Highly heat conductive insulating member, method of manufacturing the same and electromagnetic device

a technology of high heat conductivity and insulating member, which is applied in the direction of plastic/resin/waxes insulators, natural mineral layered products, transportation and packaging, etc., can solve the problems of limited use of reference techniques, insufficient documents, and insufficient heat conductivity of electro-insulating members, etc., to achieve high heat conductivity, high heat conductivity, and easy manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

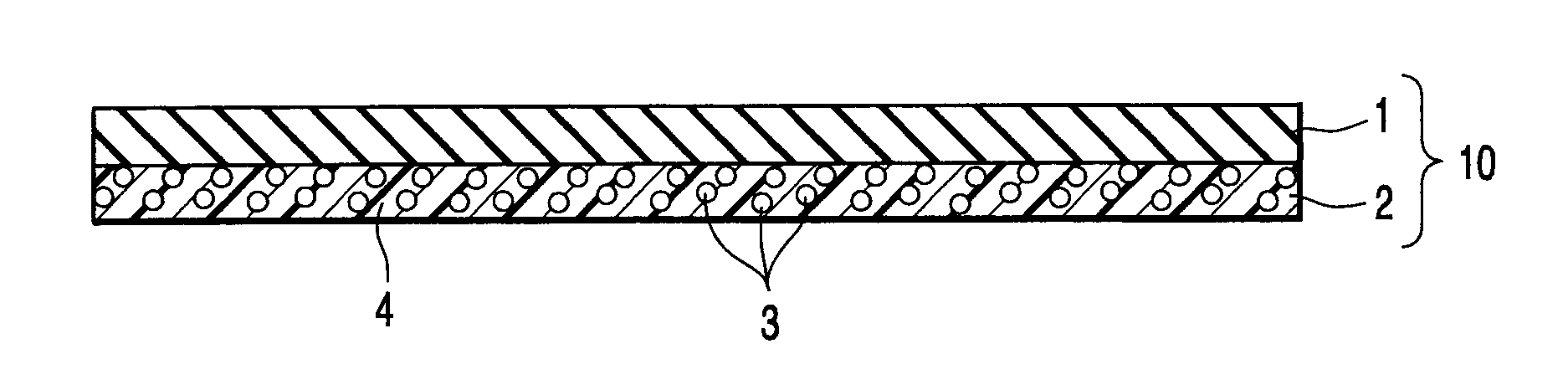

[0077]The first embodiment of the present invention will now be described with reference to FIGS. 1 to 8.

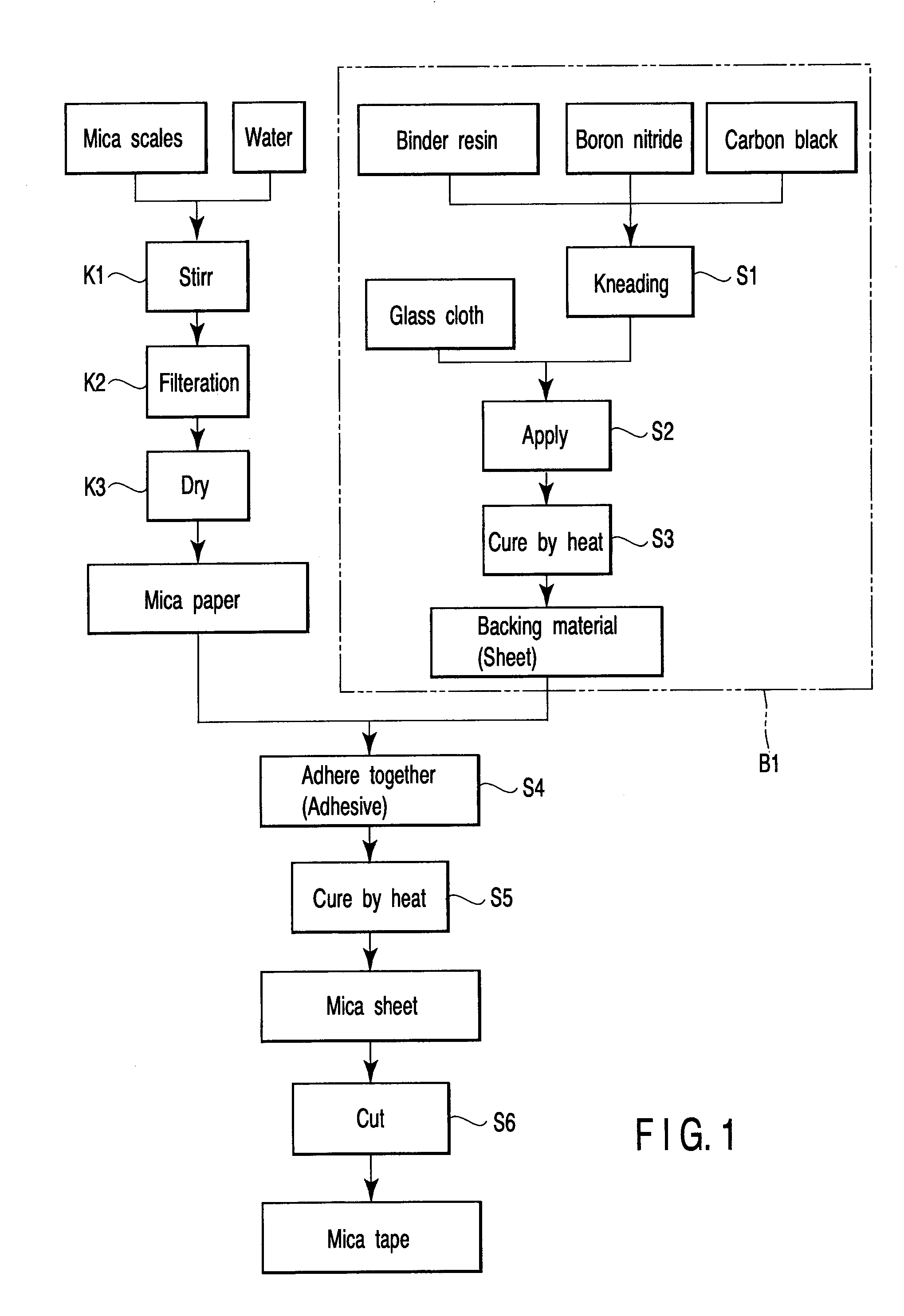

[0078]First, with reference to FIG. 1, the manufacture of the mica tape of this embodiment will be described.

[0079]300 cc of water was blended to 2.826 g of mica scales and the mixture was stirred (Step K1). Here, it is possible to add a slight amount of epoxy resin as the binder.

[0080]The thus obtained stirred mixture was allowed to pass a grid having a lattice size of, for example, 0.05 mm×0.05 mm in a manner of papermaking, thereby preparing a raw sheet (Step K2). The raw sheet was heated to a predetermined temperature and thus dried, thereby obtaining mica paper 1 (Step K3).

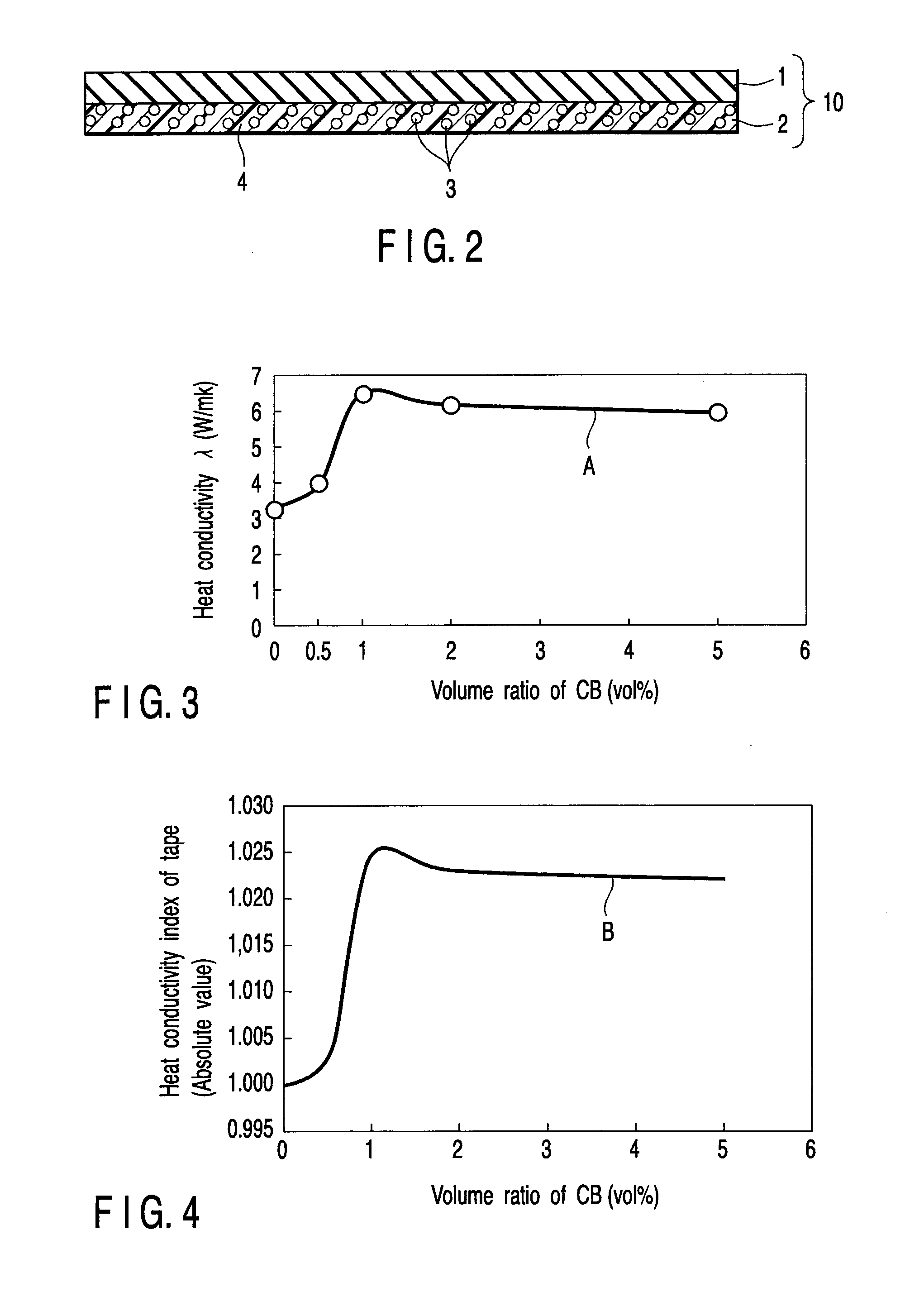

[0081]In a process B1 for manufacturing a backing material layer of this embodiment, first, a binder resin, boron nitride particles and carbon black particles were blended at a ratio of 24.7:74.2:1.1 and the mixture was kneaded (Step S1). In this embodiment, Asahi Thermal (Tradename) of Asahi Carbon Co., L...

second embodiment

[0108]Next, the second embodiment will now be described with reference to FIGS. 9 to 11.

[0109]In the member of this embodiment, highly heat conductive particles were filled in the mica layer side. As the backing material, glass cloth 25 was used. 2.83 g of mica scales and 0.125 g of alumina particles were blended to 3000 cc of water, and the mixture was stirred (Step S21). In this embodiment, NanoTekAl2O3-HT (product model number) of CI Kasei Company Ltd. was used as the alumina particles. The average diameter of the alumina particles was 70 nm. The shape of the alumina particles was spherical. As the mica particles, sintered mica was used. The average diameter of the mica scales was 15 μm.

[0110]The thus obtained stirred mixture was allowed to pass a grid having a lattice size of, for example, 0.05 mm×0.05 mm in a manner of papermaking, thereby preparing a raw sheet (Step S22). The raw sheet was heated to 120° C. and thus dried, thereby obtaining mica paper (Step S23).

[0111]The abov...

third embodiment

[0114]The third embodiment of the present invention will now be described with reference to FIG. 12. In a mica tape 10A of this embodiment, first particles having a heat conductivity of 0.5 W / mK or higher were filled and diffused in a mica layer 9. In this embodiment, a mica layer 11 was manufactured by an ordinary method and a heat conductive sheet 9 having a high heat conductivity was used as the backing material. In this case, the heat conductivity of the mica layer 11 is smaller as compared to that of the backing material layer 9, and therefore the mica layer 11 served as a heat barrier.

[0115]Here, while making the mica paper, alumina particles having an average particle diameter of 70 nm was blended into the mica paper. More specifically, the mica paper and the alumina particles were blended into distilled water and stirred, and the mixture was applied onto a cloth having a mesh of 0.05 μm. Then, the resultant was subjected to a dry process and thus a mica sheet was obtained. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| flatness | aaaaa | aaaaa |

| average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com