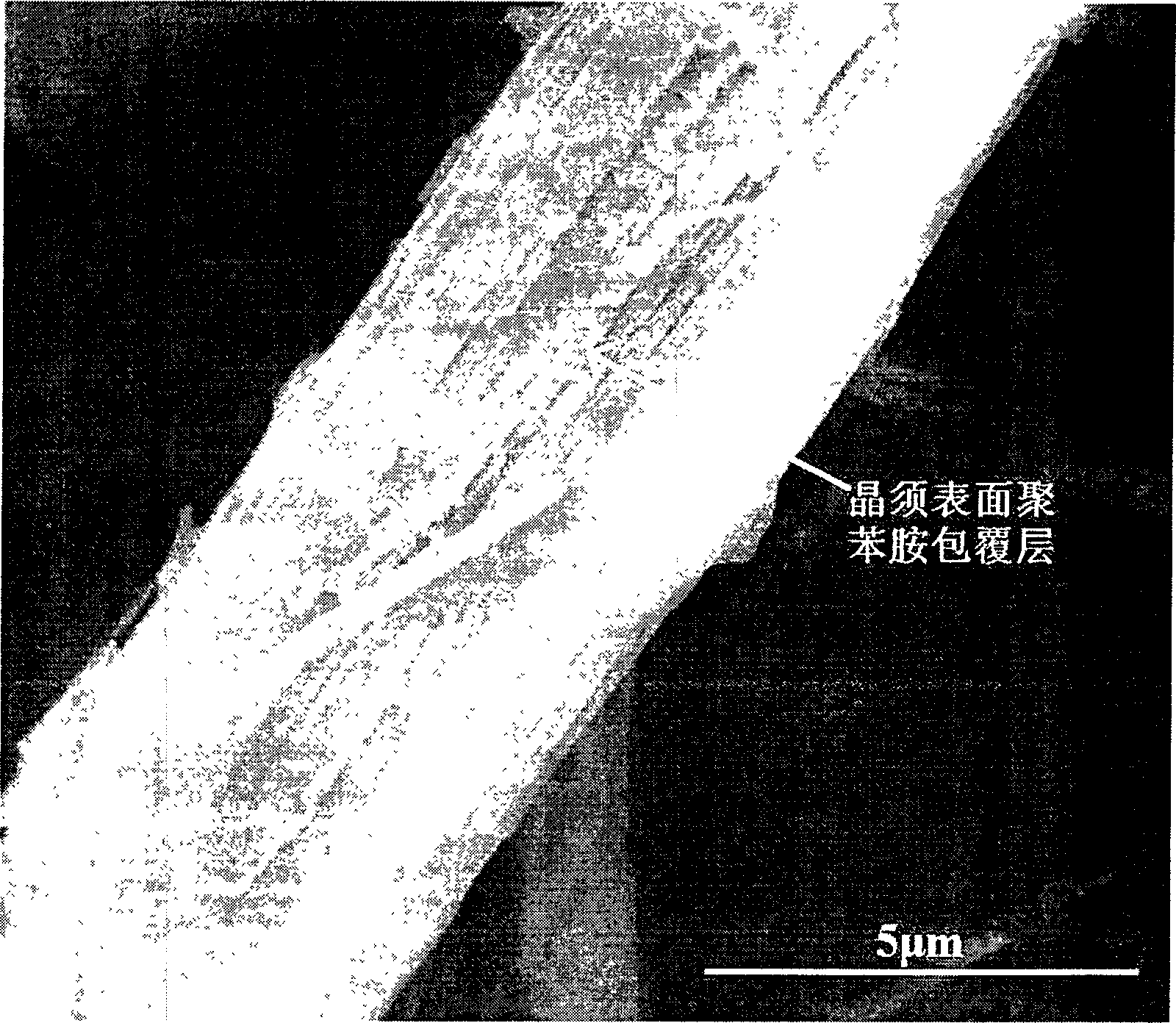

Conductive whiskers in situ polymerized and cladded by aniline and its preparation method

An in-situ polymerization and whisker technology, applied in the direction of conductive materials, conductive materials, conductors, etc., can solve the problems of difficult processing and utilization, reduced conductivity, high price, etc., and achieve the effect of solving application problems, facilitating industrialization, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Take 86.21g of potassium hexatitanate whiskers (0.15mol in total, the whisker diameter is 0.1-5μm, aspect ratio is 2-300) and deionized water to make 1000ml suspension slurry, add 15ml concentration 10mol / L aniline, 210ml ammonium persulfate solution with a concentration of 1mol / L, and 26.8g p-benzenesulfonic acid. The mixed system was mechanically stirred and continuously polymerized at room temperature for 12 hours. After the product was filtered or centrifugally dehydrated, it was used to Wash with ionized water until the pH value of the lotion reaches 7, add 1wt% dispersant sodium triphosphate to the product obtained, add water and stir to make a 20wt% slurry, spray dry, and the air inlet temperature of the spray dryer is 120 °C , the outlet temperature was 90° C., and the powder with a water content of 6 wt % was obtained, and the measured electrical conductivity was 0.7 s / cm (measured by four-probe method).

Embodiment 2

[0024] Take 150g of potassium octatitanate whiskers (0.204mol in total, the diameter of the whiskers is 0.3-3μm, and the aspect ratio is 5-500) and deionized water to make a 1000ml suspension, and add 12ml of 10mol / L aniline solution, 100ml of potassium iodate solution with a concentration of 1mol / L, 20ml of hydrochloric acid with a concentration of 8mol / L, the mixed system was mechanically stirred and continuously polymerized at room temperature for 8 hours, and the product was filtered or centrifuged. Wash with deionized water until the pH value of the lotion reaches 8, the resulting product, add 1wt% dispersant sodium triphosphate, add water and stir to make a 30wt% slurry, spray dry, the air inlet temperature of the spray drier is 180° C., the outlet temperature was 100° C., and a powder with a water content of 8 wt % was obtained, and the measured electrical conductivity was 0.1 s / cm (measured by the four-probe method).

Embodiment 3

[0026] Take 40g of titanium dioxide whiskers (0.5mol in total, the diameter of the whiskers is 0.1-4μm, and the aspect ratio is 2-400) and deionized water to make a 1000ml suspension, and add 10ml to the suspension system successively with a concentration of 10mol / L Aniline solution, 100ml of potassium dichromate solution with a concentration of 1mol / L, 20ml of sulfuric acid with a concentration of 10mol / L, the mixed system was mechanically stirred and continuously polymerized for 4 hours at room temperature, and the product was filtered or centrifuged. Wash with ionized water until the pH value of the lotion reaches 7. Add 1wt% of the dispersant sodium triphosphate to the obtained product, add water and stir to make a 15wt% slurry, and spray dry. The air inlet temperature of the spray dryer is 130°C , the outlet temperature was 100° C., and the powder with a water content of 6 wt % was obtained, and the measured electrical conductivity was 0.06 s / cm (measured by four-probe met...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com