Pressure regulated continuously variable volume container for fluid delivery

a technology of continuous variable volume and container, which is applied in the direction of laboratory glassware, instruments, and analysis using chemical indicators, can solve the problems of significant loss of chromatograph operating time or loss in whole or in part of unpurified mixed particle(s), significant problem of establishing and maintaining consistency, and contamination of fluid, so as to eliminate exposure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0078] Now referring to FIG. 8, which shows a bivariate plot generated from the analysis of fluorochrome stained sperm cells differentiated based upon the presence of an X-chromosome or a Y-chromosome utilizing a DakoCytomation, Inc., MoFlo® flow cytometer in accordance with the invention. A conventional sheath fluid tank was retrofitted with a variable volume container in accordance with the invention containing about 5 liters of sterile sheath fluid. The sheath fluid was maintained at about 20° C. during use. An amount of gas was delivered to the sealed sheath fluid tank to exert an amount of gas pressure on the exterior surface of the variable volume container resulting in the generation of a fluid stream within the flow path of a DakoCytomation, Inc., MoFlo® flow cytometer. The flow cytometer was then otherwise operated in accordance with the standard operation procedures provided by DakoCytomation, Inc. for a period of about 8 hours to analyze and sort a mixture of sperm cells ...

example 2

[0079] Similarly, a flow cytometer sorting human sperm in accordance with the invention can provide X-chromosome bearing and Y-chromosome bearing populations for the purpose of sex selected artificial insemination. Human sperm cells sufficient for artificial insemination of a human female can be flow sorted in approximately 2 hours from male human ejaculate. The enriched X-chromosome bearing or Y-chromosome bearing sperm cell populations are typically over 80% pure. Clinical procedures may require that after each sample is sorted, the sorting fluidic channels are washed with an acid wash, a base wash, a disinfectant wash, and then a water wash. The instant invention can be used to deliver four different sterile fluids to the flow cytometer, and allows computer automated cleaning steps to be performed between patients. During the automated wash procedure, the physician may perform the artificial insemination procedure.

example 3

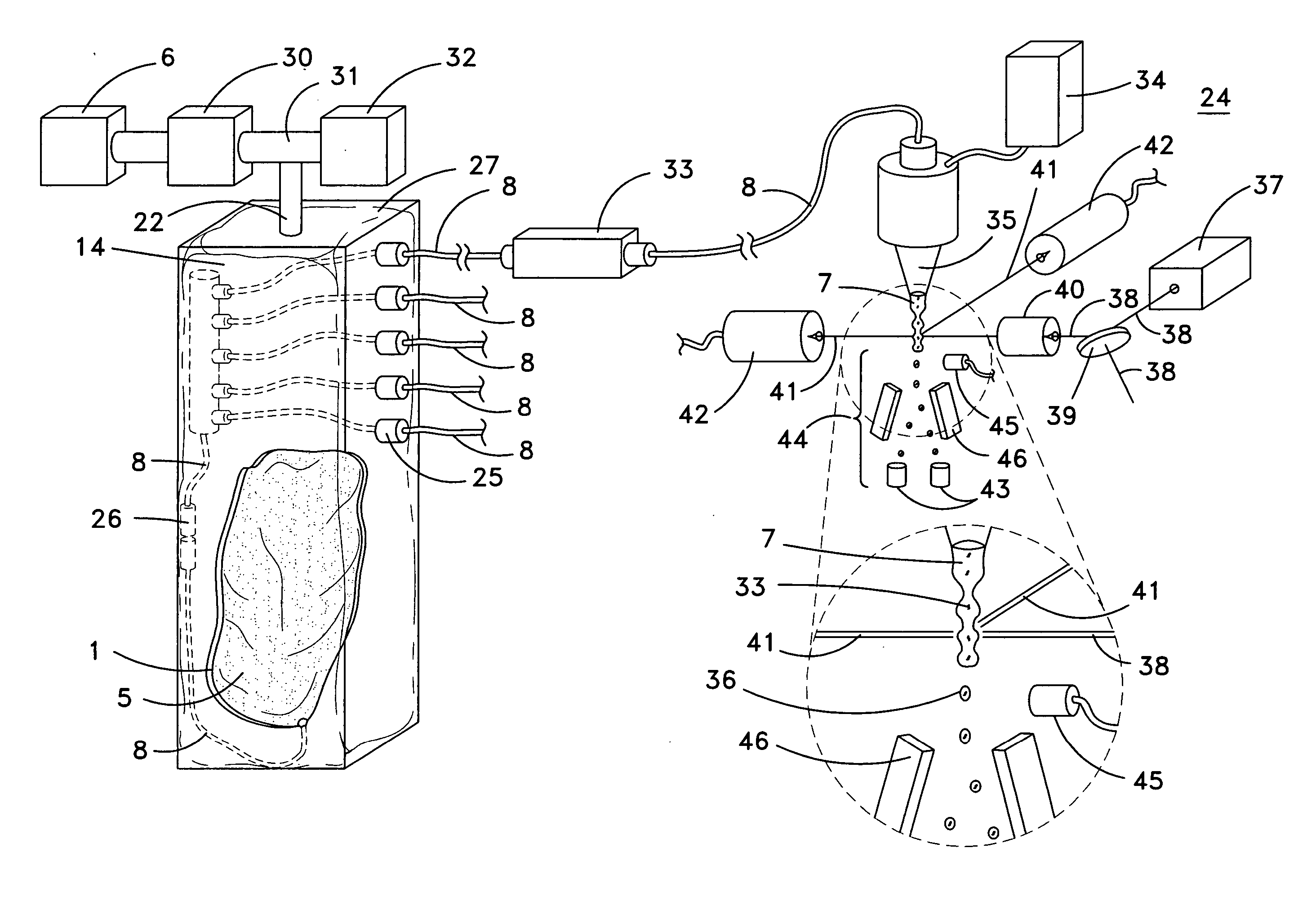

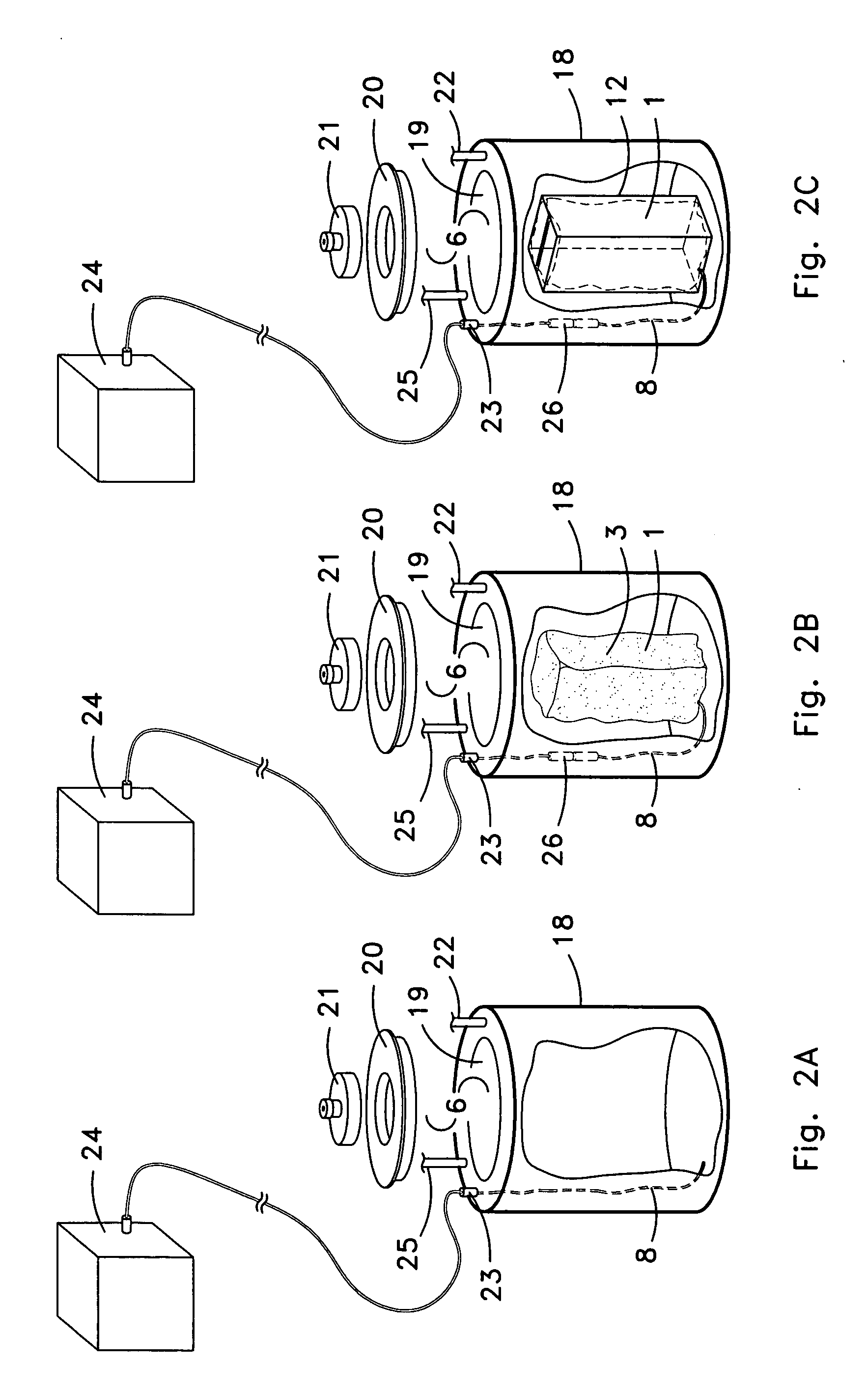

[0080] In accordance with the invention, a plurality of different microfluidic devices can be operating 24 hours per day. The variable volume containers can be located in common receptacle pressured at about 1.6 atmospheres. Each microfluidic device can be served with one or more conduits from the variable volume containers which communicate with the conventional hardware of the microfluidic device.

[0081] As can be easily understood from the foregoing, the basic concepts of the present invention may be embodied in a variety of ways. The invention involves numerous and varied embodiments of a continuously variable volume container for fluid delivery and methods of making and using such continuously variable volume container.

[0082] As such, the particular embodiments or elements of the invention disclosed by the description or shown in the figures accompanying this application are not intended to be limiting, but rather exemplary of the numerous and varied embodiments generically en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com