Method for preparing whisky lactone

A technology of whiskey lactone and n-valeraldehyde, which is applied in the field of preparation of alkyl lactone compounds, can solve the problems of large amount of methanol consumption, instability, difficult reaction, etc., so as to avoid a large amount of waste solvent and waste acid water, and effectively Conducive to environmental protection, the effect of reducing waste water discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

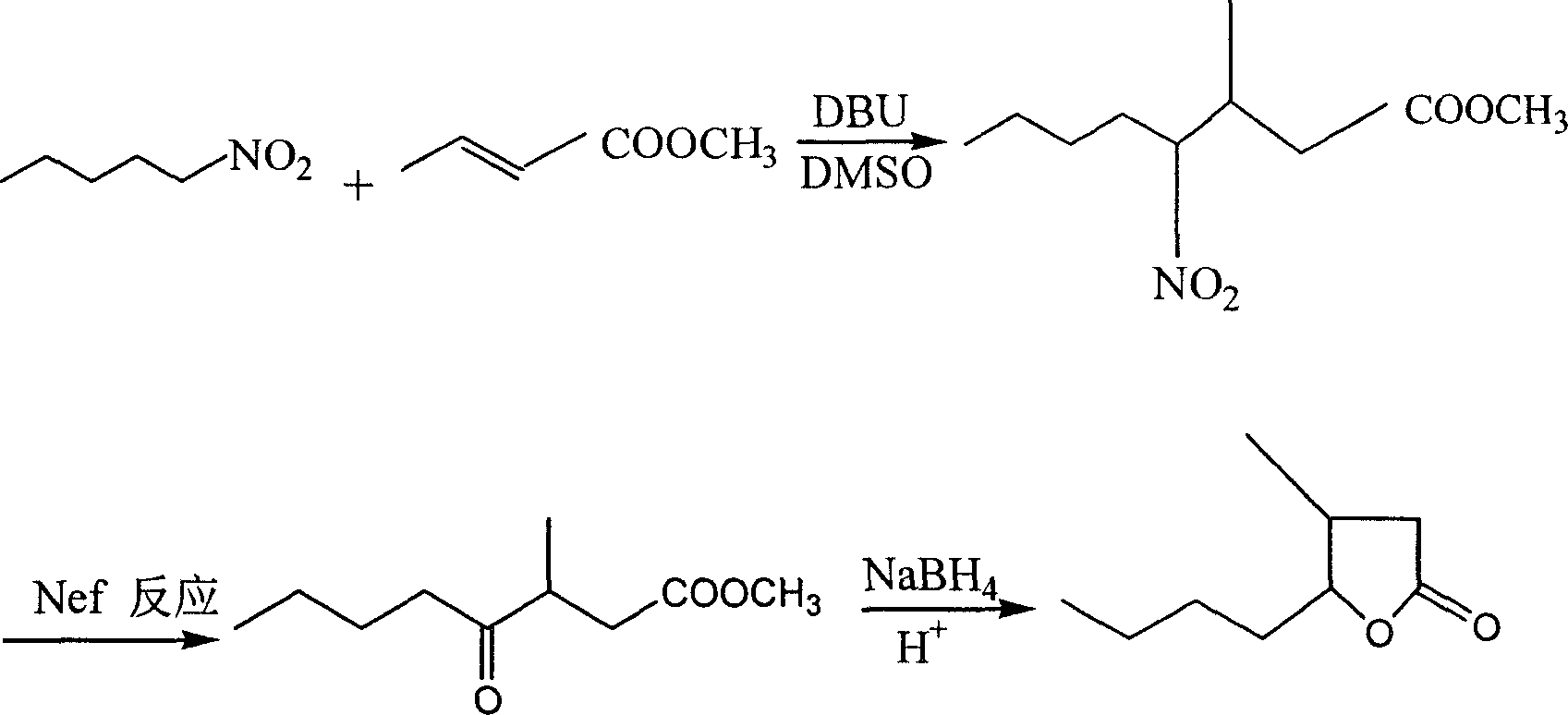

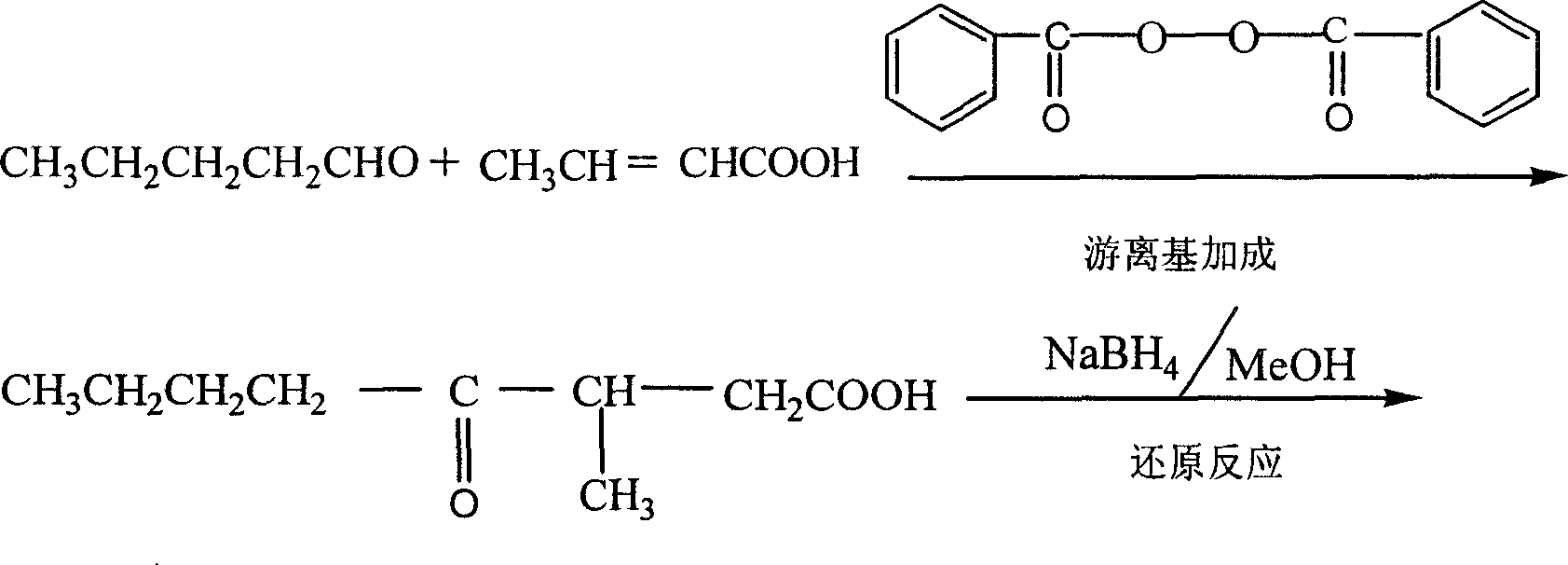

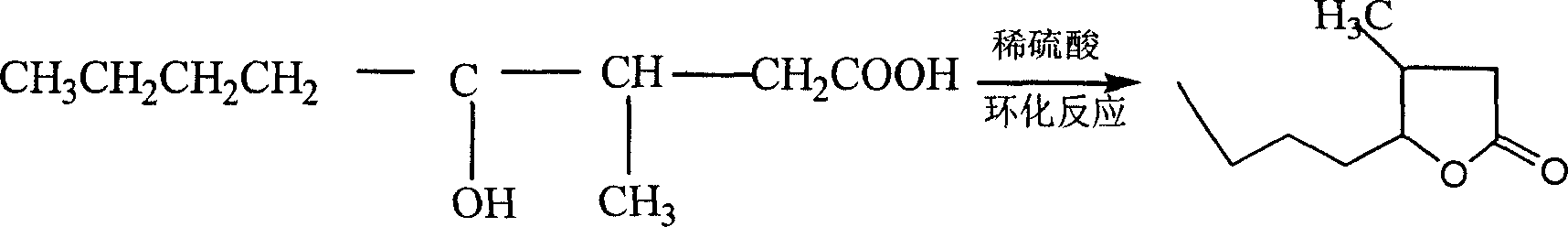

Method used

Image

Examples

Embodiment

[0021] 1. In a 1000ml four-necked flask equipped with a stirrer, a thermometer, a dropping funnel, an air guide tube and a reflux condenser, first add 172g (2M) of n-valeraldehyde, and heat it to 90-100°C under nitrogen protection. At this time, a mixed solution consisting of 172g (2M) n-valeraldehyde, 86g (1M) crotonic acid, 10g benzoyl peroxide and 0.17g boric acid was added dropwise under stirring, and the dropwise addition was completed in about 3 hours, and then the temperature was still Stir the reaction for 3 to 4 hours. After the reaction is completed, cool the reaction mixture to room temperature, then wash it with saturated brine until it is neutral, let it stand for layers, separate the organic layer, dry it with anhydrous sodium sulfate, and conduct vacuum distillation to collect The distillate at 140℃ / 270pa is keto acid, the refractive index is N D 20 1.4530, yield 131g, yield 76% (based on crotonic acid).

[0022] 2. In a 1000ml autoclave, add 86g (0.5M) of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com