Integrated assembly and substrate structure and its production for polymer ultraviolet/visible-light collimator

A visible light and polymer technology, applied in the direction of microstructure technology, microstructure devices, manufacturing microstructure devices, etc., can solve the problems of high production cost, long production cycle and complicated process of silicon wafer V-shaped groove structure for positioning, and achieve High signal-to-noise ratio, satisfying multi-index inspection, and improving coupling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

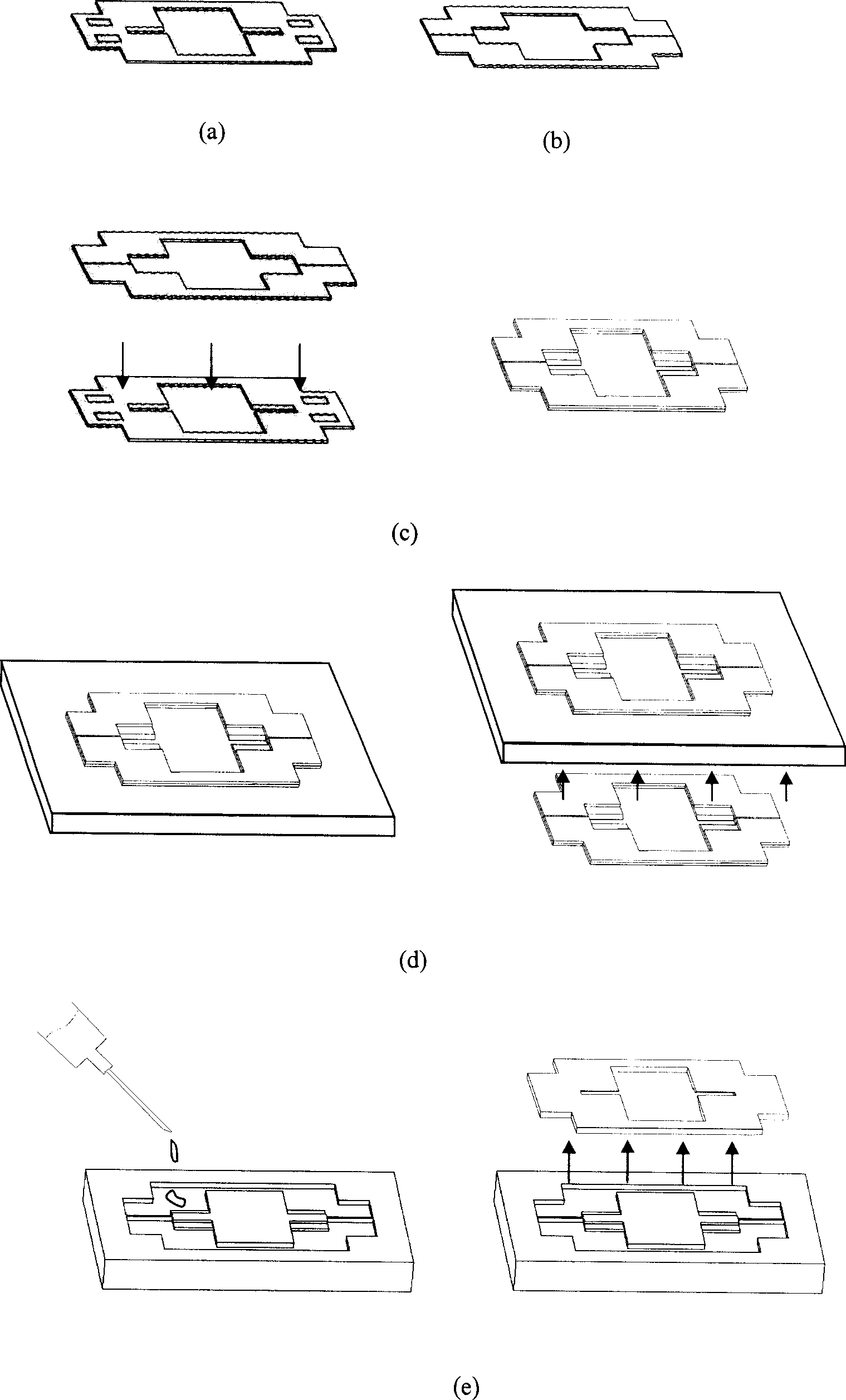

[0019] The fabrication method of the polymer ultraviolet / visible light collimator integrated component substrate structure proposed by the present invention is as follows: image 3 shown.

[0020] (1) Using photolithography, wet etching and other processes in micromechanical silicon processing technology, select a 380 μm thick double-sided polished and oxidized Si single wafer, and make a first V-shaped groove with a width of 2.16 mm on the front side of the Si single wafer 4 and the second V-shaped groove 6; and then use photolithography, dry etching and other processes to make four rectangular positioning holes 12 with a side length of 2 mm × 3 mm on the front side of the Si single wafer, and the depth of the positioning holes 12 is 0.1 mm. The first sample cup groove 13 is transparent and located at the center of the Si single wafer, and the first sample cup groove 13 adopts a rectangular structure. Make the first substrate 1 that contains the first V-shaped groove 4, the ...

Embodiment 2

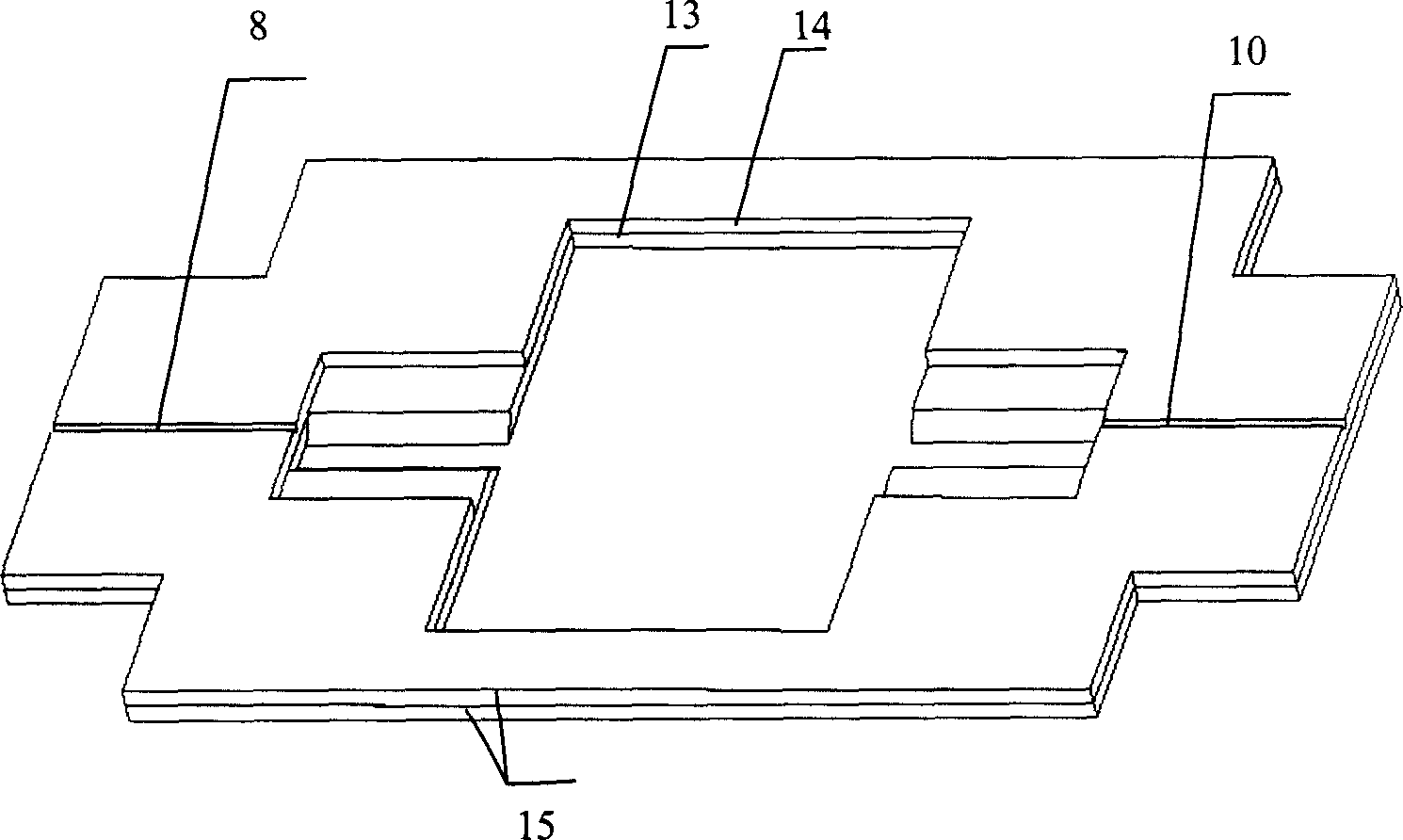

[0026] The manufacturing method of the polymer ultraviolet / visible light collimator integrated assembly structure proposed by the present invention can be utilized to manufacture the substrate structure mold, such as figure 2Shown: by the first substrate 1 and the second substrate 2, the first V-shaped groove 4, the second V-shaped groove 6, the third V-shaped groove 8, the fourth V-shaped groove 10, a plurality of positioning pins 11, A plurality of positioning holes 12, a first sample cup groove 13 and a second sample cup groove 14 are formed. On the body of the first substrate 1, a first V-shaped groove 4, a second V-shaped groove 6, a plurality of The positioning hole 12 and the first sample cup groove 13 are respectively prepared with a third V-shaped groove 8, a fourth V-shaped groove 10, a plurality of positioning pins 11 and a second sample cup groove 14 on the body of the second substrate 2 , a plurality of positioning pins 11 are placed in a plurality of positioning...

Embodiment 3

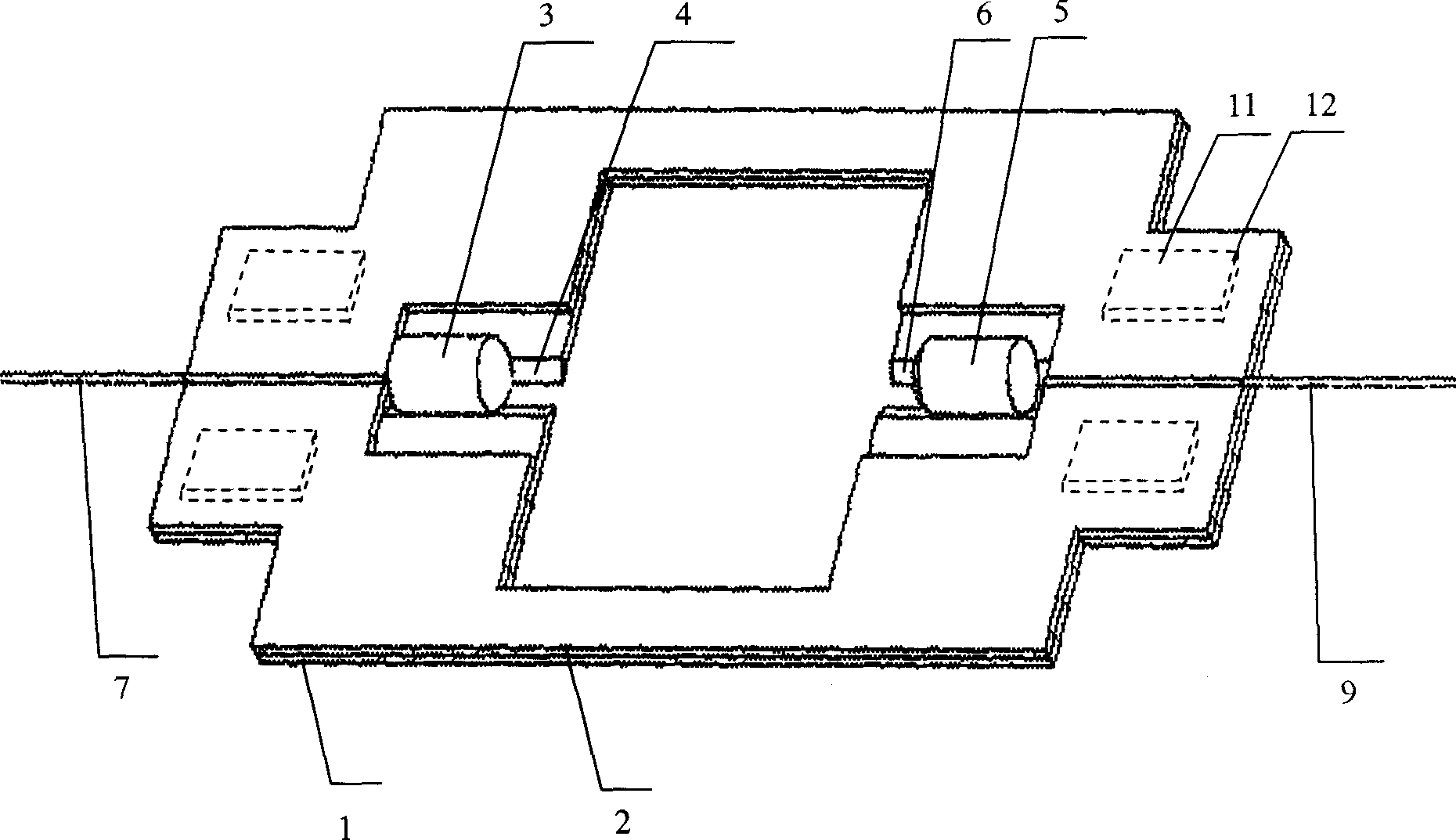

[0029] The method for making an integrated component structure of a polymer ultraviolet / visible light collimator proposed by the present invention can be used to manufacture component structures, such as figure 1 Shown: the input lens 3, the first V-shaped groove 4, the output lens 5, the second V-shaped groove 6, the input optical fiber 7, the third V-shaped groove 8, the output optical fiber 9, the fourth V-shaped groove 10, the first The sample cup groove 13, the second sample cup groove 14 and the substrate 15 are composed of the input lens 3, the first V-shaped groove 4, the output lens 5, the second V-shaped groove 6, the input optical fiber 7, the first V-shaped groove on the substrate 15 body. Three V-shaped grooves 8, output optical fiber 9, fourth V-shaped groove 10, first sample cup groove 13 and second sample cup groove 14, input lens 3 is placed in the first V-shaped groove 4, output lens 5 is placed in In the second V-shaped groove 6, the input optical fiber 7 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com