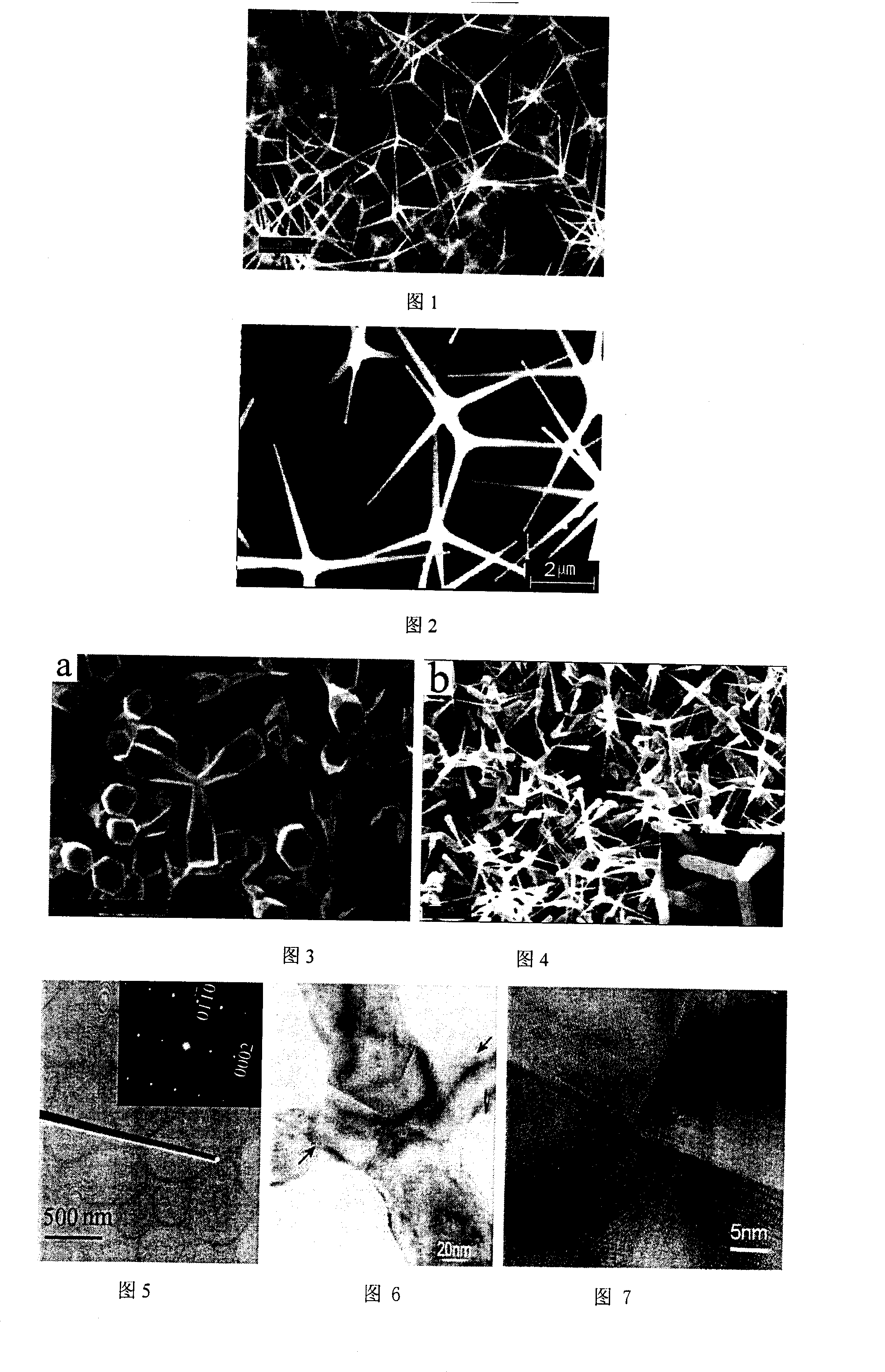

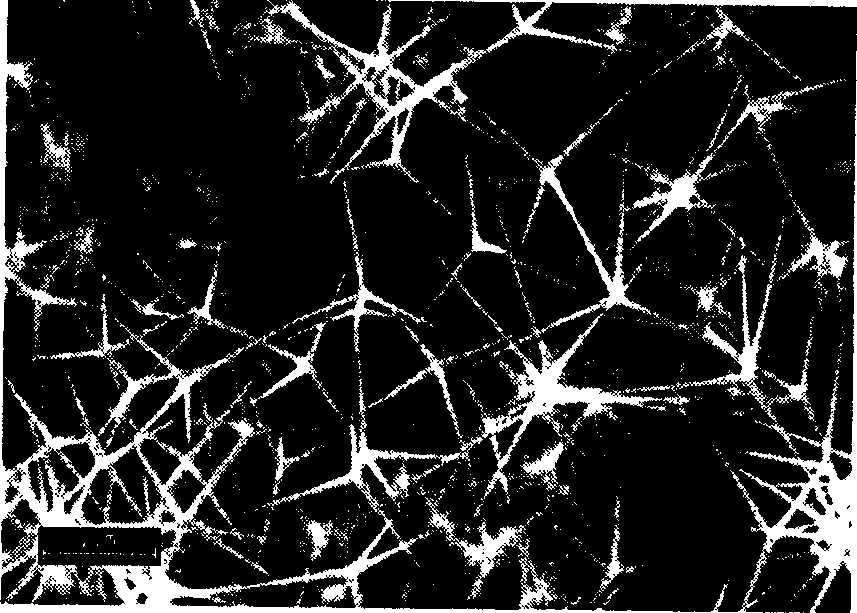

Method for preparing four needle shape zinc oxide nano stick by low temperature catalyst-free gas phase deposition

A four-needle zinc oxide, vapor deposition technology, applied in the direction of nanotechnology, nanotechnology, nanostructure manufacturing, etc., can solve the problems of high preparation temperature and product purity, and achieve the guarantee of uniformity, purity and performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Tube furnace specifications: length 75cm, tube diameter 40mm, quartz tube tube length 100cm, inner diameter 30mm.

[0026] The tetraacicular ZnO nanorods prepared under the following experimental conditions have good surface quality, regular shape, and the highest yield:

[0027] Rinse the silicon (100) substrate with deionized water and alcohol, respectively, as a deposition substrate; place Zn powder (passed through a 53 μm sieve, with a purity >99.9%) in a porcelain boat, and then place the silicon substrate upside down on the porcelain On the boat; put the porcelain boat into the middle of the quartz tube in the tube furnace, and use a flowmeter to adjust the total flow of argon and oxygen into the quartz tube and the ratio of the two gases. In this atmosphere, raise the temperature of the tube furnace to the synthesis temperature of 600°C, 650°C, and 700°C, and then keep it warm for 20 minutes. After that, take out the silicon wafer, and the white fluff deposited o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com