Liquid crystal display device and manufacturing method thereof

a liquid crystal display device and liquid crystal technology, applied in the direction of transformer/inductance magnetic core, loop antenna with ferromagnetic core, core/yokes, etc., can solve the problems of low magnetic permeability in terms of magnetic characteristics, ferrite core cannot be used for antenna elements, ferrite is brittle, etc., to improve the characteristics of inductance l, reduce the space factor of multilayer body 6, and bendability or the like of the core 2

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

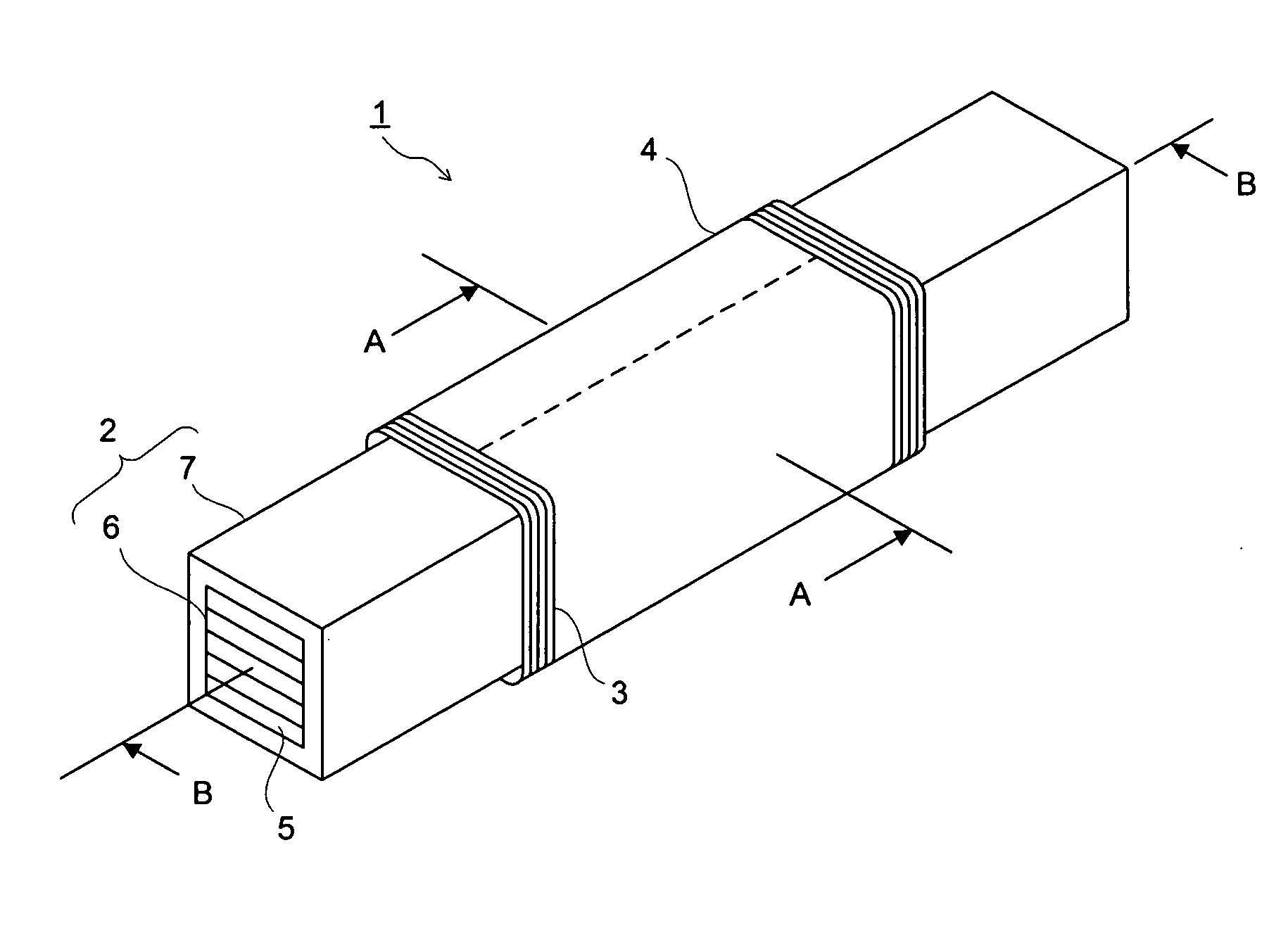

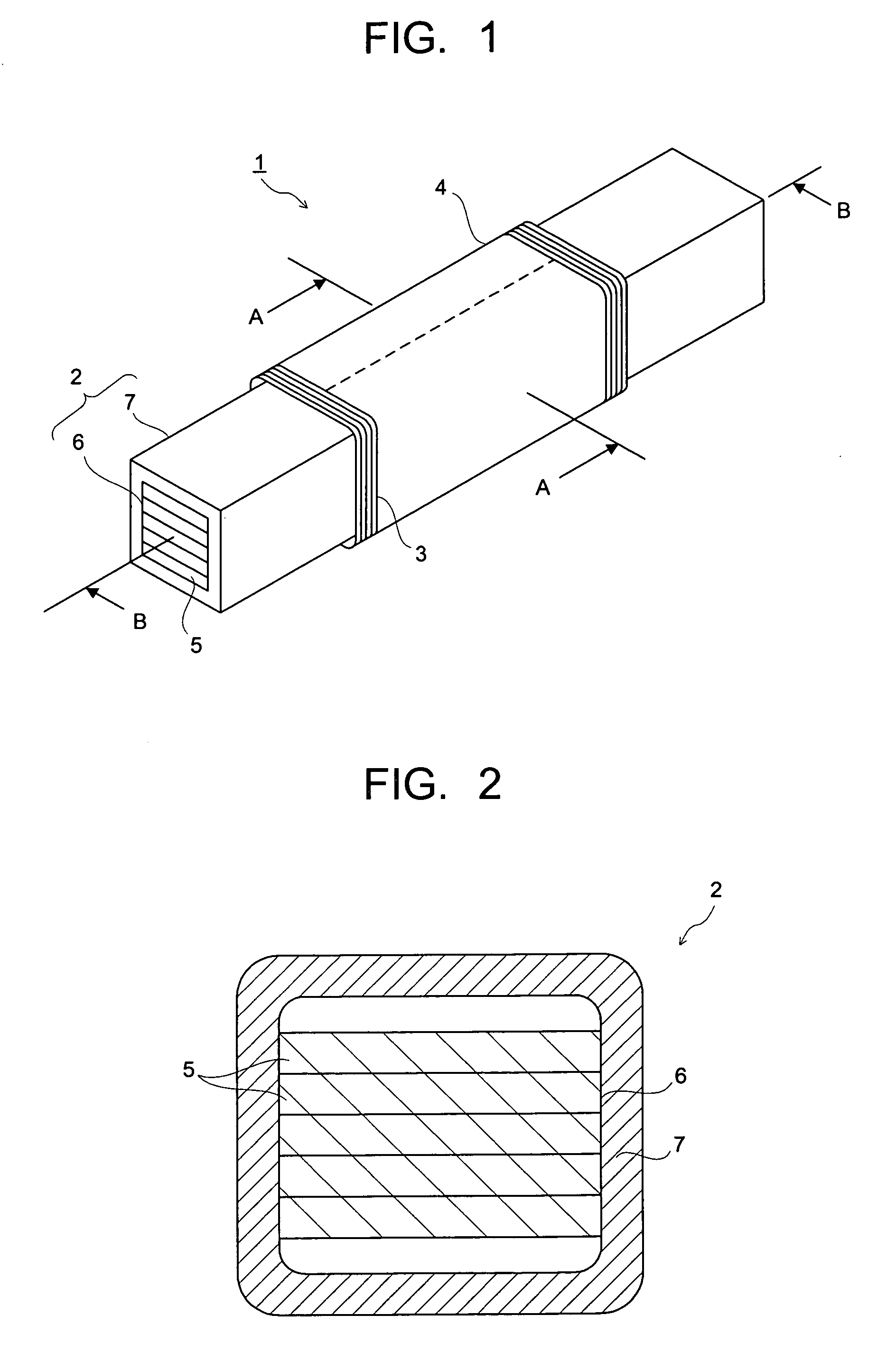

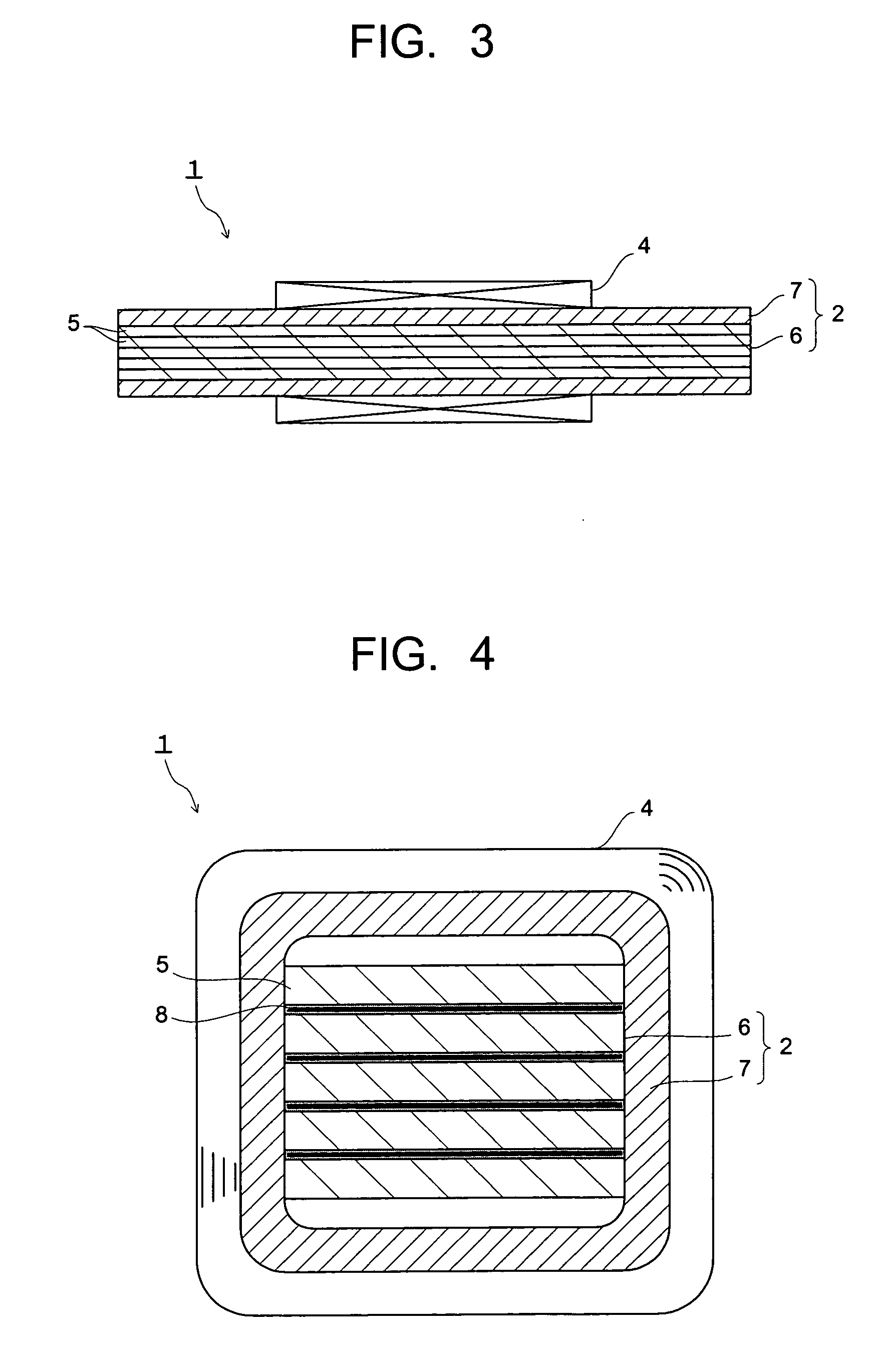

Image

Examples

examples 1 to 5

, REFERENCE EXAMPLE 1 & 2, COMPARATIVE EXAMPLES 1 & 2

[0136] First, 30 amorphous magnetic alloy thin ribbons having an alloy composition of (Co0.90Fe0.05Mn0.02Nb0.03)71Si15B14 and a thickness of 17 μm, a width of 0.8 mm and a length of 50 mm were prepared. The surfaces of the amorphous magnetic alloy thin ribbons were insulated with SiO2, and they were stacked. The multilayer body of the amorphous magnetic alloy thin ribbons was inserted into a silicone resin tube having an outer diameter of 1.5 mm, a thickness of 0.2 mm and a length of 50 mm (Example 1) to produce a core. The multilayer body of the amorphous magnetic alloy thin ribbons was inserted into the same shaped polyethylene resin tube (Example 2), polypropylene resin tube (Example 3), polyamide resin tube (Example 4), and styrene rubber tube (Example 5) to produce cores.

[0137] A phenol resin tube (Reference Example 1) and an epoxy resin tube (Reference Example 2) having the same shape were used to produce the same cores as ...

example 6

[0140] Inductors were produced in the same way as in Example 1 except that amorphous magnetic alloy thin ribbons having different surface roughness Rf were used in Example 1. A ratio (L / L0) of inductance L in a bent state (a bent state so that a distance between ends becomes 20 mm) with respect to inductance L0 in a straight state of the individual inductors, and a ratio (Q / Q0) of Q value (Q) in the bent state with respect to the Q value (Q0) in the linear state were measured and evaluated. The results are shown in Table 3 and FIG. 17.

TABLE 3SurfaceInductanceQ valueSampleroughnessInitialWhenInitialWhenNo.RfL0bent LL / L0Q0bent QQ / Q010.0510.88.90.8328.416.10.5520.1010.711.11.0328.322.20.7630.1810.712.11.1328.723.90.8140.2010.512.01.1428.924.40.8250.2510.412.31.1929.024.80.8360.3010.311.91.1629.124.00.8070.3810.110.61.0529.322.60.7580.459.99.50.9629.521.60.7190.509.58.50.9029.619.20.63100.609.46.50.6929.515.20.50

[0141] It is apparent from Table 3 and FIG. 17 that the surface roughness...

example 7

[0142] Inductors were produced in the same manner as in Example 1 except that the number of stacked layers of the amorphous magnetic alloy thin ribbons in Example 1 was changed to change the space factor in the tube. A ratio (L / L0) of inductance L in a bent state (the same bent state as in Example 6) to inductances L0, L0 of the inductors in a straight state, Q value in the same straight state, and a ratio (Q / Q0) of Q value (Q) in the bent state to Q0 were measured and evaluated. The results are shown in Table 4, FIG. 18 and FIG. 19. FIG. 18 shows changes of L and Q with respect to the space factor when the inductor is in a bent state. FIG. 19 shows changes of L / L0 ratio and Q / Q0 ratio with respect to the space factor.

TABLE 4Magneticalloy thinribbonInductanceQ valueSam-SpaceValueWhenplefactorInitialL perWhenInitialbentNo.Q'ty(%)L0layerbent LL / L0Q0QQ / Q01132.92.93.471.1813.513.30.9925146.41.37.561.1818.117.80.98310297.80.88.941.1520.720.30.98415438.70.310.01.1523.721.50.91520579.30....

PUM

| Property | Measurement | Unit |

|---|---|---|

| frequency | aaaaa | aaaaa |

| magnetic domain width | aaaaa | aaaaa |

| frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com