Double-control composite slow-release fertilizer and method for preparing same

A slow-release fertilizer and compound technology, which is applied in fertilizer mixtures, fertilization devices, applications, etc., can solve the problems of unsatisfactory slow-release effect of cemented slow-release fertilizers, reduce secondary environmental pollution, be easy to operate, and improve fertilizer The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

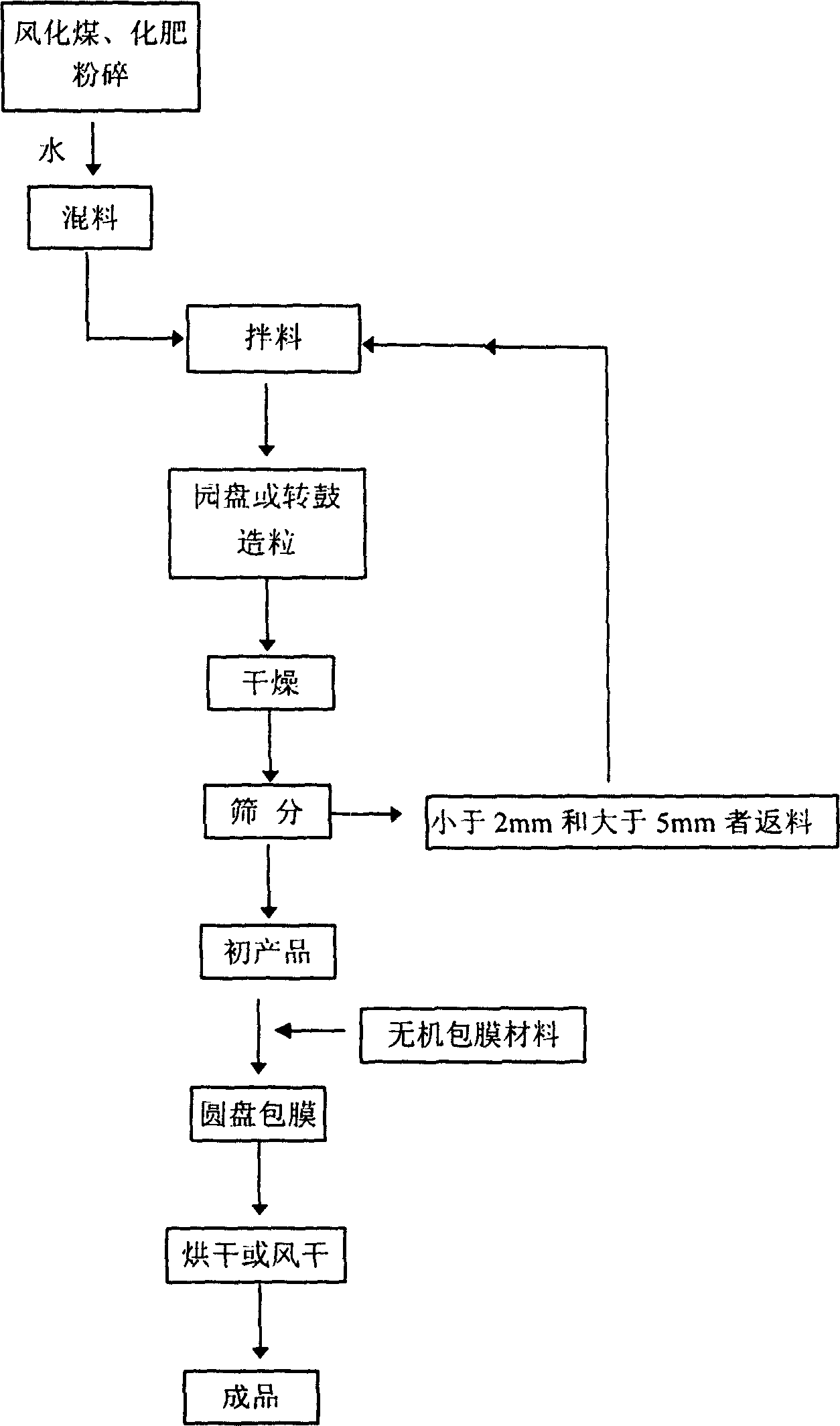

Embodiment 1

[0026] Take 27kg of urea, 18kg of monoammonium phosphate, 15kg of potassium sulfate, 30kg of weathered coal humic acid, 10kg of phosphate rock powder, crush them through a 60-70 mesh sieve, and mix 60kg of nitrogen, phosphorus, and potassium fertilizer raw materials with 30kg of weathered coal humic acid Mix well, and add about 10±2kg of water to make the raw material mixture have a certain humidity; the raw material mixture is granulated in a granulating disc machine; the granulated material is sent to a rotary drying drum for drying; After the powder and large particles larger than 5mm are sieved, they are all used as returned materials and recycled; add 10kg of phosphate rock powder to the disc granulator for particles larger than 2mm but smaller than 5mm, roll and coat them, dry or Air-dried is the finished product.

Embodiment 2

[0028] Take 20kg of urea, 26kg of monoammonium phosphate, 21kg of potassium sulfate, 23kg of weathered coal humic acid, 10kg of calcium-magnesium phosphate fertilizer, crush them through a 60-70 mesh sieve, and mix 67kg of nitrogen, phosphorus, and potassium fertilizer raw materials and 13kg of weathered coal humic acid Mix well, and add about 10±2kg of water to make the raw material mixture have a certain humidity; the raw material mixture is granulated in a granulating disc machine; the granulated material is sent to a rotary drying drum for drying; After the powder and large particles larger than 5mm are sieved, they are all used as returned materials for recycling; add 10kg of calcium magnesium phosphate fertilizer to the disc granulator for particles larger than 2mm but smaller than 5mm, roll and coat them, dry or Air-dried is the finished product.

Embodiment 3

[0030] Take 27kg of urea, 18kg of calcium phosphate, 15kg of potassium sulfate, 30kg of weathered coal humic acid, 10kg of calcium-magnesium phosphate fertilizer, pass through a 60-70 mesh sieve after crushing, and fully mix 60kg of nitrogen, phosphorus, and potassium fertilizer raw materials and 30kg of weathered coal humic acid. Mix well, and add about 10±2kg of water to make the raw material mixture have a certain humidity; the raw material mixture is granulated in a granulating disc machine; the granulated material is sent to the rotary drying drum for drying; the powder smaller than 2mm After sieving, the granules larger than 5mm and larger than 5mm are used as returned materials for recycling; add 10kg of calcium magnesium phosphate fertilizer to the disc granulator for particles larger than 2mm but smaller than 5mm, roll and coat them, and dry or air-dry , which is the finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com