A composition comprising a conductive polymer in colloidal form and carbon

A technology of conductive polymers and compositions, applied in conductive coatings, conductive materials dispersed in non-conductive inorganic materials, circuits, etc., can solve the problems of conductivity control, particle size control and reproducibility of conductive polymers, capacitors cannot display performance issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0090] Example 1: Preparation of Porous Carbonaceous Material / Conductive Polymer Composite Electrode

[0091] The coconut shell activated carbon (not yet activated) of 18g grinding is dispersed in the conductive polymer dispersion of 90.9g (ORMECON 7301-026-002, the xylene dispersion of conductive polyaniline, solid content: 2.2%), by The mixture was stirred in a planetary ball mill for 60 minutes. 57.3 g of xylene was further added to the porous carbonaceous material / conductive polymer slurry, and the mixture was stirred by a stirring motor for 30 minutes to prepare a porous carbonaceous material / conductive polymer dispersion.

[0092] Electrodes for capacitors require collecting plates suitable for the electrolyte used in the capacitor. In this example, platinum plates were used for the electrodes when sulfuric acid aqueous solution (1 mol / liter) was used as the electrolytic solution, and aluminum was used for the electrodes when propylene carbonate was used as the electrol...

Embodiment 2

[0098] Example 2: Production of Capacitor Units

[0099] Each electrode plate having the electrode active material in close contact therewith prepared as in Example 1 was cut into a disc having a diameter of 1 cm to prepare two electrodes. A glass fiber filter was cut into a circle having a diameter of 1.5 cm and used as a spacer. Furthermore, in the case of an aqueous system, a 1M sulfuric acid aqueous solution was used as an electrolytic solution. In the case of the organic solvent system, a 1M solution of tetraethylammonium tetrafluoroborate propylene carbonate was used as the electrolytic solution.

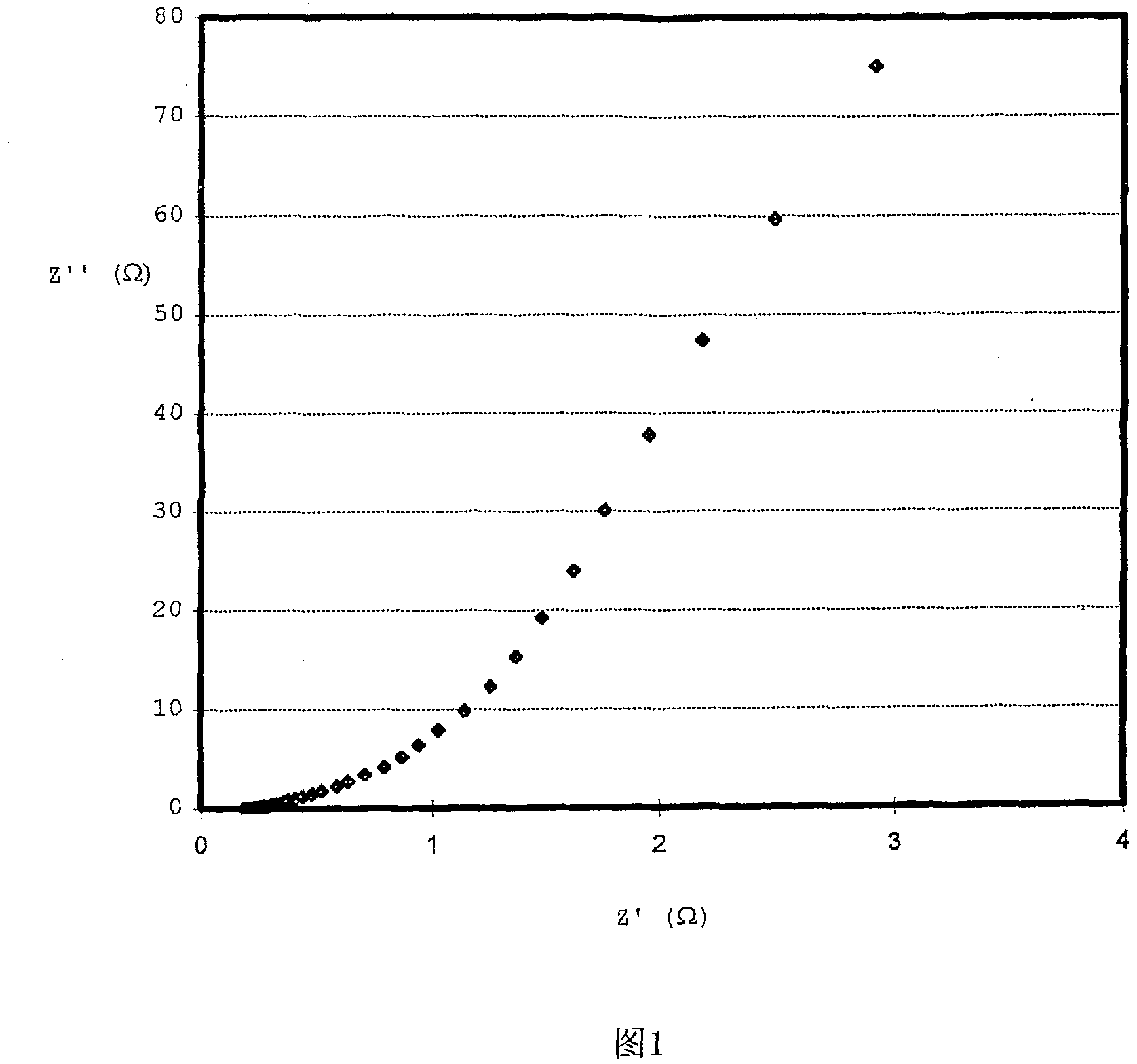

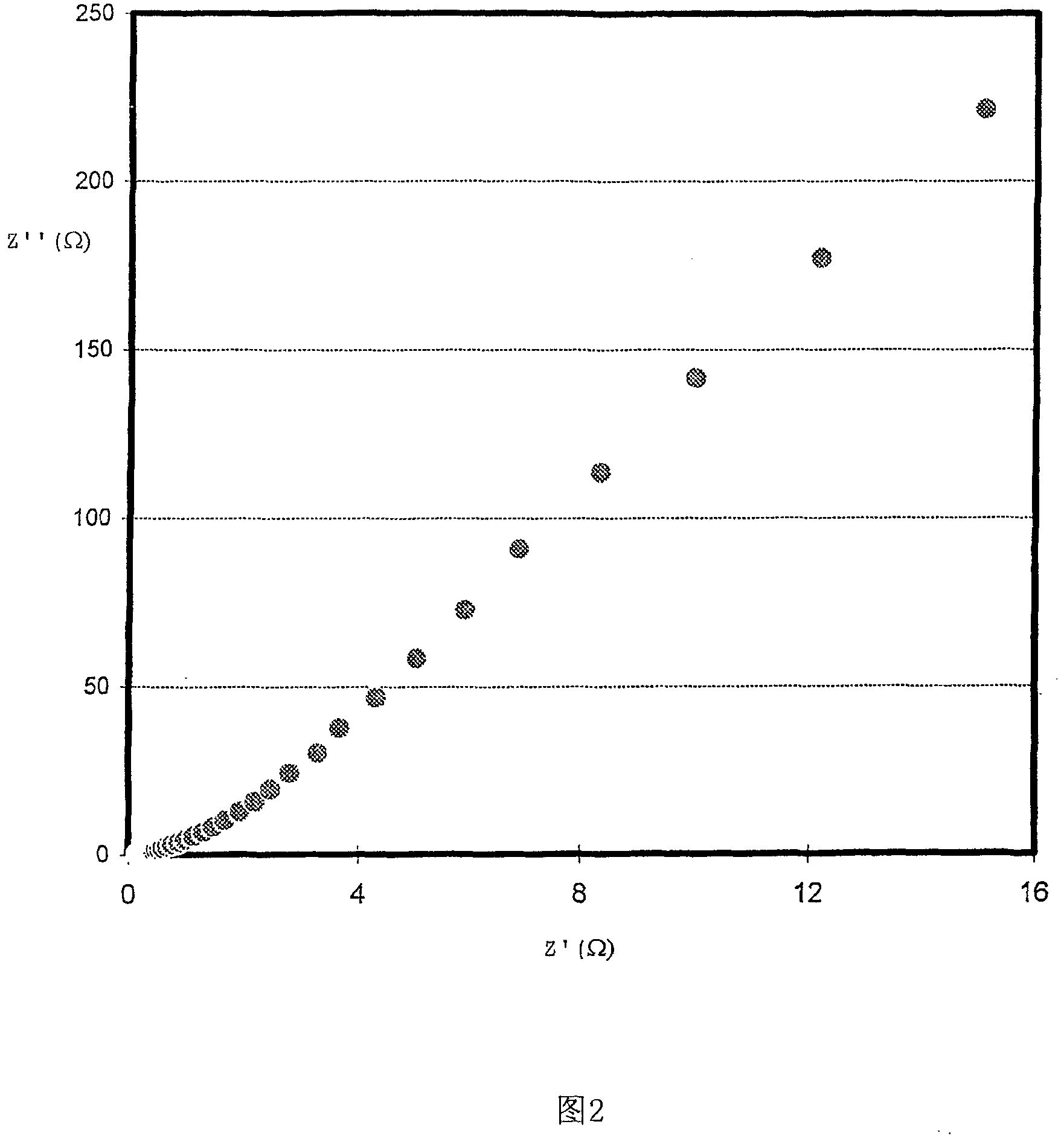

[0100] Evaluation of Capacitor Characteristics

[0101] Measuring instrument: The internal resistance of each capacitor unit was measured using a YHP4192A impedance analyzer available from Hewlett-Packard Development Company, L.P. The measurement of the charge-discharge test was performed using TOYO system TOSCAT-3100U available from TOYO SYSTEM, Co. LTD.

[0102] The resu...

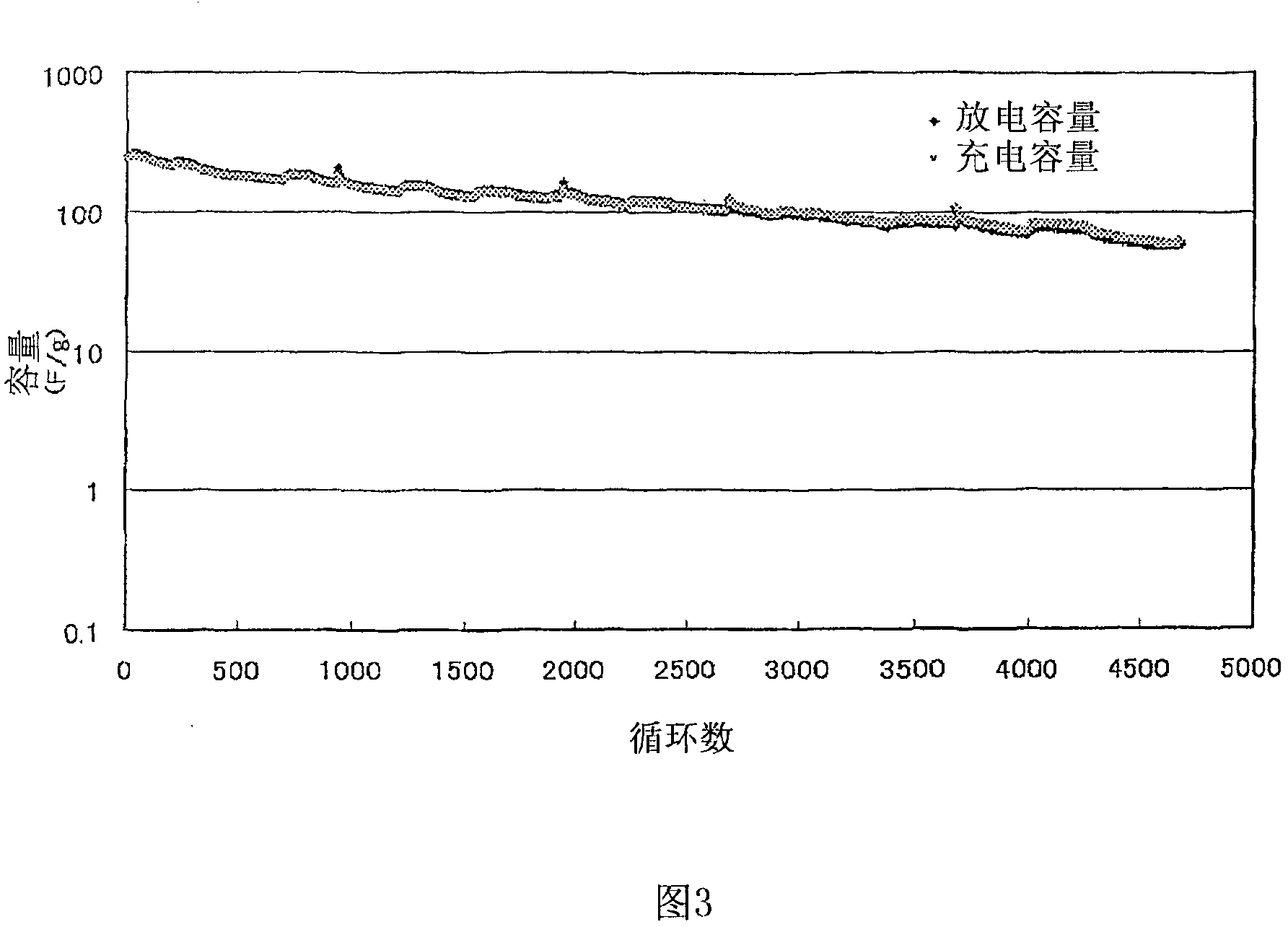

Embodiment 3

[0114] 1) Reagents and equipment:

[0115] BELLFINE AP, produced by KABEBO LTD, was used as activated carbon material.

[0116] D1005W (aqueous dispersion of polyaniline) and 7201-026-001 (polyaniline dispersion in xylene), both available from Ormecon GmbH, Ammersbek, Germany, were used as colloidal conductive polymers.

[0117] The charging and discharging test was performed by using a TOCAT-3100U battery testing device (TOYO SYSTEM, CO., LTD). Impedance properties were measured using a 4192A LF Impedance Analyzer (HEWLETT PACKARD).

[0118] 2) Preparation of conductive polymer and activated carbon mixture:

[0119] The mixture was prepared by using the following procedure. 8.0 g of activated carbon and 90.9 g of ORMECON 7201-026-001 (solids: 2.20%) were mixed for 60 minutes using a satellite ball mill. This mixture is used as an electrode material. The electrode film was produced by applying a 200 μm coating of this material on an aluminum plate. The wet film was dried...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com