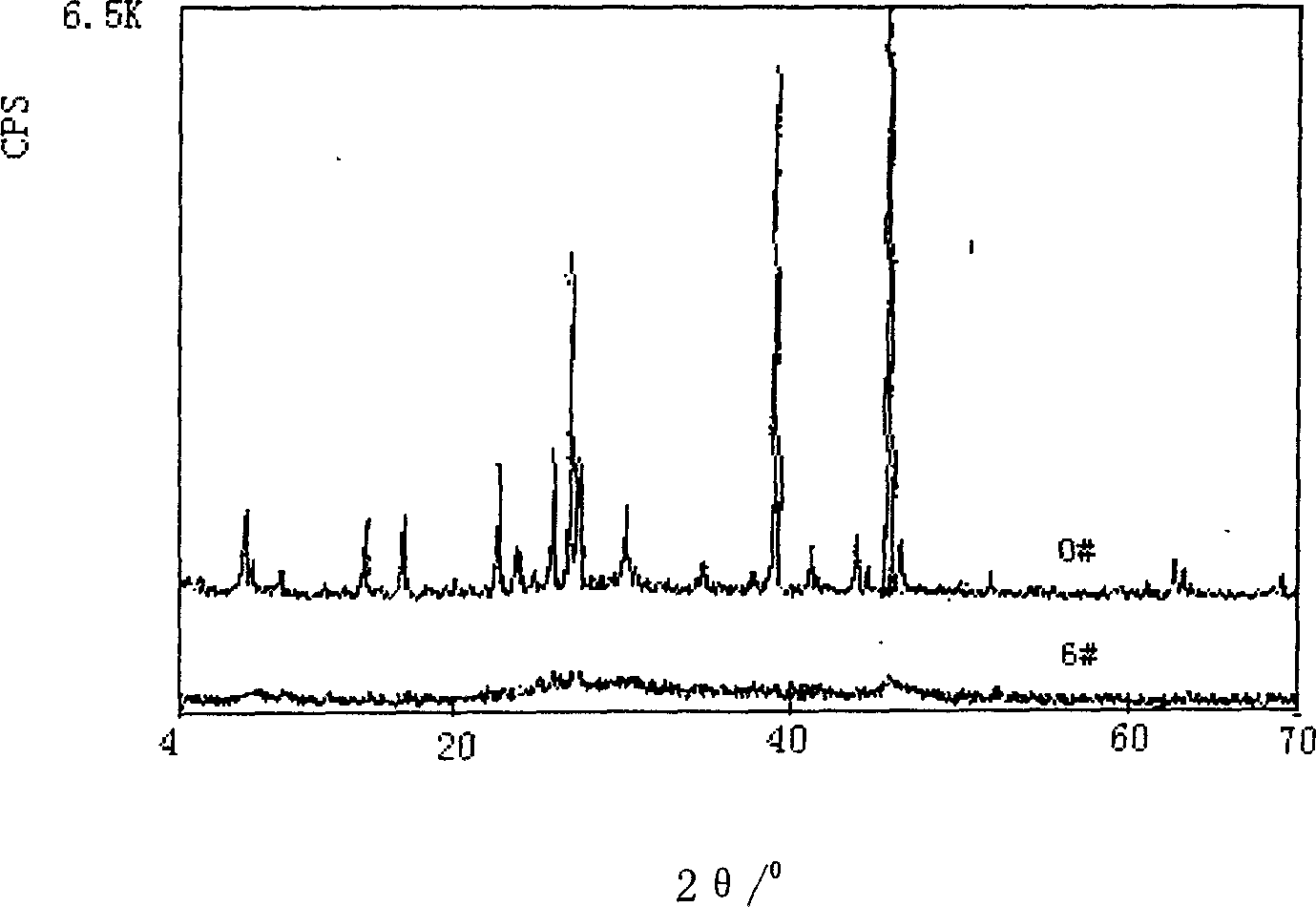

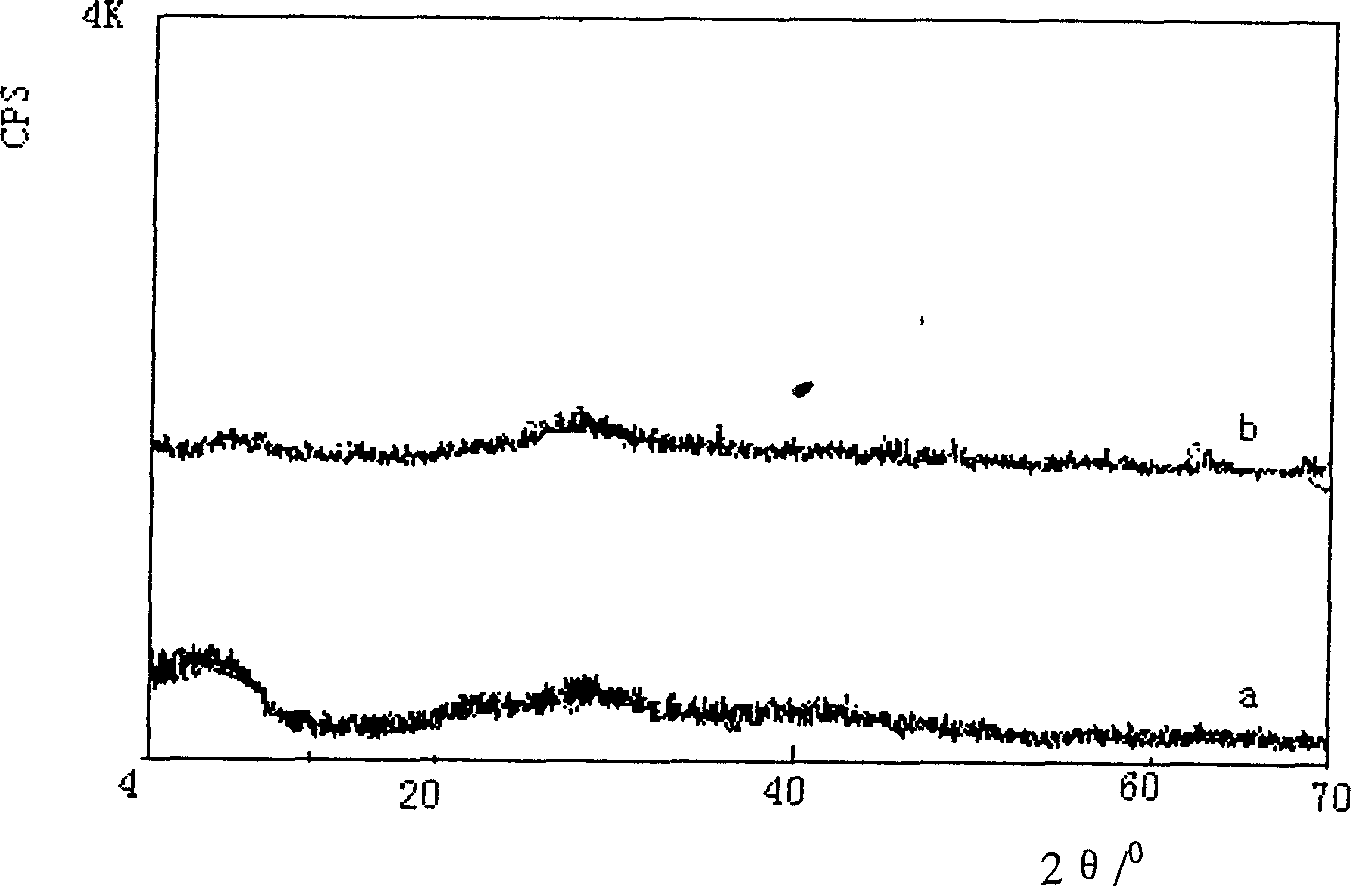

Embodiment 1

[0035] In a 250mL acid-resistant reaction kettle, measure 64mL of distilled water and add it, and then add 120mL of concentrated hydrochloric acid with a concentration of 36% (mass ratio) and a density of 1.19g / mL in the reaction kettle, and slowly add and measure under stirring conditions. 90g of aluminum hydroxide powder, after adding 4g of orthophosphoric acid catalyst A, carry out chemical reaction under the pressure of 1.5Kgf / cm2, when the reaction temperature is 110°C, keep the thermometer for 4 hours, take out the reaction mixture and put it in the sedimentation tank After aging for 16 hours, the lower sediment was returned to the reactor to continue the reaction, and the upper liquid was polyaluminum chloride sample 1#. The experimental results are shown in Table 1, and its structure is shown in Figure 1.

Embodiment 2

[0037]Adopt the condition of embodiment 1, difference is the phosphorous acid catalyst A of 12g and concentrated hydrochloric acid add simultaneously, at 2Kgf / cm 2 The chemical reaction is carried out under pressure. When the reaction temperature is 110°C, keep the thermometer for 5 hours, take out the reaction mixture and put it in the sedimentation tank for aging for 20 hours. The lower layer of sediment is returned to the reactor to continue the reaction. Aluminum sample 2#, the experimental results are shown in Table 1, and its structure is shown in Figure 1.

Embodiment 3

[0039] Adopt the condition of embodiment 1, difference is that concentrated hydrochloric acid reacts with aluminum hydroxide after 0.5 hour, then adds the ammonium dihydrogen phosphate catalyst A of 16g, at 3Kgf / cm 2 Continue the reaction under pressure. When the reaction temperature is 120°C, keep the thermometer for 6 hours, take out the reaction mixture and put it in the sedimentation tank for aging for 48 hours. Aluminum sample 3#, the experimental results are shown in Table 1, and its structure is shown in Figure 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com