Hydrolysis process of methyl acetate as by-product of producing refined terephthalic acid and apparatus thereof

A technology of purified terephthalic acid and methyl acetate, which is applied in the field of separation and purification of methyl acetate hydrolyzate and removal of impurities, and can solve problems such as failure to obtain high value-added utilization, impact on production operations, and discharge of methyl acetate , to achieve significant energy-saving effects, save energy consumption, and reduce pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

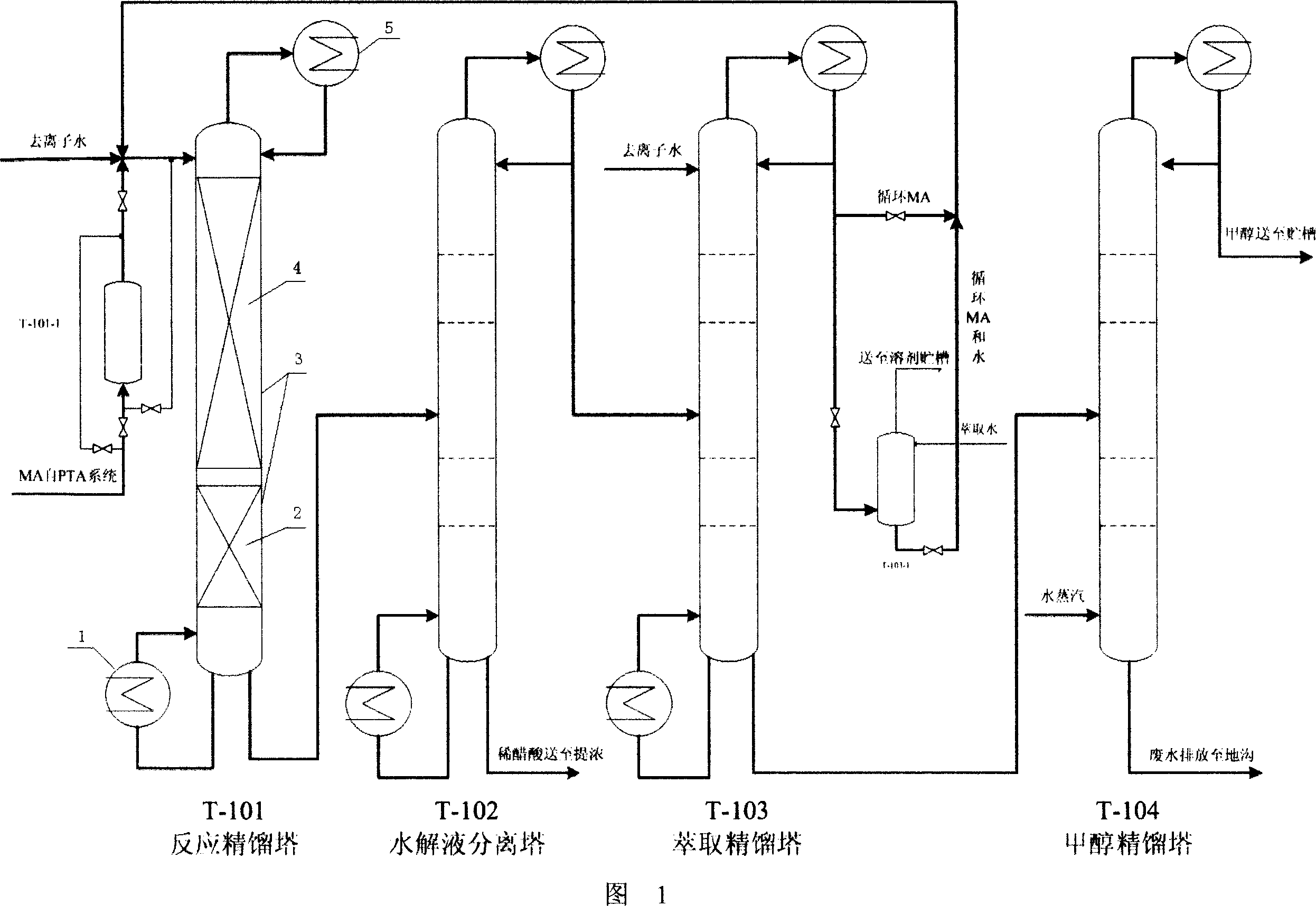

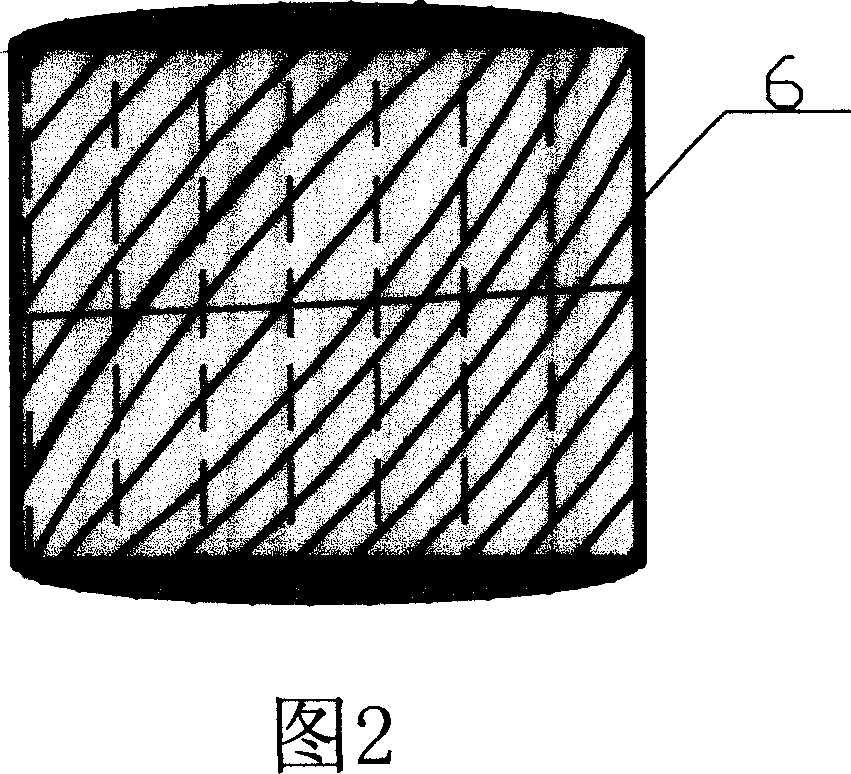

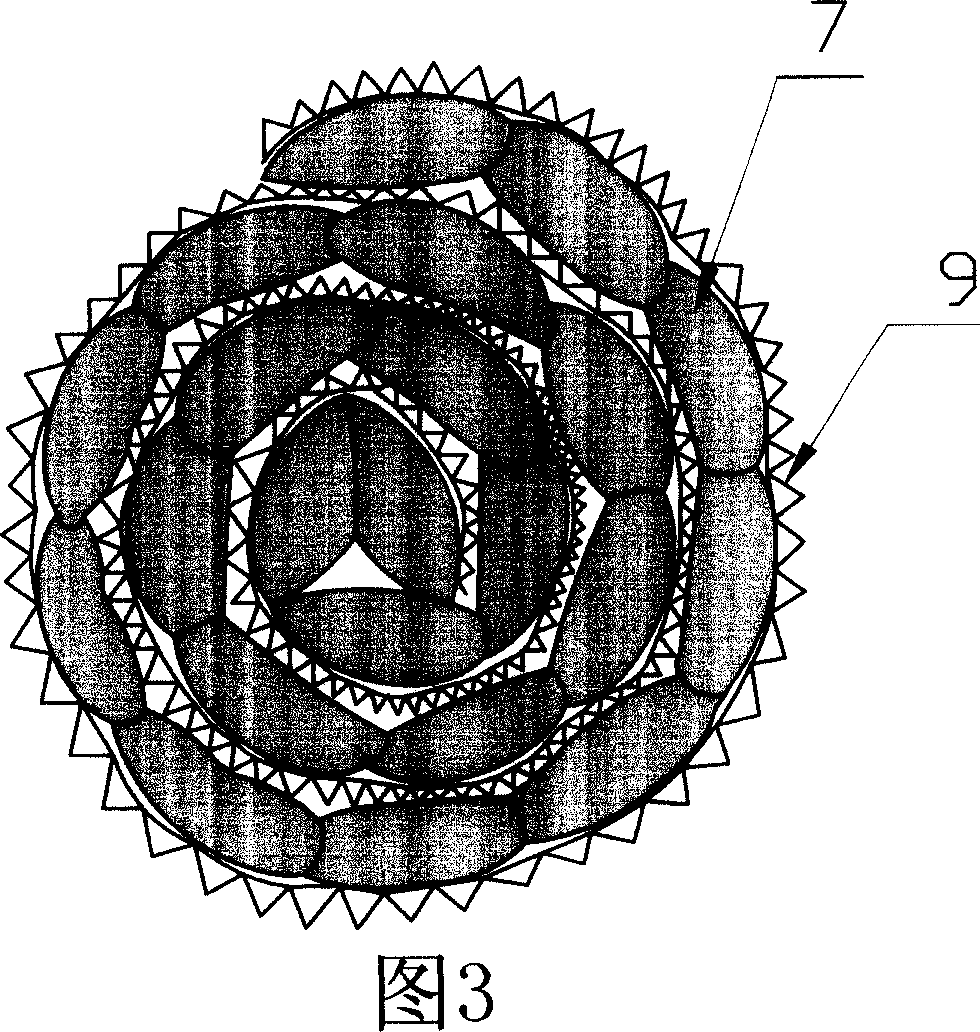

[0036] As shown in Fig. 1, Fig. 2, Fig. 3, Fig. 4, Fig. 5, Fig. 6, and Fig. 7, the process flow and a complete set of devices and equipment for the catalytic rectification and hydrolysis of by-product methyl acetate in PTA production are constituted. Schematic diagram 1 is a further invention based on the catalytic rectification and hydrolysis process of methyl acetate in the polyvinyl alcohol system. In the flow process, there is a catalytic distillation column T-101 with a catalytic active protection column T-101-1 and a water extractor The extractive distillation tower T-103 of T-103-1 is two important equipments of the present invention.

[0037] Methyl acetate from the PTA production system first enters the catalyst activity protection column T-101-1 to remove trace metal ions that may be brought in the system and achieve the purpose of protecting the catalyst activity in the catalytic rectification tower. The structure of the catalyst activity protection column T-101-1 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com