Process for electrochemical deposition preparation of solar cell film materials

A technology for solar cells and thin film materials, applied in sustainable manufacturing/processing, circuits, electrical components, etc., can solve problems such as difficulty in uniformity control, and achieve the effects of low cost, easy process control, and high raw material utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

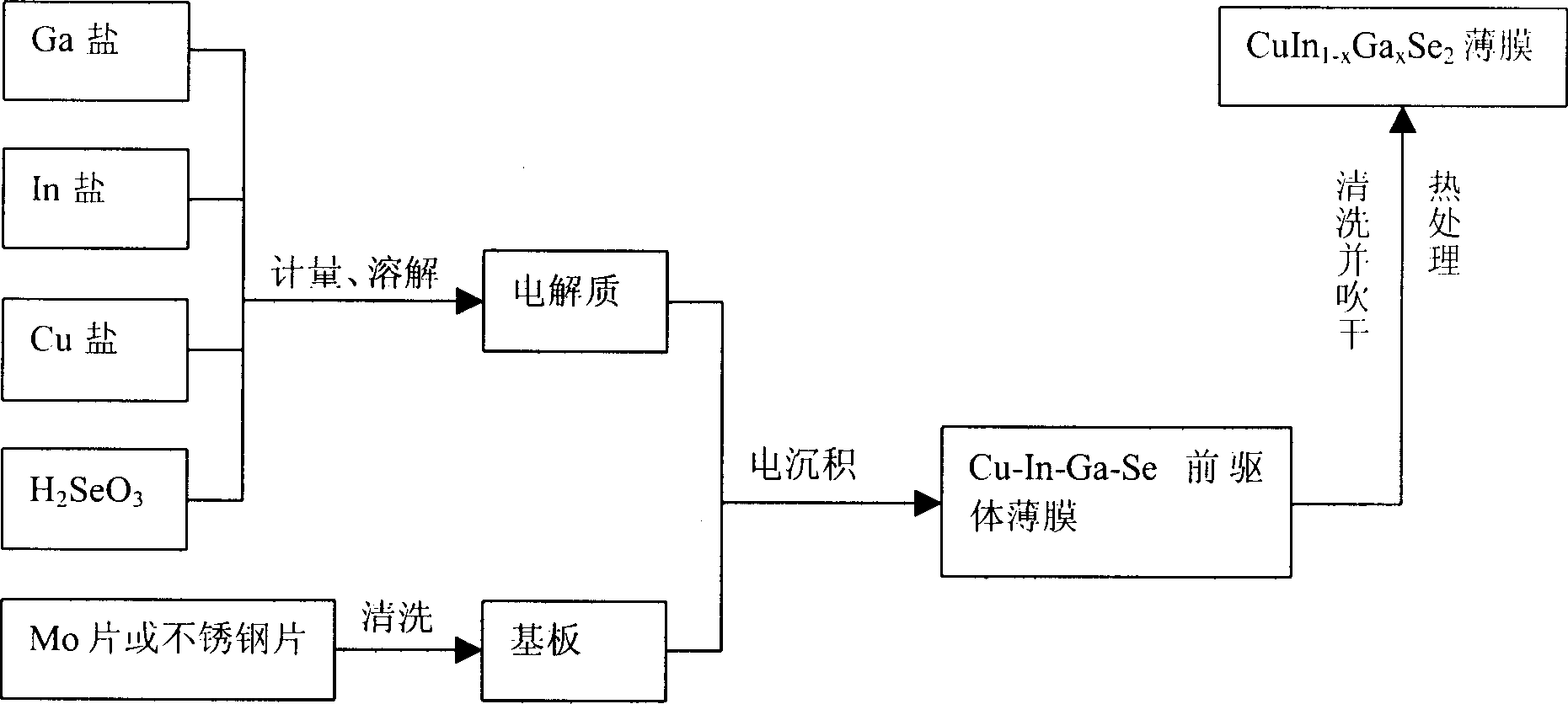

Method used

Image

Examples

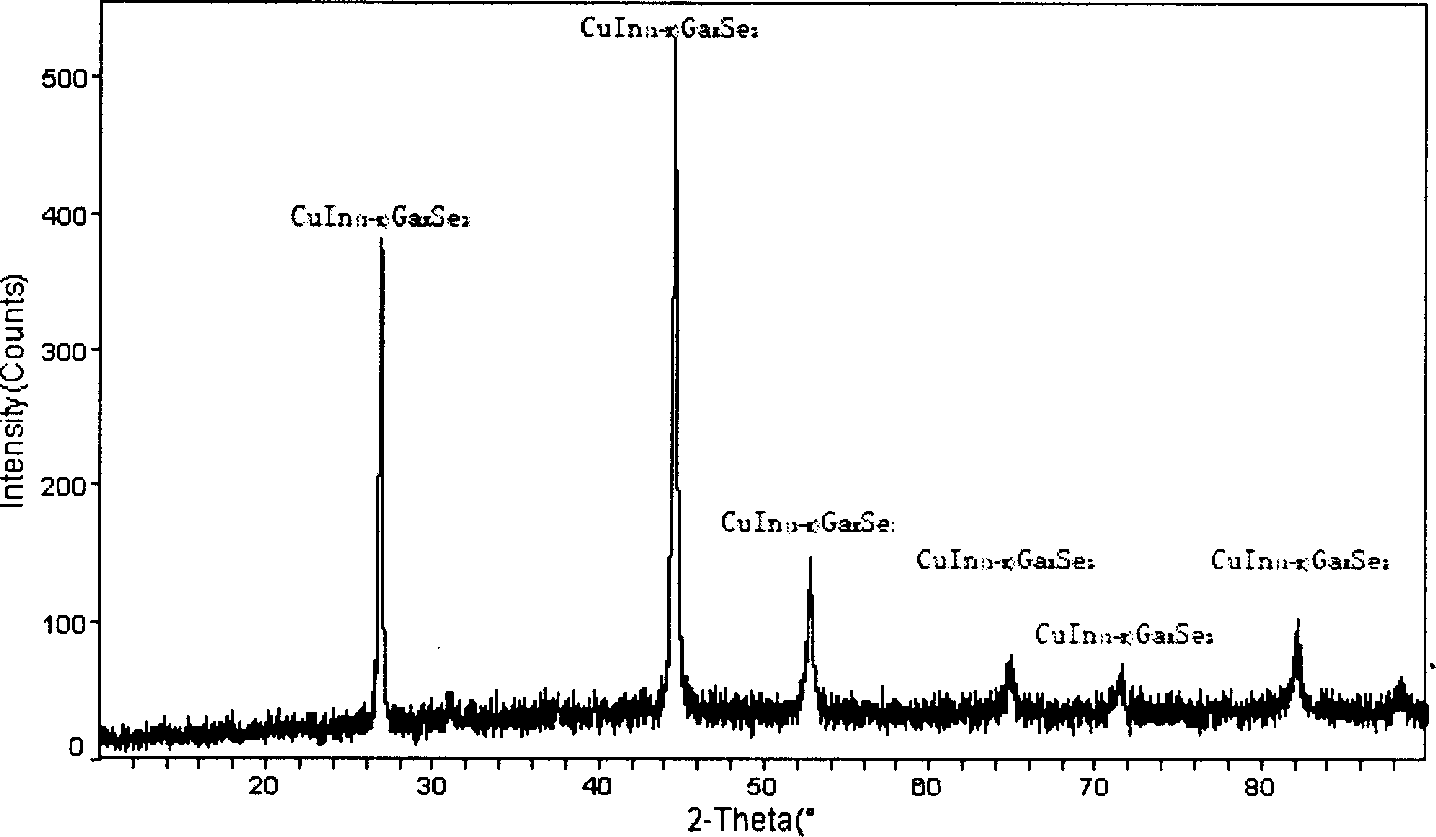

Embodiment 1

[0011] with CuCl 2 , InCl 3 , GaCl 3 , H 2 SeO 3 As raw material, proportional to 0.012mol / LCuCl 2 , 0.025mol / LInCl 3 , 0.025mol / LGaCl 3 , 0.025mol / LH 2 SeO 3 , ethanol is the solvent preparation electrodeposition solution (electrolyte solution), after the material in the solution dissolves completely, add dilute nitric acid to PH=1.5, pass into argon 30 minutes; Adopt three-electrode system, the solution prepared by the above method is Electrodeposition solution, platinum mesh as anode, molybdenum sheet as cathode, calomel saturated electrode as reference electrode, deposition voltage is -5.5V (VS.SCE), deposition time is 10 minutes, and finally dried with argon to obtain CuIn 1-x Ga x Se 2 Precursor thin film; put the above thin film into a tube furnace, and in an argon protective atmosphere, raise the temperature to 450°C at a rate of 10°C per minute and keep it warm for 30 minutes. After the heat preservation is over, cut off the power supply and cool down natura...

Embodiment 2

[0013] with CuCl 2 , InCl 3 , GaCl 3 , H 2 SeO 3 As raw material, proportional to 0.012mol / LCuCl 2 , 0.020mol / LInCl 3 , 0.020mol / LGaCl 3 , 0.025mol / LH 2 SeO 3 , dimethyl sulfoxide is used as a solvent to prepare an electrodeposition solution (electrolyte solution). After the substances in the solution are completely dissolved, dilute nitric acid is added dropwise to PH=2, and argon gas is passed into it for 30 minutes; a three-electrode system is used to prepare the above-mentioned method. The solution obtained is the electrodeposition solution, the platinum mesh is the anode, the stainless steel sheet is the cathode, the calomel saturated electrode is the reference electrode, the deposition voltage is -5.5V (VS.SCE), the deposition time is 10 minutes, and finally blown with argon CuIn 1-x Ga x Se 2 Precursor thin film; put the above thin film into a tube furnace, and in an argon protective atmosphere, raise the temperature to 450°C at a rate of 10°C per minute and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com