Lead storage battery

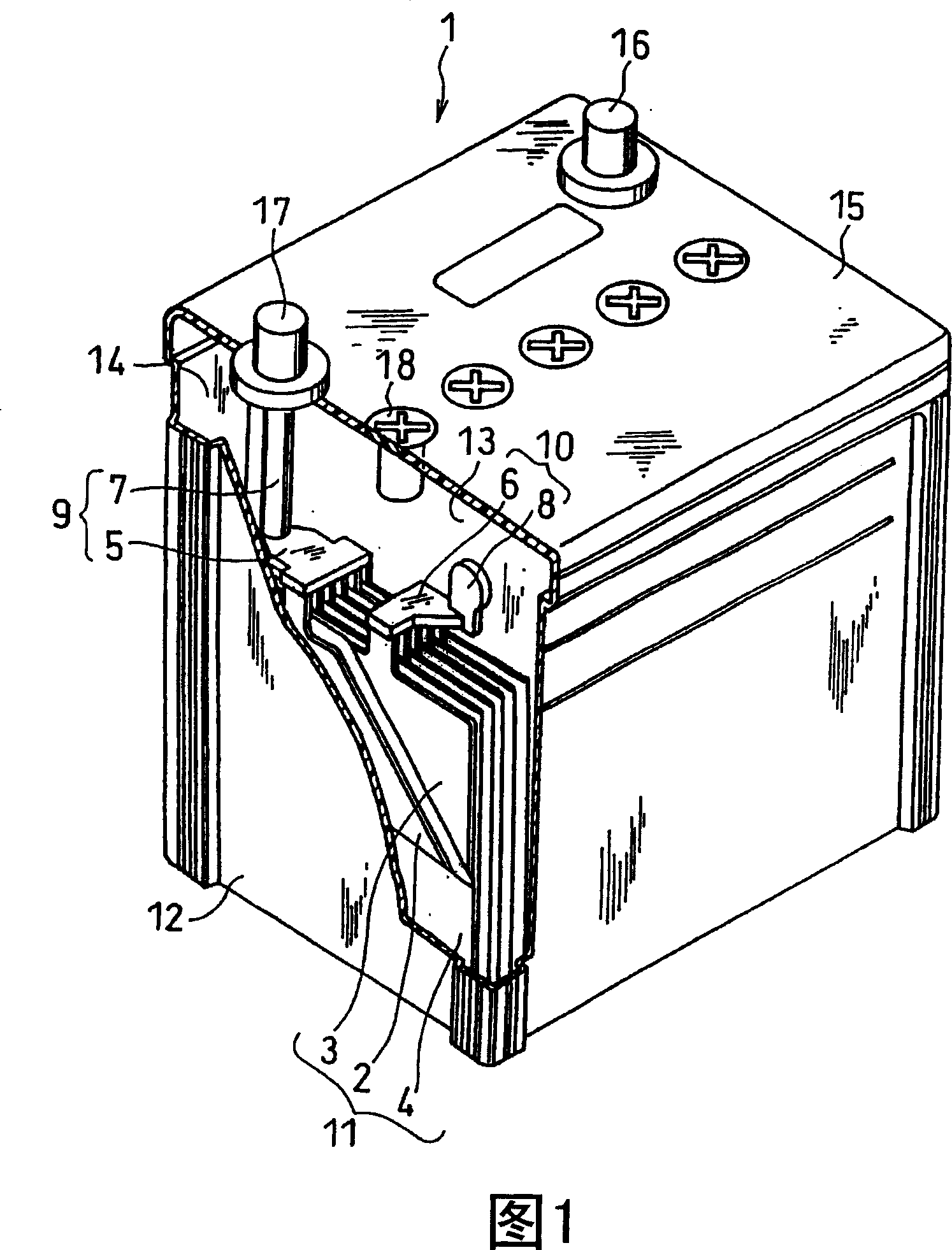

A technology of lead storage battery and negative electrode, which is applied in the field of improvement of service life characteristics, can solve the problems of corrosion of the negative electrode grid and the corrosion of the connection piece, and achieve the effect of inhibiting corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0102] (1) Manufacture of bag-shaped spacers

[0103] Silica particles, mineral oil, and carbon powder were added to polyethylene having an average molecular weight of 8,000,000, and stirred. After the kneaded mixture was molded by extrusion, the mineral oil was removed by a solvent such as hexane to obtain a polyethylene sheet containing silica particles having fine pores with a pore diameter of not more than 1 μm and having a thickness of 0.2 mm. The polyethylene sheet thus obtained was folded in two, and a bag-shaped spacer having an opening only in the upper portion was obtained by welding both end sides of the folded sheet with heat.

[0104] For the silica particles, porous particles (particle diameter: 20 μm) having fine pores with an average pore diameter of not more than 20 μm are used.

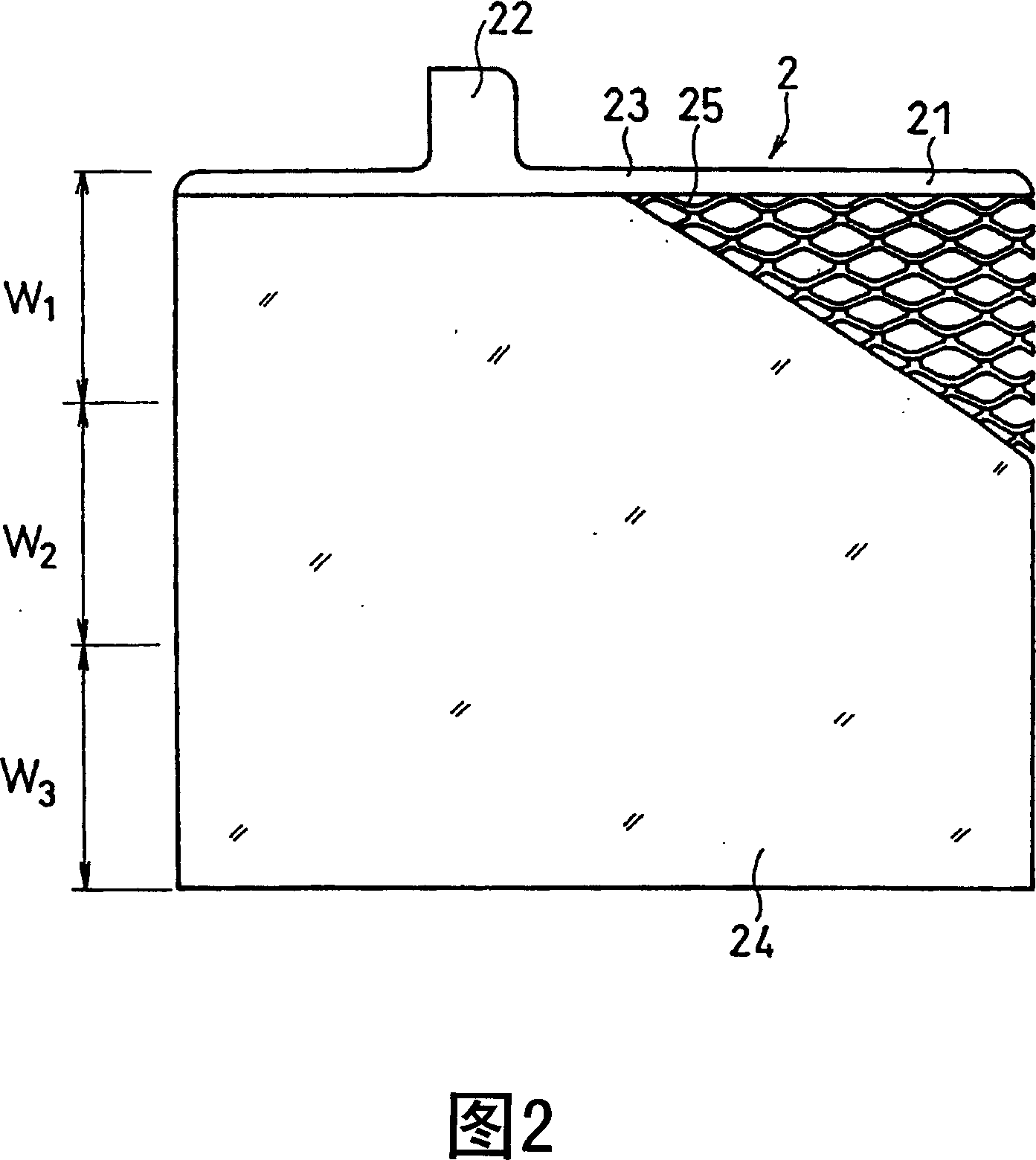

[0105] (2) Manufacture of negative electrode plate

[0106] The raw material lead powder (a mixture of lead and lead oxide), water, dilute sulfuric acid, and an expansion agent suc...

example 2

[0156] A glass fiber mat maintaining a thickness of 1.0 mm of silica particles was obtained by a papermaking process of glass fibers in an acidic aqueous solution in which silica particles were dispersed. Then, the obtained glass fiber is folded in two, and the left end portion and the right end portion are welded by heating to obtain a bag-shaped spacer having an opening only at the top. At this time, the silica particle content in the separator including the glass fiber mat holding the silica particles was set to become 0%, 5%, 10%, 40%, and 50% in mass. For the silica particles, the same silica particles as in Example 1 were used.

[0157] As shown in Tables 3 and 4, by combining separators comprising glass fiber mats holding silica particles with different silica particle contents, negative active material layers with different Sb contents, and Positive and negative electrode connection members, cells K1 to K5, L1 to L5, M1 to M5, N1 to N5, O1 to O5, P1 to P5, Q1 to Q5, R...

example 3

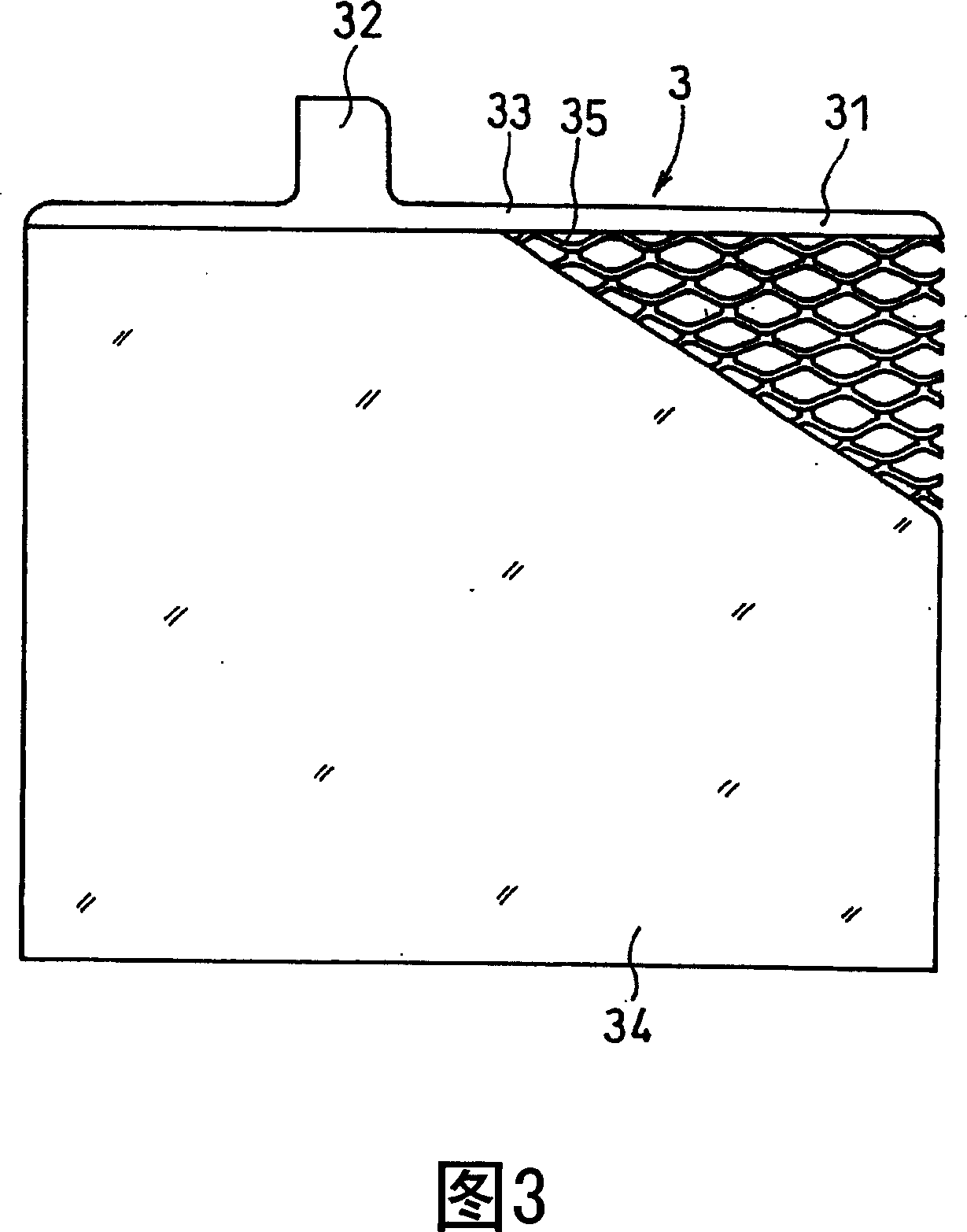

[0175] By the same method as the negative electrode grid in Example 1, in the extrusion step of manufacturing the positive electrode grid, the lead alloy sheet was extruded so as to be attached to the base material sheet to obtain a composite sheet, which was formed on a base material having a thickness of 1.1 mm. On one side of the layer there is a lead alloy layer with a thickness of 20 μm. A Pb alloy containing 5.0% by mass of Sn was used for the lead alloy flakes. The same positive electrode grid as in Example 1 was used for the base material sheet.

[0176] For the portion of the sheet of base material onto which the lead alloy flakes are to be extruded, only the portion where the expanded mesh and the frame are to be formed in the expansion process mentioned later is extruded, and the lead alloy flake is not extruded to the substrate On the central portion of the sheet of material in which the tab for the positive electrode grid will be formed, as shown in Example 1.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com