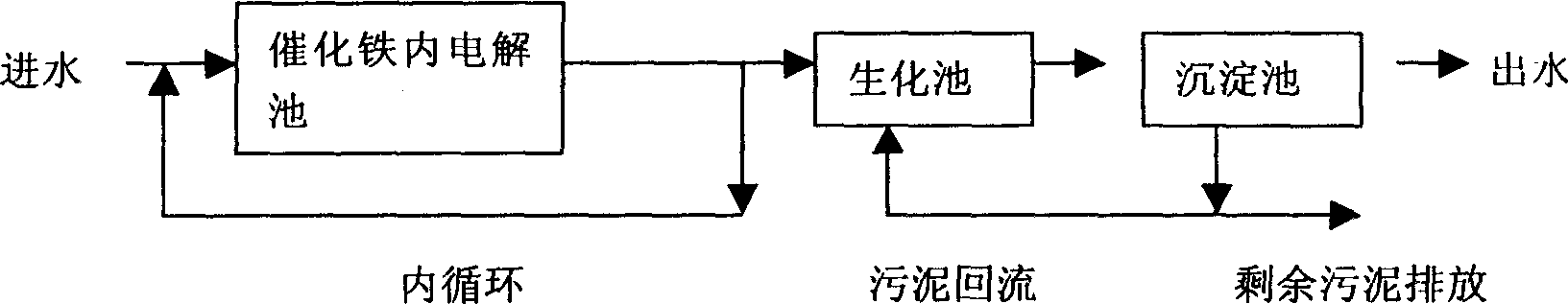

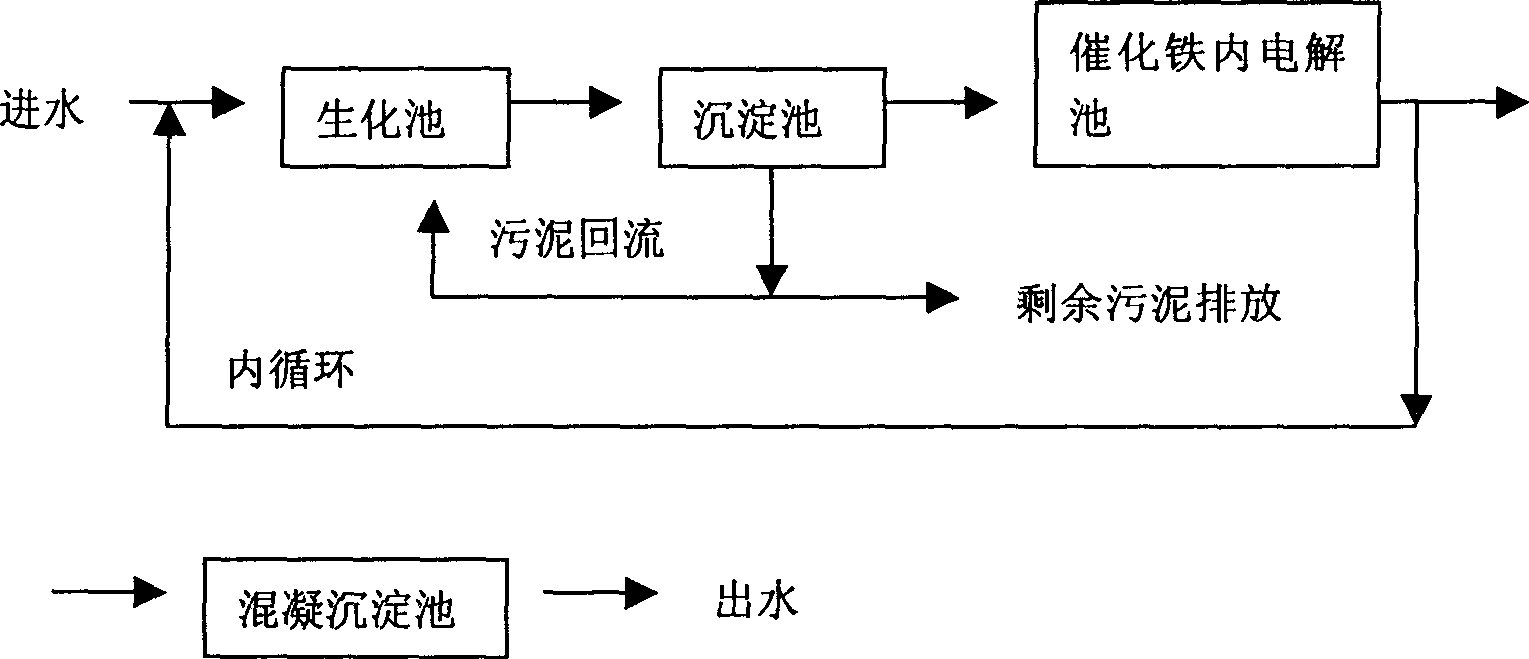

Waste water treatment method by postpositioning catalytic Fe internal electrolysis tank

A post-processing and catalytic iron technology, applied in the environmental field, can solve the problems of affecting the water treatment effect of the electrolysis process in the catalytic iron, hindering the electrolytic reaction of iron and copper, and aggravating the scaling on the surface of the iron filter material, so as to achieve enhanced water treatment Effect, avoid fouling phenomenon, improve the effect of removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: process certain chemical industry waste water with the inventive method.

[0034] COD of a chemical wastewater Cr , BOD 5 , ammonia nitrogen NH 4 -N, suspended solid SS are 1000~1500mg / L, 200~300mg / L, 100~150mg / L, 100~150 respectively, pH is 9.5~10.0, chroma is 400-500. The specific steps are as follows:

[0035] (1) The wastewater is pretreated by the grid, and then mixed with the wastewater returned from the catalytic reduction tank and enters the A / O biochemical tank for biochemical reaction. The volume load of the A / O tank is 0.5kgBOD 5 / m 3 .d;

[0036] (2) The effluent in step (1) enters the settling tank for solid-liquid separation, the settling time is 0.5 hour, and part of the precipitate produced is returned to the biochemical tank, and the rest is discharged as excess sludge, and the reflux ratio is 50%;

[0037] (3) The effluent in step (2) enters the electrolytic cell in the catalytic iron again, and the reaction time of the electrolytic...

Embodiment 2

[0041] Embodiment 2: Process the mixed industrial waste water of certain industrial zone with the inventive method.

[0042] COD of wastewater Cr 、BOD 5 , SS are 500~800mg / L, 100~200mg / L, 200~300mg / L respectively, and the pH value is 6.5~8.0. It is processed by the method of the present invention. In order to reduce the occupied area, the biochemical pool adopts the SBR process in this process. Since the wastewater contains a large amount of colloidal suspended matter, a coagulation air flotation process is set up before the SBR tank, and the specific steps are as follows:

[0043] (1) The wastewater is pretreated by the grid, and then enters the coagulation air flotation tank. The coagulant is polyaluminum, and the dosage is 30mg / L. The effluent and the wastewater returned from the catalytic reduction tank are mixed into the SBR tank for biochemical reaction;

[0044] (2) The treated water obtained in the step (1) enters the settling tank, and the settling time is 1.0 hour...

Embodiment 3

[0049] Embodiment 3: process the dye wastewater discharged from a certain factory with the method of the present invention. The effluent is required to meet the nanotube discharge standard of the industrial park: COD Cr ≤300mg / l, SS≤80mg / l, chroma≤80.

[0050] COD of wastewater Cr , SS, respectively 2000~3000mg / L, 300~400mg / L, 200~300mg / L, pH value 5.5~7.5. It is processed by the method of the present invention. Due to the COD of wastewater Cr The content is very high. In this process, the biochemical pool adopts the filler A / O process. Specific steps are as follows:

[0051] (1) The waste water is pretreated by the grid, and then mixed with the waste water returned from the catalytic reduction tank and enters the A / O biochemical tank for biochemical reaction;

[0052] (2) The effluent in step (1) enters the settling tank for solid-liquid separation. The settling time is 2.0 hours, and part of the produced sediment is refluxed to the biochemical tank, and the rest is dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com