Multi-phase, silicon-containing electrode for a lithium-ion battery

A lithium-ion battery and battery technology, applied in battery electrodes, lithium batteries, secondary batteries, etc., can solve problems such as difficult large-scale manufacturing, large volume expansion, material damage, etc., and achieve high capacity, good cycle life, easy-to-manufacture effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

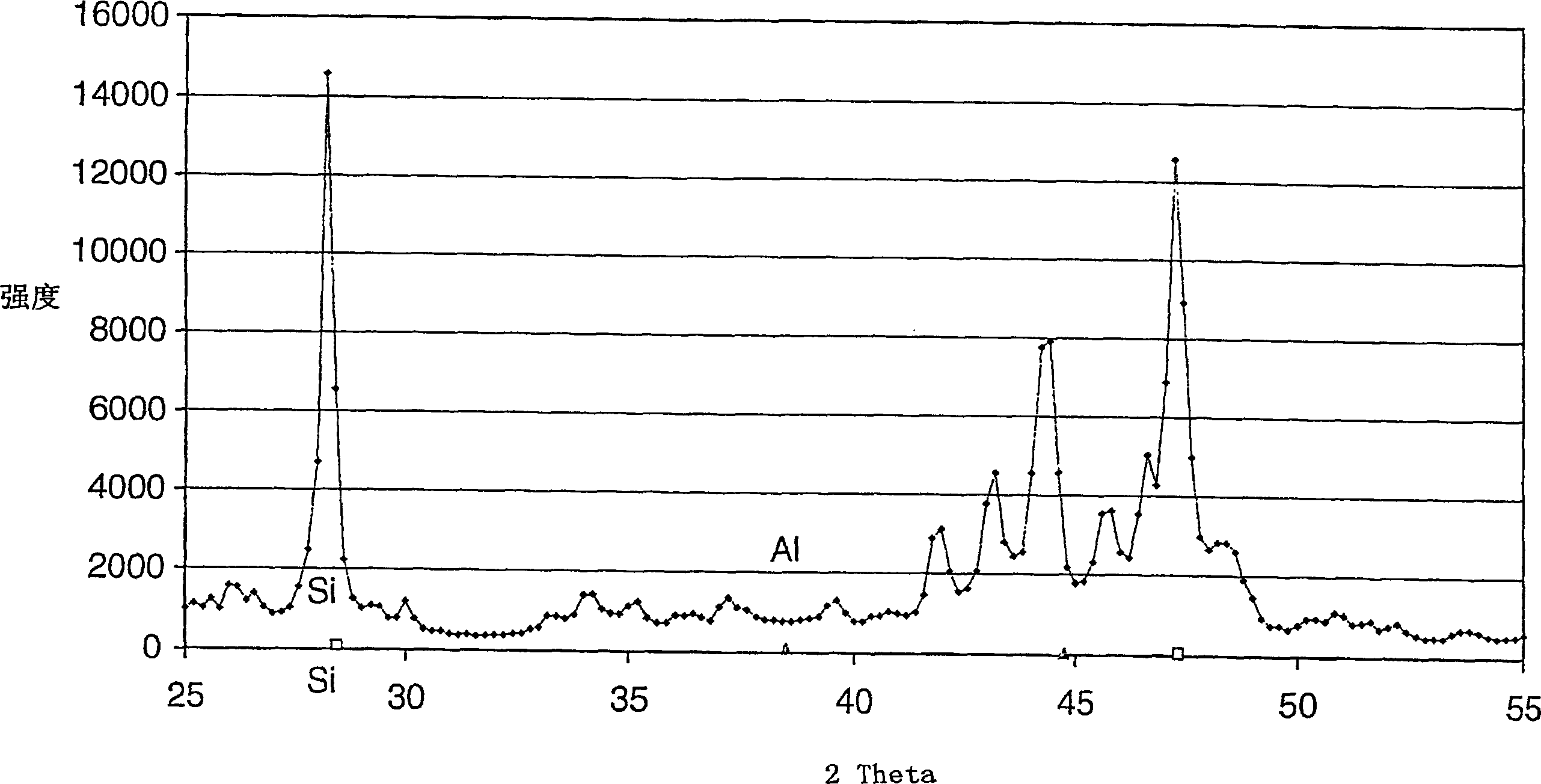

[0021] 6.34g of aluminum pellets, 12.10g of silicon flakes and 6.56g of iron flakes (all 99.9% or better in purity) were weighed in a weighing pan and placed into an electric arc furnace. In the presence of a Ti pool (pool) oxygen getter, the mixture was melted in an Ar atmosphere to produce Si with composition 55 Al 30 Fe 15 25g ingots, where all quantities are in atomic percent.

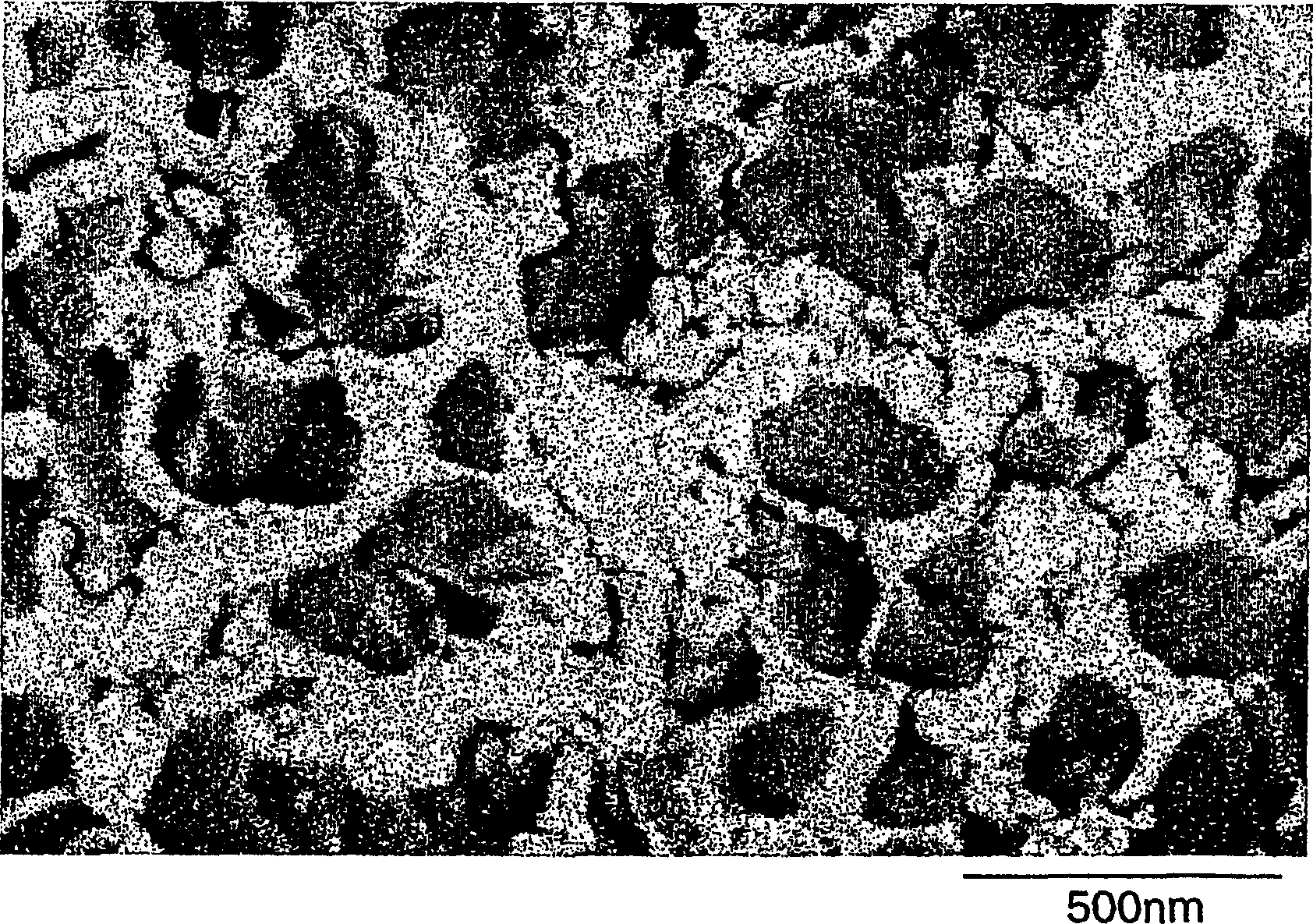

[0022] The ingot was broken into pieces smaller than 15 mm in diameter. 10 g of this material was placed in a quartz tube ending in a 0.035 mil (0.89 μm) diameter nozzle. A thin carbon sleeve is also inserted in this tube, acting as a radio frequency coupler, to initiate the melting of the ingot. The tube was placed into the chamber of a melt-spinning machine over a 200 mm diameter copper wheel so that the distance from the nozzle opening to the wheel surface was 10 mm. The chamber was then evacuated to 80 mTorr and refilled to 200 Torr with He. The ingot is then melted in a radio frequency f...

example 2

[0031] Prepare, grind and classify melt-spun Si as described in Example 1 55 al 30 Fe 15 bring. Fragments between 32 and 20 microns are isolated. Partially coated with a porous layer of Ag according to the method described in U.S.S.N. debris. 10% increase in weight. The silver-coated particles were dispersed in methyl ethyl ketone and further reacted with 3-aminopropyltrimethoxysilane (Aldrich Chemical) (60 mg silane per 1 g of powder) by shaking for 8 hours.

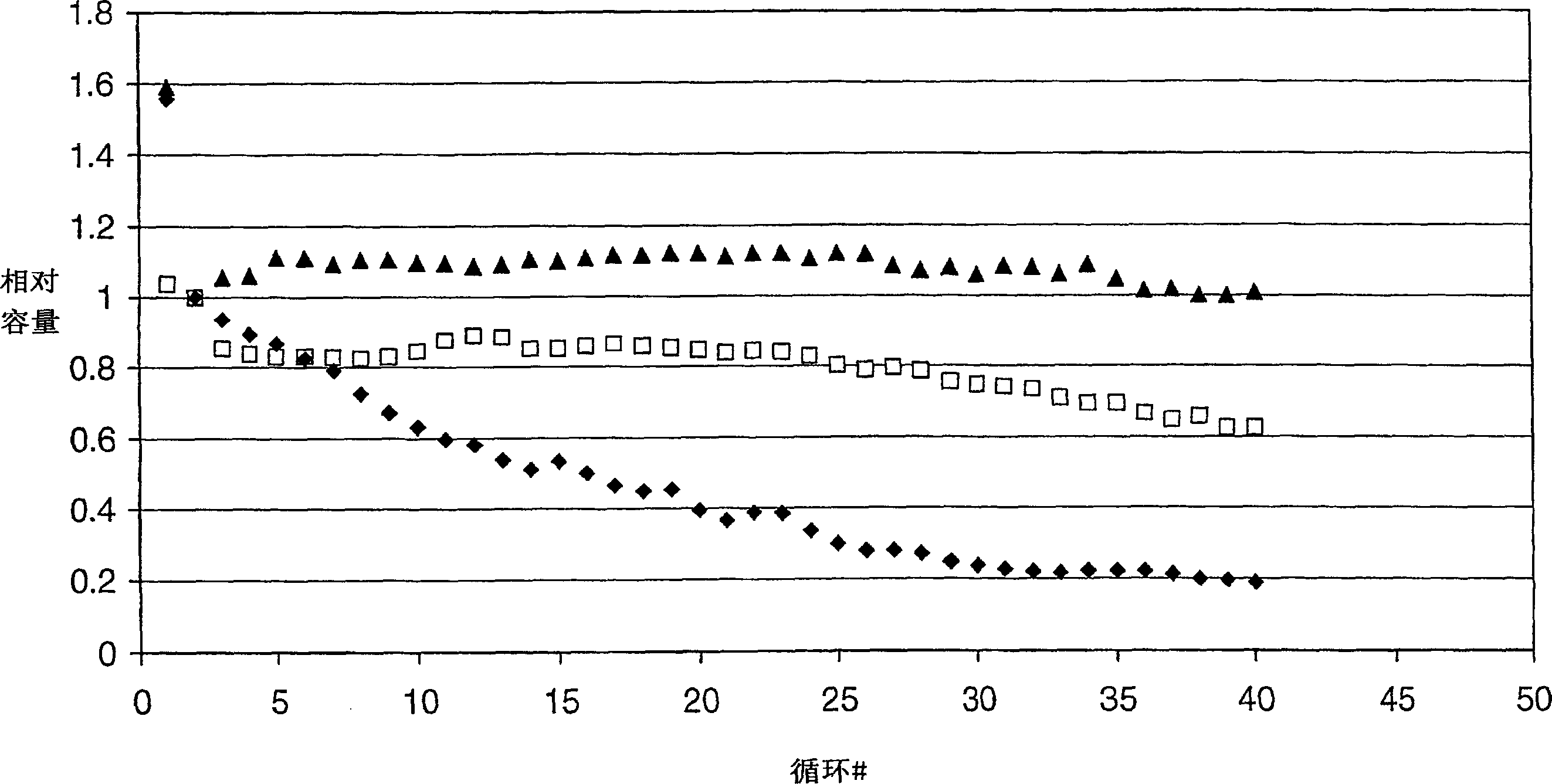

[0032] The treated powder was used to prepare an electrode as described in Example 1, except that the binder was a fluorochemical elastomer available from Dyneon LLC under the designation FC-2179, the carbon was Super S carbon, and the final coating The composition contained 80% active powder, 14% carbon and 6% binder. exist Image 6 The performance of the half-cells incorporating these electrodes is shown in terms of capacity vs. cycle number. The half-cell was prepared as described in Example 1. like Image...

example 3

[0034] 6.98g of aluminum pellets, 14.80g of silicon flakes and 8.22g of copper pellets (all 99.9% or better in purity) were weighed in a weighing pan and placed into an electric arc furnace. In the presence of a Ti pool (pool) oxygen getter, the mixture was melted in an Ar atmosphere to produce Si with composition 57 al 28 Cu 14 30g crystal ingot, all quantities are in atomic percent.

[0035] The ingot was broken into pieces smaller than 15 mm in diameter. 10 g of this material was placed in a carbon tube ending in a 0.030 mil (0.76 m) diameter nozzle. The tube was placed into the chamber of a melt-spinning machine over a 200 mm diameter copper wheel so that the distance from the nozzle opening to the wheel surface was 10 mm. The chamber was then evacuated to 80 mTorr and refilled to 200 Torr with He. The ingot is then melted in a radio frequency field. When the melt reached 1200°C, the molten liquid was sprayed under 80 Torr He overpressure on a copper wheel rotating a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com