Method for obtaining nickel sulfide from pickled liquor of laterite nickel ore

A technology of lateritic nickel ore and nickel sulfide, applied in the direction of nickel sulfide, which can solve problems such as high operating costs, environmental pollution, and complicated treatment technology, and achieve the effects of low production cost, high yield rate, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

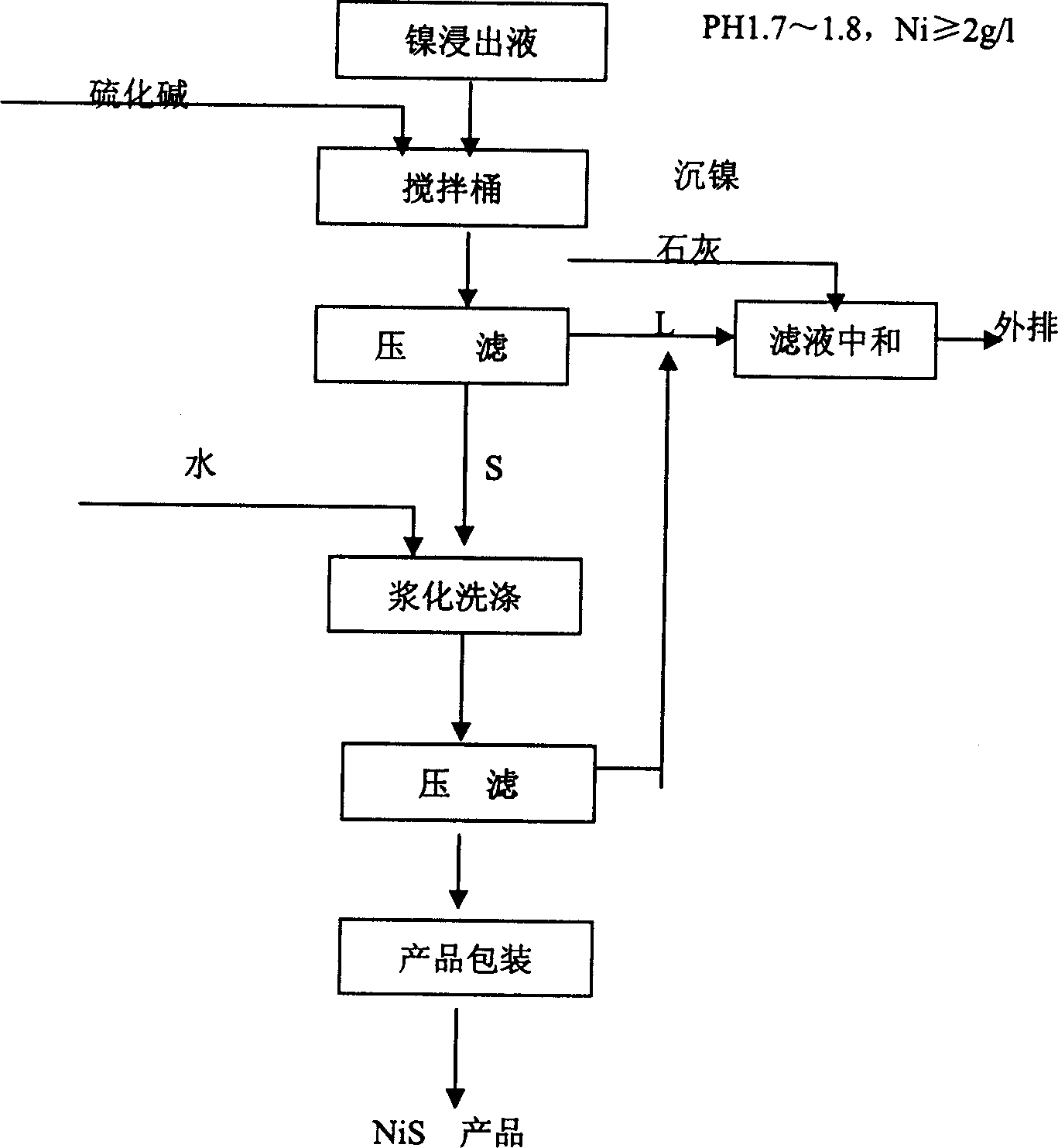

Image

Examples

Embodiment 1

[0018] A, first adjust the acidity and alkalinity of the leaching solution after atmospheric acid leaching, make the pH value reach 1.7, pump it into the stirring device, add potassium sulfide in the leaching solution by the mass ratio of nickel: potassium sulfide=1:3, stir Mix well, and when controlling the nickel ion concentration to be less than 0.02 g / liter, filter with the existing pressure filtration method;

[0019] B, filter residue is the amount of 1: 2 by solid-liquid ratio, after adding water slurrying, washing, through pressure filtration, pack to obtain nickel sulfide product;

[0020] C. In the filtrate obtained in the two steps of A and B, add lime to neutralize its acidity and alkalinity, make the pH value reach 2, and recycle.

Embodiment 2

[0022] A, adjust the pH value of the leach solution after atmospheric acid leaching to 1.8, pump it into the stirring device, add sodium sulfide in the leach solution by the mass ratio of nickel: sodium sulfide=1:6, stir and mix, control the nickel ion concentration to be less than 0.02 g / L, use the existing press filter method to filter;

[0023] B, filter residue is the amount of 1: 2 by solid-liquid ratio, add water to adjust slurry, wash, after press filtration, obtain nickel sulfide product;

[0024] C. Add lime to the filtrate obtained in the two steps of A and B. After acid-base neutralization, make the pH value reach 4 and discharge.

Embodiment 3

[0026] A, adjust the pH value of the leach solution after atmospheric acid leaching to 1.9, pump it into the stirring device, add calcium sulfide in the leach solution by nickel: calcium sulfide=1:8 mass ratio, stir and mix, control the nickel ion concentration less than 0.02 g / L, use the existing press filter method to filter;

[0027] B, filter residue is the amount of 1: 2 by solid-liquid ratio, add water to adjust slurry, wash, after press filtration, obtain nickel sulfide product;

[0028] C, in the filtrate obtained in the two steps of A and B, add alkali to carry out acid-base neutralization, make the pH value reach 3, and recycle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com