Sandwiched type structure SIC base composite material light reflection mirrow and its preparation method

A light-weight reflector and composite material technology, applied in mirrors, optics, instruments, etc., can solve the problems of surface roughness that is difficult to achieve high-resolution reflectors, SiC materials that are difficult to densify, and light-weight processing that are difficult to achieve. Processing and drilling, excellent optical performance, easy to achieve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

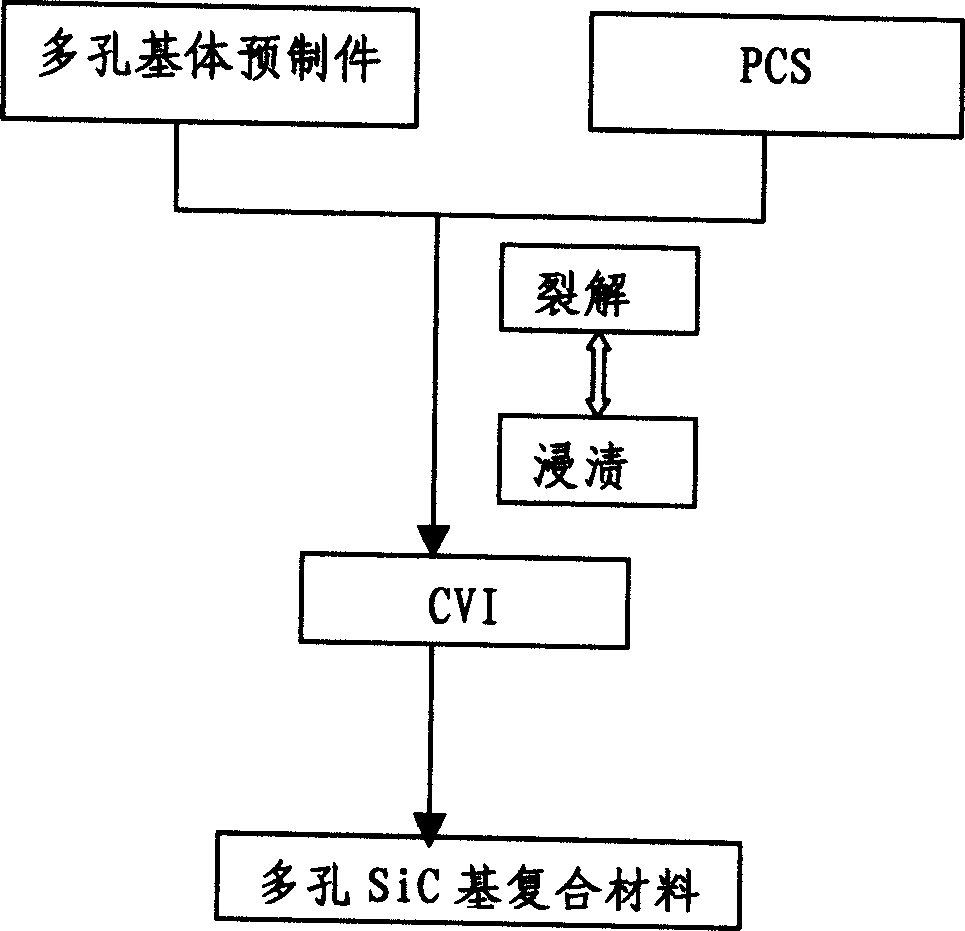

[0046] Preparation of gradient transition layer

[0047] The invention adopts a chemical vapor infiltration (CVI) process to prepare the gradient transition layer, and the CVI process can further increase the density of the surface area of the composite material, thereby relieving the stress of the coating and the substrate. The main process parameters of CVI: deposition raw material trichloromethylsilane (MTS), deposition temperature 900 ~ 1300 ℃, carrier gas H 2 The flow rate is 50-400ml / min, and the dilution gas flow rate is 100-400ml / min.

[0048] Preparation of SiC Mirror Surface Coating by CVD

[0049] The invention adopts a chemical vapor deposition (CVD) process to prepare a dense SiC coating. The main process parameters of CVD: deposition raw material trichloromethylsilane (MTS), deposition temperature 900~1300℃, carrier gas H 2 The flow rate is 100-400ml / min, and the dilution gas flow rate is 100-400ml / min.

Embodiment 1

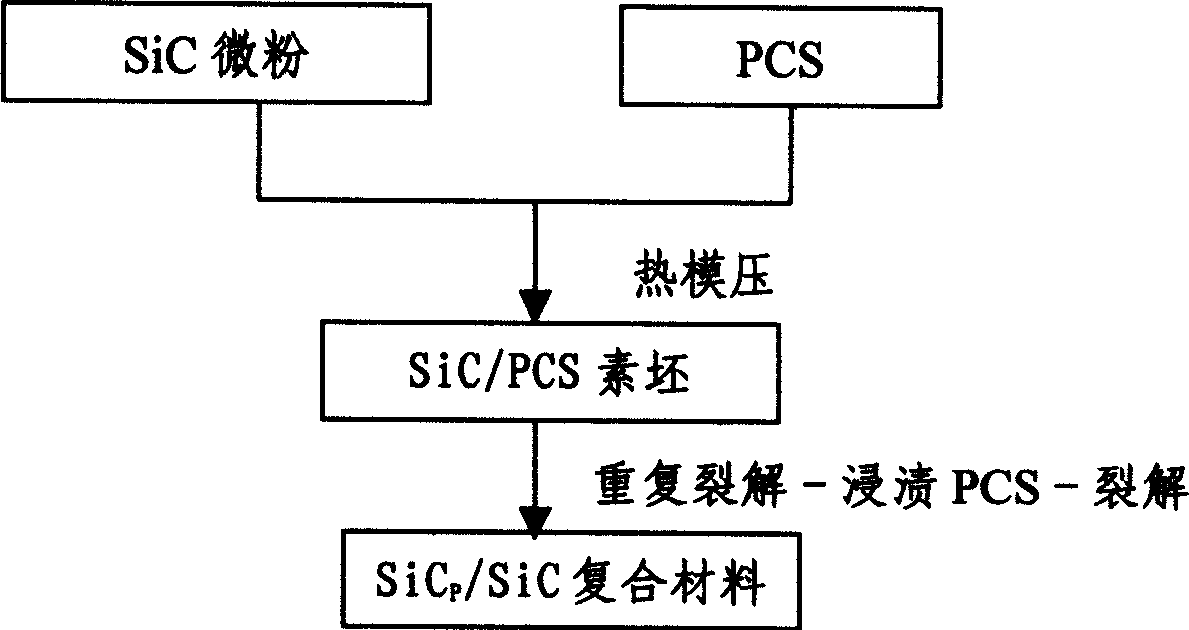

[0051] Step 1. Preparation of foamed SiC by precursor impregnation-pyrolysis method (PIP) P / SiC composite material

[0052] The basic characteristics of the process of preparing porous SiCp / SiC composite materials by cracking and transforming ceramic precursors is to use the solubility of precursors in organic solvents and low-temperature pyrolysis to convert them into ceramic matrix, which solves the problem that the reinforcement phase and the matrix are not easy to disperse. Uniform difficulty achieves low temperature firing.

[0053] Taking polycarbosilane (PCS) as the precursor of SiC matrix as an example, the process of preparing silicon carbide-based composite materials is to dissolve 20-40% polycarbosilane in 30-60% xylene, and add 5-30% reinforcing phase % (chopped fibers, whiskers or ceramic particles), dispersed by ball milling for 2-48 hours, ultrasonically dispersed for 1-8 hours, volatilized to remove the solvent xylene, and as a result, a layer of precursor po...

Embodiment 2

[0065] Step 1: Preparation of SiC-based foam composite green body by liquid phase silicon impregnation (LSI)

[0066] (1) Preparation of C / C porous green body

[0067] The carbon felt was impregnated with the ethanol solution of phenolic resin, and after being pressurized and solidified at 150°C, it was carbonized in a cracking furnace (temperature 1000°C, time 1 hour, heating rate 5°C / min), and the impregnation-cracking process was repeated 5 times to obtain C / C porous green body, the density of the green body is 1.1g / cm 3 , porosity 35vol%.

[0068] (2) Silicon infiltration and sintering of honeycomb sandwich structure SiC mirror body

[0069] Put the C / C honeycomb structure preform into a graphite crucible containing silicon powder, heat it in a high-temperature vacuum furnace to 1450 ° C, and keep the vacuum state in the furnace for 3 hours, thereby preparing a C / Si / SiC reflector with a honeycomb sandwich structure Mirror body. Steps 2, 3, and 4 are the same as steps 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com