Processing technology for converting mud into fertilizer

A treatment process and transformed technology, applied in the field of environment and resource utilization, can solve the problems of waste of resources, occupation of land resources, secondary pollution, etc., and achieve the effects of promoting the development of plant roots, reducing manufacturing costs, and reducing pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

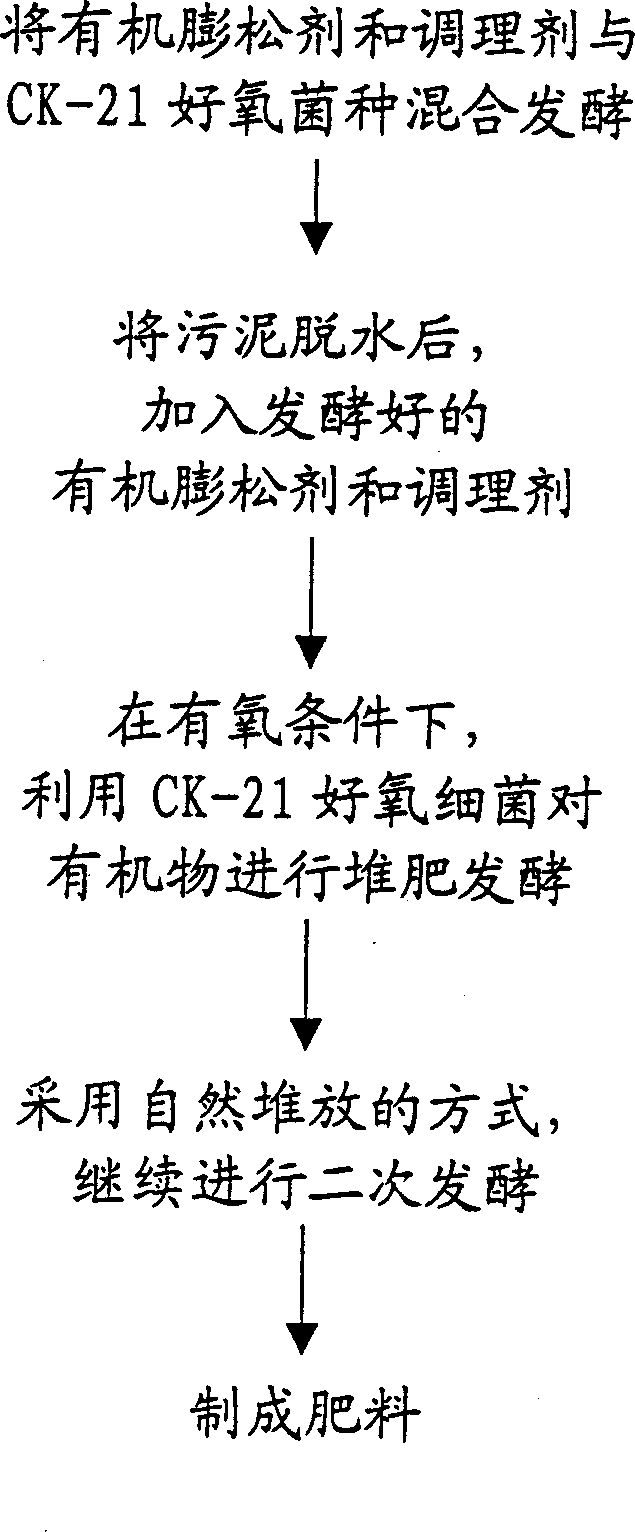

[0021] Such as figure 1 Shown, be preferred embodiment of the present invention, the step of its specific processing technology is:

[0022] 1. Adjust materials.

[0023] Mix and ferment the organic leavening agent and conditioner with CK-21 aerobic bacteria first to reduce the water content of the organic leavening agent and conditioner, increase the number of bacteria per unit, and avoid too long growth time in the early stage of sludge fermentation. The time for sludge fermentation and maturation is greatly shortened. The organic leavening agent can be crop straw powder, sawdust, rice husk, etc. Adding these dry, light and easy-to-decompose materials can reduce the specific gravity of the entire material, increase the degree of looseness, and increase the contact area with the air. conducive to aerobic fermentation. The conditioner can use fly ash, bentonite and other dry substances to reduce moisture, or according to the resource situation, the leftovers of mushroom cul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com