Method for degrading rice grass cellulose by multi-bacterium step fermentation

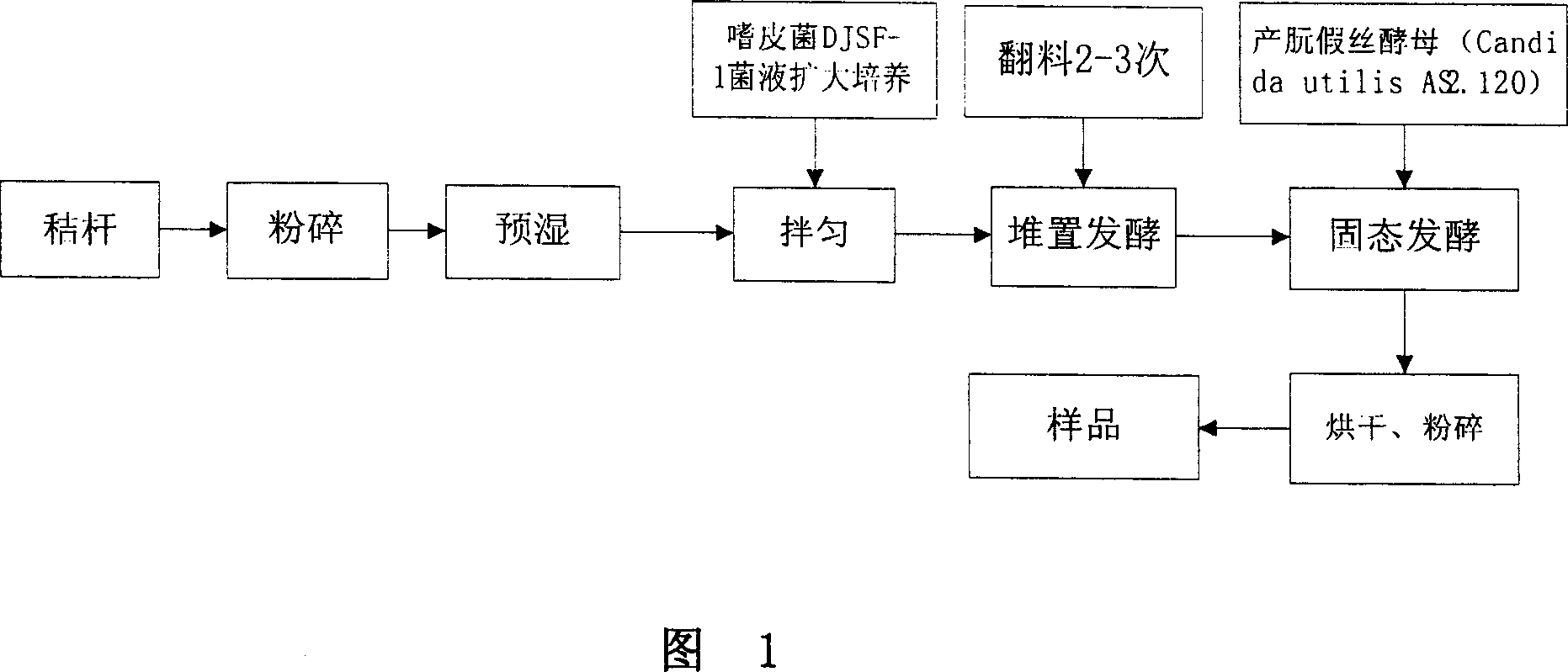

A stepwise, multi-strain technology, applied in animal feed, animal feed, application, etc., can solve the problems of low protein content of the transformant, harsh overall operating conditions, and low cellulose degradation rate, so as to increase protein content and prepare The effect of scientific and reasonable method and wide source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The composition of the culture medium for dermatophilus DJSF-1 slant culture and preservation is (g / L): 2g peptone, MgSO 4 0.5g, K 2 HPO 4 1g, NaCl 0.5g, cellulose powder 10g, agar; pick the dermatophilus DJSF-1 bacterial classification in the corresponding culture medium, and the thalline growth medium consists of (unit is g / L): rice straw powder 30, bran Skin 5, soybean cake powder 5, urea 5, KH 2 PO 4 3.0, CaCl 2 2H 2 O 1.0, MgSO 4 ·7H 2 O1.0, cellulose powder 3.0; culture pH 5.5~7.0, temperature 50~70°C, 120~160rpm shaker culture for 4~5 days to obtain bacteria and fermented enzyme liquid; take 120Kg of mechanically crushed straw material, its The water content is 30%; Inoculate the enriched dermatophilus species and enzyme liquid into the above-mentioned rice straw material for accumulation and fermentation, press bacteria liquid: rice straw powder=1:50v / m, ferment at 60~65°C for 3 days The crude protein content in the fermentation product is 10.35%, and...

Embodiment 2

[0020] The composition of the culture medium for dermatophilus DJSF-1 slant culture preservation is (in g / L): peptone 2, MgSO 4 0.5,K 2 HPO 4 1. NaCl 0.5, cellulose powder 10, agar; pick Dermophilus DJSF-1 strains in the corresponding culture medium, and the bacterial growth medium consists of (g / L): straw powder 50, bran 10, soybean cake powder 7, urea 7, KH 2 PO 4 7. CaCl 2 2H 2 O3, MgSO 4 ·7H 2 O 3, cellulose powder 3; culture pH 5.5~7.0, temperature 50~70°C, 120~160rpm shaker culture for 4~5 days to obtain bacteria and fermented enzyme liquid; get 120Kg of mechanically crushed straw material, which contains The amount of water is 50%; the enriched dermatophilus species and enzyme liquid are inoculated into the above-mentioned rice straw material for accumulation fermentation, wherein bacterial liquid: rice straw powder = 1: 100v / m, fermented product after 5 days of fermentation at 60-65°C The crude protein content is 15.72%, and the ammoniacal nitrogen content i...

Embodiment 3

[0022] The composition of the culture medium for dermatophilus DJSF-1 slant culture preservation is (in g / L): peptone 2, MgSO 4 0.5,K 2 HPO 4 1. NaCl 0.5g, cellulose powder 10g, agar; pick the dermatophilus DJSF-1 bacterial classification in the corresponding culture medium, and the bacteria growth medium consists of (unit is g / L): rice straw powder 70, bran Skin 15, soybean cake powder 10, urea 10, KH 2 PO 4 10, CaCl 2 2H 2 O5, MgSO 4 ·7H 2O 5, cellulose powder 5; culture pH 5.5~7.0, temperature 50~70°C, 120~160rpm shaker culture for 4~5 days to obtain bacteria and fermentation enzyme liquid; get 120Kg of mechanically crushed straw material, which contains The amount of water is 80%; the enriched dermatophilus species and enzyme liquid are inoculated into the above-mentioned rice straw material for accumulation and fermentation, wherein the bacterial liquid: rice straw powder = 1: 200v / m, fermented at 60-65°C for 7 days and then fermented The medium crude protein c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com