Medicine composition contg. sodium azulene sulfonate and L-glutamine water-soluble precursor

A technology of glutamine and sodium azulene sulfonate, which is applied in the direction of drug combination, drug delivery, and pharmaceutical formulations, and can solve problems affecting product performance, L-glutamine instability, and unfavorable product storage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

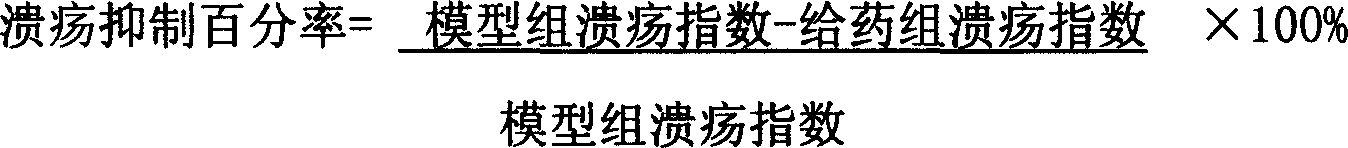

Method used

Image

Examples

Embodiment 1

[0050] The preparation method of sodium azulene sulfonate

[0051] Dissolve 40.0g (0.20mol) of guaiazulene in 200ml of acetic anhydride, stir in an external ice-salt bath, add 76.0mL (0.18mol) of concentrated sulfuric acid dropwise at below 5°C, and complete the addition within 1 hour. The ice bath was removed, and stirring was continued to room temperature. After stirring at room temperature for 2 hours, the sulfonation reaction was completed. The reactant was slowly poured into 500 mL of ice water, and the aqueous layer was extracted with petroleum ether (60-90° C., 3×200 mL) to remove unreacted guaiazulene. Add 25% sodium hydroxide to the water layer to neutralize the pH value to 8, precipitate the crude sodium azulene sulfonate, filter, and quickly wash with 200mL water until the lotion is blue-purple. An appropriate amount of water was recrystallized once to obtain 31.7 g of sodium azulene sulfonate, with a yield of 79.3%.

Embodiment 2

[0053] Preparation method of glycyl-L-glutamine

[0054] Add 46.0g (0.22mol) benzyloxyformylglycine, 26.5g (0.23mol) hydroxysuccinimide and 1300mL ethyl acetate in sequence to a dry 2L reaction flask, stir and dissolve, then cool in an ice bath to below 5°C, Add 49.4g (0.24mol) of dicyclohexylcarbodiimide, and stir at room temperature (25±5°C) for 8 hours. After the reaction was finished, the dicyclohexyl urea generated by the reaction was removed by filtration to obtain the ethyl acetate solution I of the active ester (standby).

[0055] Add 36.5g of L-glutamine and 400mL of 10% sodium bicarbonate aqueous solution into a 3L reaction flask, cool with ice water to room temperature 10-15°C, add the active ester ethyl acetate solution I dropwise under stirring, and add for about 1 hour. use up. When adding about 2 / 3 volume active ester solution, add 200mL 10% sodium bicarbonate aqueous solution again in reaction bottle. After the addition of the active ester, the stirring was ...

Embodiment 3

[0058] The preparation method of L-alanyl-L-glutamine

[0059] Add 1000mL ethyl acetate and dry 48.0g (0.54mol) L-alanine fine powder to the 2L reaction flask in turn, and after stirring and refluxing for half an hour, add 97.0g (82.0mL, 0.57mol) benzyloxymethyl from the upper end of the condenser tube Acyl chloride, continue to stir and reflux for 12h. After the reaction liquid is cooled, filter to remove L-alanine hydrochloride and a small amount of unreacted L-alanine, concentrate under reduced pressure (ethyl acetate can be recovered and apply), and add 500mL petroleum ether to the residue to soak, filter and wash with a little petroleum ether After washing (recovered after petroleum ether distillation), and drying, 48.4 g of benzyloxyformyl-L-alanine was obtained, with a melting point of 80-84° C. and a yield of 80%.

[0060] In a dry 2L reaction flask, add 48.4g (0.22mol) benzyloxyformyl-L-alanine, 28.0g (0.24mol) hydroxysuccinimide and 1500mL ethyl acetate in sequence,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com