Seaweed product for agriculture and preparation method of fucoidin

A technology of fucoidan and seaweed is applied in the production of fucoidan, the comprehensive utilization of seaweed, and the production of agricultural products such as seaweed fertilizer and soil conditioner by using seaweed, which can solve the problem of restricting the large-scale production and wide application of seaweed polysaccharide. , Ignoring the separation and extraction of fucoidan, and ignoring the comprehensive utilization of seaweed, etc., to achieve the effect of improving crop quality, significant inhibitory effect, and saving lye

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

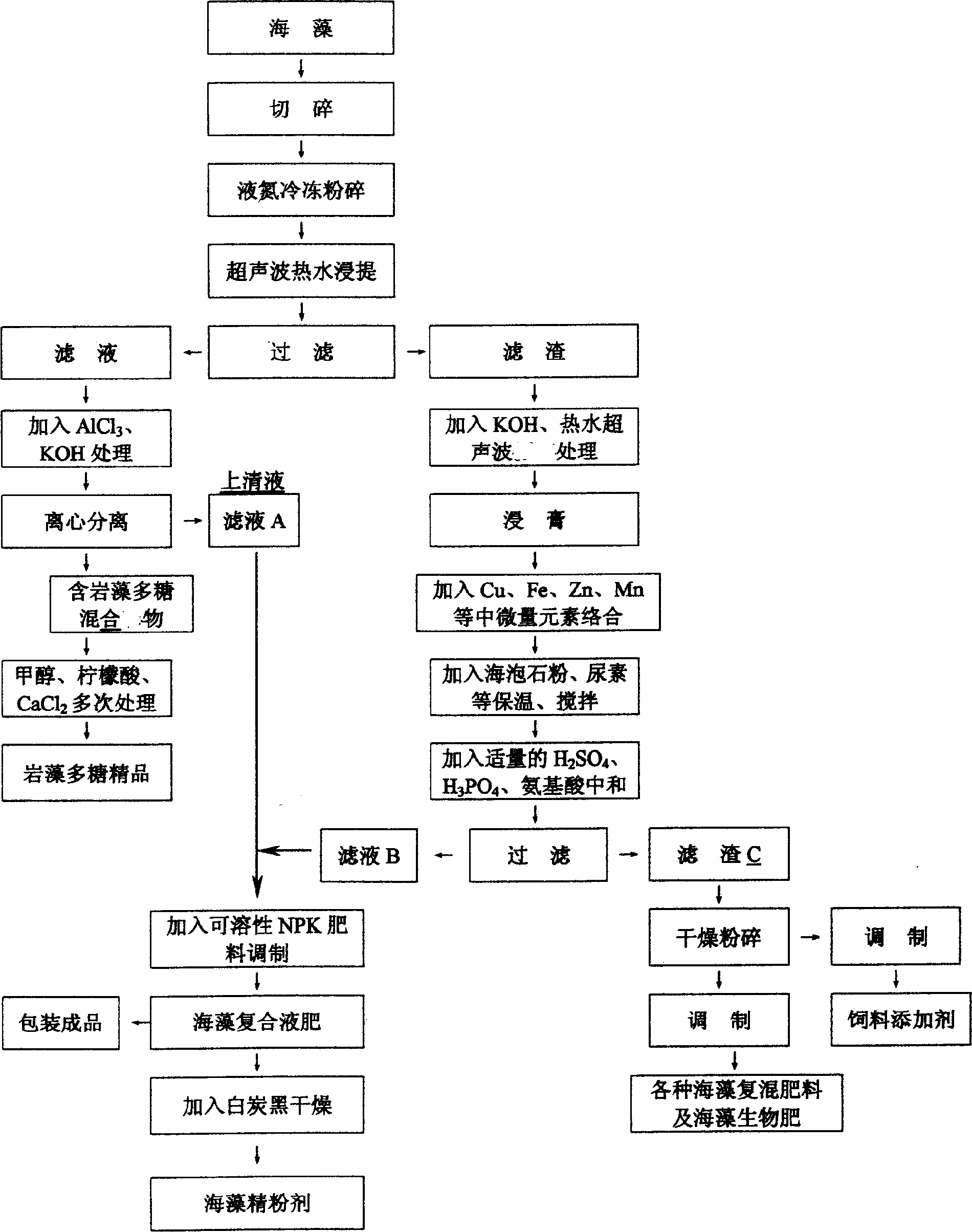

Image

Examples

Embodiment 1

[0048] Agricultural product of the present invention adopts following steps to prepare:

[0049] 1). Cut clean fresh brown algae into 20-40cm 2 The left and right blocks were pulverized at a low temperature of -120~-140°C with a liquid nitrogen freezing ultrafine pulverizer (DFZ-2 Jiangyin Jinke Crushing Machinery Co., Ltd.).

[0050] 2). Put 10kg of the above-mentioned seaweed powder into the submerged ultrasonic extractor (TY-type KS and KS-C Ningbo Haishu Kesheng Ultrasonic Equipment Co., Ltd.), add 40kg of hot water at 60°C, stir with a stirrer, and use a frequency of Ultrasonic vibration at a frequency of 100KHz, the vibration breaks the seaweed cells for 30 minutes, filtering to obtain a filtrate, and the filter residue for later use.

[0051] 3). Take 100kg of the above filtrate, add 20kg of 10% AlCl 3 Mix the solutions, then slowly add 20kg of 10% KOH solution to form a precipitate, filter to obtain a filtrate and a precipitate, and the obtained precipitate is a mixt...

Embodiment 2

[0059] Agricultural product of the present invention adopts following method to prepare:

[0060] 1). Cut clean dry brown algae into 20-40cm 2 The left and right blocks were pulverized at a low temperature of -120~-140°C with a liquid nitrogen freezing ultrafine pulverizer (DFZ-2 Jiangyin Jinke Crushing Machinery Co., Ltd.).

[0061] 2). Put 10kg of the above-mentioned seaweed powder into the submerged ultrasonic extractor (TY type KS and KS-C Ningbo Haishu Kesheng Ultrasonic Equipment Co., Ltd.), add 100 kg of 80°C hot water, stir with a stirrer, and use a frequency of Ultrasonic vibration at a frequency of 50KHz, the vibration breaks the seaweed cells for 50 minutes, and filtering to obtain a filtrate, and the filter residue is used for later use.

[0062] 3). Take 100kg of the above filtrate, add 50kg of 10% AlCl 3 Mix the solutions, then slowly add 30kg of 10% KOH solution to generate a precipitate, filter to obtain a filtrate and a precipitate, the resulting precipitate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com