Process for producing a rhamnolipid produced by Pseudomonas or Enterobacter using andiroba or murumuru seed waste

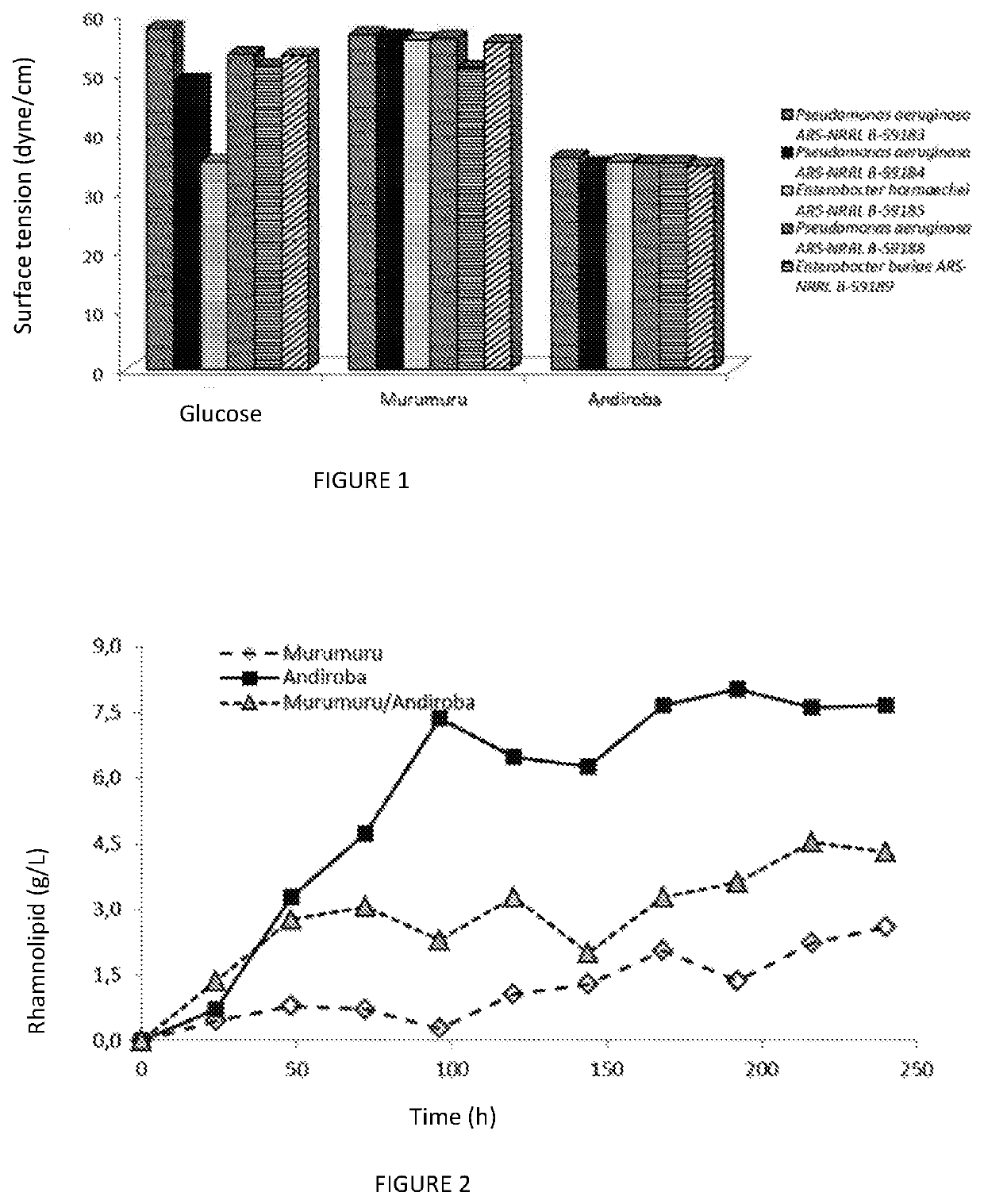

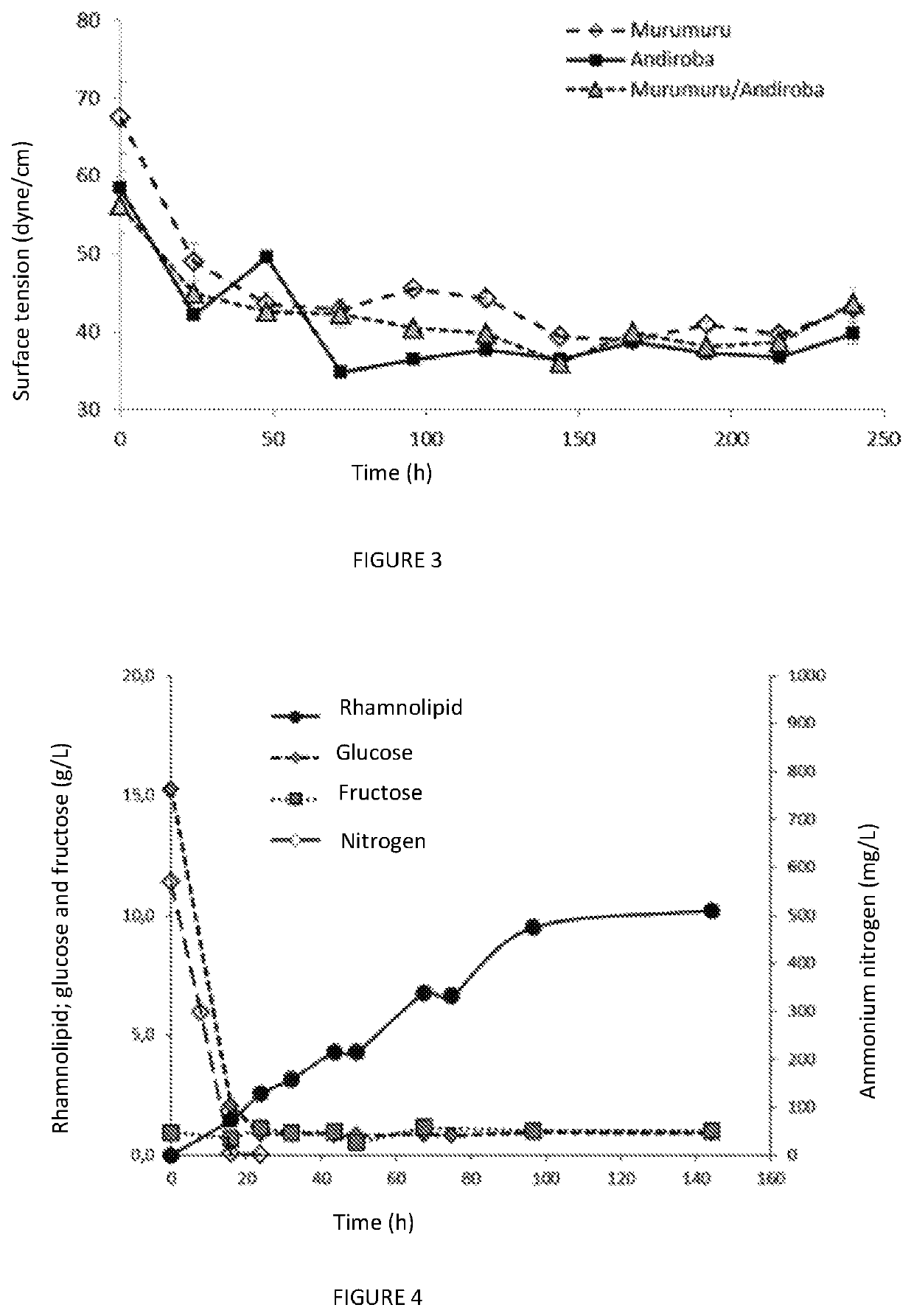

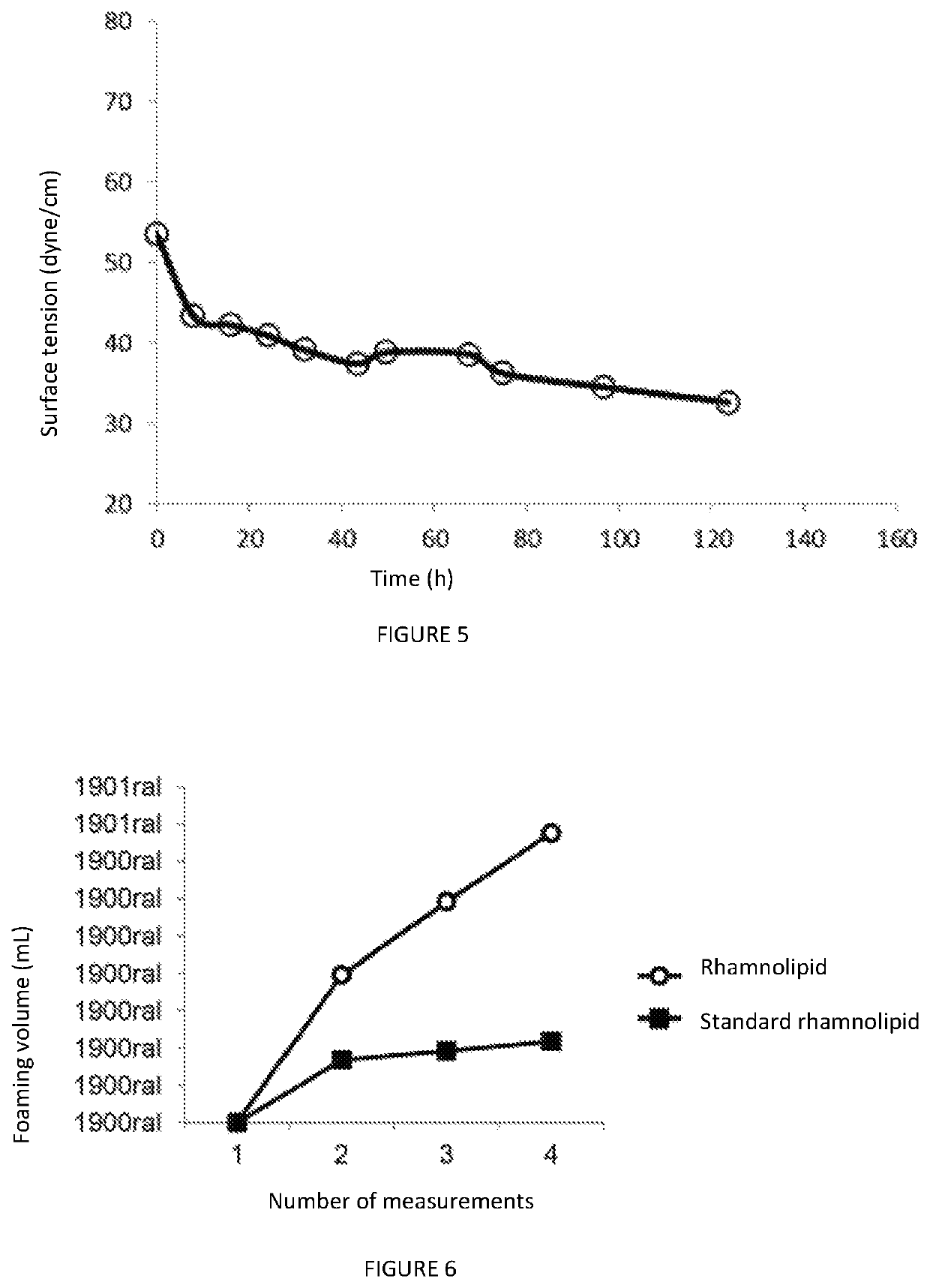

a technology of rhamnolipid and andiroba, which is applied in the field of lipid compounds, can solve the problems of high raw material cost, biosurfactant commercialization is difficult, and biosurfactant is still unable to compete with synthetic surfactants for commercial purposes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045]Rhamnolipid production is carried out according to the following steps:

[0046]step (a) of the process consists of reactivating the microorganism maintained under refrigeration at a temperature of from −70 to −100° C. by means of growth in nutrient broth for 10 to 30 hours, preferably 15 to 25 hours, preferably 21 hours, between 25 and 40° C., preferably at 28° C. and 35° C., more specifically 30° C., on a stirring platform at a stirring speed of 170 rpm to 200 rpm, preferably 180 rpm.

[0047]The microorganism of step (a) consists of one of the bacteria listed in Table 1, preferably Pseudomonas aeruginosa, which is preferably kept refrigerated under cryopreservation in ultrafreezer at a temperature of from −70 to −100° C., the nutrient broth preferably comprising 3 g / L meat extract and 5 g / L peptone. These nutrients are mixed with the aid of a magnetic stirrer and subjected to wet heat sterilization at 121° C., 1 atm, for 15 minutes.

[0048]Step (b) consists of the preparation of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com