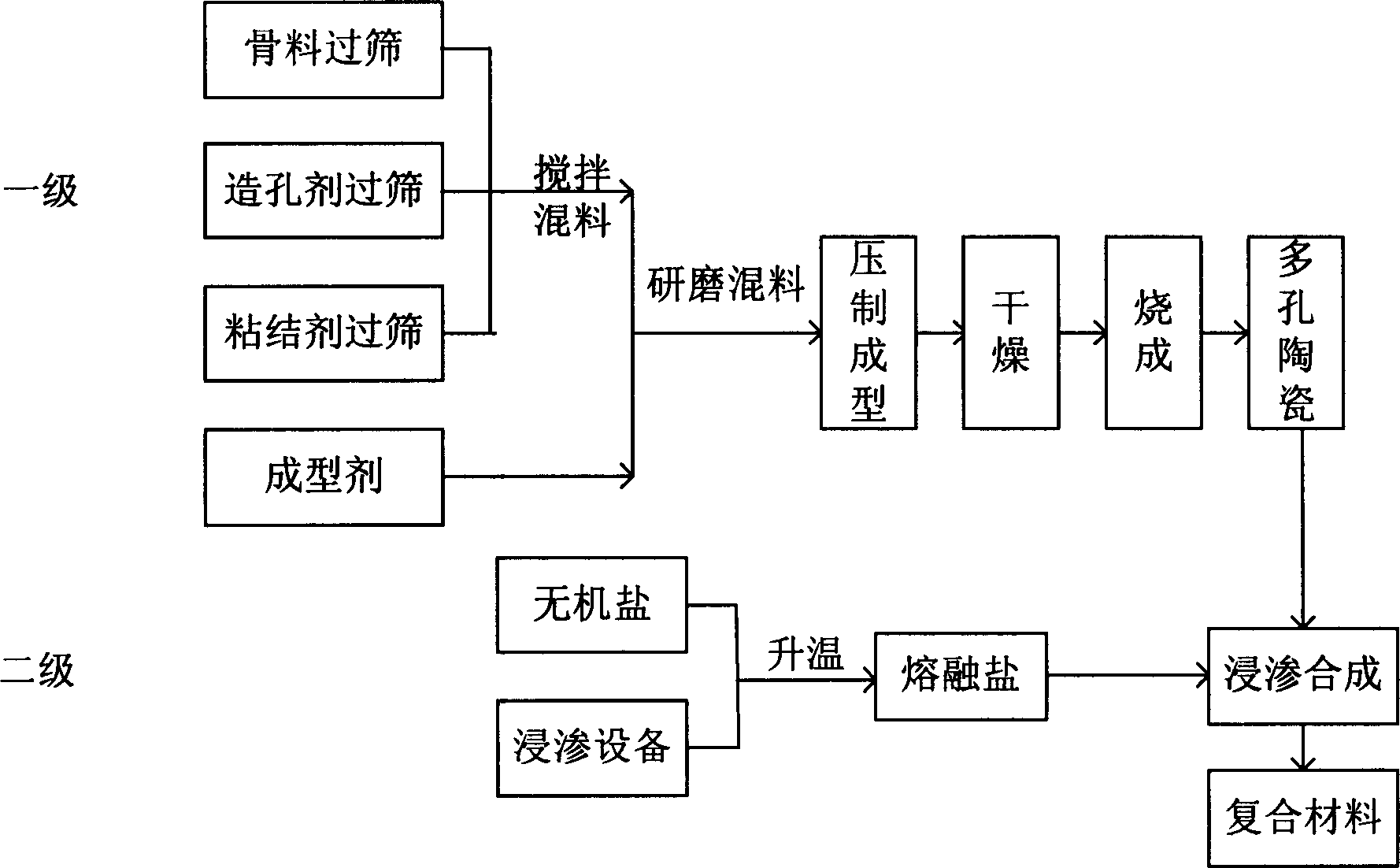

Process for preparing organic salt/ceramic base high temperature phase-changing energy-storing material

A preparation process, high-temperature phase change technology, applied in the direction of heat exchange materials, sustainable manufacturing/processing, chemical industry, etc., can solve the problem of affecting the appearance of material compactness and mechanical strength, low mechanical strength of composite energy storage materials, mechanical strength decrease and other problems, to achieve the effects of large latent heat of phase change, improved heat storage performance, and improved heat transfer performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] 1. Implementation conditions

[0016] The silica powder passes through the 180-mesh standard inspection sieve, the pore-forming agent starch and the high-temperature binder bentonite pass through the 325-mesh standard inspection sieve, and the ratio is: 80% silicon dioxide, 15% pore-forming agent, and high-temperature binder 5%, add an appropriate amount of forming agent water glass solution, mix the ingredients evenly through repeated stirring and sieving, and form a short cylinder with a diameter of about 30mm and a h of about 25mm on a hydraulic universal material testing machine, and the molding pressure is 15Mpa; The pressed samples were dried in an electric blast drying oven at 200°C for 2 hours, and fired in a resistance furnace at a firing temperature of 1250°C; the porous ceramic preform was obtained after being slowly cooled in the furnace. Then use the prepared porous ceramic preform and inorganic salt sodium sulfate to impregnate and synthesize. The synthesi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com