Bamboo shoots amino acid peptide extract its production and use

A technology of extracts and amino acids, which is applied in the preparation methods of peptides, cyanide reaction preparations, and organic compounds, and can solve problems such as the single form of bamboo shoot processing products and blank reuse of bamboo shoot processing waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

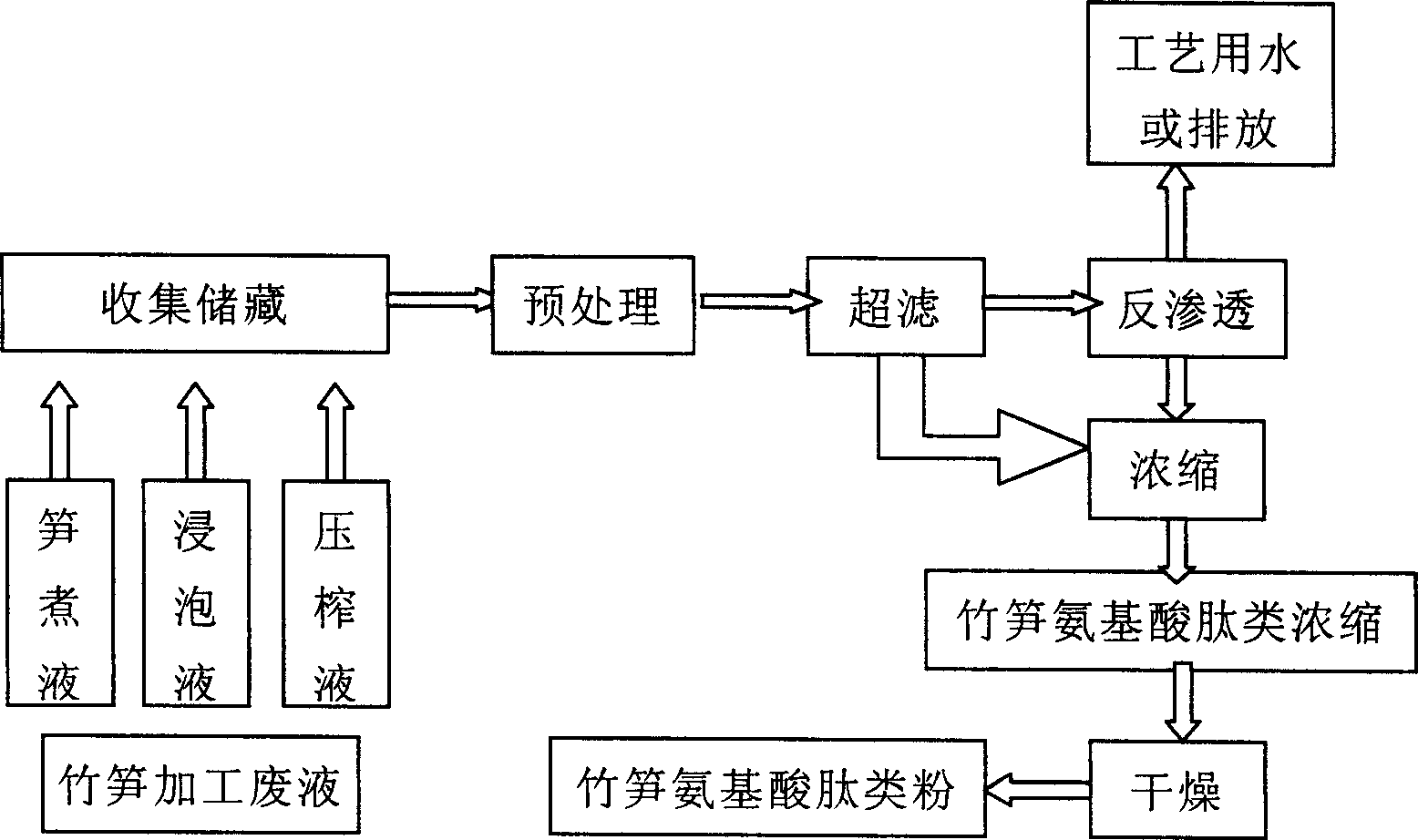

[0057] The preparation method of extract of the present invention generally comprises the following steps:

[0058] (1) Pretreatment: adjust the pH value of bamboo shoot processing waste liquid to 4-5, centrifuge to separate impurities, pre-concentrate to a certain volume, and go through coarse filtration and microfiltration before use.

[0059] (2) Ultrafiltration treatment: The feed liquid with a temperature between 40 and 50°C is passed through an ultrafiltration membrane system (such as an ultrafiltration membrane with a molecular weight cut-off of 5,000 to 100,000) at an operating pressure of 0.2 to 1Mpa, thereby achieving macromolecular filtration. Separation of substances from small and medium molecules such as amino acids, peptides, sugars, etc., to obtain ultrafiltration permeate.

[0060] (3) Reverse osmosis treatment: pass the above-mentioned ultrafiltration permeate through the reverse osmosis membrane system under the operating pressure of 1-2.5Mpa to achieve the ...

Embodiment 1

[0074] Preparation of Amino Acid Peptide Concentrate of Phyllostachys pubescens

[0075] The amino acid peptide extract of Phyllostachys pubescens (in the form of concentrate) was prepared according to the following steps.

[0076] Step 1) Preprocessing:

[0077] Collect the blanching waste water from the processing of moso bamboo shoots to the waste water tank, enter the pretreatment device through the waste liquid booster pump, adjust the pH value of the system to 4.2 with 0.1mol / L HCl solution, and centrifuge to remove the flocculent precipitate; After concentrating under reduced pressure to one-fifth of the volume, the particles and bacteria above 5 μm and 0.2 μm were removed by coarse filtration and microfiltration respectively, and the temperature of the feed liquid was kept at about 45°C.

[0078] Step 2) ultrafiltration treatment:

[0079] Pass the pretreated feed liquid through a closed roll-type ultrafiltration membrane system (polysulfone membrane with a molecular...

Embodiment 2

[0085] Preparation of Amino Acid Peptide Concentrate of Green Bamboo Shoots (Horseshoe Shoots)

[0086] According to the method similar to Example 1, green bamboo shoot amino acid peptide extract (in the form of concentrate) was prepared through the following steps.

[0087] Step 1) Preprocessing:

[0088] Collect green bamboo shoots (horseshoe shoots) processing and soaking waste liquid into the waste water tank, enter the pretreatment device through the waste liquid booster pump, adjust the pH value of the system to 4.5, and centrifuge to remove the flocculent precipitate; concentrate the clear liquid under reduced pressure to After about one-fifth of the volume, the particles and bacteria above 5 μm and 0.2 μm were removed by coarse filtration and microfiltration respectively, and the temperature of the feed liquid was kept at about 45°C.

[0089] Step 2) ultrafiltration treatment:

[0090] The pretreated feed liquid passes through the closed ultrafiltration membrane syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com