Edible barriers

a barrier and edible technology, applied in the field of barriers, can solve the problems of affecting the appearance, taste, shelf life and consumer satisfaction, and the inability of edible moisture barrier technology to effectively stop moisture migration, and achieve excellent temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

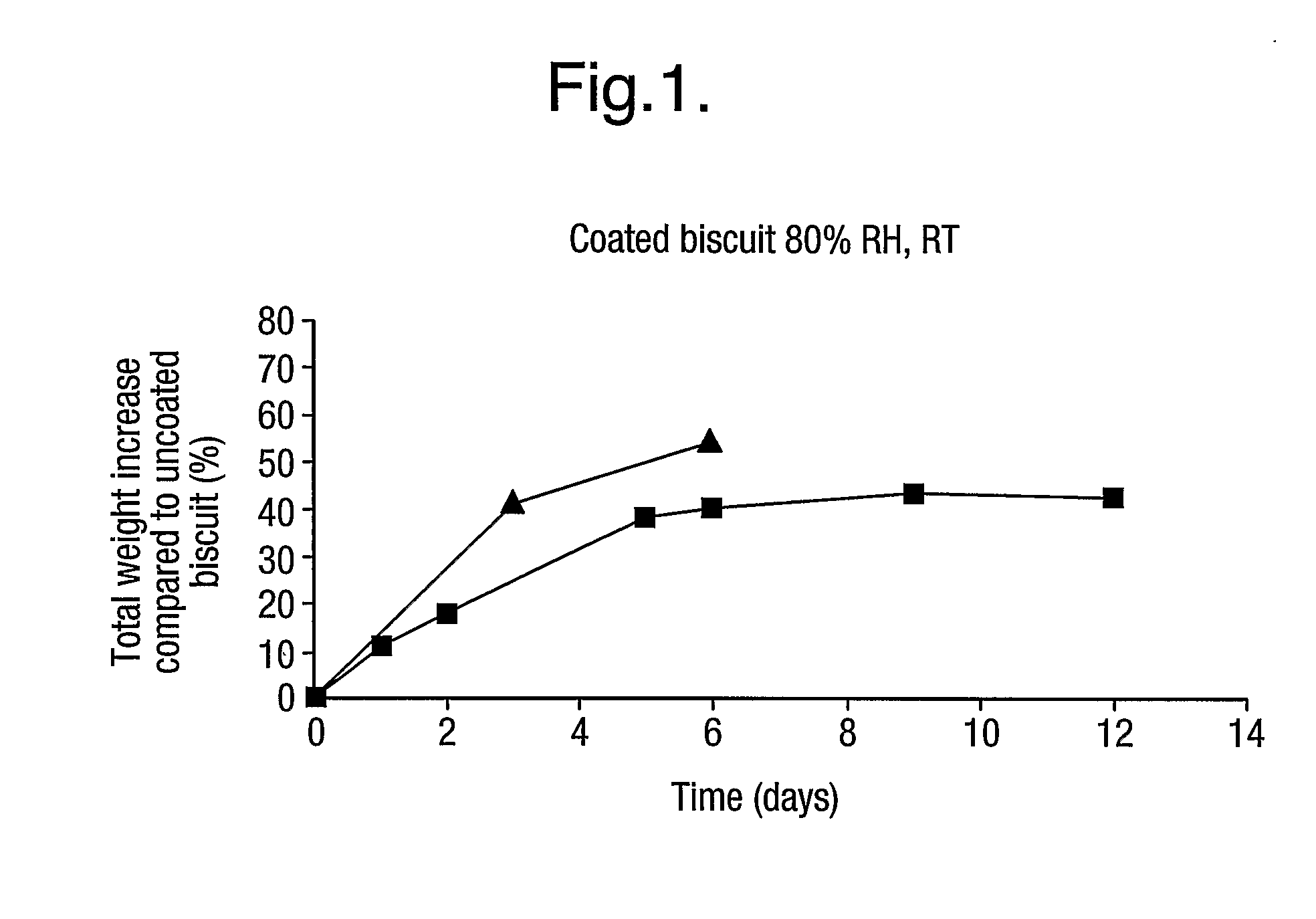

Image

Examples

example 1

Moisture Barrier Films

Materials:

[0039] Sugar beet pectin was obtained CP Kelco, GmbH, batch genu β pectin. Chitosan and sodium caseinate were obtained from van Erven BV. Soybean peroxidase and vanillin were obtained from Quest. Peroxidase is a non-GM, food grade Biobake Wheat from Quest, the Netherlands. The cofactor hydrogen peroxide used is 30% solution of Merck, Germany. Glucose oxidase, non-GM, food grade from Amano in combination with glucose and Biobake wheat were used for some examples. Novozym 435 lipase and pectinex ultra SP-L were obtained from Novozymes. Beeswax, carnauba wax and ethylferulate were obtained from Sigma Aldrich Chemicals. Solid fats MGLA41, coco nut oil, PO58 flakes, and RPLE70 were obtained from W. T. Hogervorst, SCC, URDV. All other chemicals used were obtained from Merck.

Film Components: Chitosan Modified with Vanillin (Chitosan-V)

Synthesis A

[0040] Vanillin was dissolved in 97% Ethanol and chitosan powder was added to this solution. The resulting...

example 2

Cheese—Yeast Extract

[0076] A new savoury spread, consisting of cheese and yeast extract or vegetable protein hydrolysate, with an original two coloured appearance was developed. Over time, however, colour migration caused serious appearance problem. Water migration occurred from the high water containing cheese (aw=+ / −0.8) to the low water containing yeast extract (aw=0.2-0.4). Besides water migration, also the dark brown yeast extract colour migrates into the cheese phase, leading to one large brown coloured transition layer between the two components. An edible layer was used to prevent dye and water migration. Chitosan films containing up to 50% lipid appeared to be very successful. Based on these results, it can be concluded that chitosan with a high lipid content can prevent water migration between two components with different water activities.

The Method for preparation of Chitosan-Vanillin Films:

[0077] Chitosan-vanillin film containing 20% (v / v) sunflower seed oil: 5 ml s...

example 3

Salami Sausages

[0080] Due to its adhering properties it is not possible to form a homogeneous layer covering the complete sausage surface with non-cross-linked pectin. The use of cross-linked pectin, however, resulted in a film with amazingly good surface adherence properties, probably due to covalent interaction between pectin molecules and tyrosine groups of proteins located on the sausage surface.

[0081] The pectin layer was applied on the sausage by dipping it into a 4% pectin solution containing enzyme (1 ml / 100 ml) and 25% ethanol. Ethanol will decrease drying time and at the same time increase solution viscosity, which promotes the adherence of the gel onto the sausage. Subsequently the dipped sausage was sprayed with a solution containing 1 mM peroxide and 2% pectin (maximum concentration for spraying device) and dried in a hot air oven for 4 hrs at 40° C. The appearance of the pectin coated sausage is the same as the uncoated one.

[0082] The coated and uncoated sausages we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com