Cataplasma of bulleyaconitine A

A technology of aconitin and cataplasm, applied in the direction of anti-inflammatory agents, non-central analgesics, organic active ingredients, etc., which can solve the problems of biocompatibility, affinity, breathability, poor sweat resistance, continuous patching, etc. If it is applied on the skin for a long time, it is prone to skin discomfort and other problems, and achieves the effect of good moisturizing performance, favorable transdermal absorption and fast onset of action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

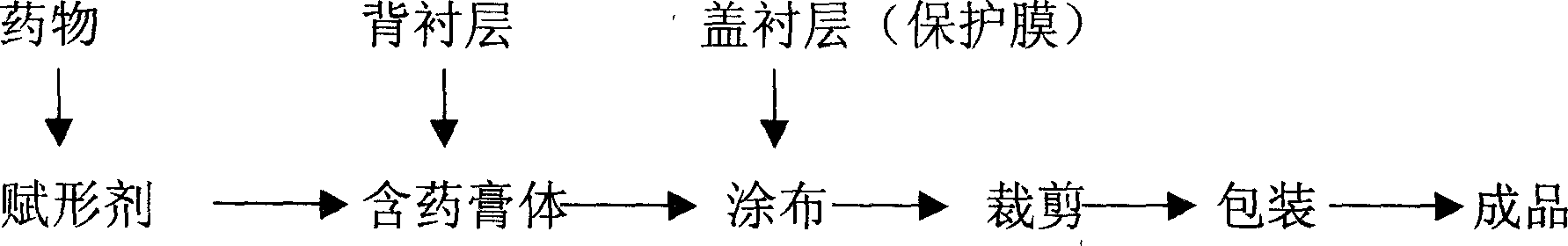

[0063] Backing layer: non-woven fabric

[0064] Cover lining: polyester film

[0065] The composition of the medicated ointment layer is as follows by weight:

[0066] Aconitin (micronized) 0.05g

[0067] Gelatin 1.3g

[0068] Tragacanth Gum 1.8g

[0069] Macrogol-400 2.2g

[0070] Polyacrylic acid 1.8g

[0071] Glycerin 1.8g

[0073] Azone 1.0g

[0074] borneol 0.05g

[0075] Preparation method: Micronize and pulverize aconitin, weigh gelatin and tragacanth gum according to the prescription, add 65 grams of water, heat in a water bath to dissolve, mix polyacrylic acid, glycerin and zinc oxide evenly, add the above glue , stir and mix evenly, then add polyethylene glycol-400 to disperse borneol and aconitin, and finally add azone to obtain a paste. Then spread it evenly on the non-woven fabric, cover it with a polyester film, and cut it to get 10,000 pieces of gentianin cataplasm.

Embodiment 2

[0077] Backing layer: non-woven fabric

[0078] Cover lining: aluminum foil-polyethylene composite film

[0079] The composition of the medicated ointment layer is as follows by weight:

[0080] Aconitine 0.06g

[0081] Sodium Polyacrylate 2.0g

[0082] Gelatin 1.5g

[0083] Polyvinyl alcohol 2.5 grams

[0084] Glycerin 2.5g

[0086] Azone 0.3g

[0087] Propylene Glycol 1.0g

[0088] Menthol 0.06g

[0089] Preparation method: prepare aconitin solid dispersion, pulverize; weigh gelatin, sodium polyacrylate and polyvinyl alcohol according to the prescription amount, add 72 grams of water to make swelling, stir and mix evenly, mix glycerin and zinc oxide evenly, add the above In the swelling liquid, stir and mix evenly, then add the suspension liquid in which menthol and aconitin are dispersed with propylene glycol and azone to obtain a paste. Then spread it evenly on the non-woven fabric, cover it with a polyester film, and cut it into a suita...

Embodiment 3

[0091] Backing layer: non-woven fabric

[0092] Lid lining: Polyethylene film

[0093] The composition of the medicated ointment layer is as follows by weight:

[0094] Aconitin (micronized) 0.07g

[0095] Sodium polyacrylate 1.3g

[0096] Carbomer 934p 0.1g

[0097] Glycerin 5.3g

[0098] Propylene Glycol 1.4g

[0099] Kaolin 1.3g

[0100] Citric acid 0.04g

[0101] Aluminum trichloride 0.08 g

[0102] Menthol 0.07g

[0103] Preparation method: Micronize and pulverize aconitin, weigh sodium polyacrylate, carbomer 934p and add 55 grams of purified water to swell according to the prescription amount, add aluminum trichloride, stir and mix evenly; 2. Mix glycerin and kaolin and add to 1; 3. Use propylene glycol to add menthol and aconitin dispersion to 2; 4. Finally add citric acid, stir and mix evenly to obtain a paste. Then spread it evenly on the non-woven fabric, cover it with a polyethylene film, and cut it into pieces of suitable size to obtain 10,000 pieces of g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com