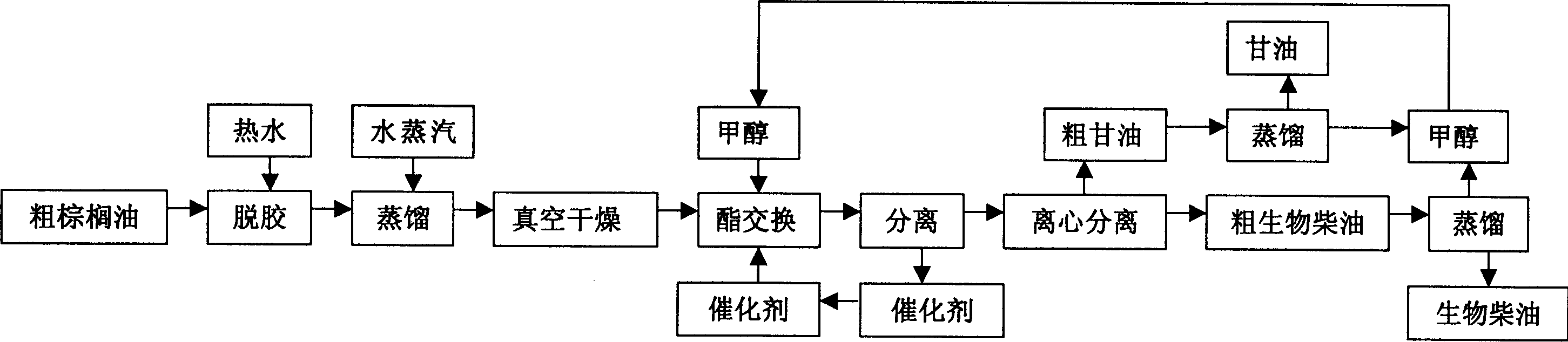

Process for preparing biological diesel oil using palm oil

A biodiesel and palm oil technology, applied in the field of oleochemistry, can solve the problems of reducing the yield of biodiesel, reducing catalyst activity, and difficult separation of glycerin, achieving simple and easy separation, improving conversion rate and rate, and good economy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] After filtering, 100 parts of crude palm oil containing 4.60% of free fatty acid content by weight, 0.50% of moisture, and 0.08% of solid impurities are heated to 90°C, and enter the proportioning machine together with 11 parts of 90°C hot water to mix, and the oil and water pass through After 23S reaction, enter the butterfly centrifuge to separate the oil feet and grease; the grease is heated to 265°C, and sent to the plate distillation tower for steam distillation. All layers in the tower are directly steamed to distill fatty acids, and the amount of direct steam is 2.5 parts. Maintain an absolute pressure of 3mmHg in the tower, a temperature of 260°C, and flow through the entire tower for 80 minutes. The oil after removing fatty acids is cooled to 88°C and enters a vacuum dryer. The absolute pressure in the dryer is maintained at 55mmHg, and the temperature is 100°C. After drying and dehydration The oil is cooled to 70°C through a heat exchanger, and the free fatty a...

Embodiment 2

[0027] After filtering, 100 parts of crude palm oil containing 7.50% of free fatty acid content by weight, 0.24% of moisture, and 0.12% of solid impurities are heated to 85°C, and enter the proportioning machine together with 10 parts of 90°C hot water to mix, and the oil and water pass through After 25S reaction, enter the butterfly centrifuge to separate the oil feet and grease; the grease is heated to 270°C, and sent to the plate distillation tower for steam distillation. All layers in the tower are directly steamed to distill fatty acids, and the amount of direct steam is 3.5 parts. Maintain an absolute pressure of 2mmHg in the tower, a temperature of 270°C, and flow through the entire tower for 80 minutes. The oil after removing fatty acids is cooled to 90°C and enters a vacuum dryer. The absolute pressure in the dryer is maintained at 50mmHg, and the temperature is 95°C. After drying and dehydration The oil is cooled to 65°C through a heat exchanger, and the free fatty ac...

Embodiment 3

[0029]After filtering, 100 parts of crude palm oil containing 2.10% of free fatty acid content, 0.37% of moisture, and 0.05% of solid impurities are heated to 88°C by weight, and then enter the proportioning machine together with 9.5 parts of 90°C hot water to mix, and the oil and water are mixed through After the 23S reaction, enter the butterfly centrifuge to separate the oil feet and grease; the grease is heated to 260°C, and sent to the plate distillation tower for steam distillation. All layers in the tower are directly steamed to distill fatty acids, and the amount of direct steam is 2 parts. The tower maintains an absolute pressure of 2mmHg, a temperature of 265°C, and a time of 80 minutes to flow through the entire tower. The oil after removing fatty acids is cooled to 85°C and enters a vacuum dryer. The absolute pressure of the dryer is maintained at 60mmHg, and the temperature is 90°C. The oil is cooled to 68°C through a heat exchanger, and the free fatty acid content...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com