Beverages and foodstuffs resistant to light induced flavor changes, processes for making the same, and compositions for imparting such resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0083] A light stabilizing composition according to the present invention was prepared from caramel (type D35 ex Devolder S.A.-N.V.) as follows: 20 gram liquid caramel (60-80% dry wt. solid) was dissolved in 200 mL distilled water and ultrafiltered using a Millipore Amicon® series 8000 (model 8400, 400 mL) stirred cell, equipped with a Millipore® YM10 regenerated cellulose ultrafiltration membrane (10,000 nominal molecular weight limit, diameter: 76 mm, cat. no. 13642).

[0084] 150 mL of filtrate was collected and applied to a 70 g, 5×6.5 cm C18-RP SPE bed (Supelco® LC-18 material) that had been conditioned with 50% (v / v) ethanol / water and percolated with 200 mL distilled water before usage. After elution of 150 mL distilled water was applied to the column and another 50 mL was collected. The collected fractions were freeze-dried before usage.

example 2

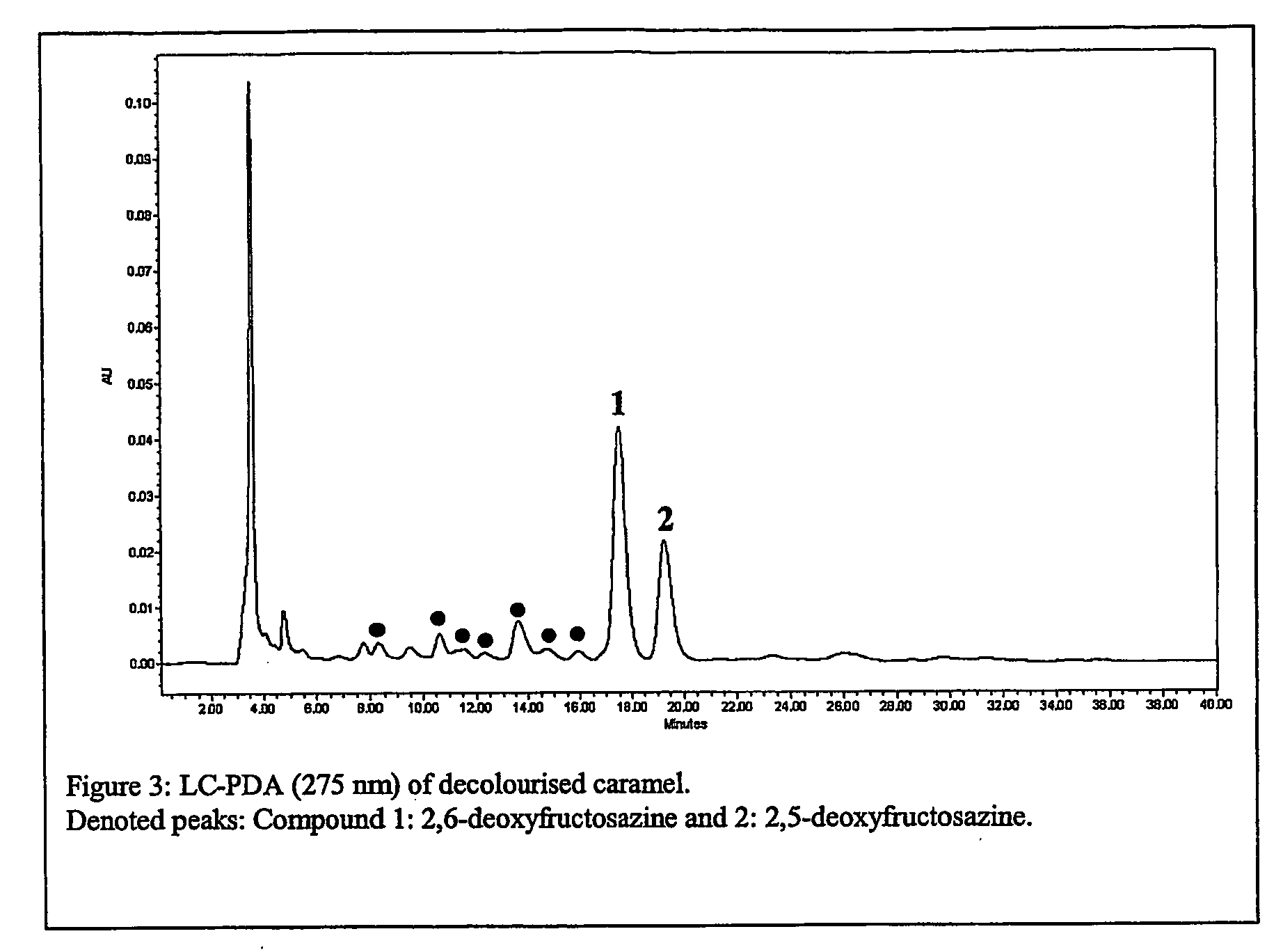

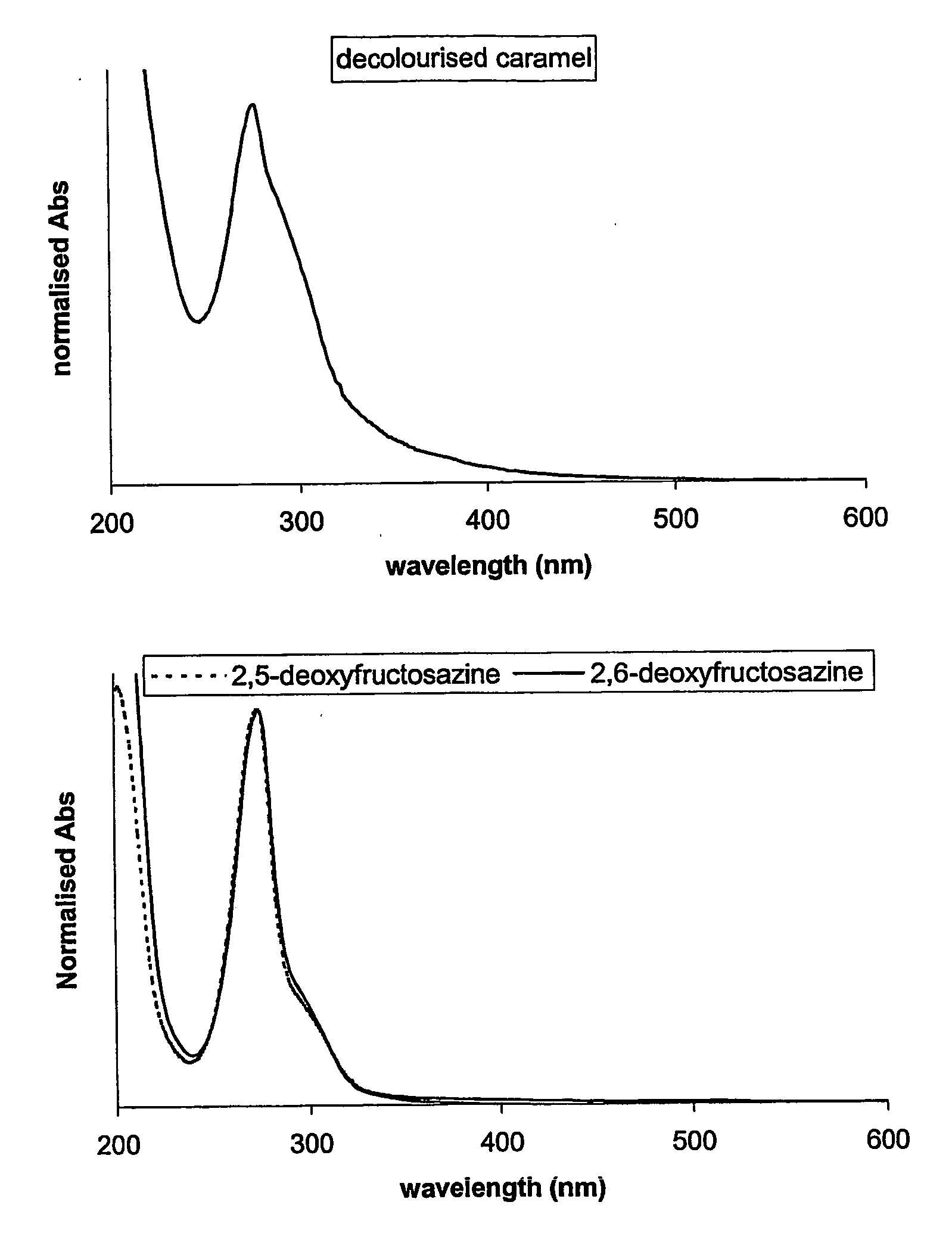

[0085] An LC-PDA analysis was performed to identify the substances that are mainly responsible for the UV absorption characteristics of the light stabilising composition described in example 1.

[0086] Methodology: [0087] Waters Alliance® 2690 HPLC system with Waters® Diode array 996 detector, scanning between 210-400 nm, Millennium 32 software [0088] Prevail® Carbohydrate ES (5 μm, 250×4.6 mm) column from Alltech (cat no. 35101) [0089] Isocratic, 40 minute run-time, flow-rate 0.5 ml / min [0090] Solvents: 75% Acetonitrile (Sigrna-Aldrich, cat no: 34998), 25% (v / v) aqueous solution of formic acid (Milli-Q plus water adjusted to pH 3 with formic acid (98-100%), ACS reagent ex Riedel-de Haën) [0091] Sample temperature: 5° C. [0092] Column temperature: 25° C. [0093] Degassing: Continuous [0094] Samples prepared by 1:1 (v / v) dilution with acetonitrile and then filtered prior to analysis (PVDF 0.45 μM syringe filters)

[0095] In order to determine the accurate masses of components 1 and 2, a...

example 3

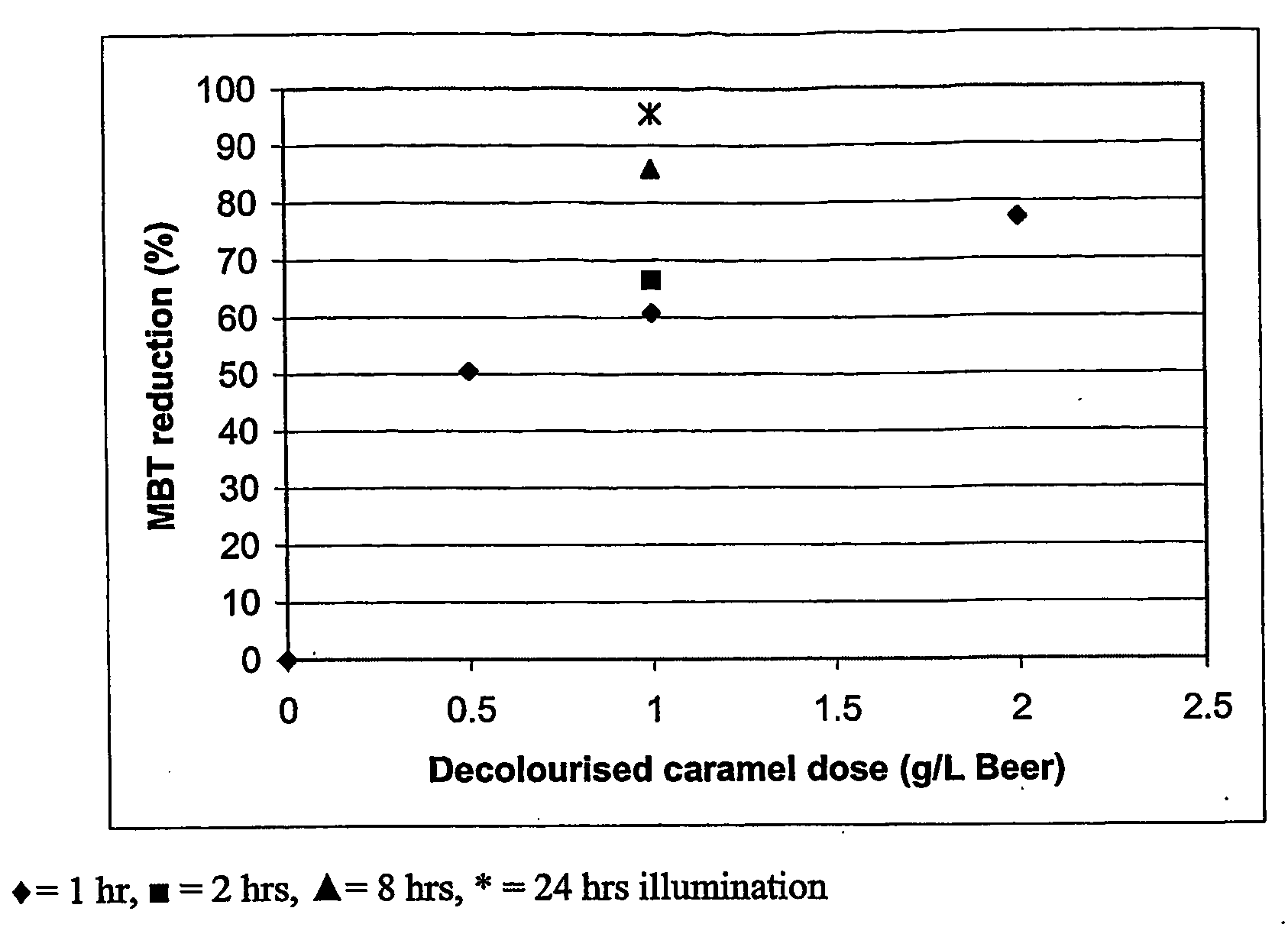

[0104] The light stabilising properties of a caramel derived composition according to the invention were assessed by adding the light stabilising composition described in Example 1 to Heineken® pilsner (the Netherlands) in dosages of 0.5, 1.0 and 2.0 g / L (dry weight). The composition was added to freshly brewed beer, which was subsequently bottled in a 300 mL green glass bottle (Heineken® export, BSN or Rexam bottle 35.5 EB-5 GR). Bottling was performed in such a way that entrapment of atmospheric oxygen in the beer and headspace was minimised.

[0105] The bottles containing the light stabilising composition in the indicated amounts as well as a bottle with a control sample were exposed to simulated sunlight by a Xenon lamp (Atlas Material Testing Technology). The light dose was 2700 KJ / m2 during 60 minutes. In addition, the samples containing 1.0 g / L of the stabilising composition were illuminated under the same conditions for 2, 8 and even 24 hrs.

[0106] The concentration of MBT in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com