Sc-2 based pre-thermal treatment wafer cleaning process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

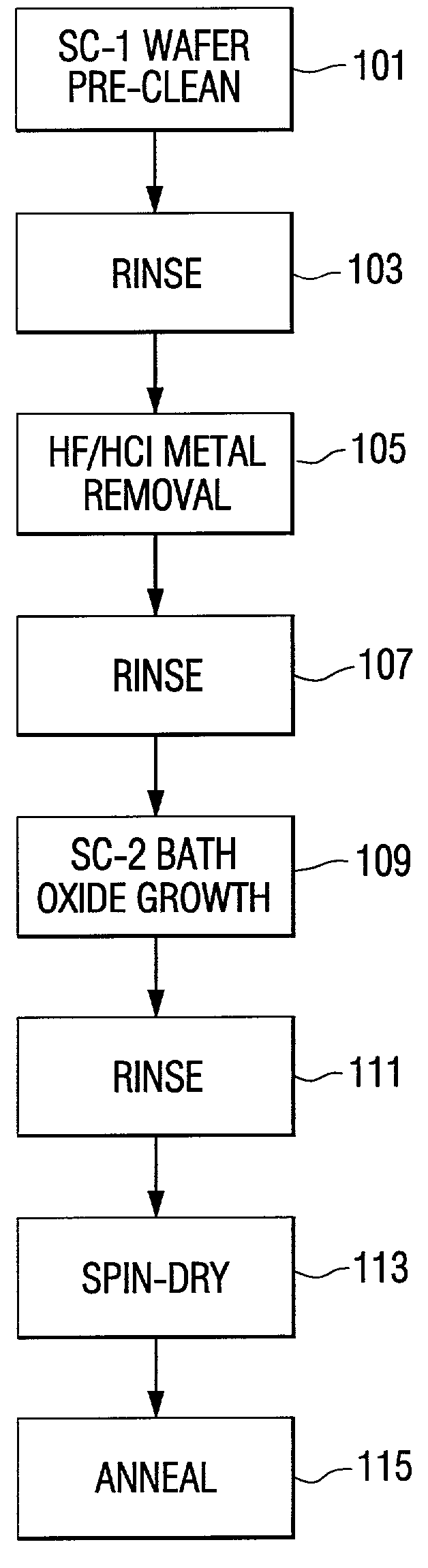

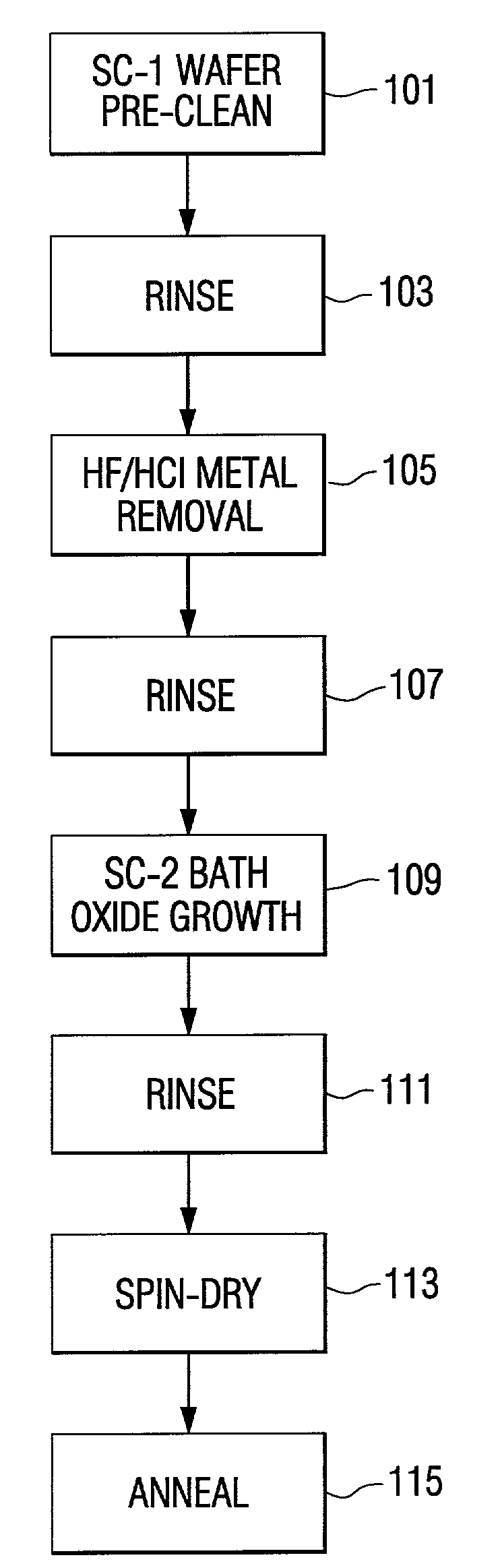

[0025] A cleaning process was carried out on smooth P-type silicon wafers having a resistivity of 5-20 ohm-cm, using a conventional wet bench cleaning apparatus. The cleaning sequence for one set of the wafers (set "A") was as follows:

[0026] STEP 1: 10 minutes in an SC-1 bath (1:1:5 NH.sub.4O:H.sub.2O.sub.2:-H.sub.2O) with megasonics at 50.degree. C.;

[0027] STEP 2: Ultra pure water rinse for 5 minutes;

[0028] STEP 3: 1 minute in a metallic-containing oxide removal solution (5:2:200 HF:HCl:H.sub.2O);

[0029] STEP 4: Overflow deionized water rinse for 5 minutes;

[0030] STEP 5: Immersion in an SC-2 bath (1:1:5 HCl:H.sub.2O.sub.2:H.sub.2-O) for 5 minutes;

[0031] STEP 6: Ultra pure water ines for 5 minutes;

[0032] STEP 7: Spin dried for 10 minutes; and

[0033] STEP 8: Processed through a diffusion furnace (600.degree. C. for 60 minutes) in a nitrogen atmosphere.

[0034] A second set of wafers (set "B") was subjected to steps 1-2 and 5-8.

[0035] The wafers of sets A and B were analyzed for minority ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Time | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

| Diffusion length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com