Method of producing zinc oxide thin film, method of producing photovoltaic device and method of producing semiconductor device

a technology of photovoltaic devices and thin films, which is applied in the direction of pv power plants, light radiation electric generators, generators/motors, etc., can solve the problems of high cost of vacuum equipment, and insufficient light confinement effect at wavelengths of 600 to 1000 nm, etc., to achieve excellent optical properties, low material cost, and excellent optical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

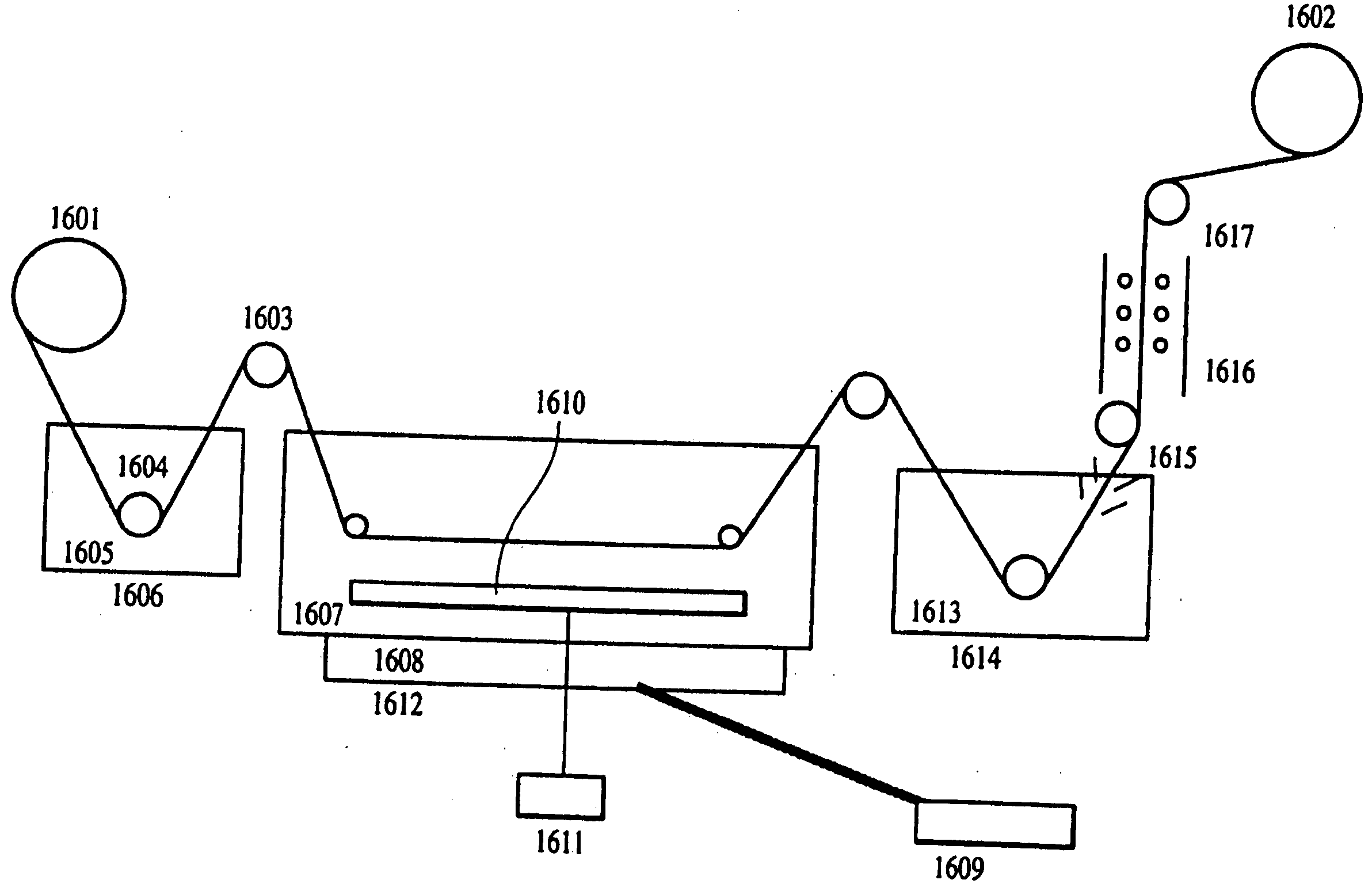

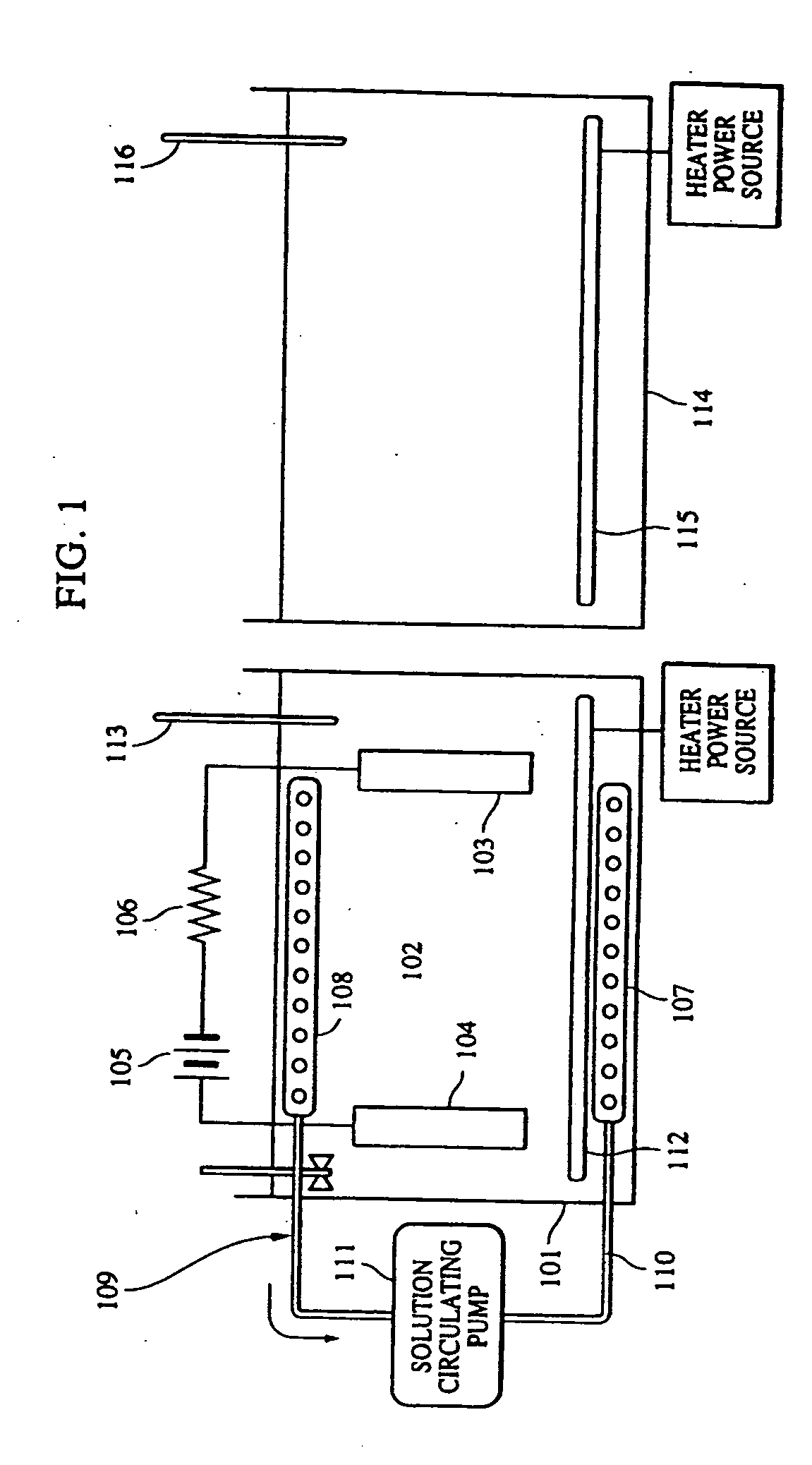

[0129] The zinc oxide thin film was produced by using the apparatus shown in FIG. 1.

[0130] As the conductive substrate 103 on the cathode side, a substrate of stainless 430BA having a thickness of 0.15 mm, and comprising Ag deposited to 300 nm by sputtering, with the back covered with an insulating tape (not shown in the drawing), was used. As the counter electrode 104 on the anode side, 4-N zinc having a thickness of 1 mm was used. The aqueous solution 102 was an aqueous solution of 0.03 mol / l zinc hydroxide in 10% ammonia at 65° C. and a pH of 10.3. The applied current was 1.0 mA / cm2 (0.1 A / dm2).

[0131] The thus-obtained electrodeposited film was examined by X-ray diffraction, and the deposition rate and reflectance at a wavelength of 800 nm were measured from optical-characteristics. The results are shown in Table 1.

TABLE 1Type of electrodeposited filmZinc oxideDeposition rate (μm / h)2Reflectance (%)90

[0132] The above results indicate that an excellent zinc oxide thin film can ...

example 2

[0133] Electrodeposition was carried out by the same method as Example 1 except that as the conductive substrate 103, a substrate of stainless 430BA having a thickness of 0.15 mm, and comprising Ag deposited to 100 nm by sputtering and zinc oxide deposited to 100 nm on Ag by sputtering, with the back covered with an insulating tape (not shown in the drawing), was used.

[0134] The thus-obtained electrodeposited film was examined by X-ray diffraction, and the deposition rate and reflectance at a wavelength of 800 nm were measured from optical characteristics. The results are shown in Table 2.

TABLE 2Type of electrodeposited filmZinc oxideDeposition rate (μm / h)3Reflectance (%)72

[0135] The above results indicate that an excellent zinc oxide thin film can be obtained by the method of producing a zinc oxide thin film of the present invention.

example 3

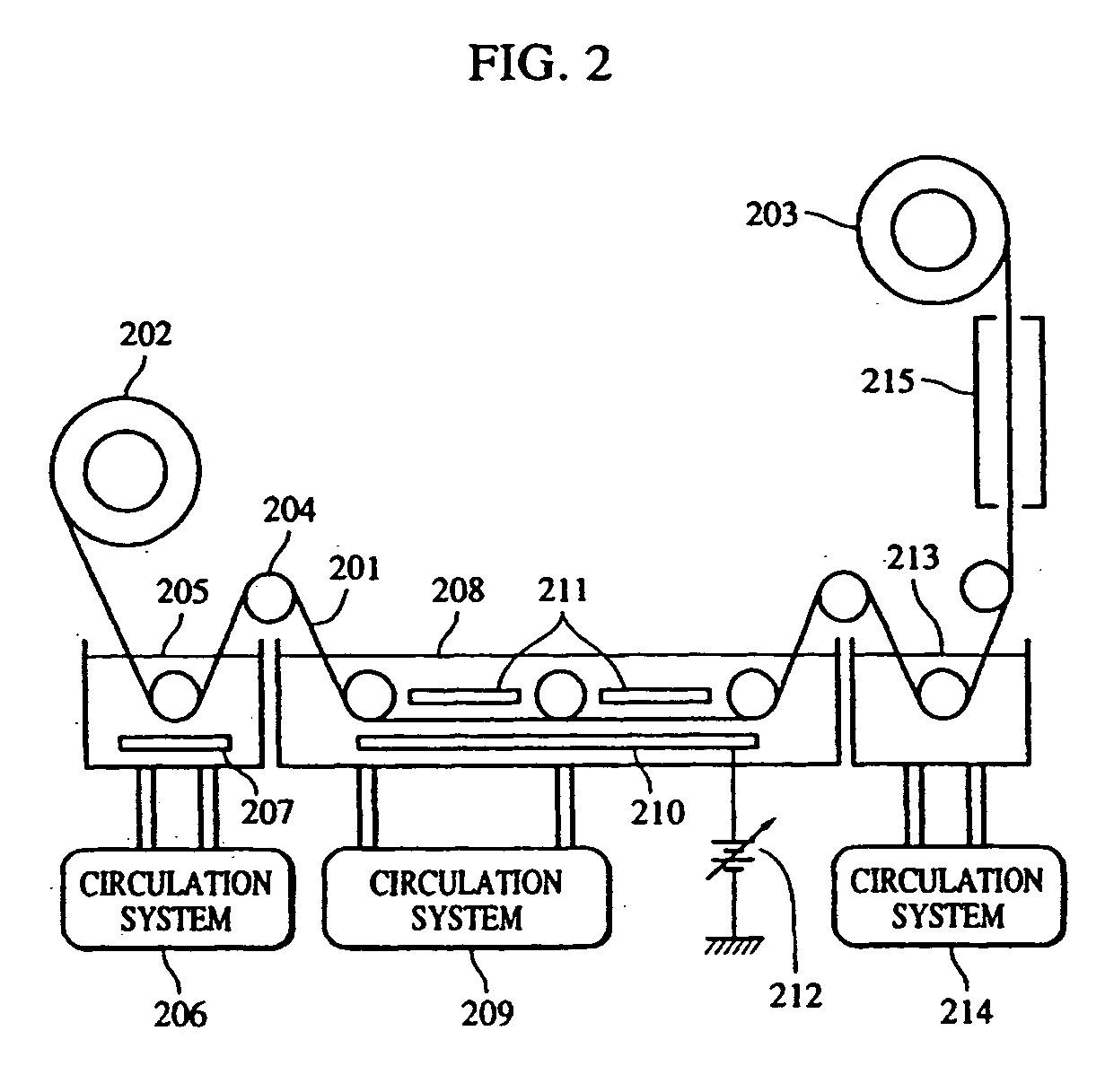

[0136] The solar cell shown in FIG. 3 and having a semiconductor layer having three p-i-n junctions, as shown in FIG. 4, was produced.

[0137] Specifically, the solar cell comprised the support 301-1 (conductive substrate of stainless steel SUS430, 10×10 cm2, thickness 0.2 mm), the metal layer 301-2 (Al), the transparent conductive layer 301-3 (zinc oxide thin film), the zinc oxide layer 302, the semiconductor layer 303, the transparent conductive layer 304, and the collecting electrodes 305 (Cu wire / Ag / C).

[0138] The metal layer 301-2 and the transparent conductive layer 301-3 were formed by the general vacuum deposition or sputtering method.

[0139] The zinc oxide layer 302 was formed by the same method as Example 1 except that 3 g / l of sucrose was added to the aqueous solution.

[0140] The semiconductor layer 303 was formed under the conditions shown in Table 3.

TABLE 3DepositionFormingtemperatureThicknessSemiconductor layermethod(° C.)(μm)First doped layer n-type a-Si:H:PRFCVD3000...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pH | aaaaa | aaaaa |

| pH | aaaaa | aaaaa |

| pH | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com