Organic thin film transistor having surface-modified carbon nanotubes

a carbon nanotube, organic technology, applied in the direction of thermoelectric devices, solid-state devices, nanoinformatics, etc., can solve the problems of relatively high driving voltage, relatively high threshold voltage of organic thin film transistors, and relatively low charge carrier mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 4

Preparative Example 4

Introduction of Oxirane Group into Surfaces of Carbon Nanotubes

[0056]40 mg of the carbon nanotubes surface-modified with an acetyl chloride group, which were prepared in Preparative Example 3, were dispersed in 20 ml of chloroform by sonication for 30 minutes. 4 ml of pyridine and 1 ml of glycidol were sequentially added to the dispersion. The mixture was allowed to react with stirring under refluxing conditions for 48 hours. After completion of the reaction, the reaction mixture was washed several times with methanol to remove unreacted glycidol, and the remaining black solid was dried under reduced pressure at room temperature to yield carbon nanotubes whose surfaces were modified with a glycidyl ether group.

example 5

Preparative Example 5

Introduction of Anhydride Group into Surfaces of Carbon Nanotubes

[0057]40 mg of the carbon nanotubes surface-modified with an acetyl chloride group, which were prepared in Preparative Example 3, were dispersed in 2 ml of dimethylformamide by sonication. 10 ml of pyridine and 2 g of dimethyl 4-hydroxyphthalate were sequentially added to the dispersion. The mixture was allowed to react at 70° C. for about 18 hours. After completion of the reaction, the reaction mixture was washed several times with distilled water. 20 ml of acetone and 10 ml of a solution of sodium hydroxide (0.2 g) in distilled water were sequentially added to the remaining black solid. The mixture was allowed to react with stirring at 60° C. for about 18 hours. After completion of the reaction, the reaction mixture was washed several times with a dilute aqueous hydrochloric acid solution, distilled water, and ethyl acetate, and dried under reduced pressure at room temperature. The dried solid wa...

example 1

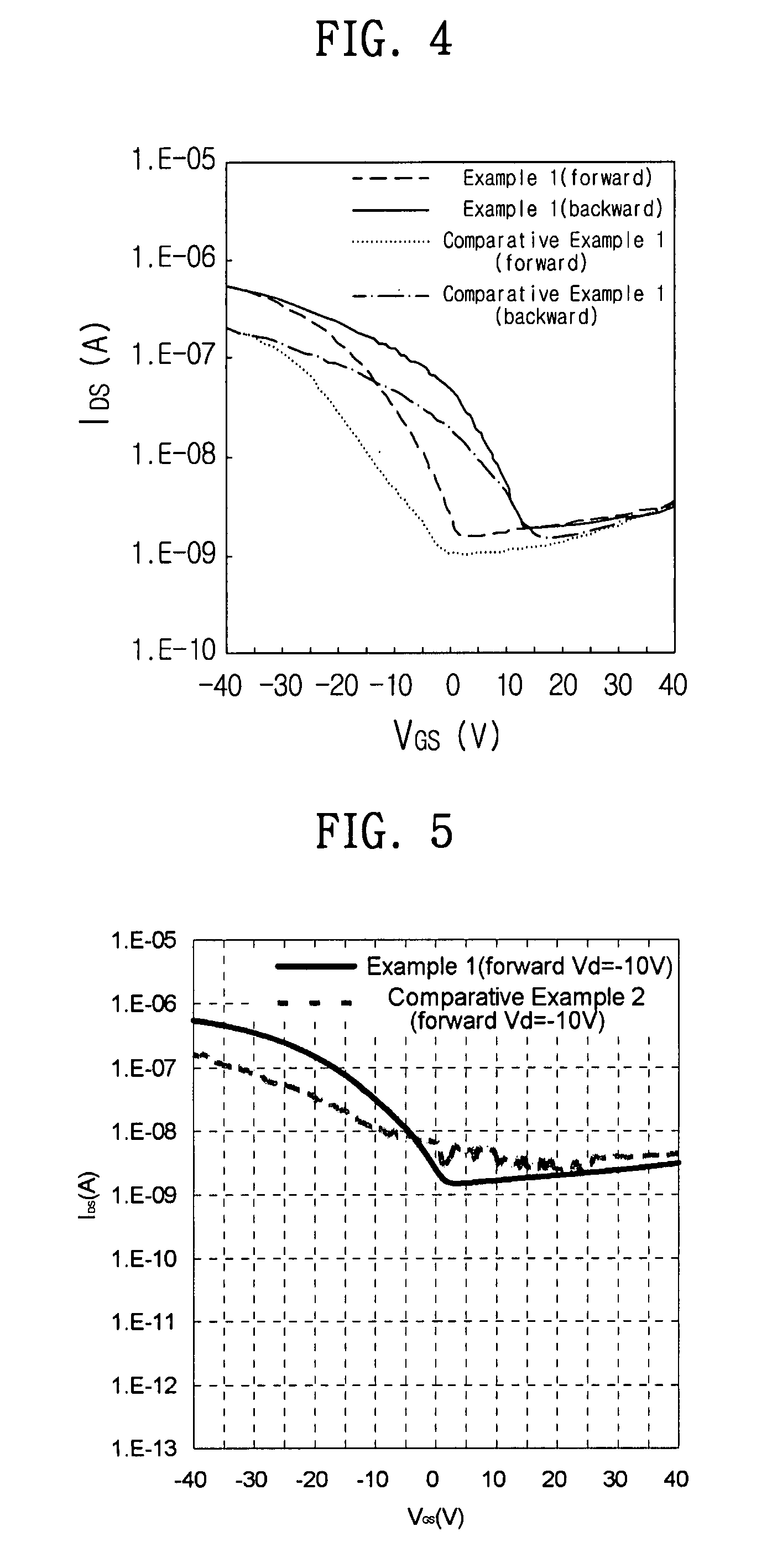

[0058]Polythiophene-thiazole (weight average molecular weight: 15,000) was dissolved in chlorobenzene or chloroform to obtain a polymer solution (1 mg / mL). The carbon nanotubes surface-modified with an oxirane group, which were prepared in Preparative Example 4, were dispersed in a mixed solvent of dimethylformamide and chloroform to obtain a solution of the carbon nanotubes (1 mg / ML). The polymer solution was mixed with the solution of the carbon nanotubes in a weight ratio of 1:1 to prepare a solution for the formation of an organic semiconductor layer 5.

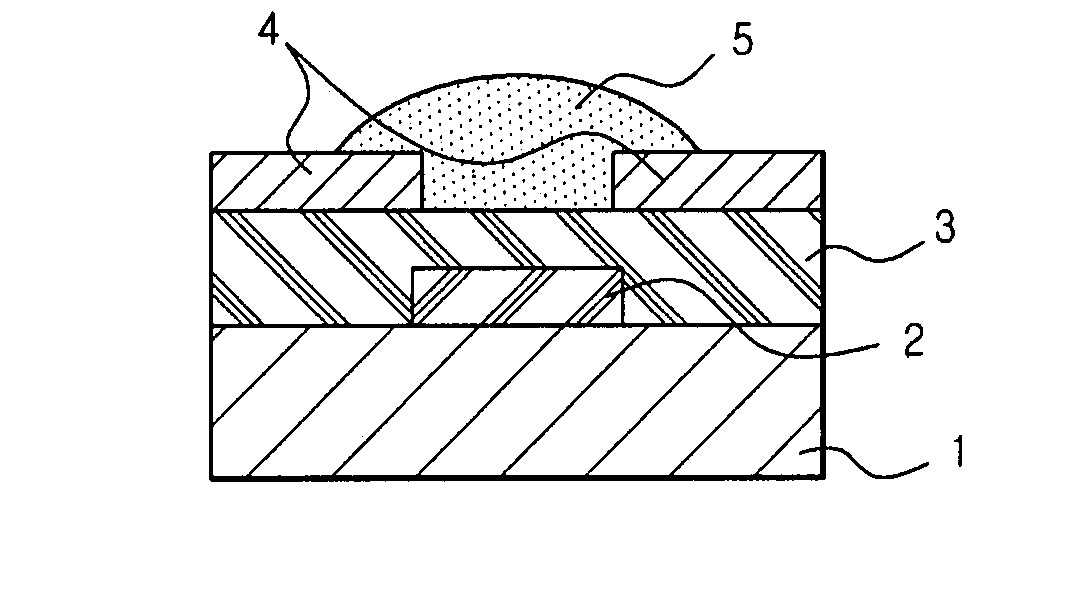

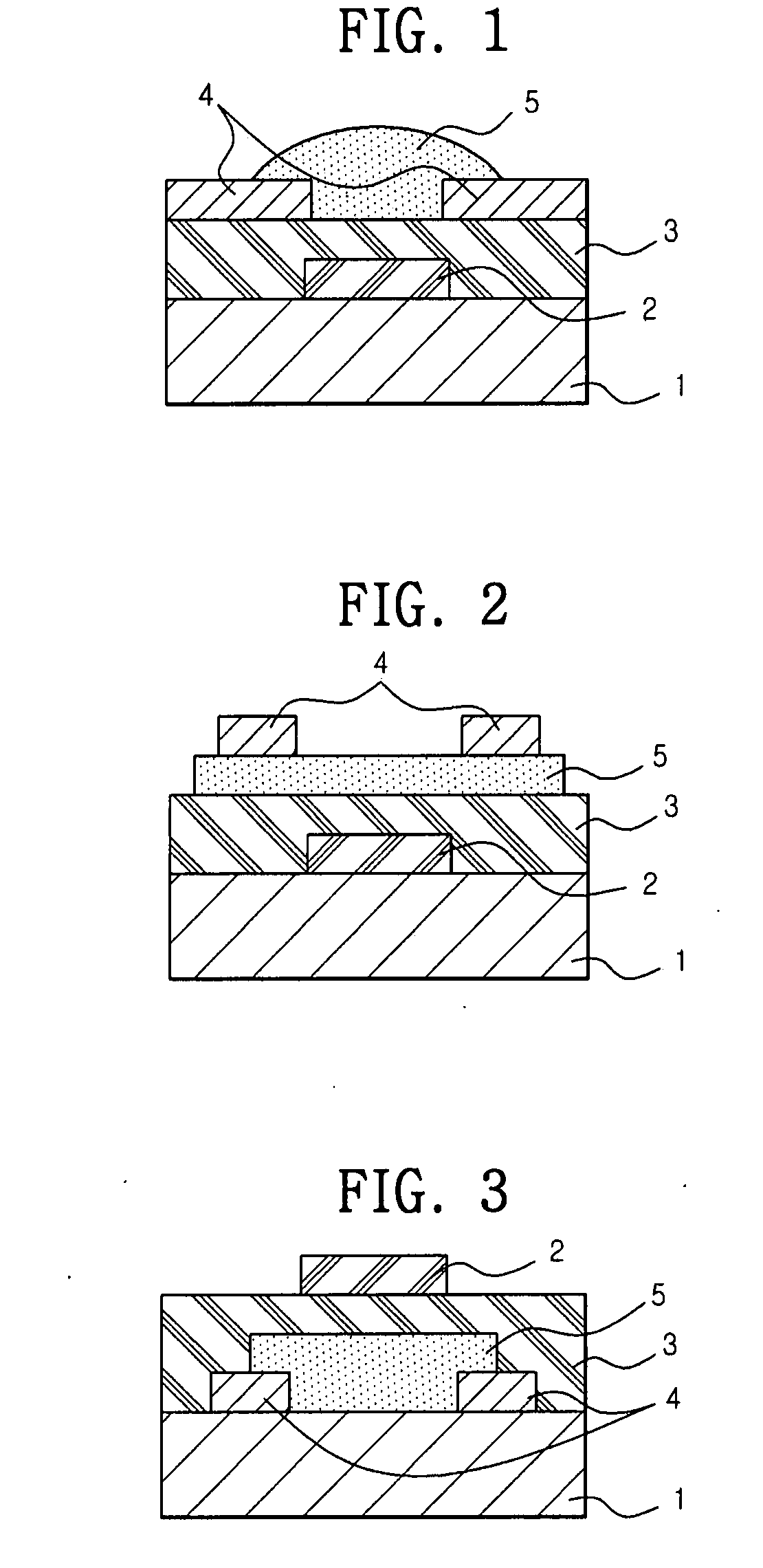

[0059]Aluminum (Al) was deposited to a thickness of 1,000 Å on a clean glass substrate 1 by sputtering to form a gate electrode 2. An organic-inorganic hybrid insulating material was applied by spin casting and dried at 200° C. for 2 hours to form a 7,000 Å-thick gate insulating layer 3. Gold (Au) was deposited to a thickness of 700 Å on the gate insulating layer by thermal evaporation to form source / drain electrodes 4. The soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com