Modified mesoporous silicon dioxide powder, presolution for forming low dielectric opoxy resin and low dielectric polysub amido resin, low dielectric constant base board and its forming method

A technology of mesoporous silica and low dielectric constant, applied in the direction of circuit substrate materials, circuits, insulators, etc., can solve the problems of poor stability, flame resistance and processability, limited, and the effect of reducing the dielectric value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0066] Preparation of Modified Mesoporous Silica Powder

[0067] The modified mesoporous silica powder of the present invention is that the mesoporous silica powder is added to a solution of a silane coupling agent compound, and the solution is fed with an inert gas (for example: nitrogen) to Heating the oil bath to control the reaction temperature at 100-200°C, and reflux the solution for 1-5 hours to lower the solution to room temperature. After the powder is taken out by suction and filtration, and washed several times with solvent, the silane coupling agent compound solution The solvent can be toluene or acetone. After drying the powder in an oven at 50-150°C for 1-5 hours, the surface-modified mesoporous silica powder can be obtained to improve the affinity of the mesoporous silica powder. Oily. Among them, the modification step is to use the mesoporous silica powder to carry out a bonding reaction with a silane coupling agent compound to improve the lipophilicity of the...

Embodiment 1

[0078] Example 1: Synthesis of Mesoporous Silica Powder

[0079] Weigh and form a silicon-containing compound sodium silicate (Na 2 SiO 3 ) 2.71 grams and 4.69 grams of tetramethylammonium hydroxide in a beaker, add 27.42 grams of pure water, stir it with a glass rod for 1 minute to make it evenly mixed, in addition take by weighing the surfactant cetyltrimethylammonium chloride ( Cetyltrimethylammonium chloride, CTACL) 16.46 grams, add in the beaker and stir 3 hours with rotor, this moment state is white solution. Prepare 1M sulfuric acid, suck it with a dropper and slowly add it to the beaker to stabilize the pH value at 11, then let it stand for 24 hours to wait for solid-liquid separation. Stir the solid-liquid separated solution to make it uniform, pour it into a high-pressure reaction ax (autoclave), place it in an oven at 150°C for 48 hours, and take it out. At this time, the state is solid-liquid layered. Put the solid stream on the filter paper by means of suction ...

Embodiment 2

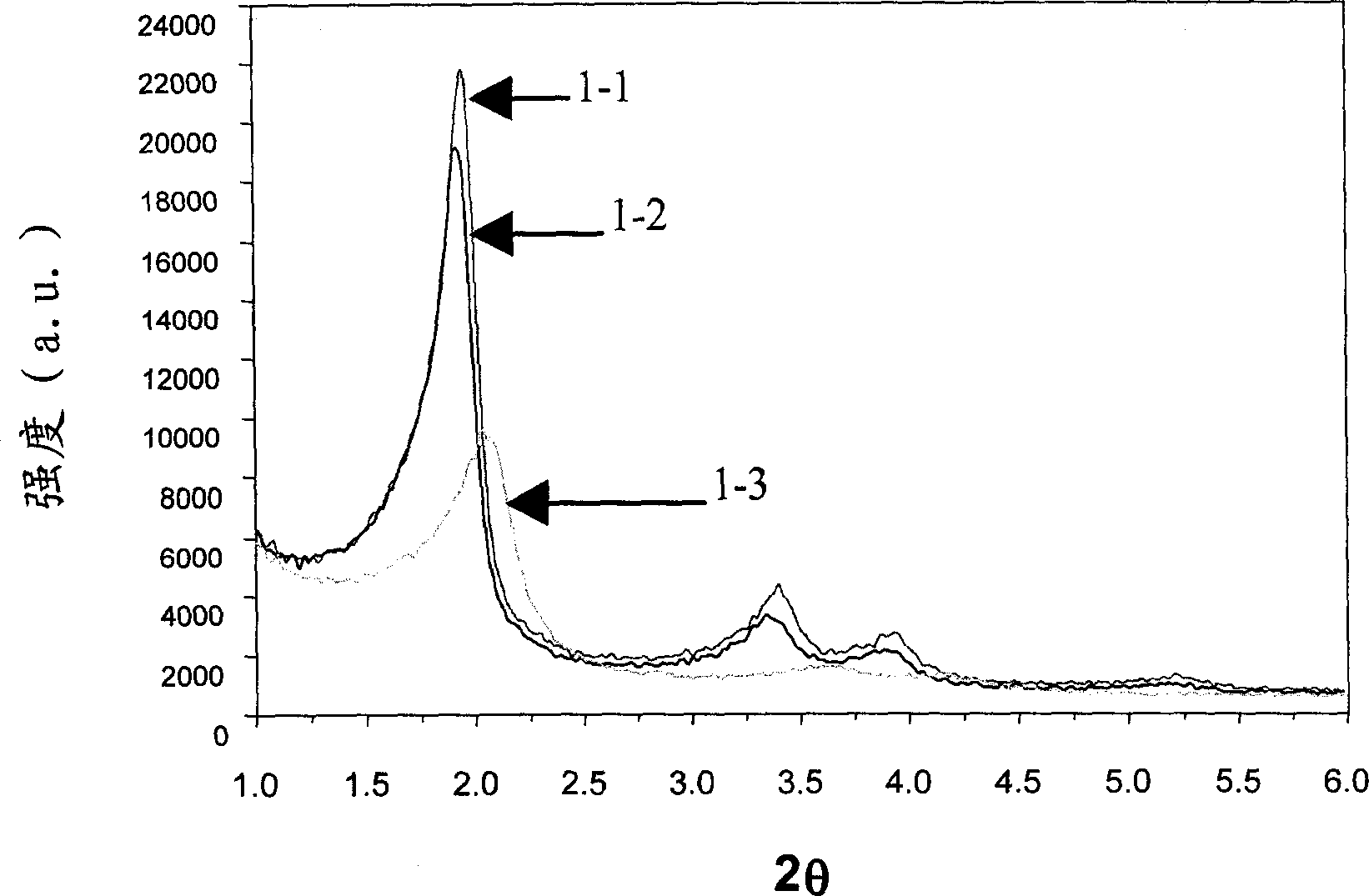

[0081] Example 2: Synthesis of Mesoporous Silica Powder

[0082] Weigh 150 milliliters of 2M hydrochloric acid and add 75 milliliters of deionized water to configure an aqueous hydrochloric acid solution, and 2.4 grams of (polyethylene glycol) 20 (polyglycerol) 70 (polyethylene glycol) 20 three-block copolymer poly (ethylene glycol) 20-block-poly (propylene glycol) 70-block-poly (ethylene glycol) 20, referred to as P123, stir slowly until completely dissolved, then add 8.85 grams of tetraethyl orthosilicate (tetraethyl orthosilicate , TEOS), kept stirring at 35°C for 20 hours, and then continued to stir at 90°C for 24 hours, then filtered the solid in the solution using filter paper and washed it with pure water for several times, and put the obtained solid at 100°C drying, and finally calcining at 550°C for 3 hours to obtain 1-2.5 grams of silica mesoporous powder. Table 2 sorts out the effects of different TEOS / P 123 addition ratios on lattice constant, diffraction intensit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com