Low drift planar waveguide grating sensor and method for manufacturing same

a technology sensor, which is applied in the field of planar waveguide grating (pwg) sensors, can solve the problems of high yield and low cost of disposable pwg sensors, performance of these disposable pwg sensors, and difficulty in balancing cost and performance in making a disposable pwg

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example b

[0123] Another experiment was conducted so the assay performance of Fl-biotin interacting with immobilized Streptavidin could be compared by using 384 well microplates which had either inorganic PWG sensors 900b or prior art PWG sensors 500 incorporated therein.

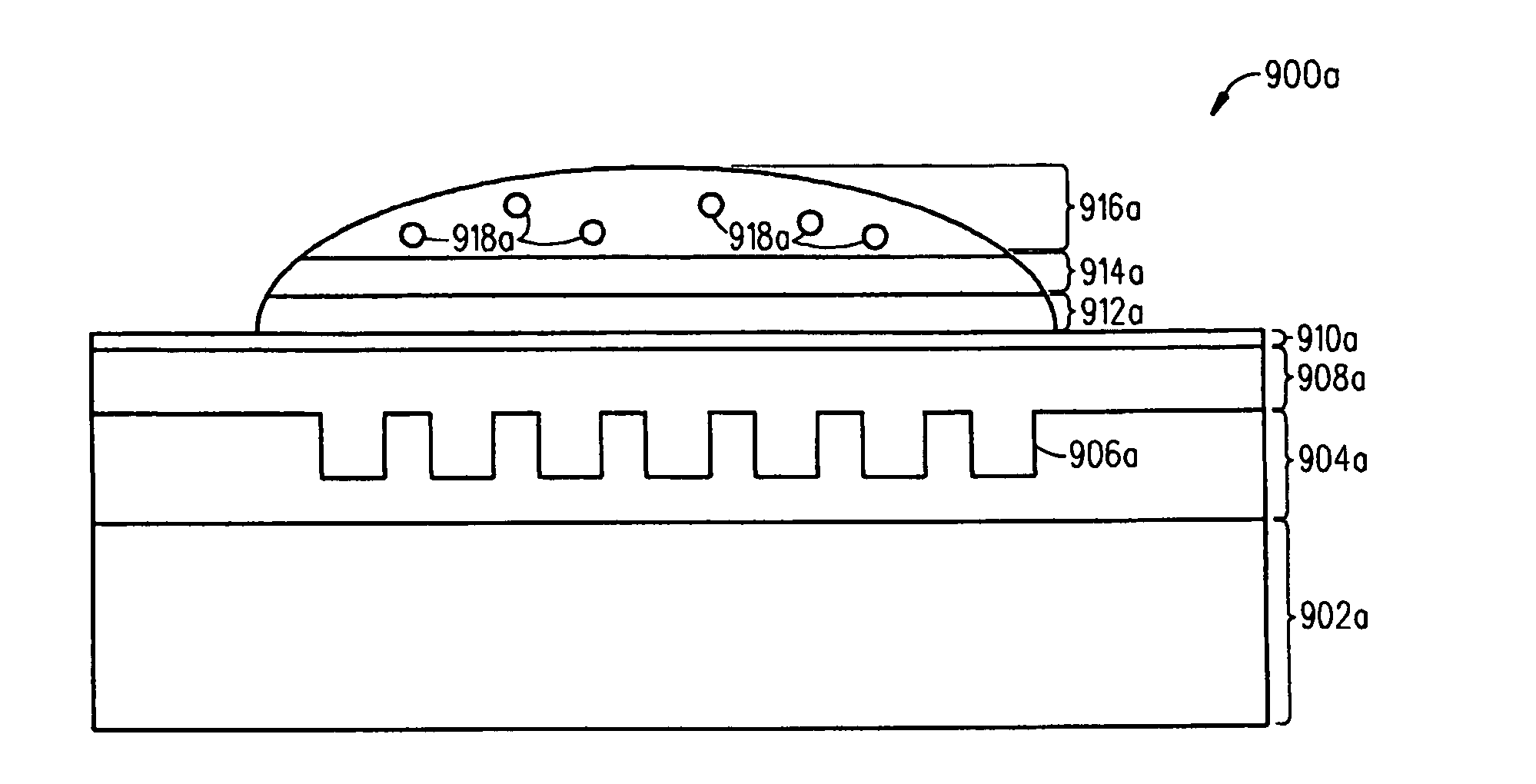

[0124] The inorganic PWG sensor 900b array was fabricated by depositing onto a glass substrate 902b a 200 nm FSG cladding layer 904b which had a refractive index of 1.41 at 830 nm by PECVD. Then, grating patterns 906b were formed in the FSG cladding layer 904b by exposing a photoresist with a deep UV stepper, and 45 nm deep diffraction gratings 906b were etched into the FSG cladding layer 904b by using a RIE process and fluorocarbon gas CHF3. Then, a ˜148 nm thick Si-rich silicon nitride monomode waveguide 908b with a refractive index of 2.5 at 830 nm was deposited by PECVD over the diffraction gratings 904b. The prior art PWG sensor 500 array was fabricated by forming diffraction gratings 504 in a UV cured polymer layer 505...

example c

[0129] This experiment was conducted to examine if the origin of the higher assay signal for the inorganic PWG sensors 900a and 900b was due to the higher index contrast of the waveguide structure, or to the surface interaction between the waveguide structure, the surface chemistry layer 912a and 912b, and the solution containing the molecules 914a and 914b of interest. Eight microplates of either inorganic PWG sensors 900a or 900b as described above with respect to FIGS. 9A and 9B but with different waveguides and surface layers where tested and the Fl-biotin to Streptavidin assay results compared. The waveguide materials compared were the Nb2O5 waveguides (PWG sensor 900a) as was typically used in prior art example PWG sensor 500, and silicon rich silicon nitride (PWG sensor 900b). The surface layers compared were SiO2 surface as was typically used in prior art example PWG sensor 500, and silicon rich silicon nitride surface layers described in PWG sensors 900a and 900b. Both sil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com