Electrochemical cross-linking process for surface modification of biological material

A biomaterial and surface modification technology, applied in the field of biomedical materials, can solve the problems of the influence of the material body structure, the complex operation process, the expensive equipment and other problems, to improve the anticoagulant performance, the process is simple, and the reproducibility is good. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

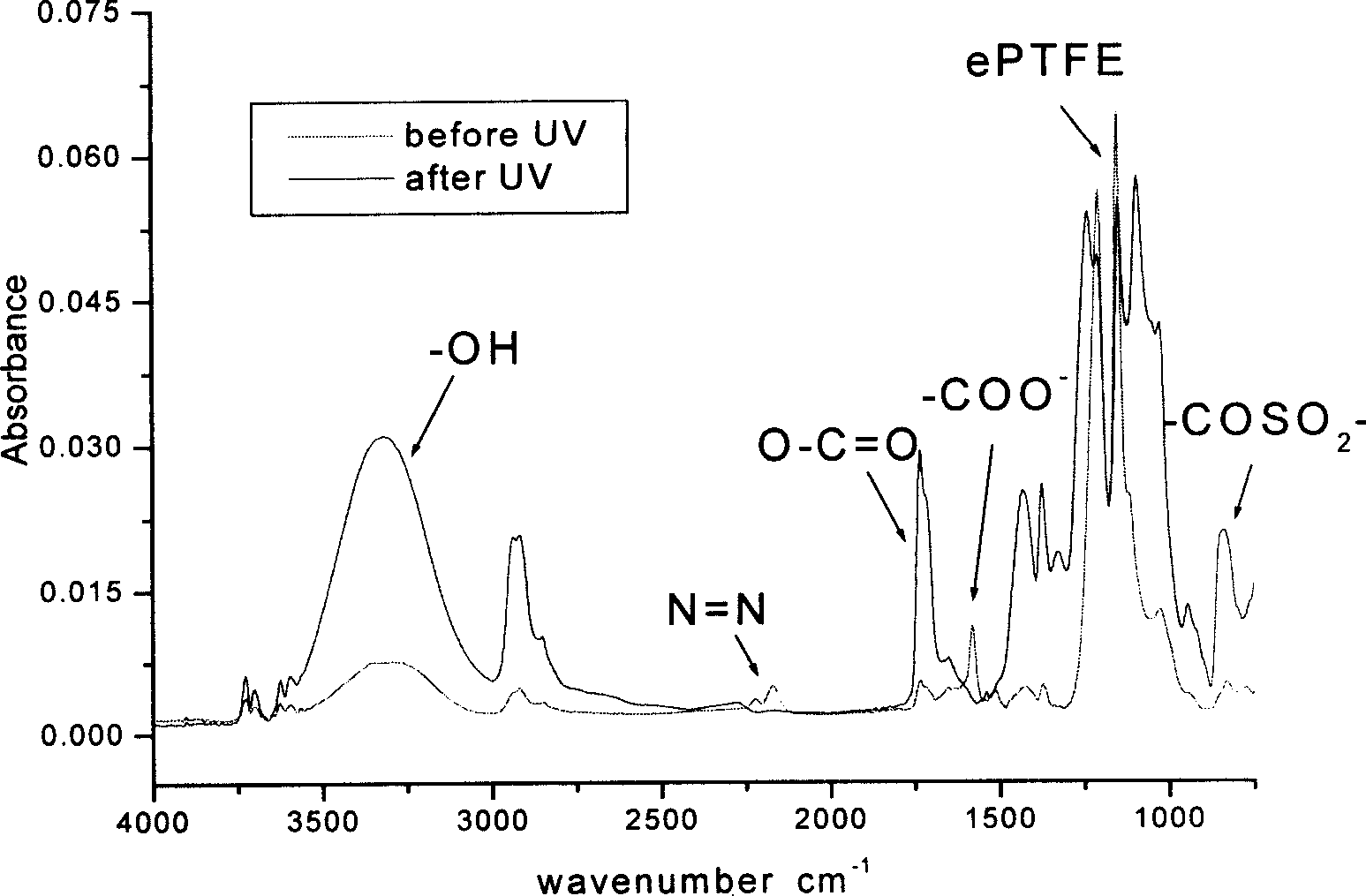

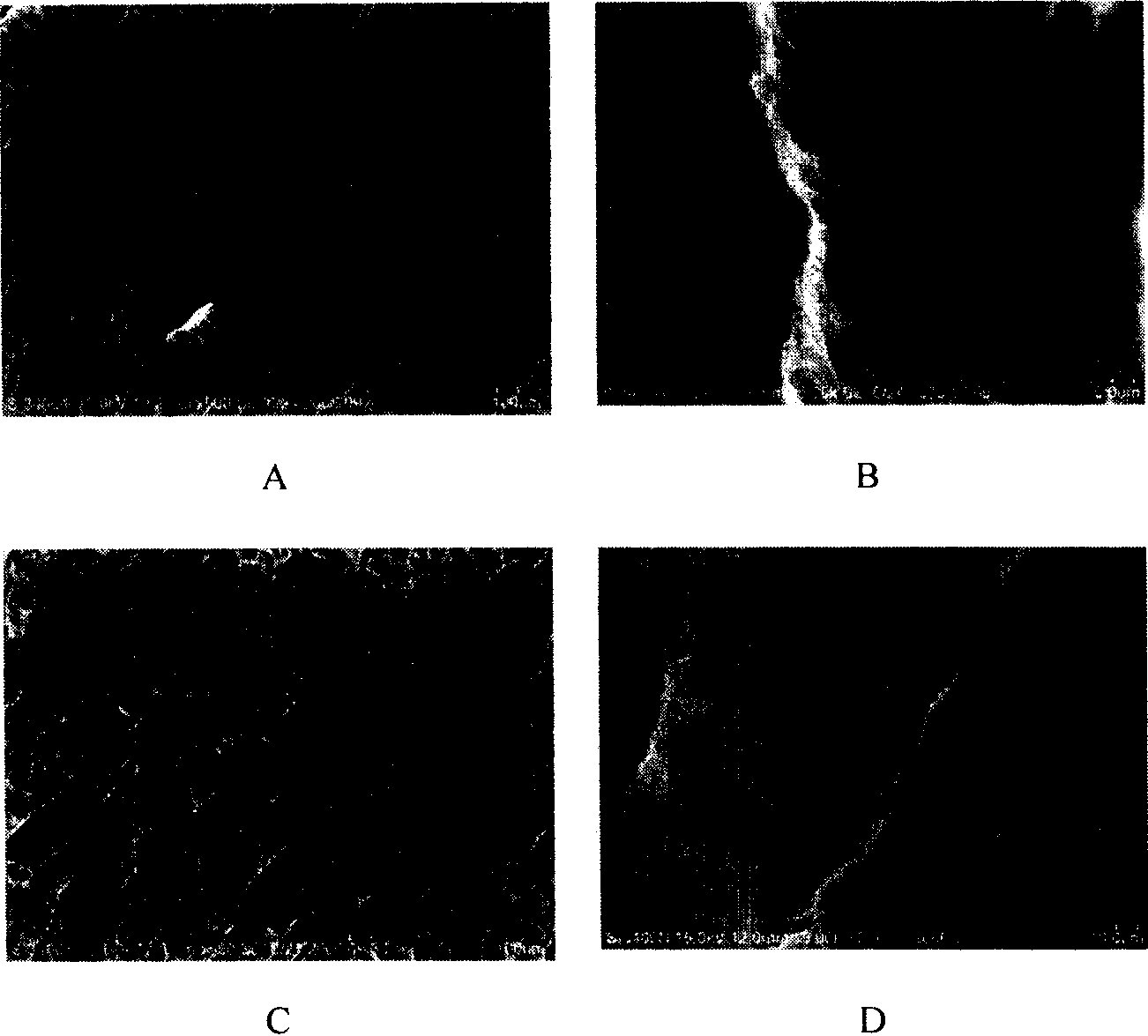

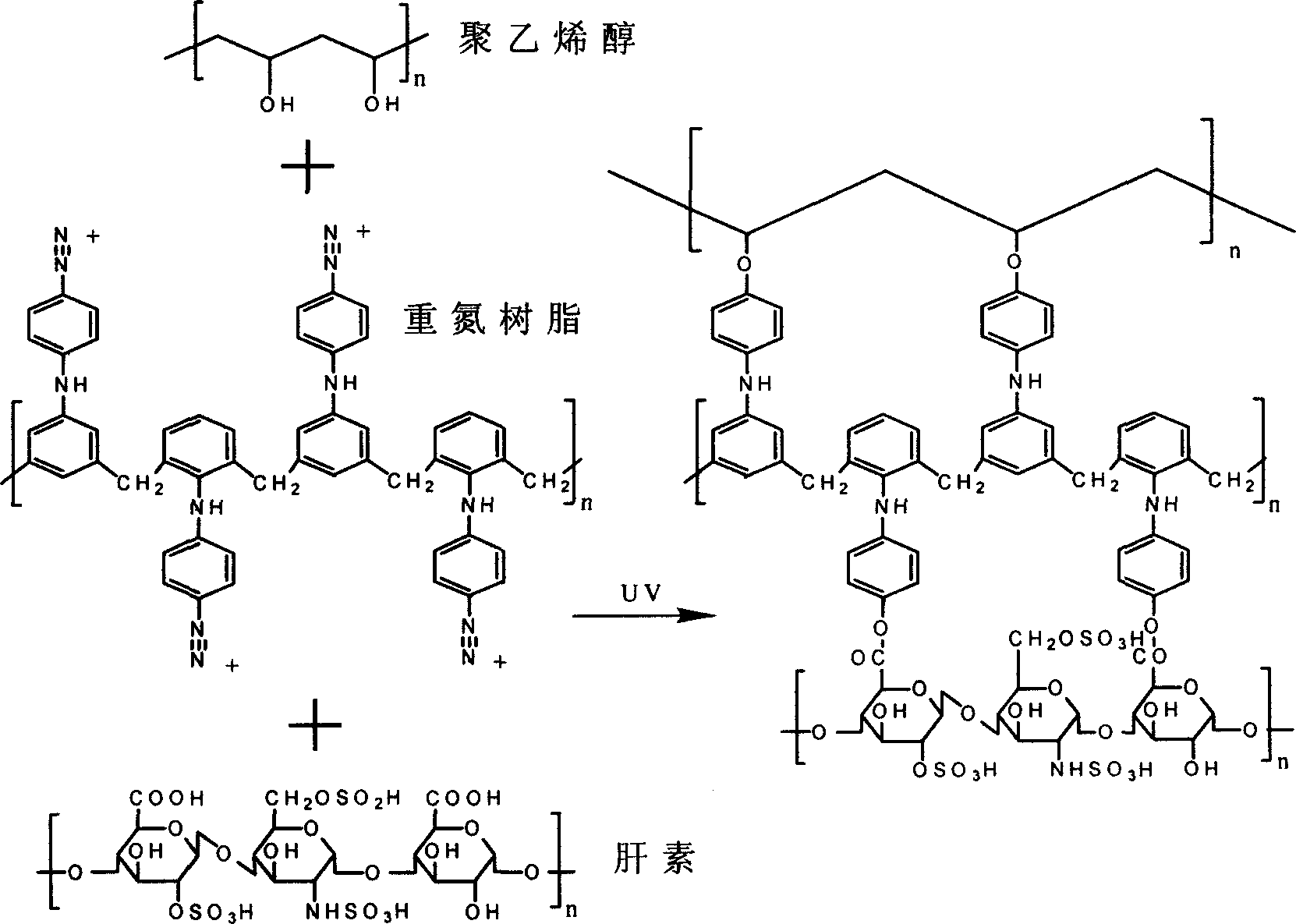

specific Embodiment approach 1

[0015] Specific embodiment 1: This embodiment is achieved in this way: a, soak the biological material in an organic solvent, ultrasonically clean it, and dry it; b, coat perfluorosulfonic acid on the surface of the biological material; c, prepare polyvinyl alcohol, A mixed solution of diazo resin and biologically active substances, and apply it on the surface of the biological material; d, after drying, irradiate the polymer coating with ultraviolet light, and make the polymer in the coating covalently react through photochemical reaction bonded crosslinks.

[0016] In this embodiment, the biological material can be artificial blood vessels of various calibers made of various materials including expanded polytetrafluoroethylene, or blood catheters of various calibers made of various materials, polymer Membranes or porous scaffolds, and biomedical devices of various shapes made of materials such as glass, ceramics, silicon, various metals or various polymers, preferably polyte...

specific Embodiment approach 2

[0021] Specific implementation mode two: this implementation mode is realized in this way:

[0022] (1) Artificial blood vessel pretreatment: ultrasonically clean the artificial blood vessel in absolute ethanol for 1-300 minutes, and dry at 10-150° C. for 0.1-24 hours.

[0023] (2) The artificial blood vessel is perfused with 0.01-30 wt% perfluorosulfonic acid solution, soaked for 1-300 minutes, and dried.

[0024] (3) Prepare a mixed aqueous solution of polyvinyl alcohol, diazo resin and heparin, perfuse the dried artificial blood vessel, and let it dry.

[0025] (4) The artificial blood vessel is irradiated with ultraviolet light, and covalent bond cross-linking occurs between polymers in the coating through photochemical reaction.

[0026] In step (1) of this embodiment, the ultrasonic time is preferably 30 minutes, the drying temperature is preferably 60° C., and the drying time is preferably 0.5 hour.

[0027] In step (2) of this embodiment, the concentration of the per...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mw | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com