Composite organic-inorganic material film as immobilized cell carrier

An inorganic composite material, immobilized cell technology, applied in the direction of being fixed on/in organic carriers, fungi, etc., can solve the problems of small specific surface, poor strength, accelerated microbial reproduction, etc. The effect of good cell affinity and increasing the advantages of industrial application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

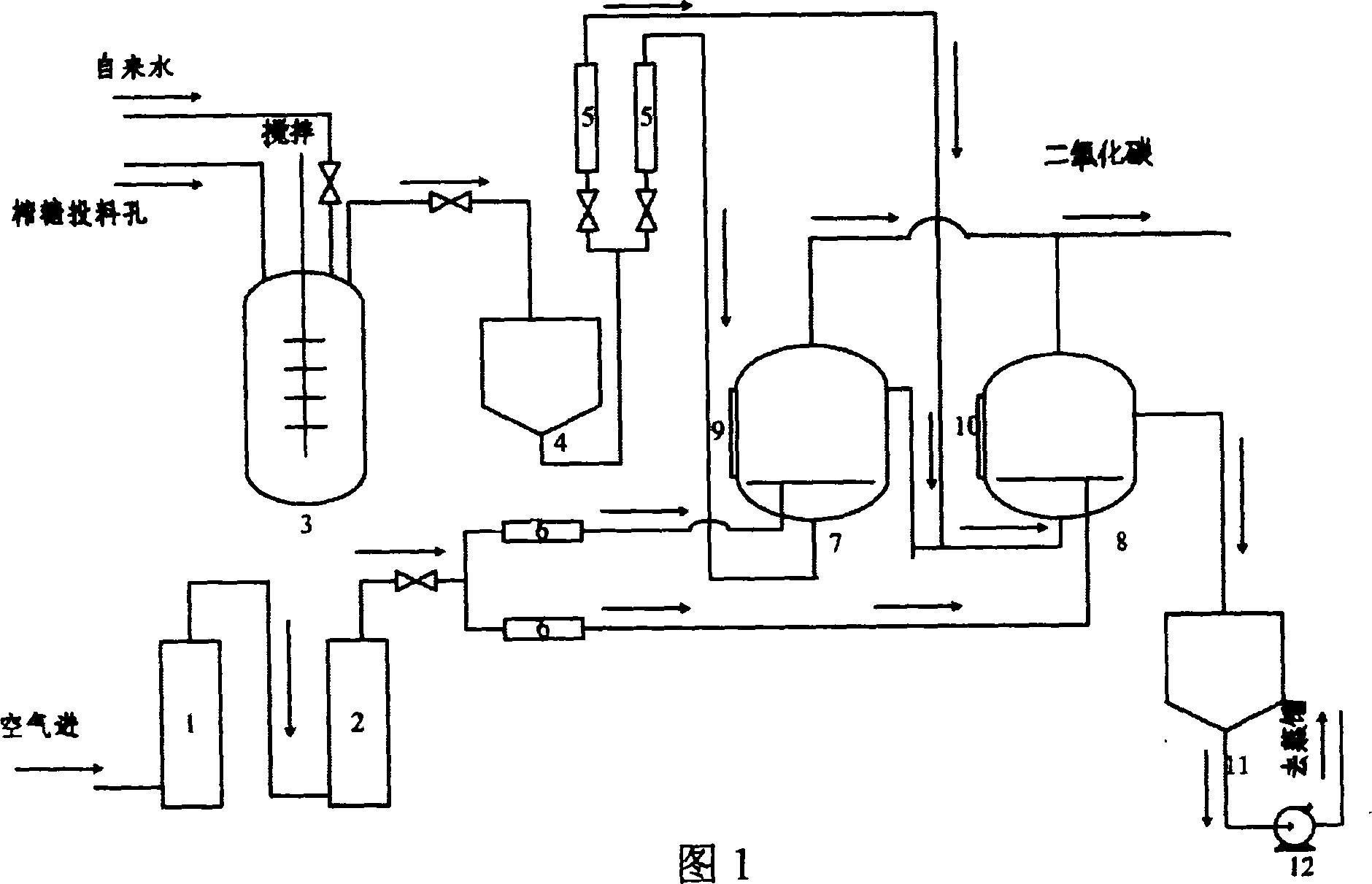

Image

Examples

Embodiment 1

[0016] According to the quality, take 2.50 parts of polyether, 0.02 parts of silicone oil, 0.01 parts of triethylenediamine, 0.01 parts of stannous octoate, and 0.08 parts of water. 0.40 parts, 0.40 parts of MCM-41 mesoporous molecular sieve, 1.20 parts of toluene diisocyanate was added under stirring, and after mixing, it was placed in a mold and foamed into a film to obtain a microorganism-immobilized carrier; the microorganism-immobilized carrier was added to yeast In the bacterial suspension with a concentration of 1.5-2 billion / mL, put it into the molasses medium (the added ingredients are similar to the YEPD medium, the same below) for proliferation and culture; after training for 3-6 days, the amount of carrier embedding can reach 3-5 billion cells / mL, when the number of exuded free cells reaches more than 100 million cells / mL, it is transferred to the fermentation stage.

[0017] In a columnar fermenter with a volume of 1L, add the above-mentioned immobilized carrier a...

Embodiment 2

[0019] According to the quality, take 5.00 parts of polyether, 0.05 parts of silicone oil, 0.02 parts of triethylenediamine, 0.02 parts of stannous octoate, and 0.18 parts of water. 1.00 parts of stone, 1.00 parts of MCM-41 mesoporous molecular sieve, add 2.40 parts of toluene diisocyanate under stirring, mix well and place in a mold to form a film. The microorganism immobilization carrier is added into the bacterial suspension with a yeast concentration of 1.5-2 billion / mL, and put into the molasses medium for proliferation and cultivation. After training and culturing for 3-6 days, the amount of carrier embedding can reach 3-5 billion / mL, and the number of exuded free cells can reach more than 120 million / mL, and then transfer to the fermentation stage.

[0020] In a columnar fermentation tank with a volume of 1L, immobilized carriers were added according to a filling rate of 15.00%, 200g / L of raw molasses was added, and oxygen was continuously pumped to carry out batch ferm...

Embodiment 3

[0022] According to the mass, take 4.00 parts of sodium alginate, 8.00 parts of polyvinyl alcohol, and 88.00 parts of water, stir and heat at 100-120°C until dissolved and mixed uniformly, then add 0.40 parts of boehmite and 0.40 parts of MCM-41 and mix well; After sterilization, cool to room temperature, add 20 parts of yeast suspension with a concentration of 1.5-2 billion / mL, stir evenly, and use a film coating machine to coat the film with a film thickness of 3 mm; immerse the film in 2% chlorinated Solidified in calcium solution for 4 hours; after washing with a large amount of water, put it into molasses culture medium and proliferate with oxygen. After 40-72 hours of cultivation, the amount of carrier embedding can reach 3-5 billion / mL, and the number of exuded free cells can reach More than 160 million / mL, transfer to the fermentation stage.

[0023] In a columnar fermenter with a volume of 1L, add the above-mentioned immobilized carrier according to the filling rate o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com