Method of preparing nano titanium dioxide crystallization induced by nano microcrystalline cellulose

A technology of nano-titanium dioxide and nano-crystallite, which is applied in the direction of titanium dioxide, chemical instruments and methods, titanium oxide/hydroxide, etc., to achieve the effects of regular shape, cheap raw materials, and shortened reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Step 1: Preparation of nanocrystalline cellulose

[0026] According to the method in Chinese invention patent No. 00117261, a kind of nano-microcrystalline cellulose and its preparation method, that is, natural cellulose is used, pre-treated with alkali, dimethyl sulfoxide, and quaternary ammonium salt, and then hydrolyzed with strong acid and ultrasonically oscillated. Prepare nano-microcrystalline cellulose;

[0027] Step 2: Preparation of Nano Titanium Dioxide

[0028] First in 100 grams of water, add 0.03 gram of nano-microcrystalline cellulose prepared in step 1, prepare a weight percentage concentration of 0.03% nano-microcrystalline cellulose aqueous dispersion, and then after ultrasonic treatment, add nano-crystalline cellulose to the nano-crystalline cellulose aqueous dispersion 0.5 milliliters (0.86 grams) of titanium tetrachloride was added dropwise, that is, the weight ratio of dry nano-microcrystalline cellulose and titanium tetrachloride was 1: 28.8, then...

Embodiment 2

[0032] Step 1: Preparation of nanocrystalline cellulose

[0033] Prepared according to the method in Chinese Invention Patent No. 00117261, a kind of nano-microcrystalline cellulose and its preparation method;

[0034] Step 2: Preparation of Nano Titanium Dioxide

[0035] First in 100 grams of water, add 0.06 gram of nano-microcrystalline cellulose prepared in step 1, prepare a weight percentage concentration of 0.06% nano-microcrystalline cellulose aqueous dispersion, and then after ultrasonic treatment, add nano-microcrystalline cellulose to the nano-microcrystalline cellulose aqueous dispersion 1.5 milliliters (2.59 grams) of titanium tetrachloride was added dropwise in the solution, that is, the weight ratio of dry nanocrystalline cellulose and titanium tetrachloride was 1: 43.2, and then stirred and reacted at 120° C., and the reaction time was 5.5 hours;

[0036] Step 3: Post-processing

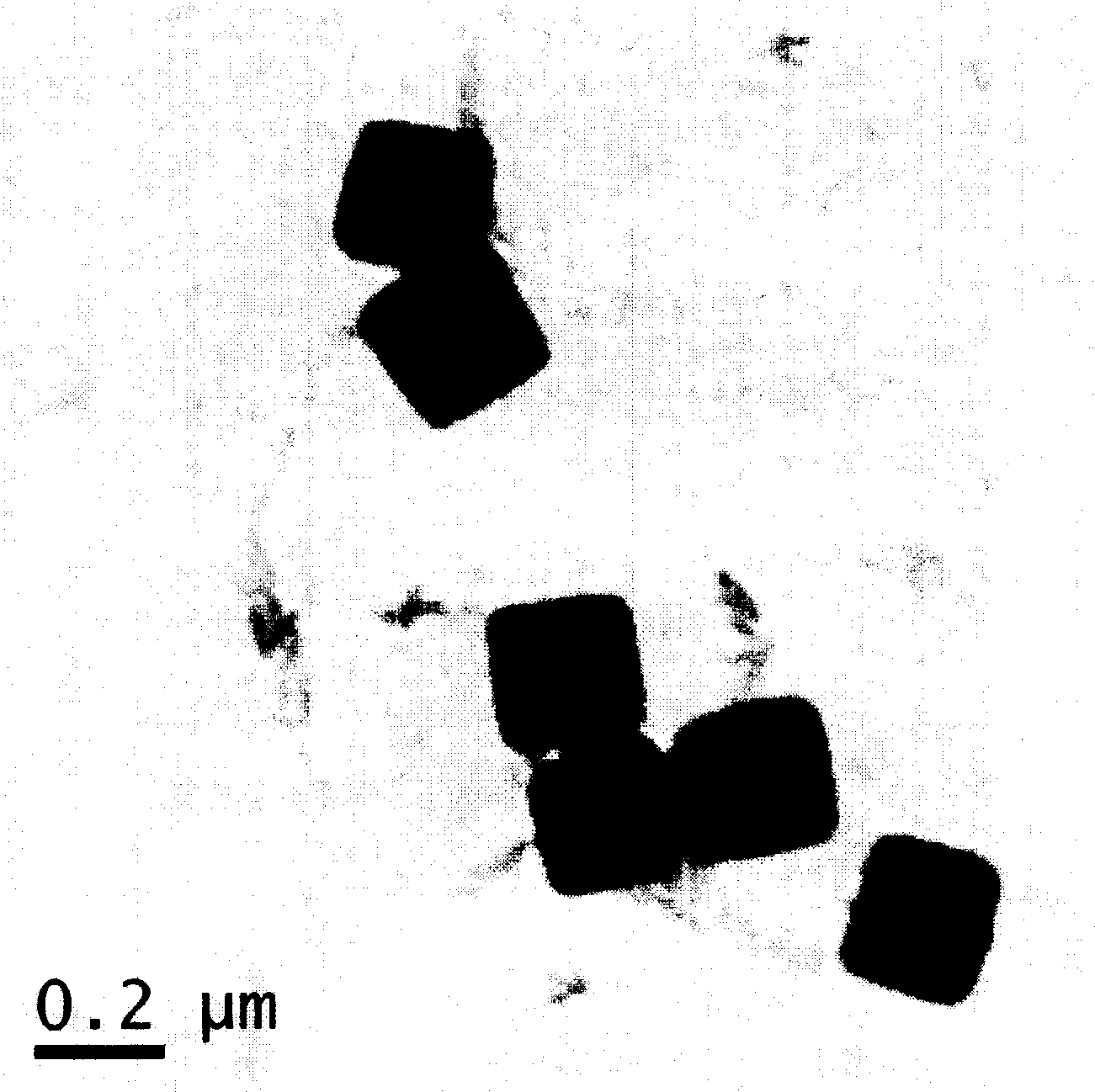

[0037] After filtering, washing, and vacuum drying, a square nanometer titanium d...

Embodiment 3

[0039] Step 1: Preparation of nanocrystalline cellulose

[0040] Prepared according to the method in Chinese Invention Patent No. 00117261, a kind of nano-microcrystalline cellulose and its preparation method;

[0041] Step 2: Preparation of Nano Titanium Dioxide

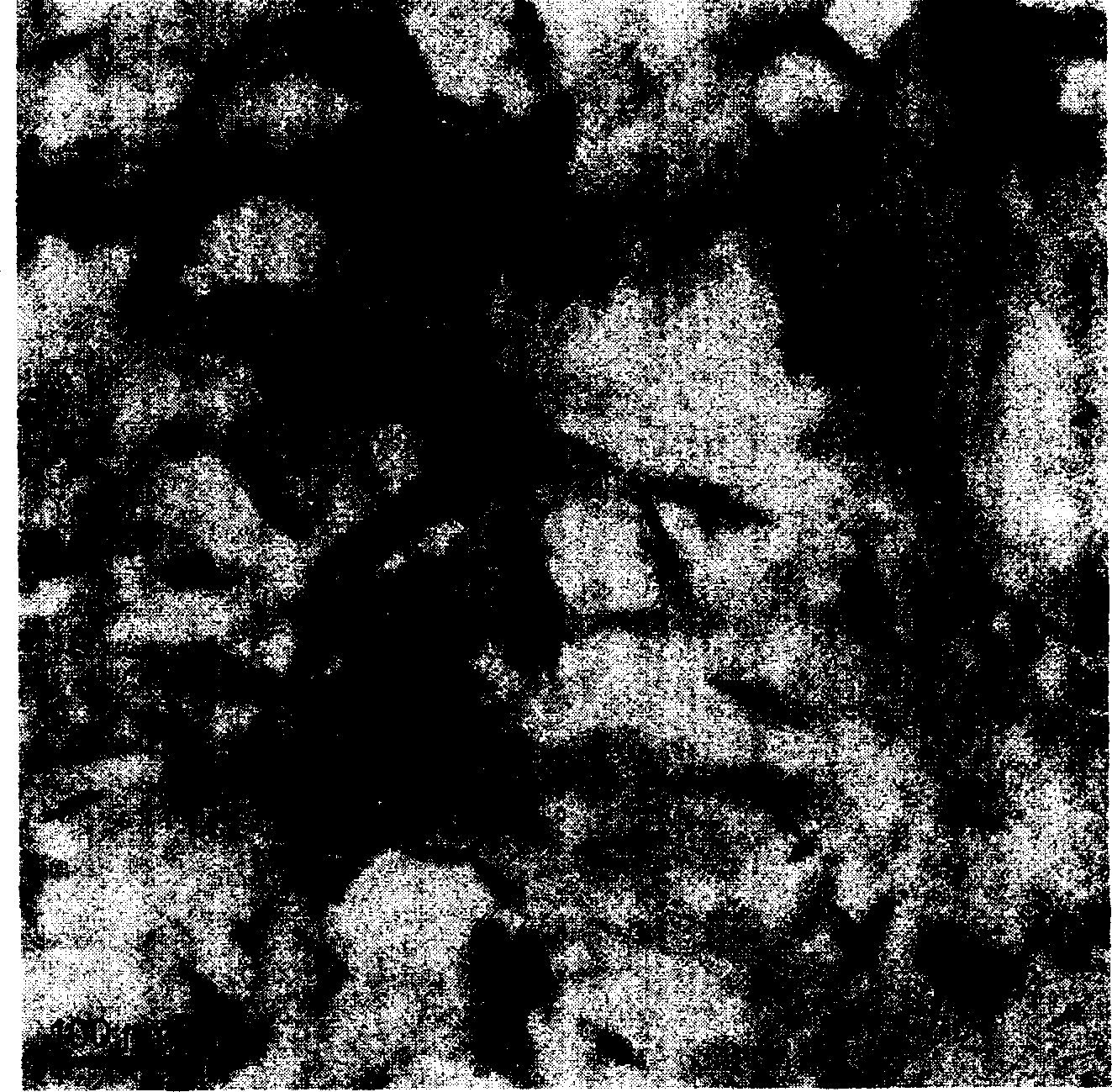

[0042] First in 100 grams of water, add 0.1 gram of nanocrystalline cellulose prepared in step 1, prepare a weight percentage concentration of 0.1% nanocrystalline cellulose aqueous dispersion, add 0.2 gram of polyethylene glycol (molecular weight is 200), make it The weight percent concentration relative to water reaches 0.2%, and after ultrasonic treatment, 1 milliliter (1.726 grams) of titanium tetrachloride is added dropwise in the nano-microcrystalline cellulose aqueous dispersion, promptly press dry nano-microcrystalline cellulose and tetrachloride The weight ratio of titanium chloride is 1: 17.3, then stirred and reacted at 90° C., and the reaction time is 4 hours;

[0043] Step 3: Post-processing

[0044]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com