Copper-idium-selenium CuInSe solar cell and preparing method thereof

A solar cell, copper indium selenide technology, applied in circuits, electrical components, photovoltaic power generation and other directions, can solve problems such as cost reduction, difficulty in realizing industrialization, large waste of precious metals, etc. good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

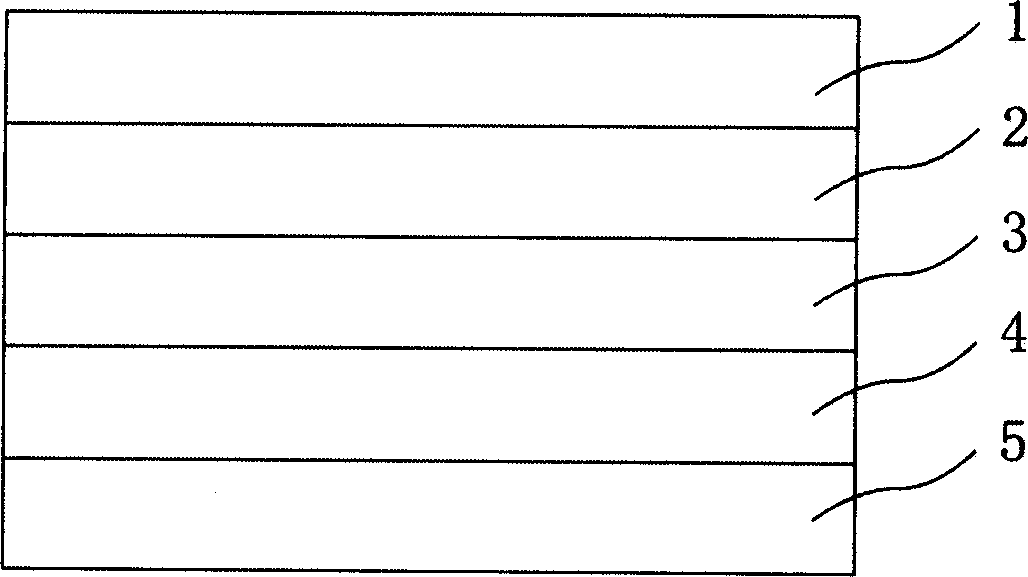

[0019] Such as figure 1 As shown, the high-efficiency copper indium selenium CuInSe described in the present invention 2 A solar cell consists of a lower electrode 1, a P-type copper indium selenium CuInSe 2 Sheet 2, transition layer CdS 3, N-type ZnO layer 4 and upper electrode 5. P-type Copper Indium Selenium CuInSe 2 The absorber layer is CuInSe 2 Single wafer, the lower electrode adopts Cu / Mo (copper / molybdenum) alloy.

[0020] In order to prepare the above-mentioned high-efficiency copper indium selenium CuInSe 2 Solar cell, preparation method of the present invention, comprises the following steps:

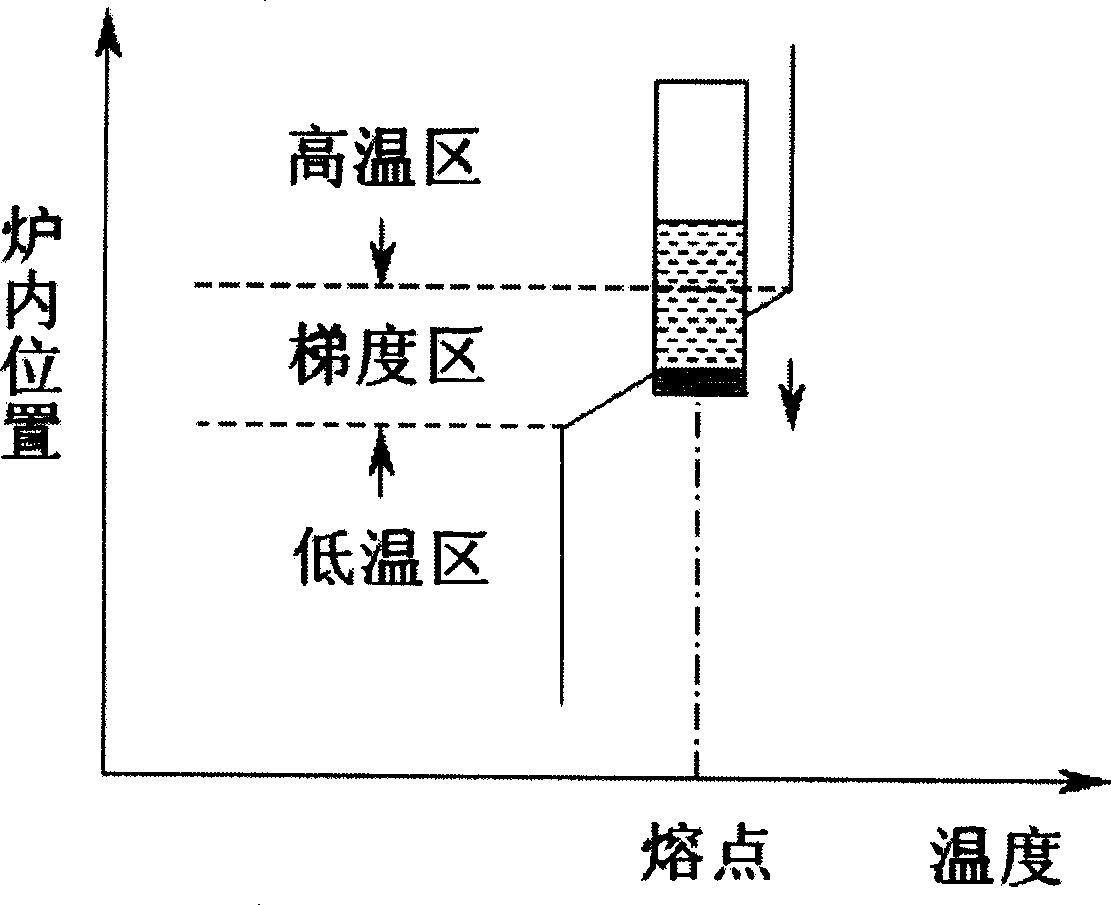

[0021] A certain amount of high-purity copper (99.999%), indium (99.999%) and selenium (99.999%) particles are removed from the surface oxide layer and then fully mixed according to the molar ratio of Cu:In:Se=1:1:2. Put it into a cleaned thick-walled quartz tube (crucible), which has been sealed at one end. Vacuum the quartz tube to 10 -6 , the other end of the quar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com