Resource-reutilizing circulating process of biological garbage

A biomass and resource-based technology, applied in the direction of biological sludge treatment, biological organic part treatment, waste fuel, etc., can solve the problems of large investment, waste of resources, irreplaceable, etc., achieve huge economic benefits, save urban land, eliminate Effects of Toxic Components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

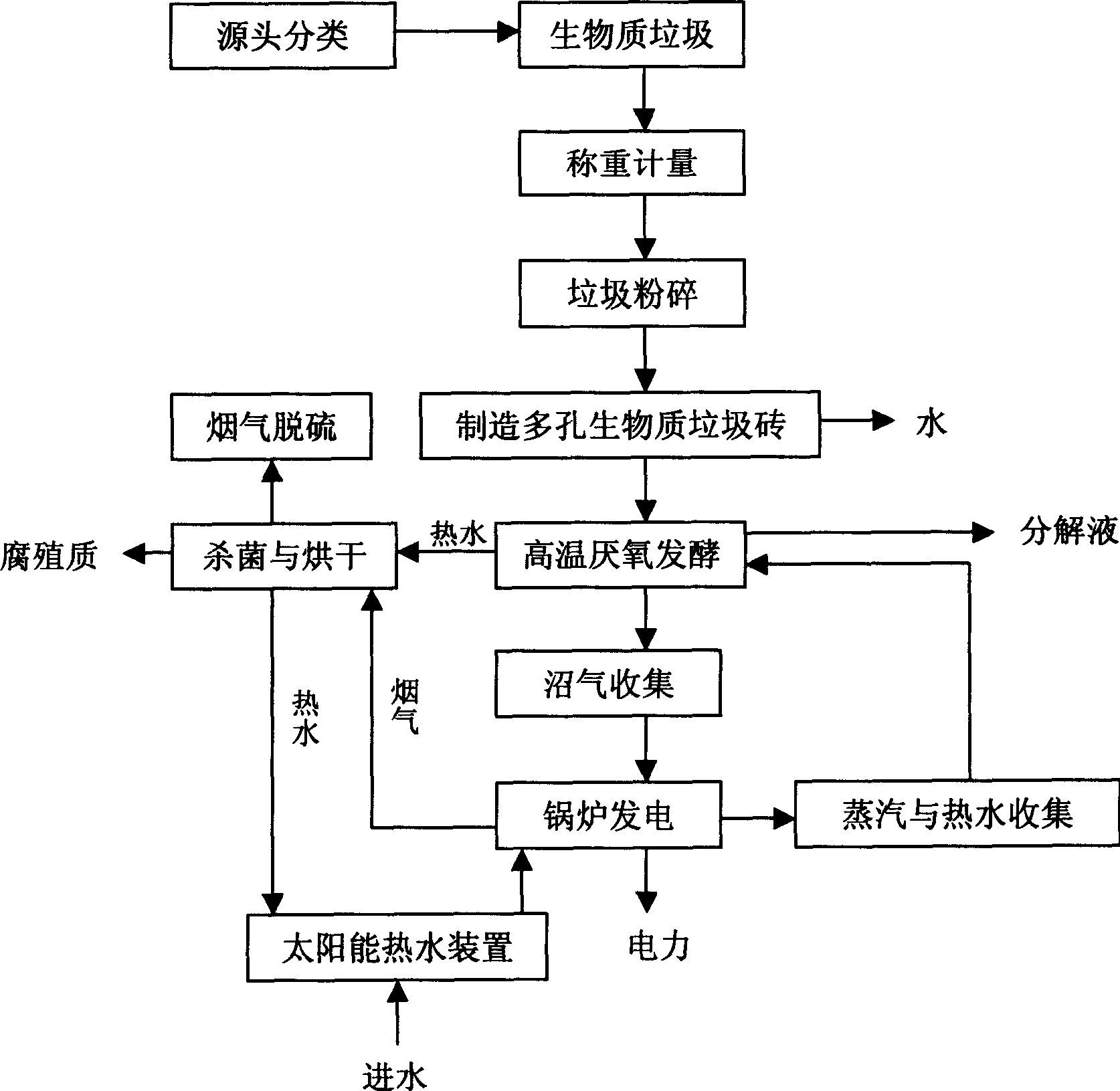

[0030] Biomass waste resource recycling process of the present invention, the technical feature of its technical solution is that it mainly includes the following steps:

[0031] 1. Source sorting: source sorting or sorting of municipal solid waste to obtain biomass waste. The biomass waste includes vegetable residues, leaves, melon rinds, fruit shells, animal residues, leftover rice, and small amounts of broken ceramics, floating ash, etc., which account for 78-87% of municipal solid waste.

[0032] 2. Crushing: Crushing the biomass waste with a crusher to obtain particles with a particle size of less than 1cm.

[0033] 3. Manufacture of porous biomass waste bricks: use a high-pressure molding machine to perform high-pressure extrusion on the shredded biomass waste to make high-density biomass waste bricks; the density of the biomass waste bricks is to hold uncompressed biomass waste per cubic meter Not less than 6 tons; during this process, 60-80% of the physical water cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com