Patents

Literature

31results about How to "Unevenness easily" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

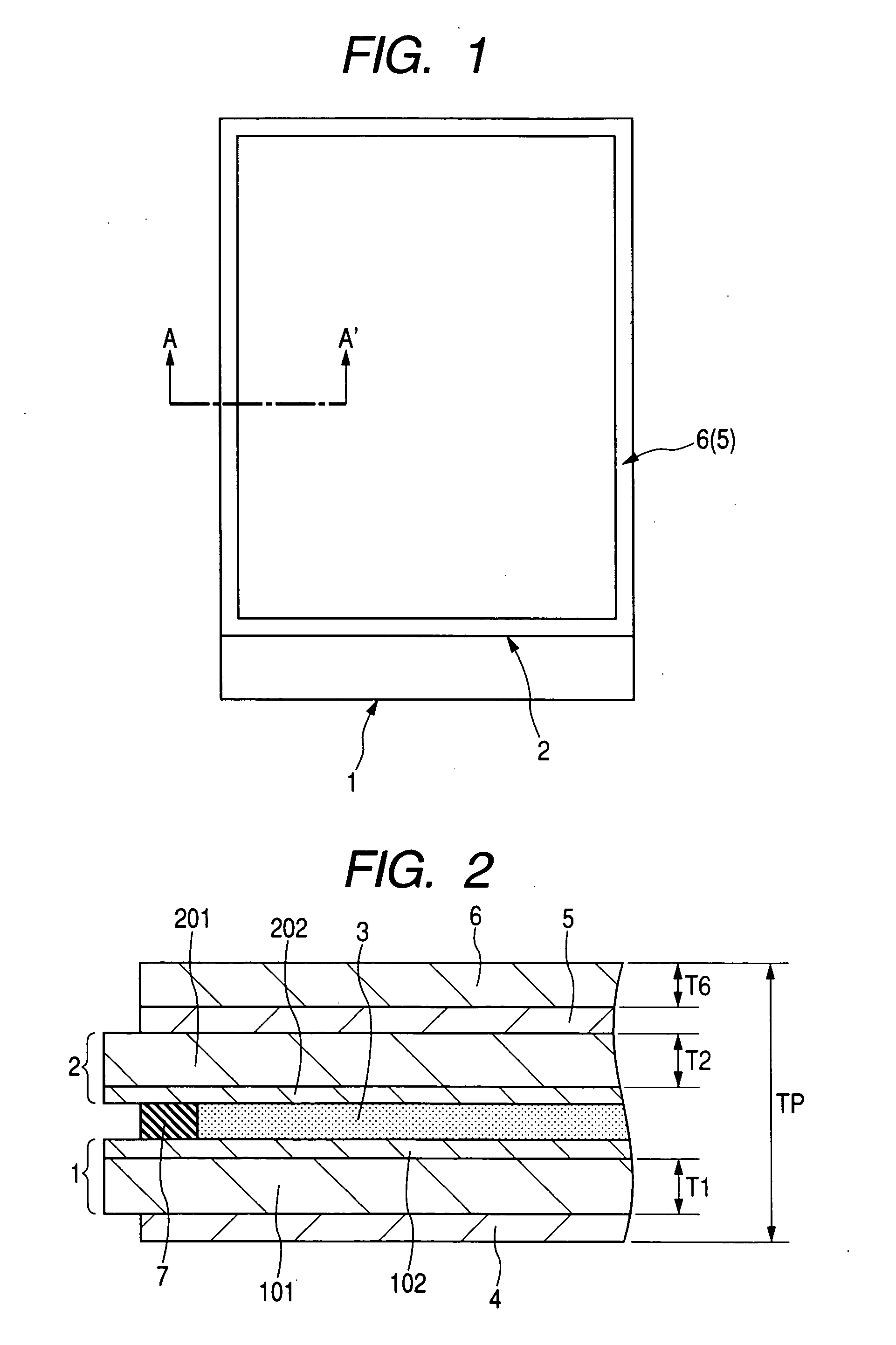

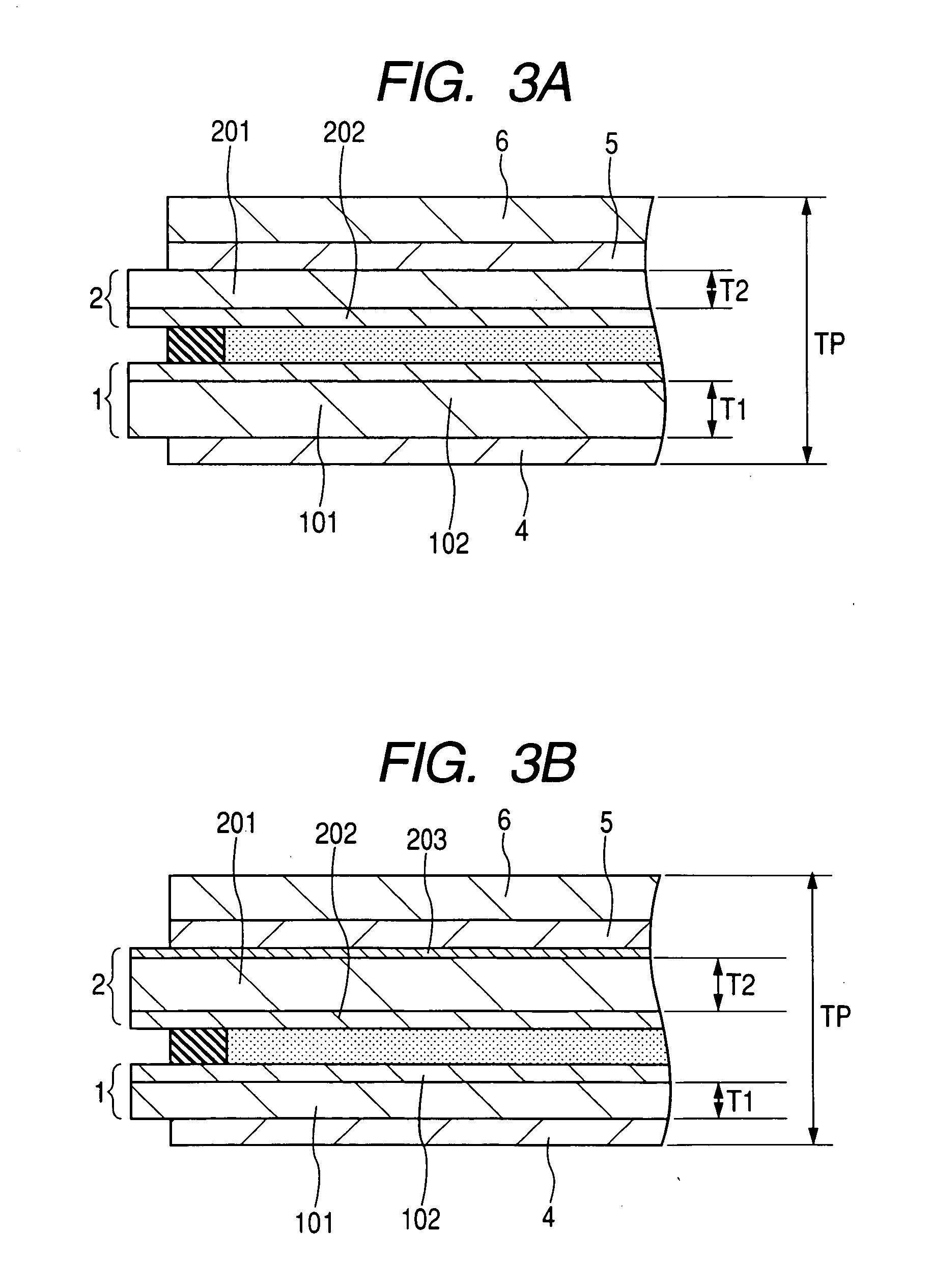

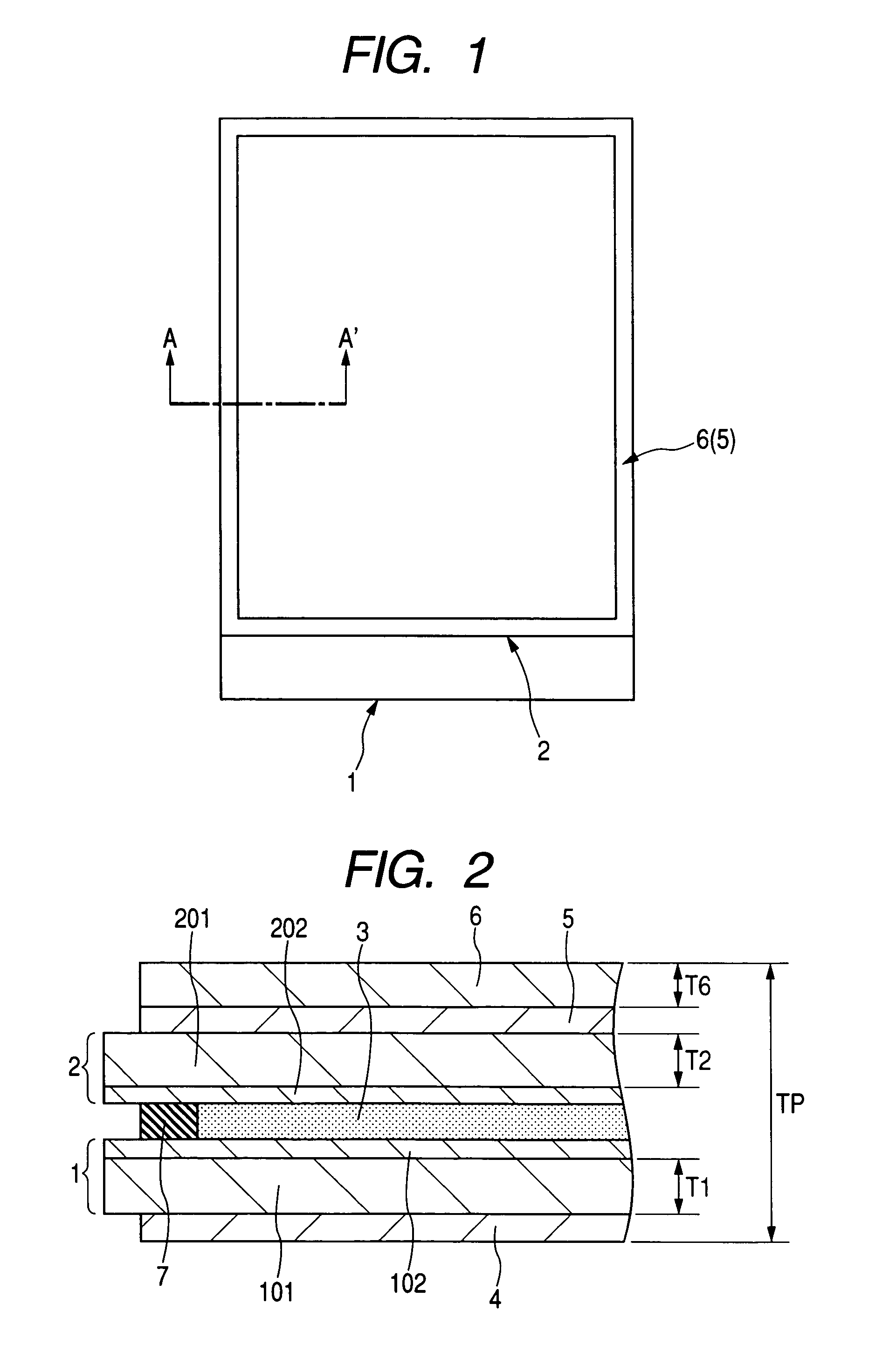

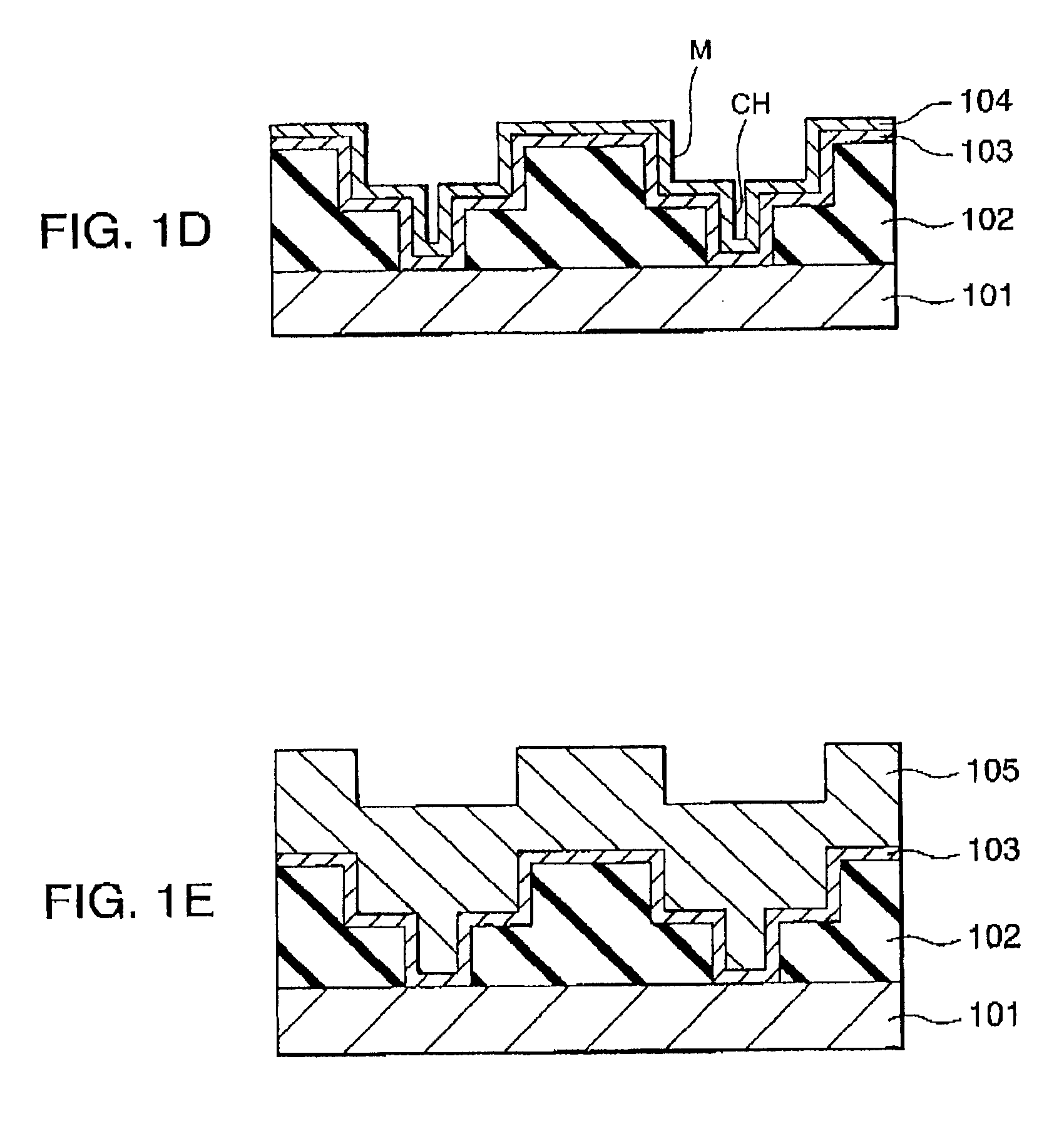

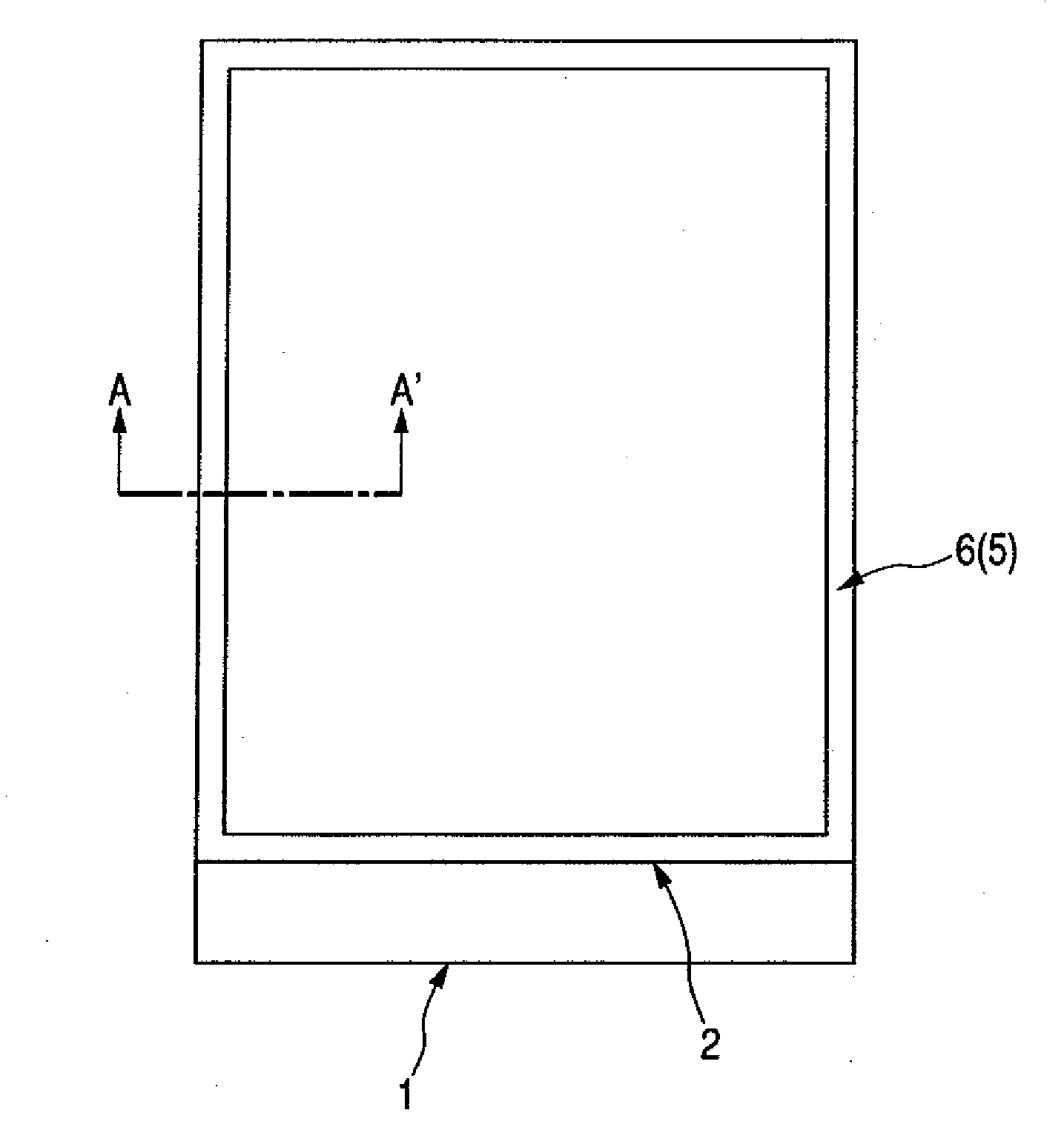

Liquid crystal display and display

ActiveUS20070165170A1Reduce thicknessSufficient strengthNon-linear opticsLiquid-crystal displayLiquid crystal

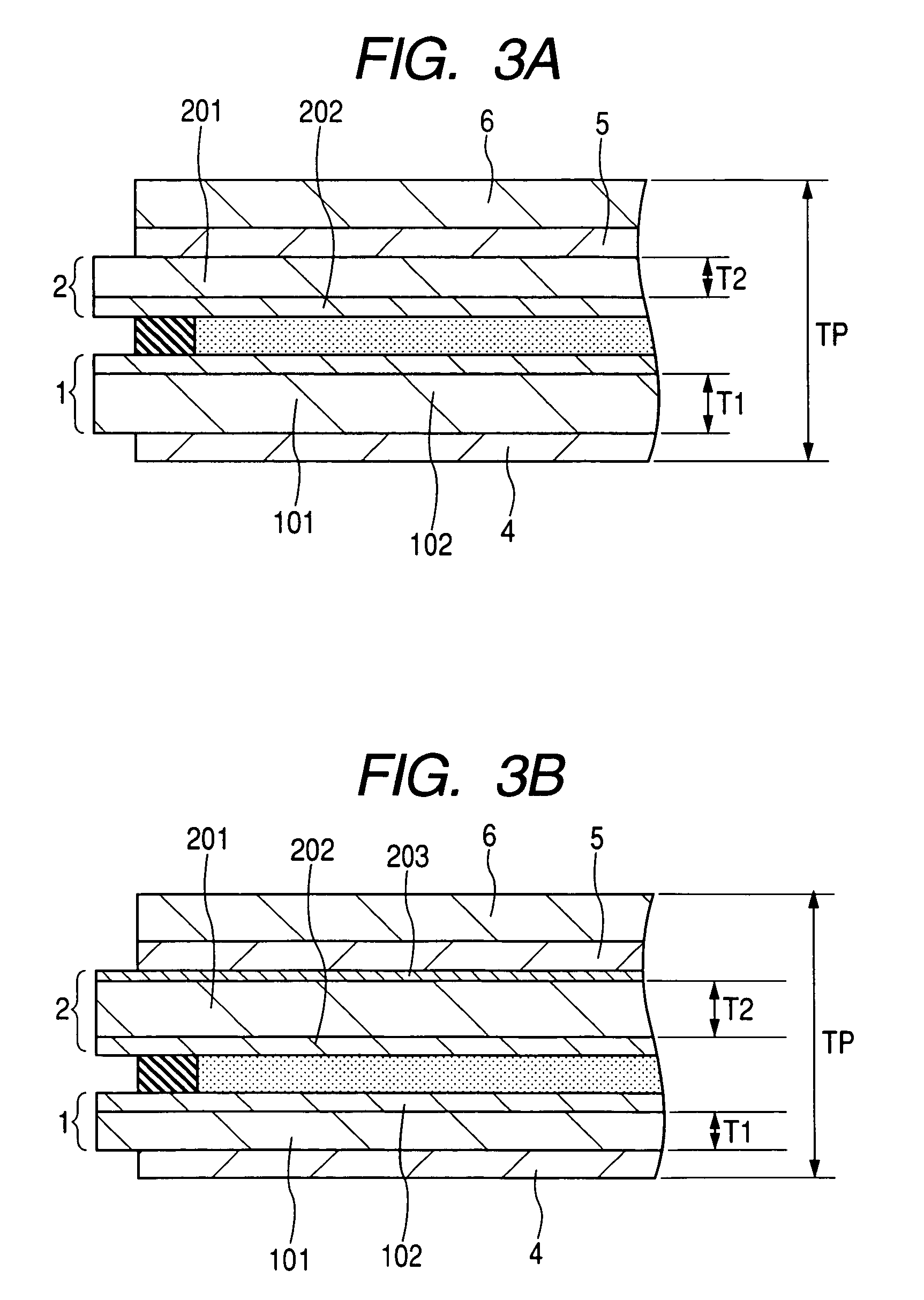

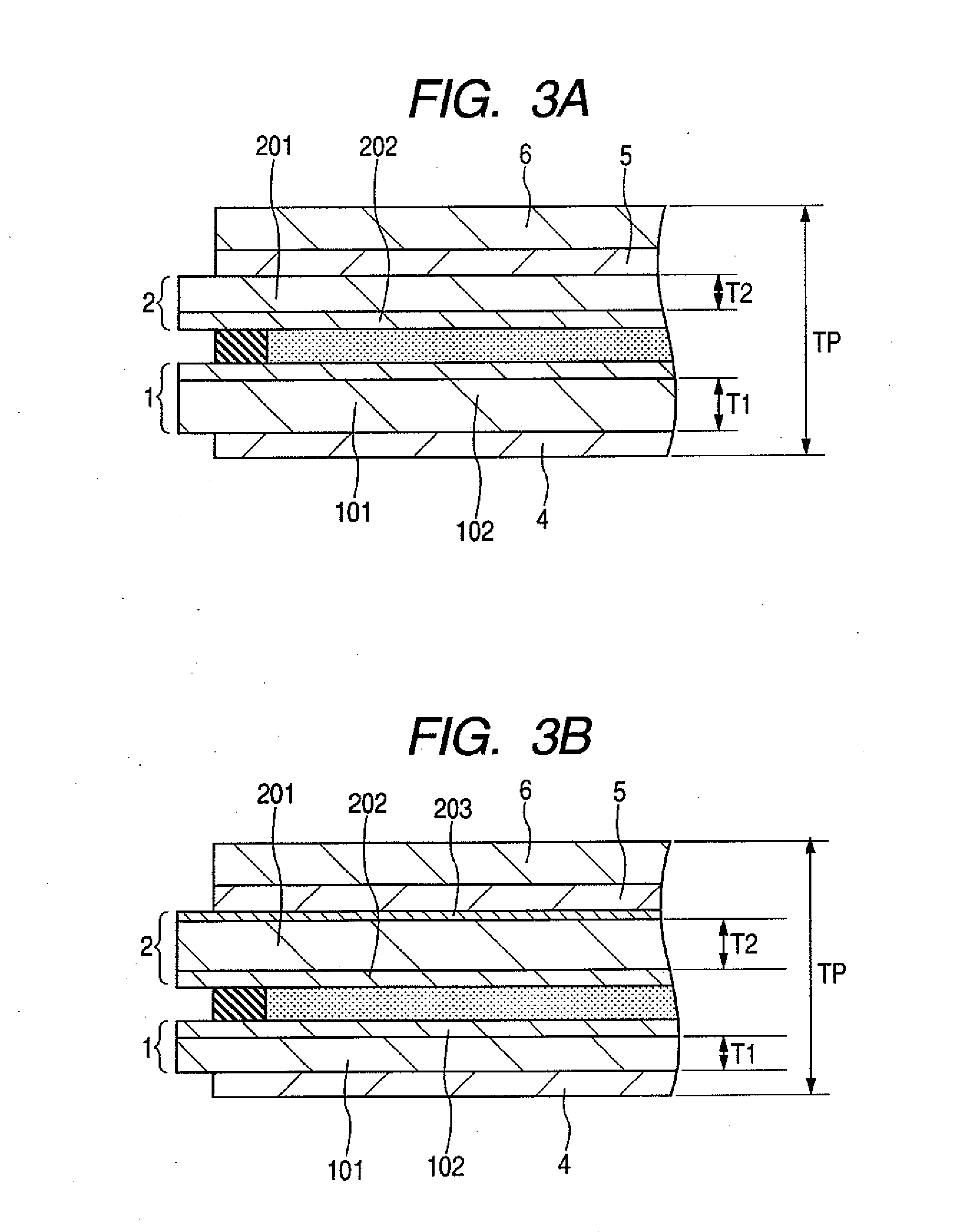

A liquid crystal display comprises a liquid crystal display panel, the liquid crystal display panel comprising a first substrate; a second substrate disposed on an observer side with respect to the first substrate and opposed to the first substrate; a liquid crystal held between the first substrate and the second substrate; an upper polarizing plate disposed on the observer side with respect to the second substrate; and a resin film disposed on the observer side with respect to the upper polarizing plate and affixed in contact with the upper polarizing plate, the resin film being higher in surface hardness than the upper polarizing plate. Both reduction in thickness of the liquid crystal display panel and ensuring of a sufficient strength are attained.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

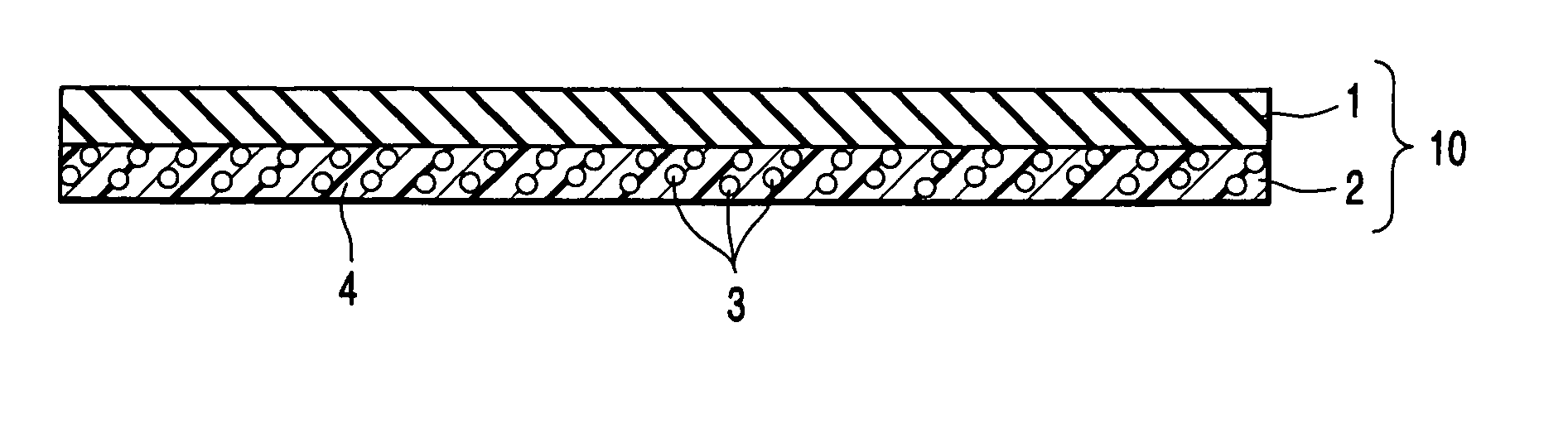

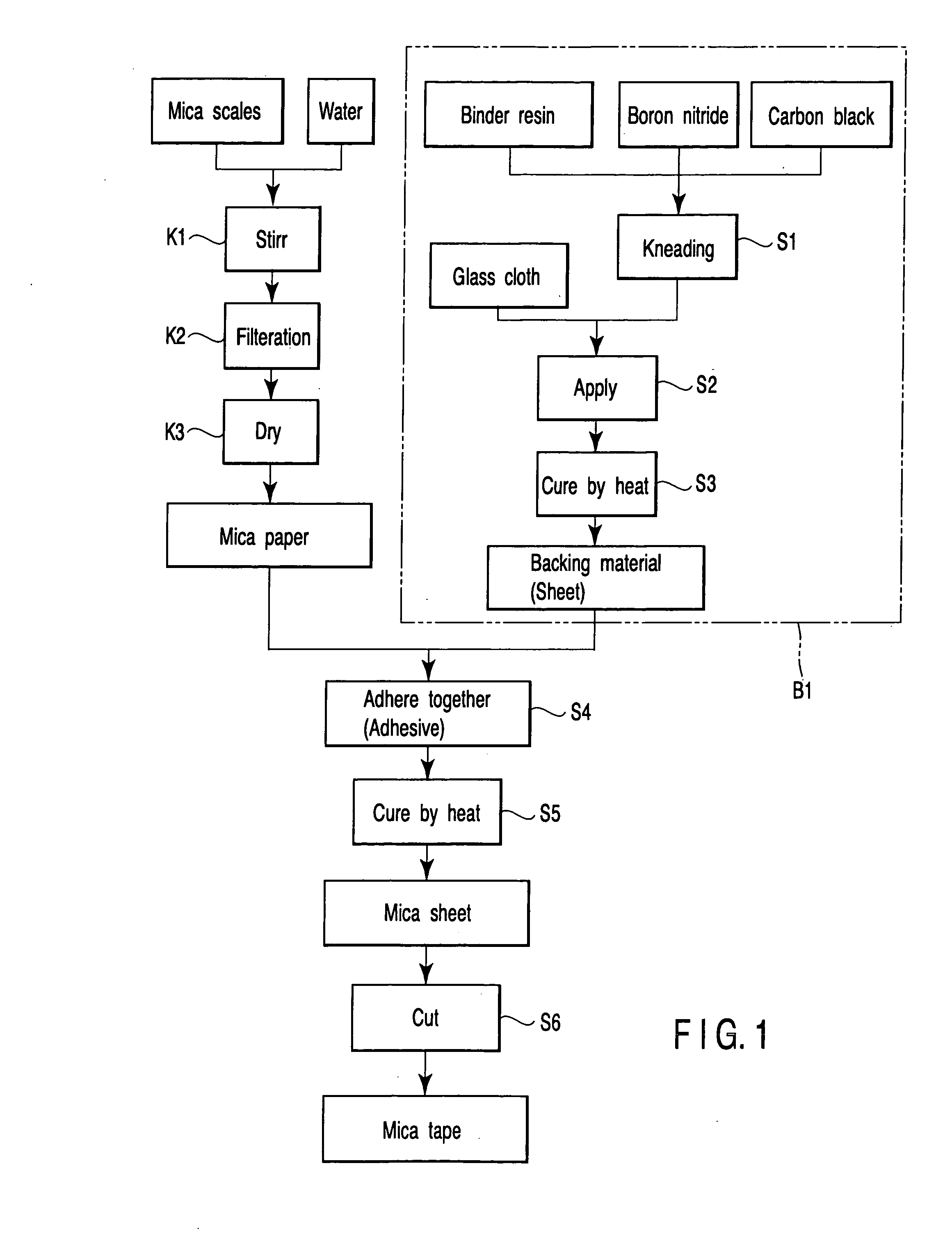

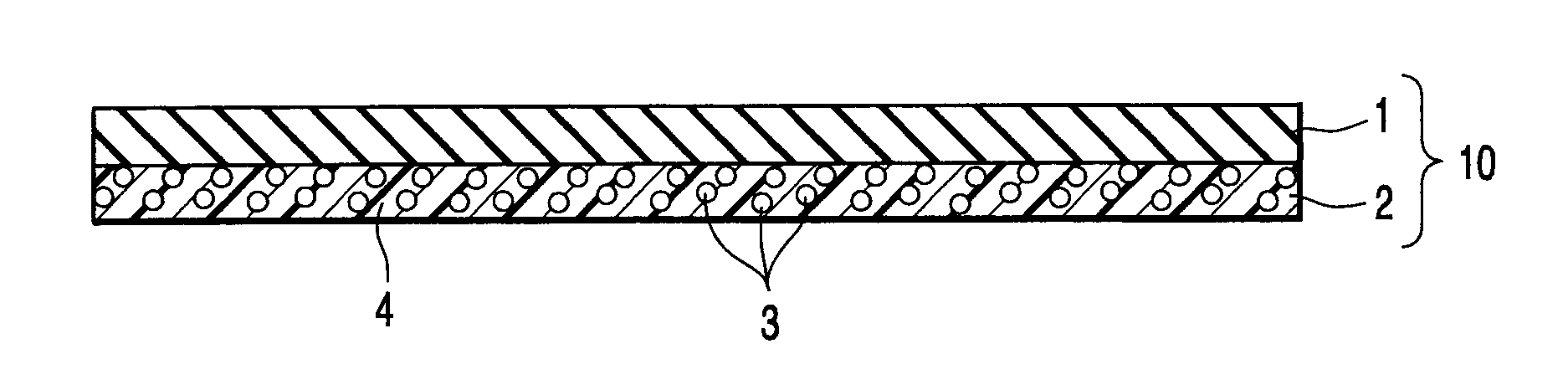

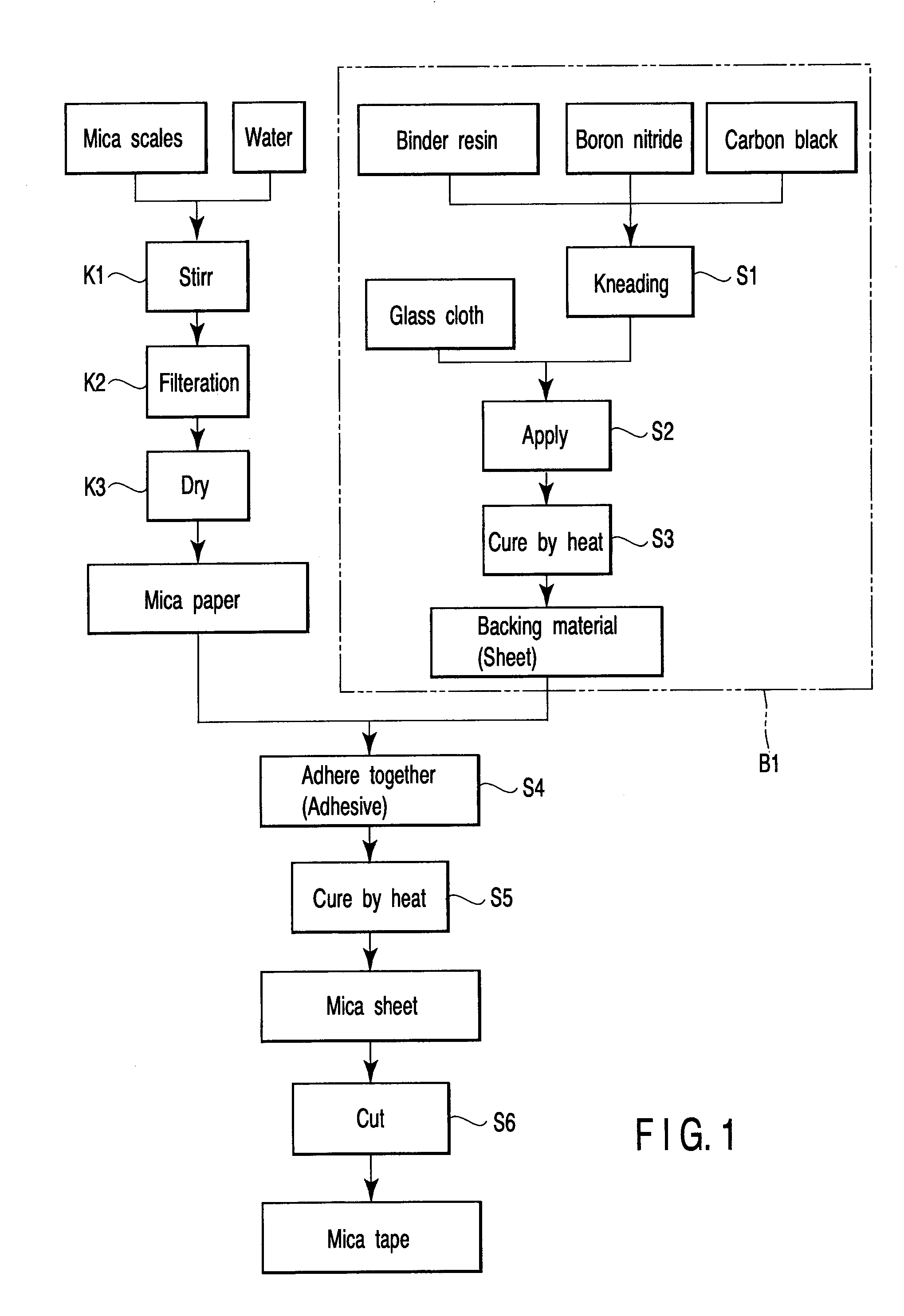

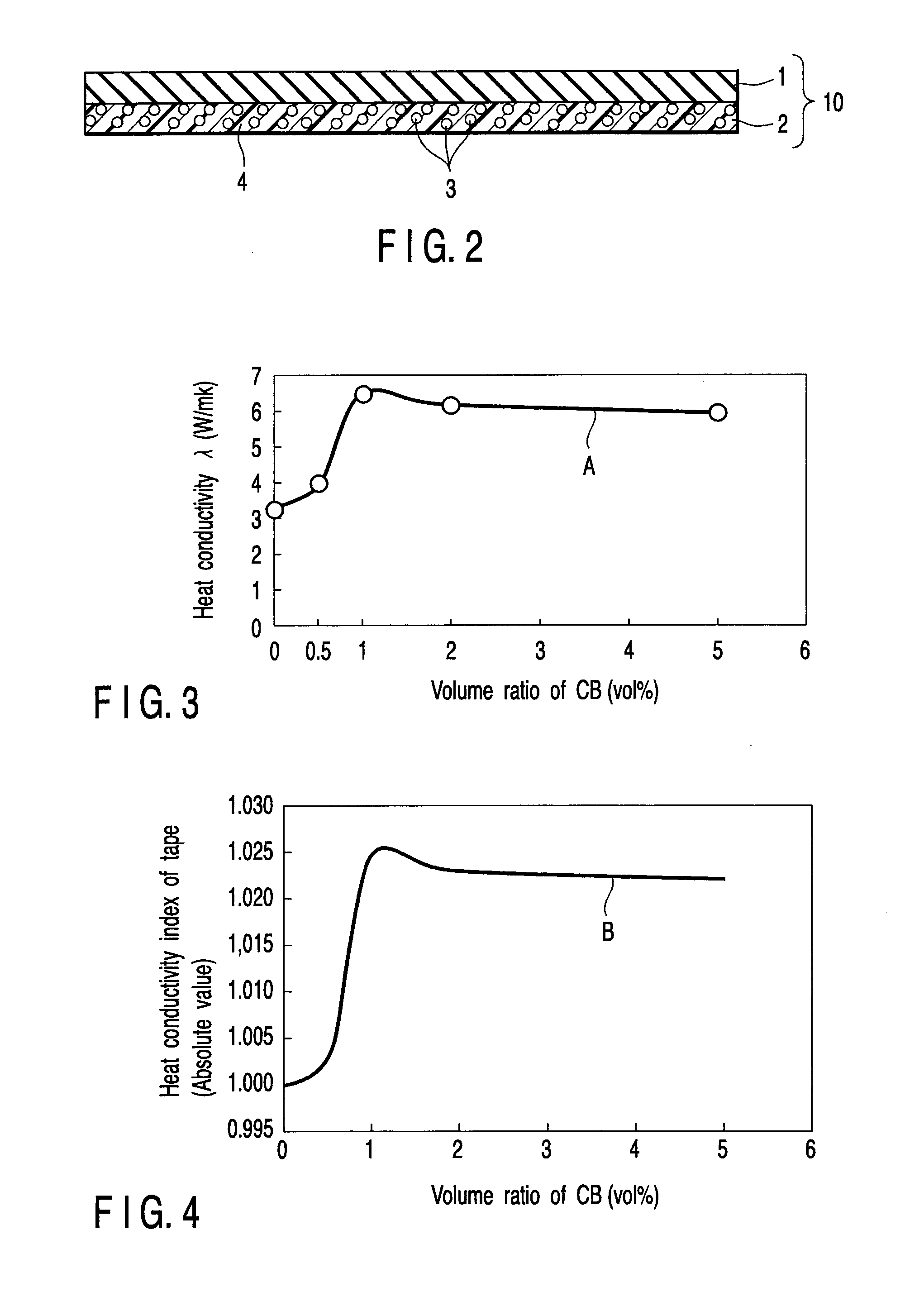

Highly heat conductive insulating member, method of manufacturing the same and electromagnetic device

ActiveUS20050208301A1Easy to manufactureImprove thermal conductivityPlastic/resin/waxes insulatorsSynthetic resin layered productsResin matrixMaterials science

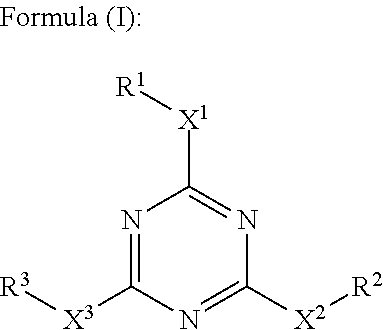

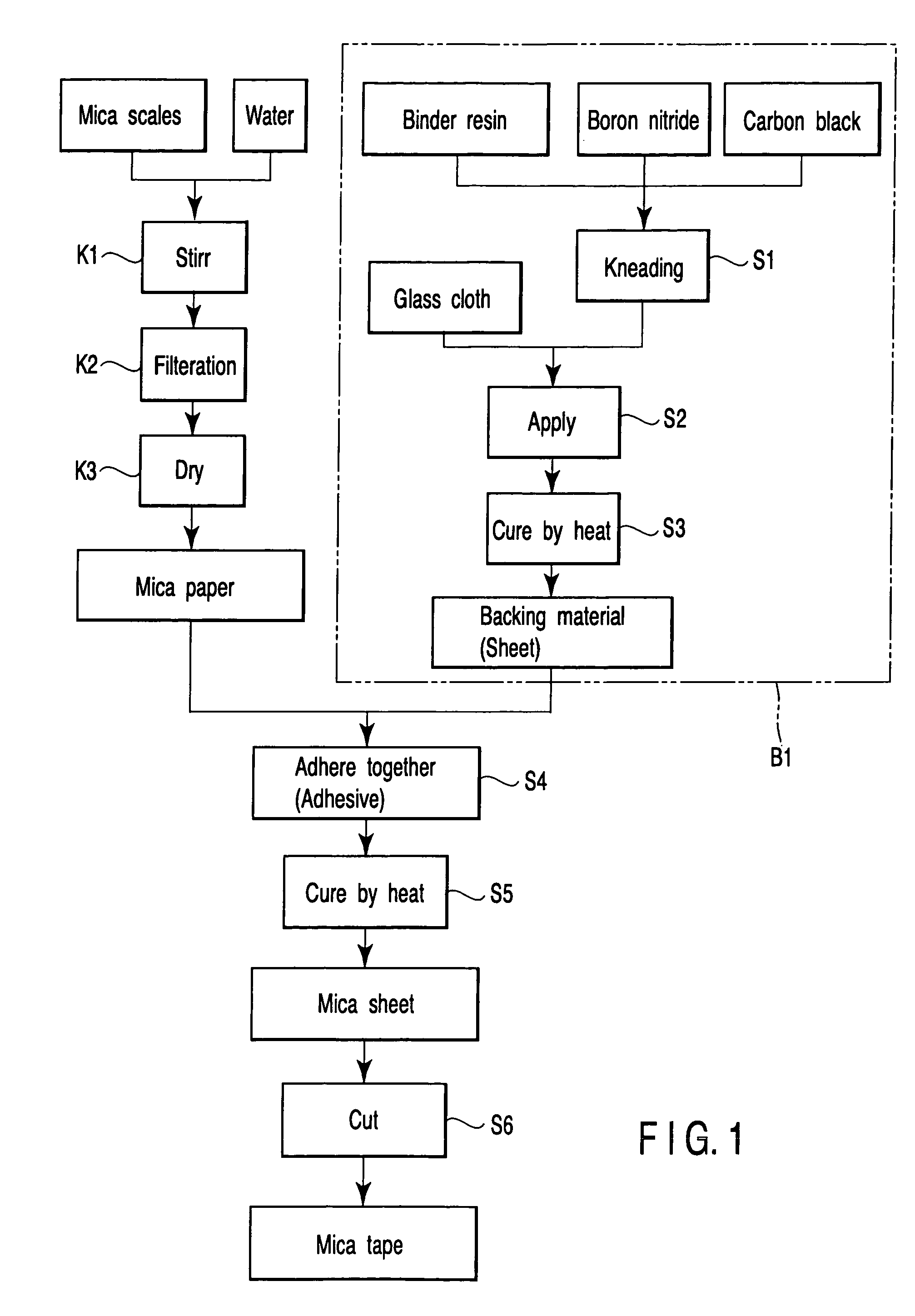

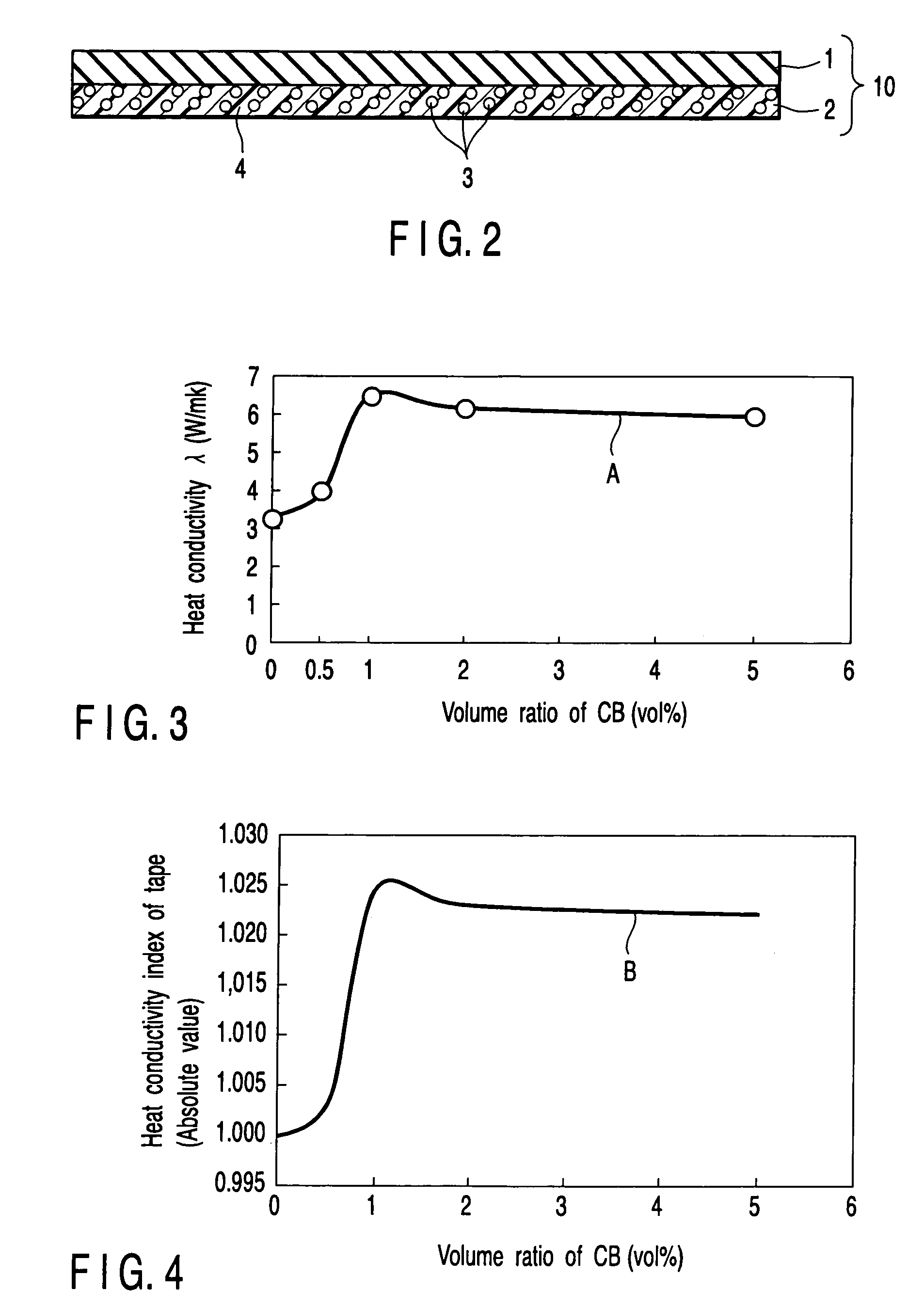

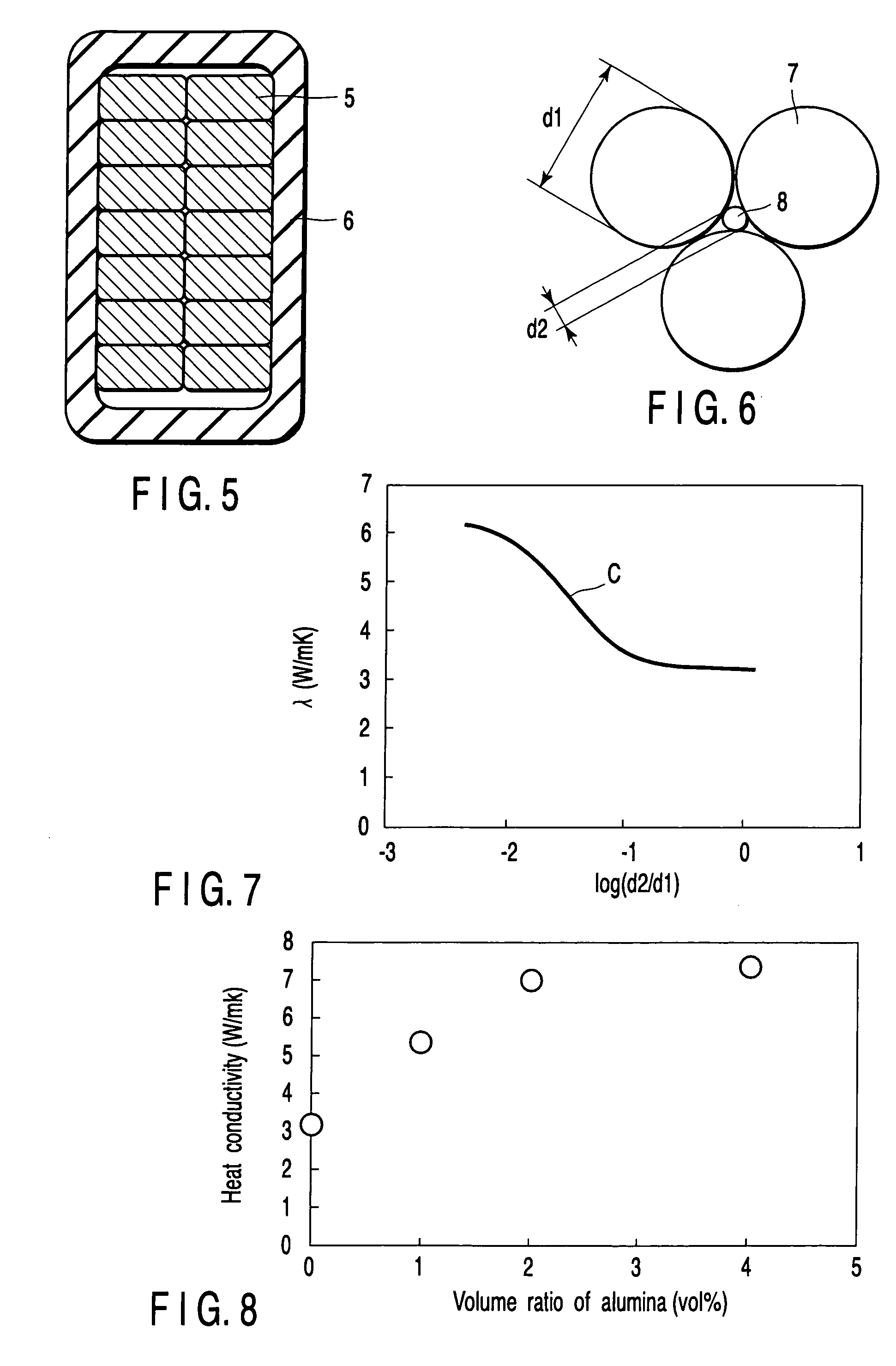

The present invention provides a solution to the above-described drawbacks, and more specifically, as the tape-like or sheet-like insulation member, the resin matrix in which the first particles having a heat conductivity of 1 W / mK or higher and 300 W / mK or lower, that are diffused in the resin matrix, and the second particles having a heat conductivity of 0.5 W / mK or higher and 300 W / mK or lower, are diffused, is employed.

Owner:KK TOSHIBA

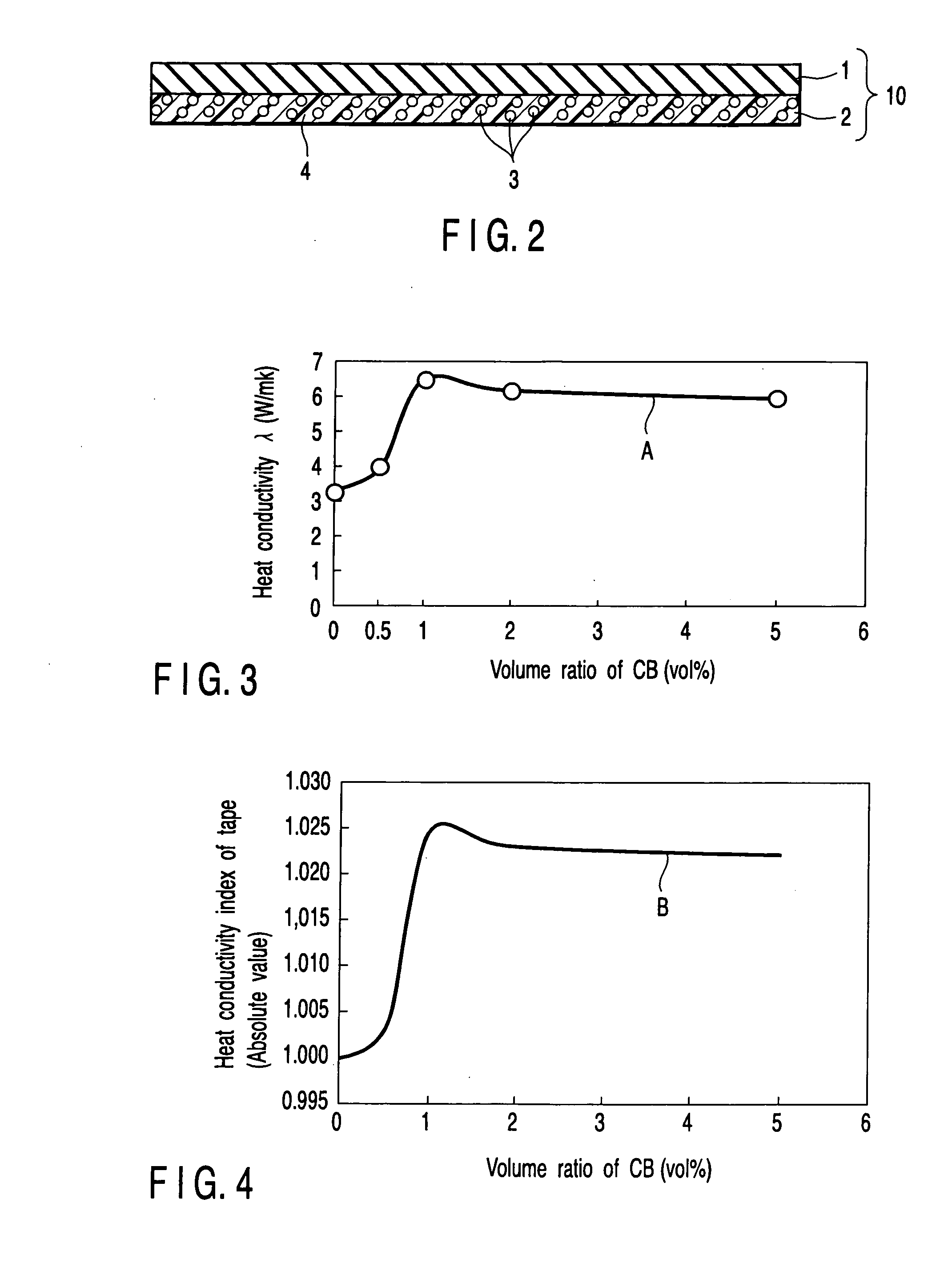

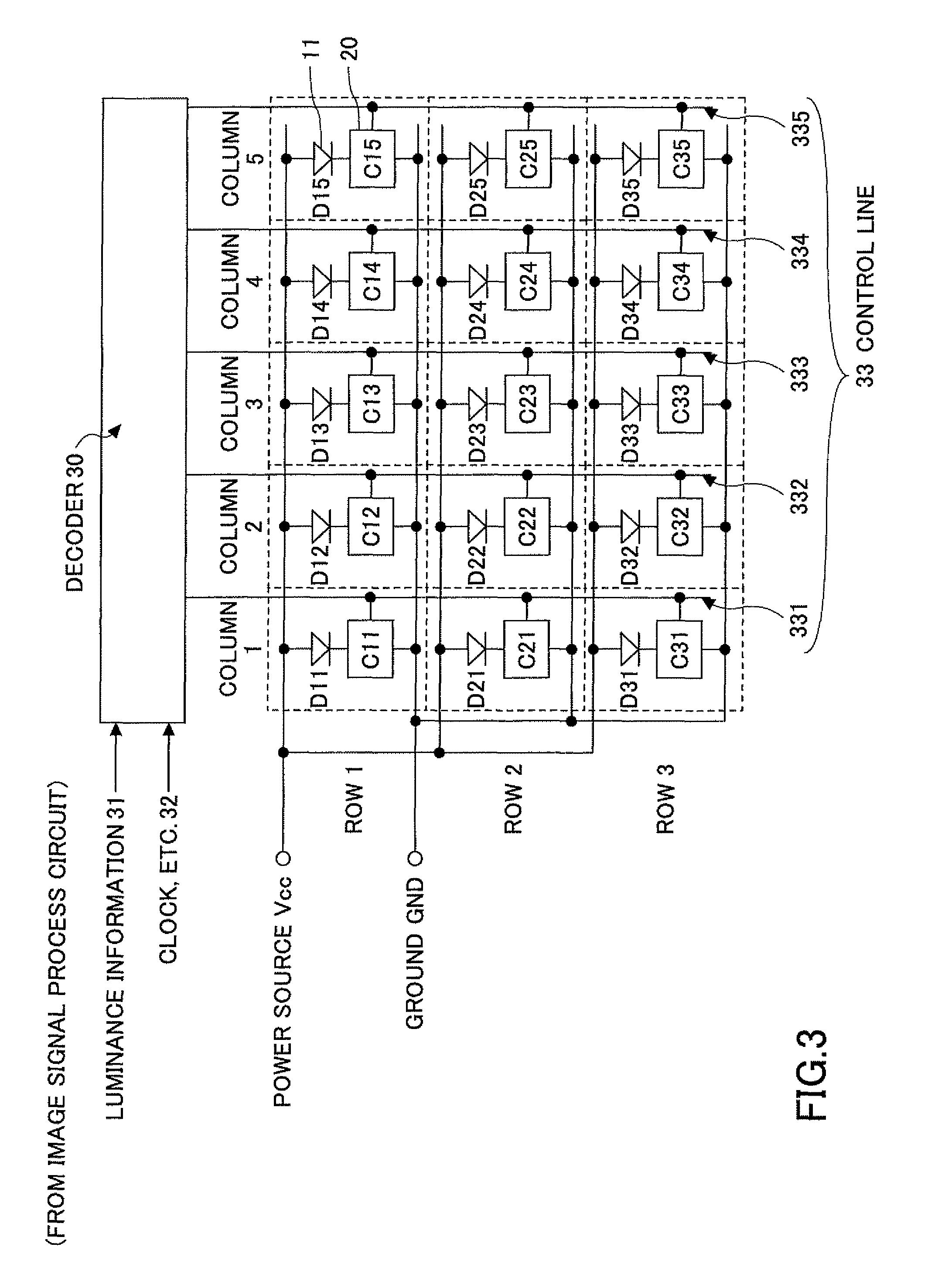

Liquid crystal backlight apparatus

InactiveUS8482512B2Unevenness easilyIncrease rangeCathode-ray tube indicatorsInput/output processes for data processingLiquid-crystal displayEngineering

A liquid crystal backlight apparatus being placed behind a liquid crystal display panel in a manner facing the liquid crystal display panel and illuminating the liquid crystal display panel from behind with a backlight having plural light emitting diodes as a light source, the liquid crystal backlight apparatus including a control part configured to use 0.1-0.5 watt white light emitting diodes as the plural light emitting diodes and independently control luminance of the white light emitting diodes separately.

Owner:MITSUMI ELECTRIC CO LTD +1

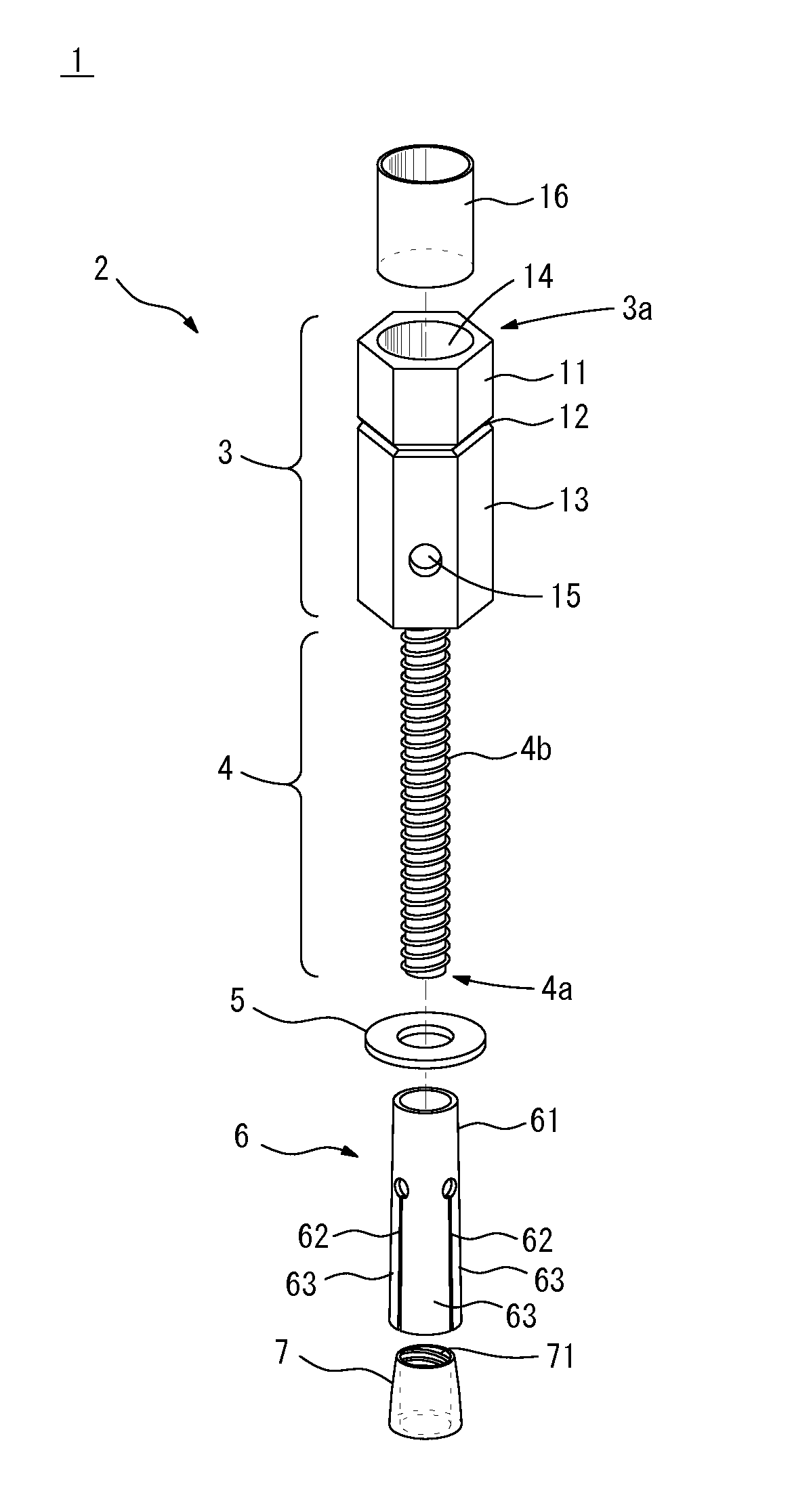

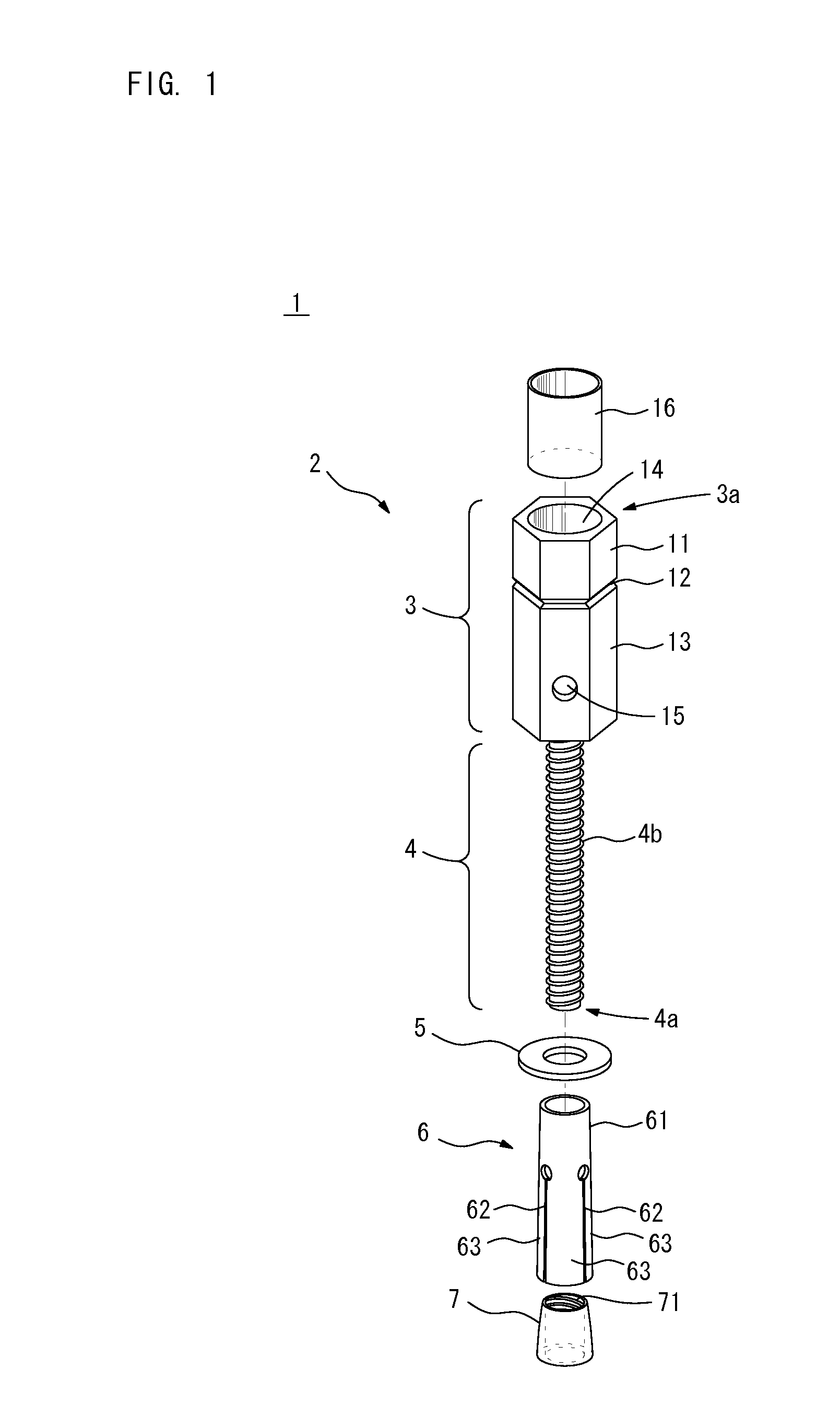

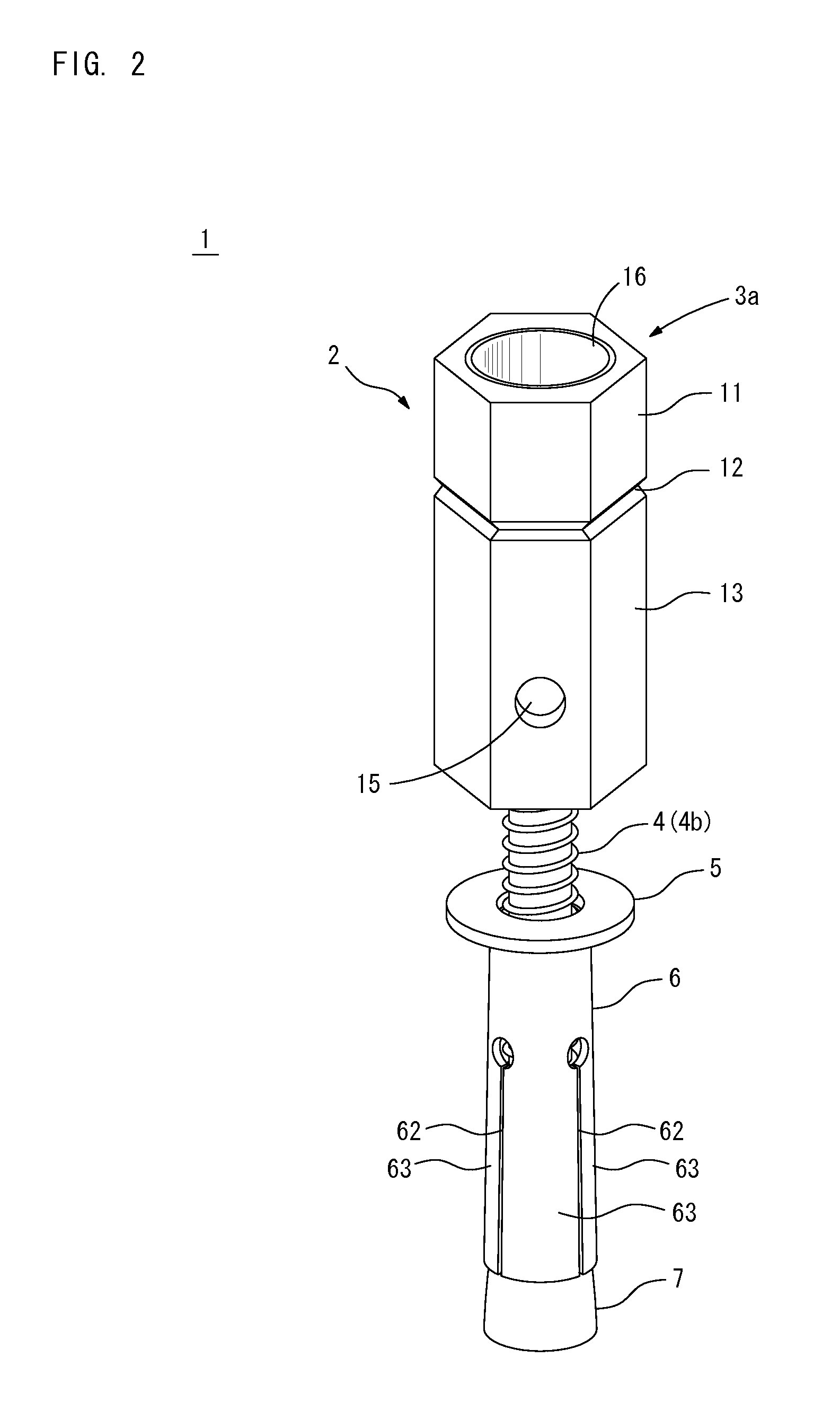

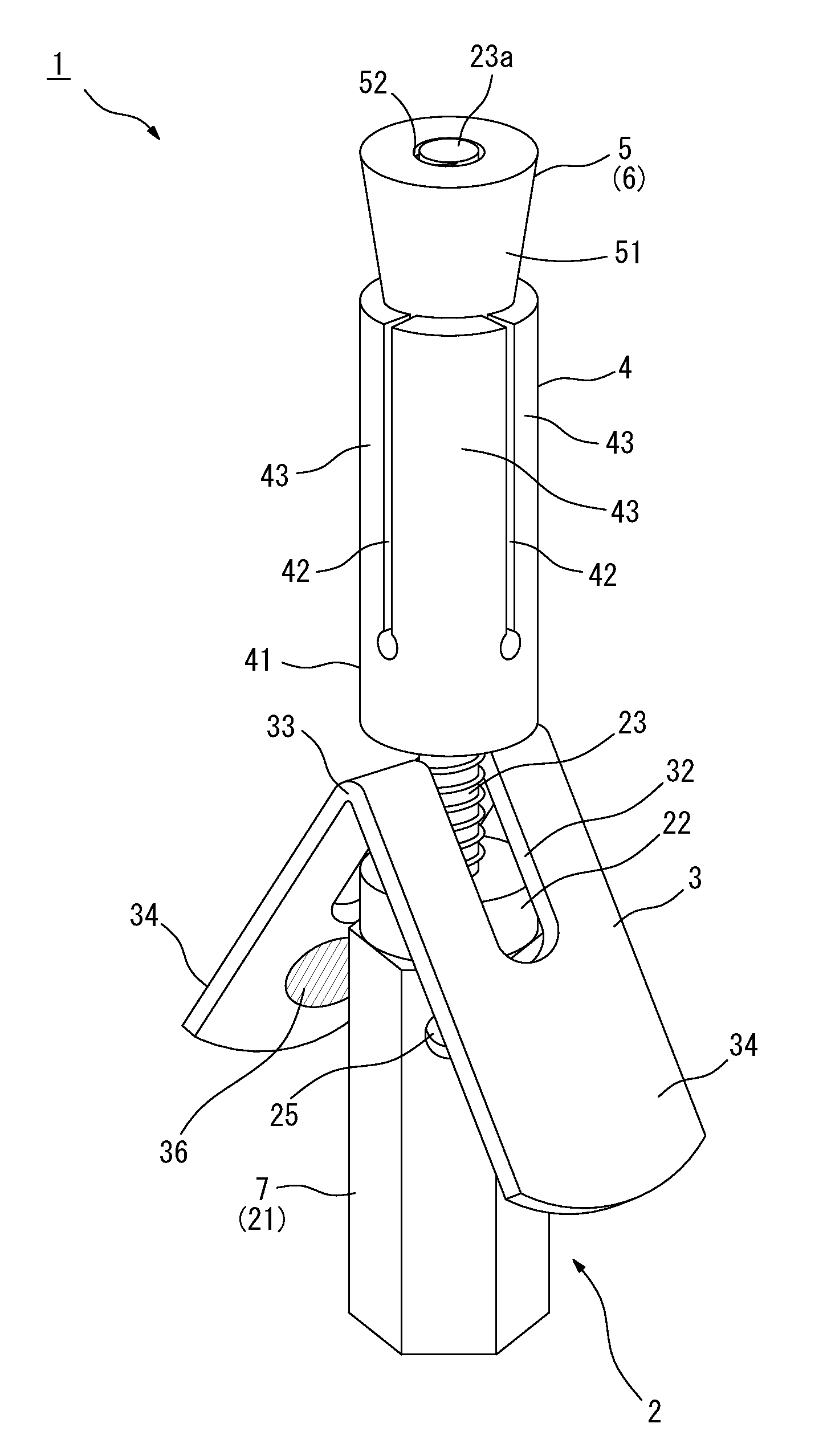

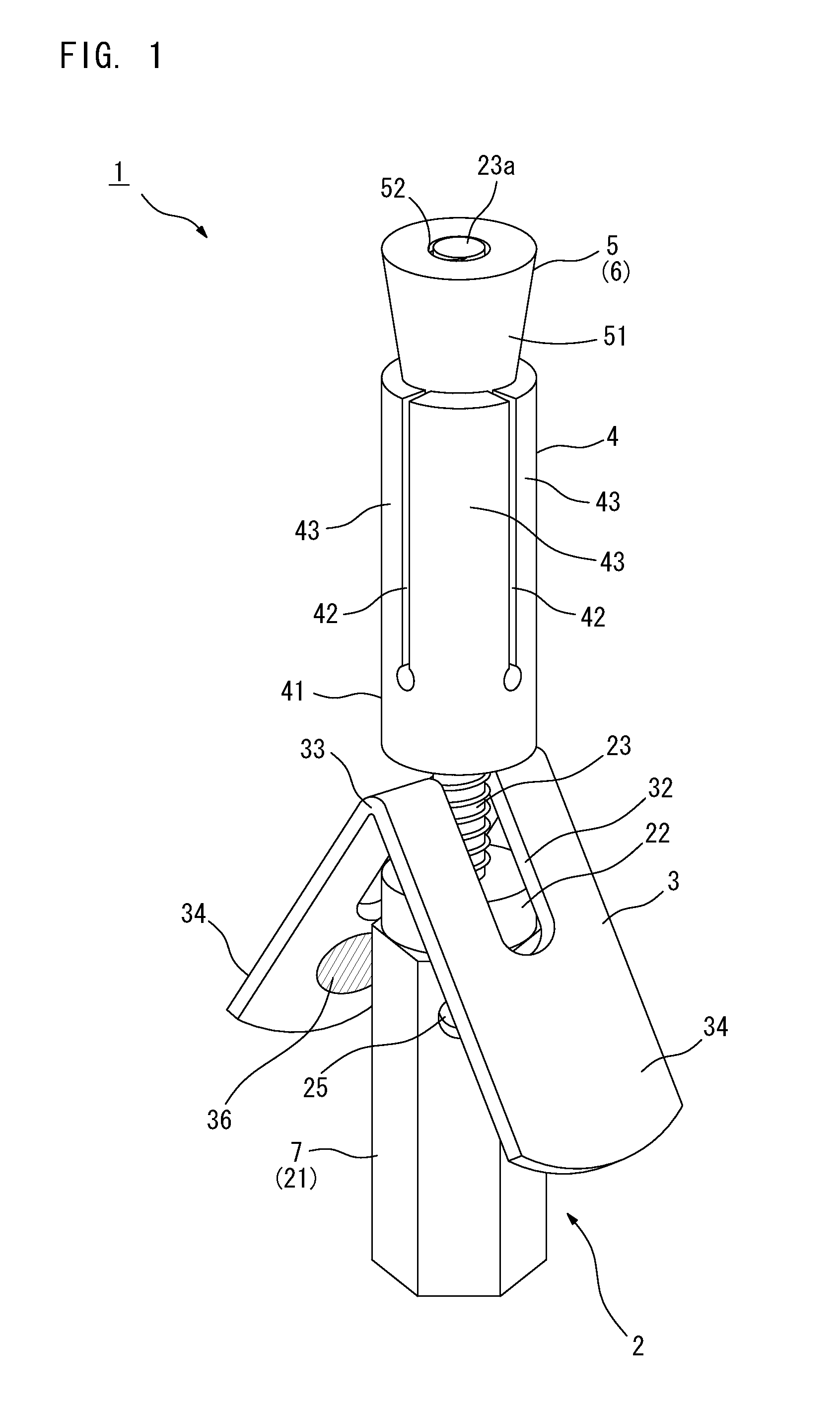

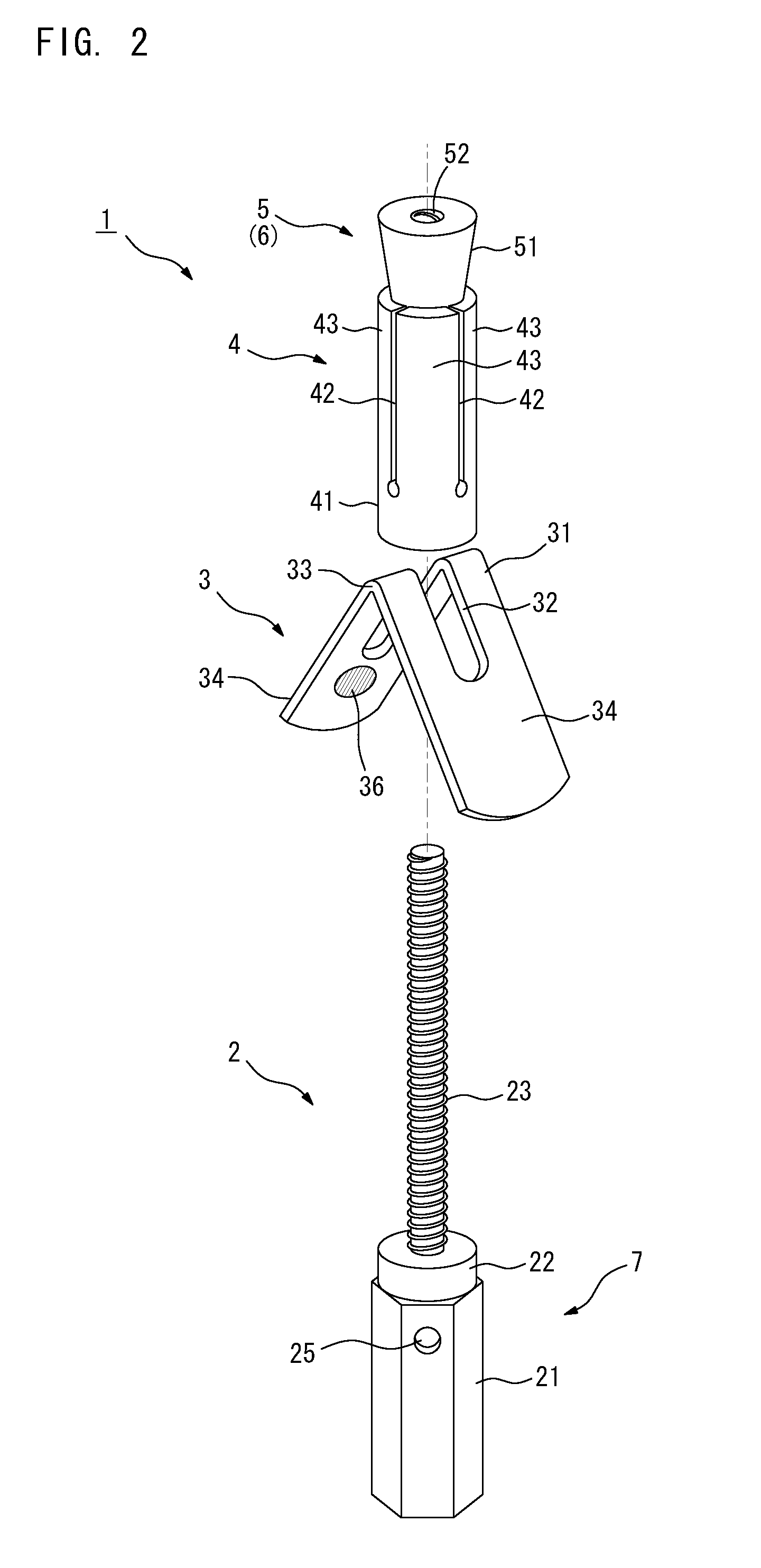

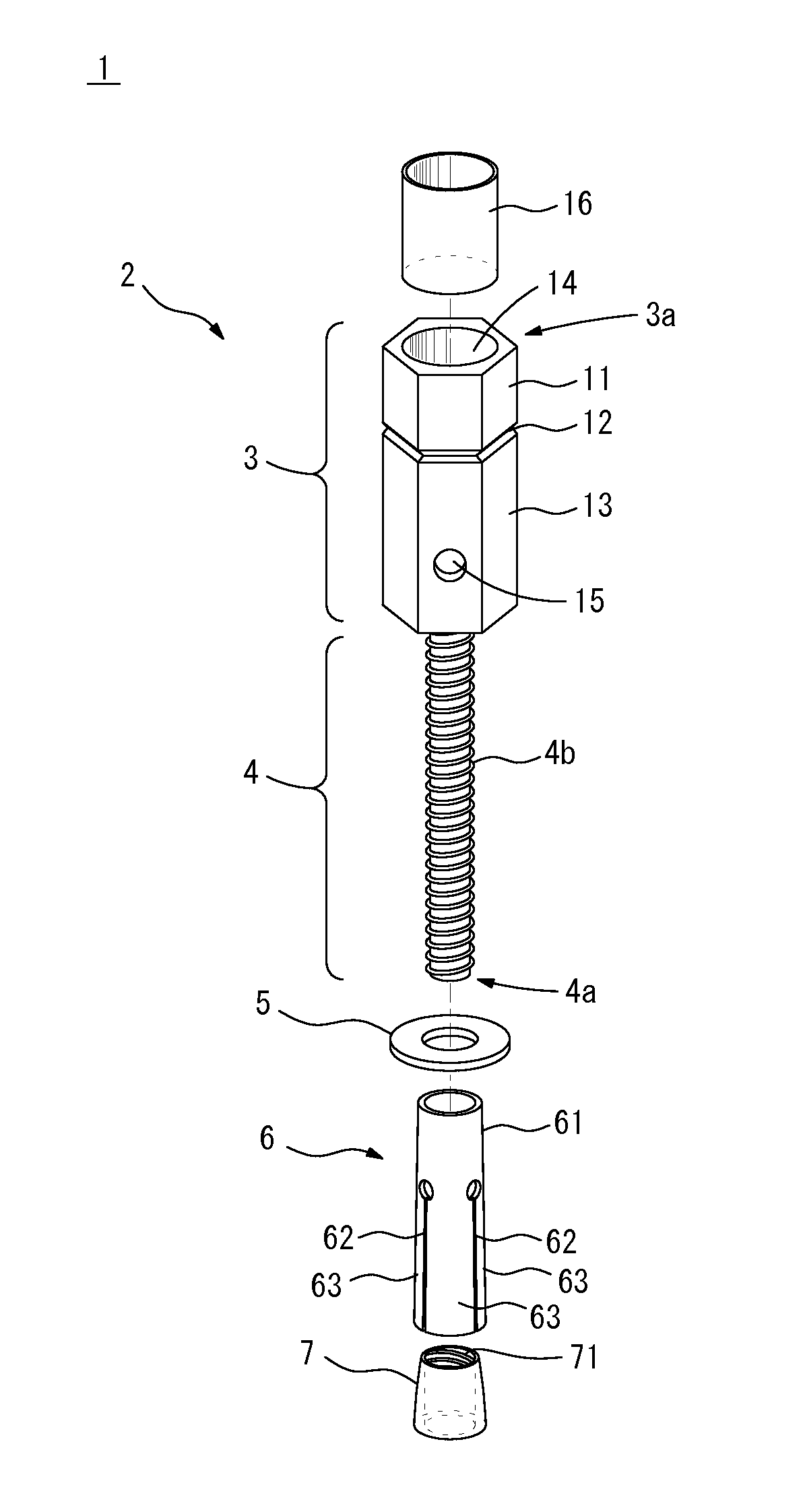

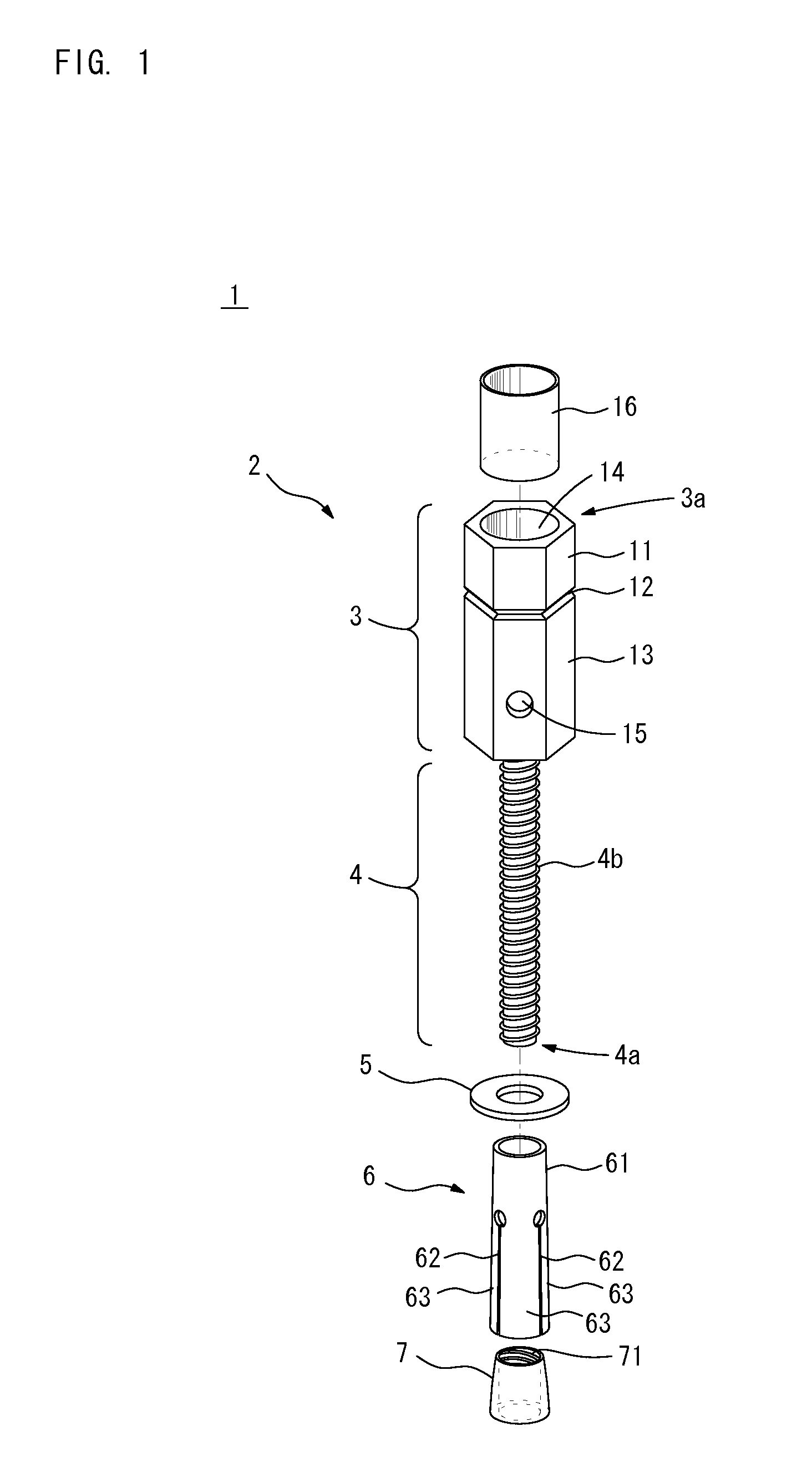

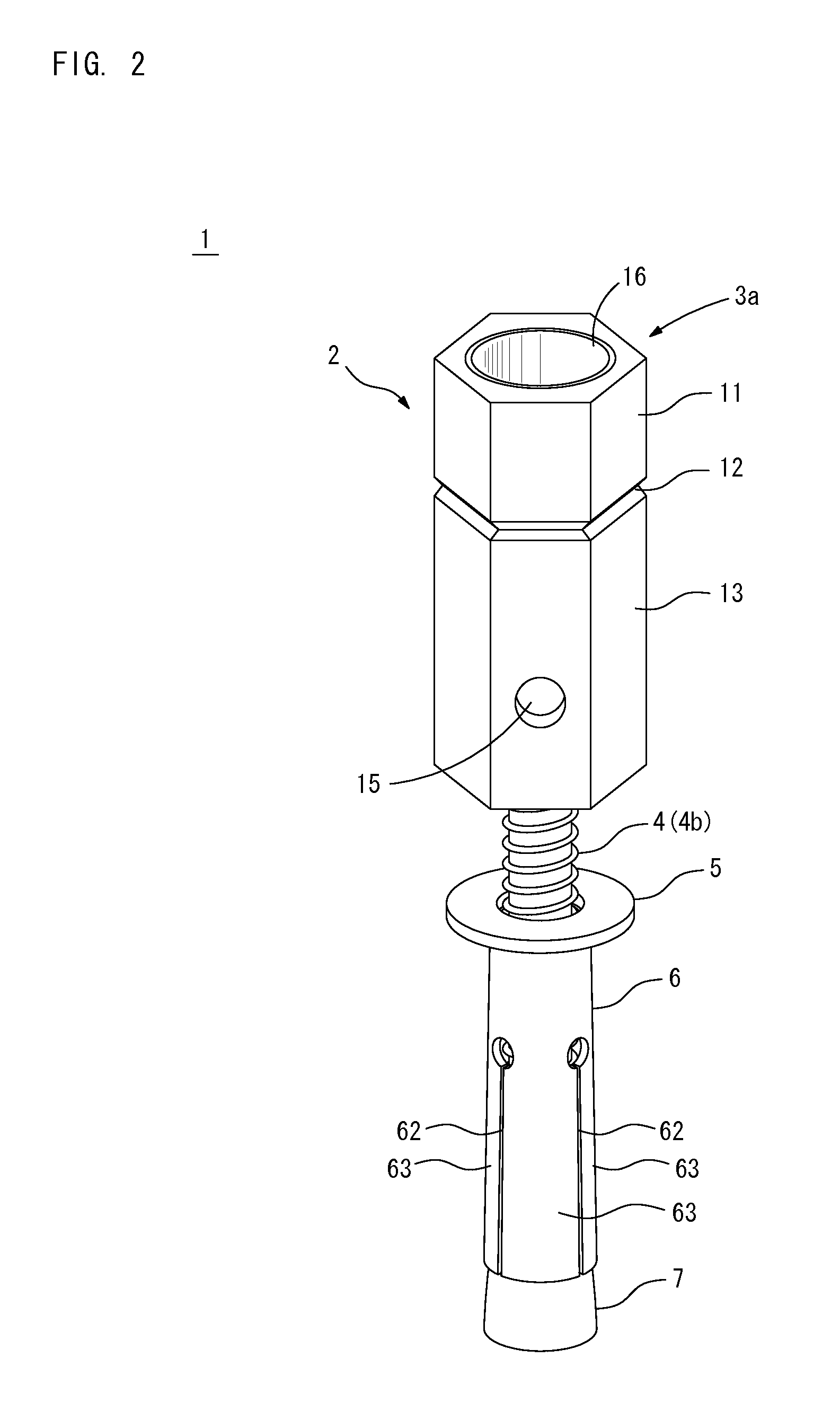

Anchor bolt, anchor, connecting nut and clamping nut

ActiveUS20120201625A1Hard to findCauses unevenness of the placing quality of anchorsNutsLoad modified fastenersEngineeringScrew thread

An anchor bolt comprising: a shaft part with a male screw thread; and a head part connected to the shaft part and having an attachment hole with a closed-end bottom to receive a bolt therein defined at a tip surface of the head part and a breaking groove provided at an outer side surface of the head part. The breaking groove is formed at an outer surface of a portion in which the attachment hole is defined. A torque equal to or greater than a fixed value exerted on a tip portion between the tip surface and the breaking groove of the head part causes the breaking groove to be broken, thereby causing the tip portion between the tip surface and the breaking groove of the head part to be removed.

Owner:ENUPATTO

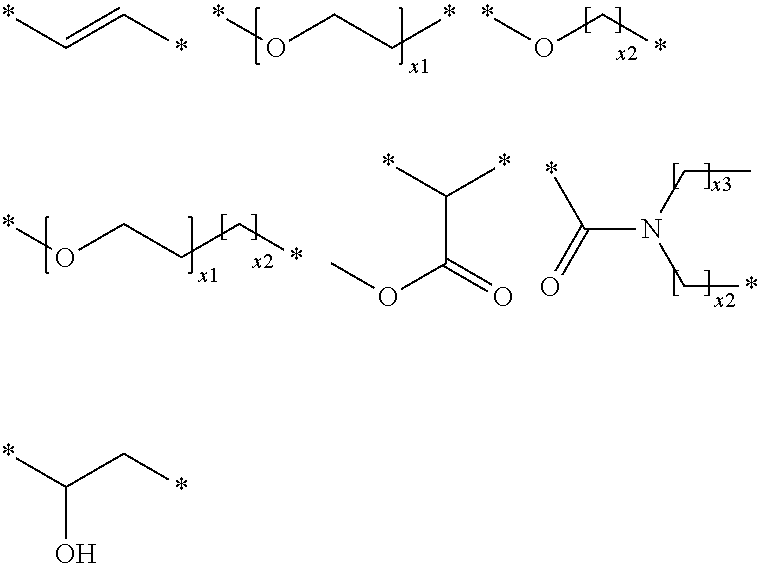

Ink set and image forming method

ActiveUS20160222238A1High water repelling propertyLow wettabilityDuplicating/marking methodsInksImage formationSURFACTANT BLEND

An ink set including an ink composition including resin particles, a colorant, and water, and a treatment solution including an anionic surfactant, water, and a compound configured to aggregate at least one of the colorant or the resin particles in the ink composition, in which the ratio of the content of the anionic surfactant with respect to the content of the compound configured to aggregate at least one of the colorant or the resin particles is 0.001 to 0.600 in terms of mass. An image forming method in which the ink set is used.

Owner:FUJIFILM CORP

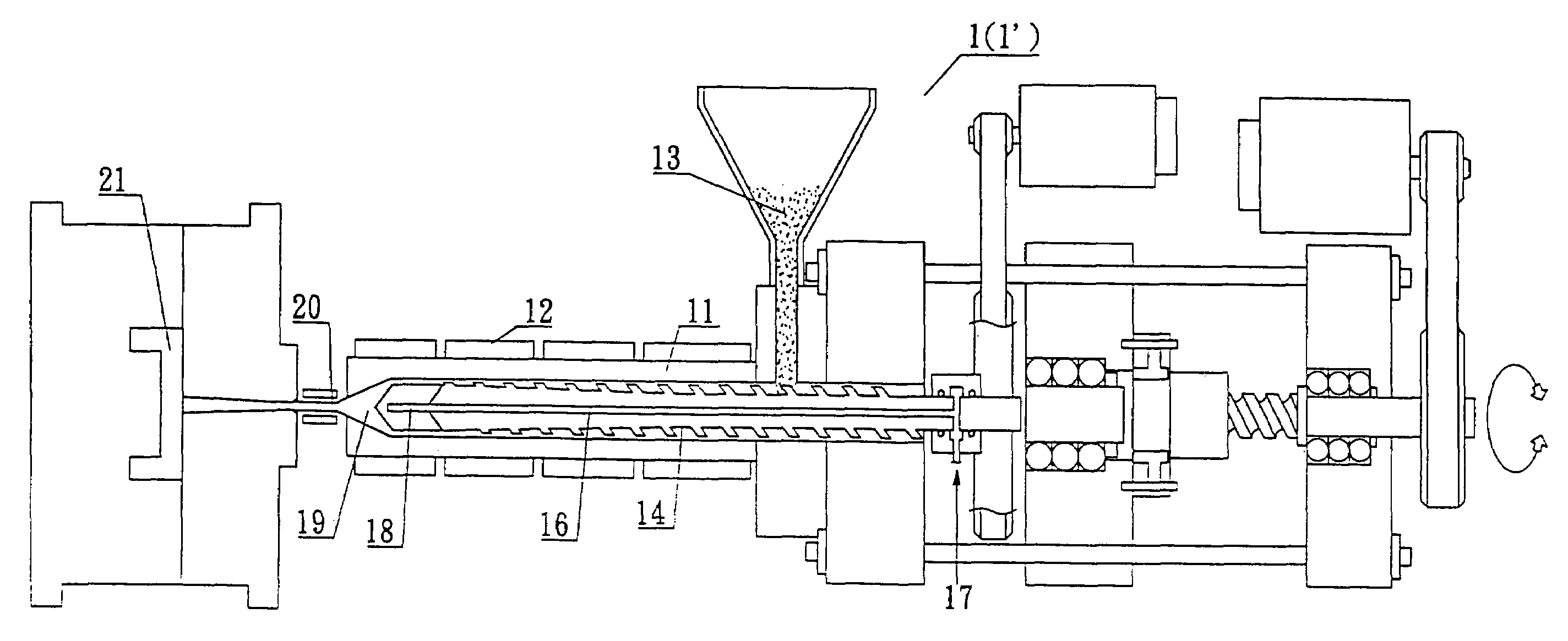

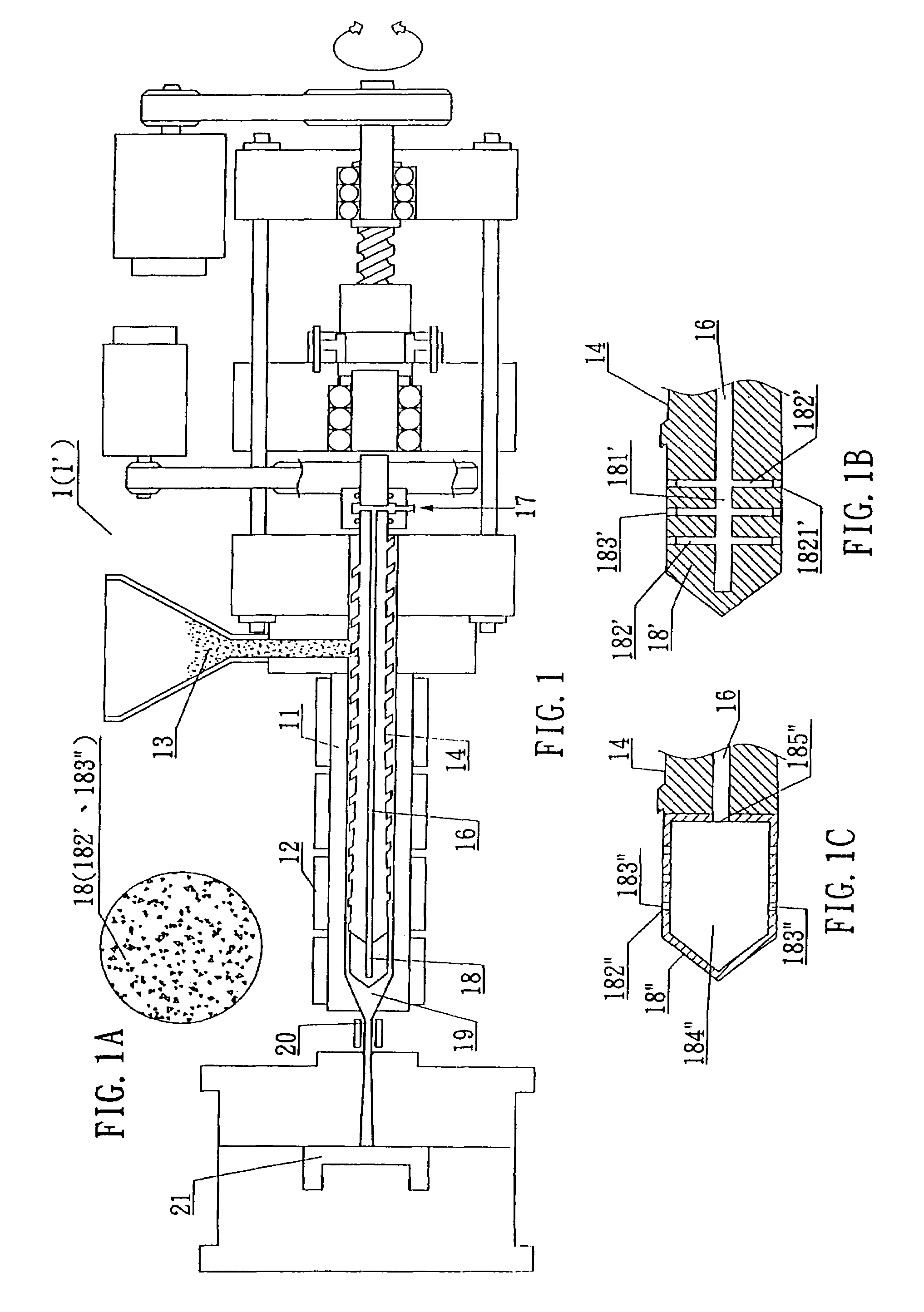

Controllable microscopic bubble nucleation in fluid polymer material production method and its apparatus

InactiveUS7264757B2Unevenness easilyEqually distributedDough homogenizationFrozen sweetsEngineeringHigh pressure

Owner:EVERFOCUS WORLDWIDE

Liquid crystal display and display

A liquid crystal display comprises a liquid crystal display panel, the liquid crystal display panel comprising a first substrate; a second substrate disposed on an observer side with respect to the first substrate and opposed to the first substrate; a liquid crystal held between the first substrate and the second substrate; an upper polarizing plate disposed on the observer side with respect to the second substrate; and a resin film disposed on the observer side with respect to the upper polarizing plate and affixed in contact with the upper polarizing plate, the resin film being higher in surface hardness than the upper polarizing plate. Both reduction in thickness of the liquid crystal display panel and ensuring of a sufficient strength are attained.

Owner:JAPAN DISPLAY INC +1

Carbon fiber package and carbon fiber packed member

By using carbon fibers having a fineness of 25,000 deniers or more, the present invention provides a carbon fiber package including a cheese winding package or a coreless package in which an outside diameter of the package, a diameter of a bobbin or an inside diameter of the package, and a winding width are regulated in the specific ranges, a square-end type package in which a yarn width per fineness, wind angles at the start of winding and at the end of winding, and shifting of the yarn are regulated in the specific ranges, and a carbon fiber packed member in which an average bulk density is regulated in a specific range. Those carbon fiber packages and the carbon fiber packed member solve troubles and inconveniences during use, and also packages which have a high winding density and which do not break easily can be obtained.

Owner:TORAY IND INC

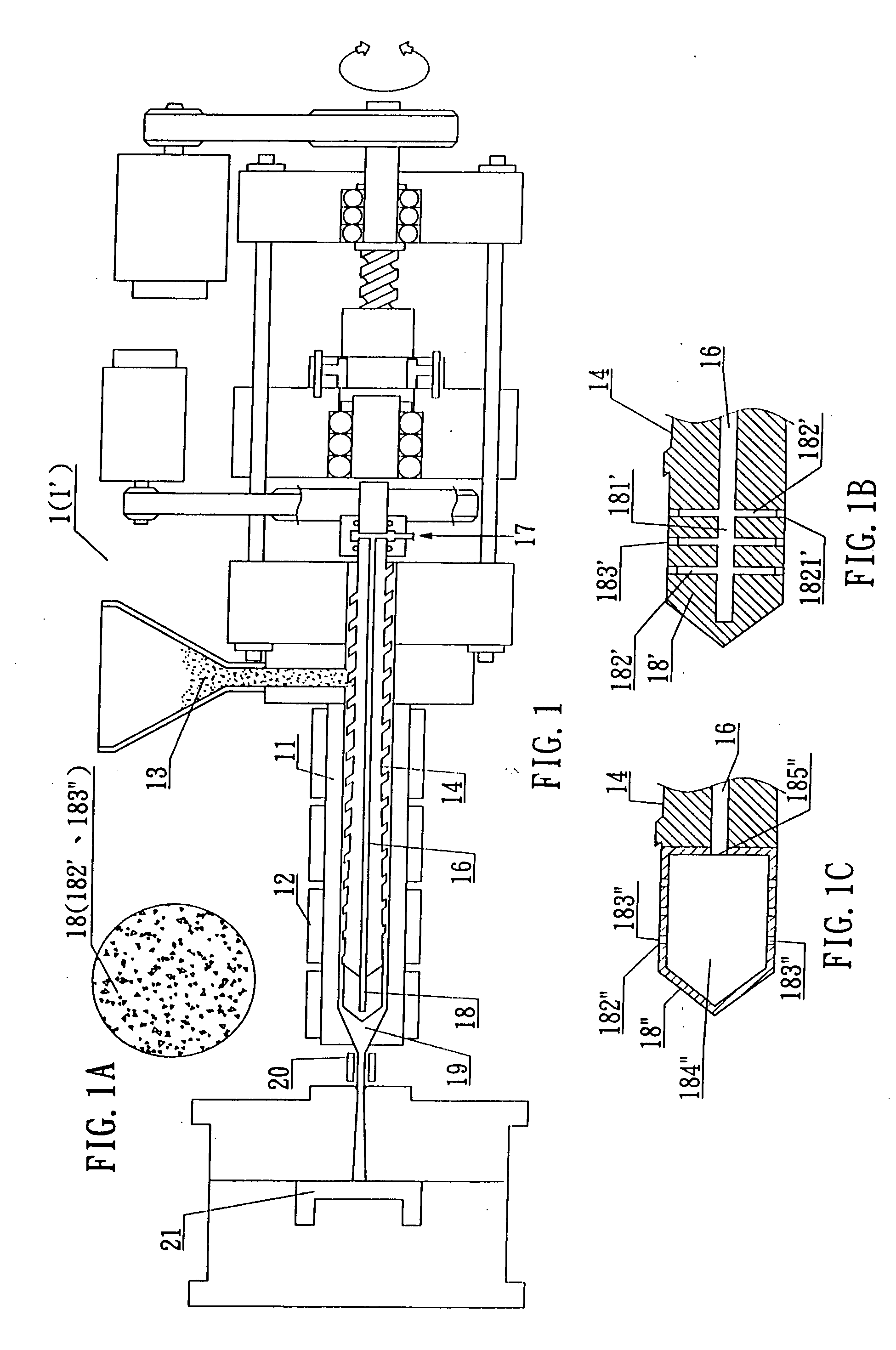

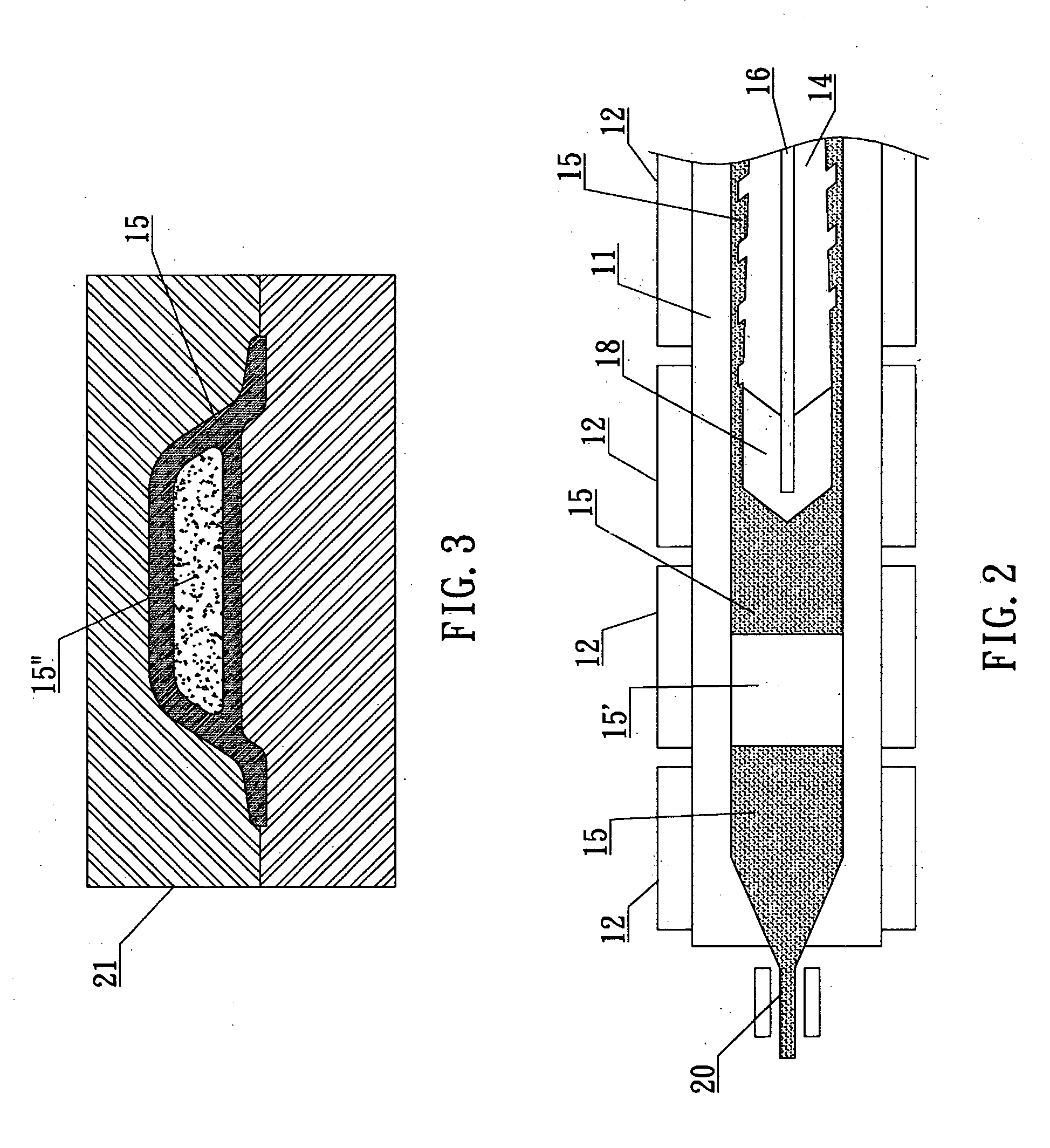

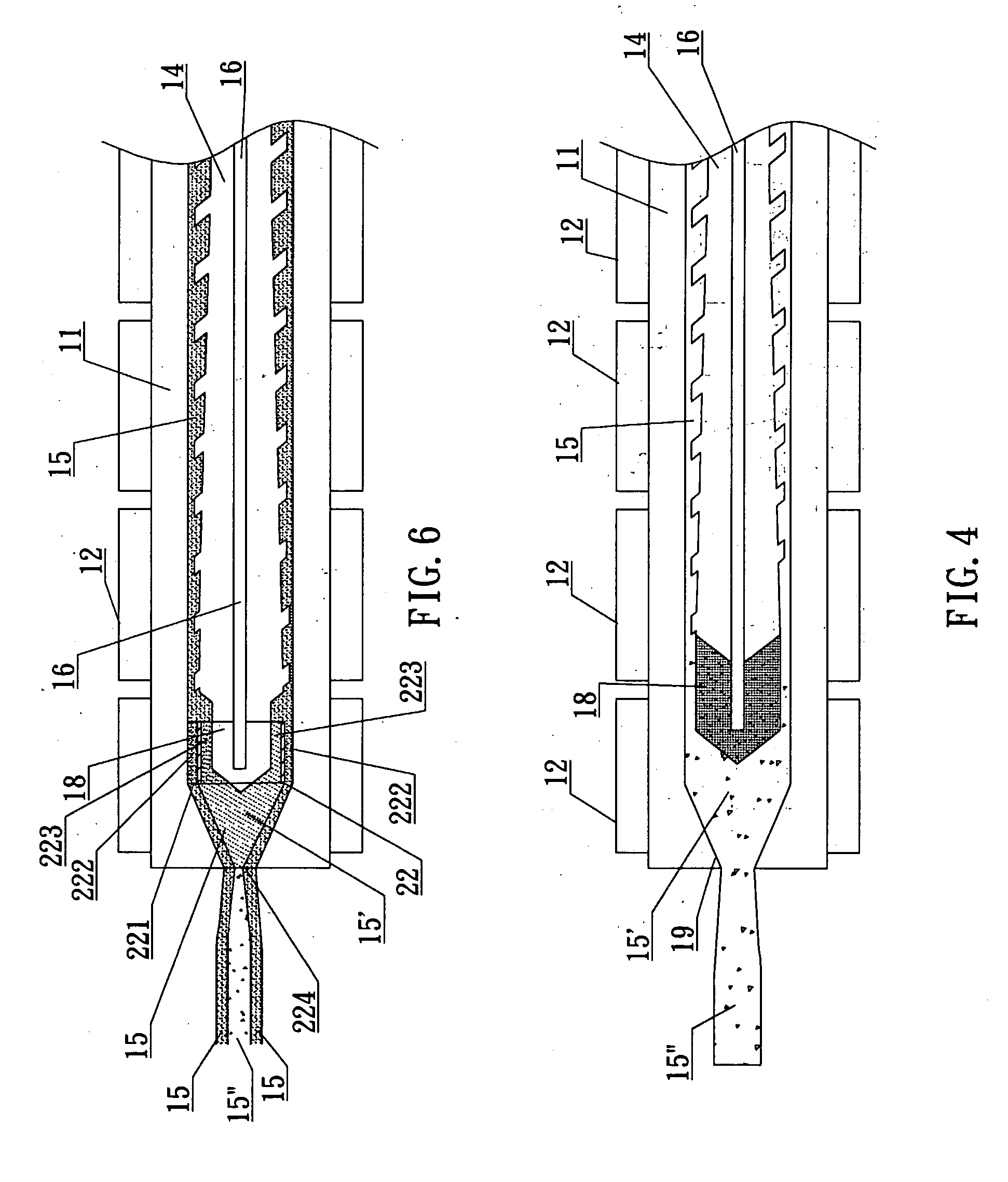

Controllable microscopic bubble nucleation in fluid polymer material production method and its apparatus

InactiveUS20050189667A1Easily controlReduction in equipment costDough homogenizationFrozen sweetsMicrobubblesLiquid polymer

A controllable microscopic bubble nucleation in fluid polymer material production method and its apparatus that utilizes a gas pipe disposed in the conveyance screw shaft of a conventional injection or extraction forming mechanism and, furthermore, a microbubble generating component (such as a microscopic perforation vented metal head or a microscopic perforation ceramic head, etc.) installed at the front extremity of the conveyance screw shaft. At the rear extremity of the gas pipe, a pressurization pump or a high pressure gas storage tank is admitted from an air intake opening, enabling the gas to be indirectly heated by an electric heater on the materials pipe. The high temperature gas is thereafter outputted from the microscopic perforations of the microbubble generating component such that high temperature microscopic bubbles are directly admitted into the section of liquid polymer material which is then uniformly amalgamated by the conveyance screw shaft and then deposited into a forming die. As a result, high pressure gas conveyance or termination is controllable; control is afforded as to whether each section of liquid polymer material is microbubble nucleated and amalgamated. The present invention thereby provides a microbubble nucleation production method in which the non-bubble nucleated is at the surface and the bubble nucleated is at the interior section when the liquid polymer material is poured into a forming die.

Owner:EVERFOCUS WORLDWIDE

Anchor

The present invention is intended to provide an anchor that makes it possible to check the placement condition of the anchor easily to realize efficient and safe check after the placement. An anchor includes an expansion member that permits a shaft part to pass therethrough while being placed between a base portion of an anchor bolt and a spreading sleeve. The expansion member includes wing-like expansion parts that are caused to expand by pressing force exerted in the axial direction of the shaft part. The anchor bolt causes the shaft part to rotate in response to the rotation of the base portion of the anchor bolt, thereby driving a cone nut into the spreading sleeve. As a result, spreading parts spread outwardly. Further, the base portion of the anchor bolt presses the expansion member in response to threaded insertion of the shaft part to cause the wing-like expansion parts to expand.

Owner:ENUPATTO

Anchor bolt, anchor, connecting nut and clamping nut

ActiveUS8979452B2Hard to findCauses unevenness of the placing quality of anchorsNutsLoad modified fastenersEngineeringScrew thread

Owner:ENUPATTO

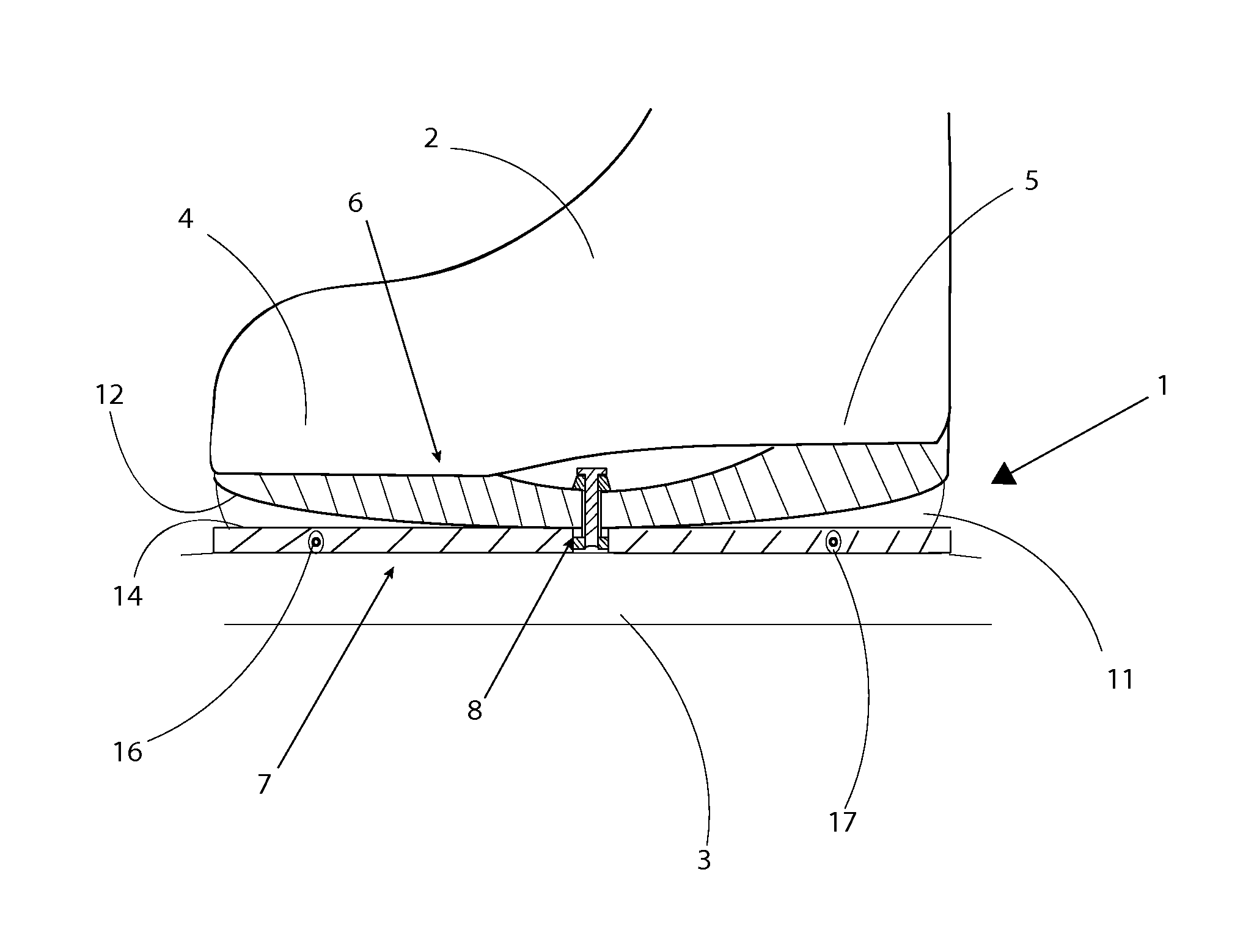

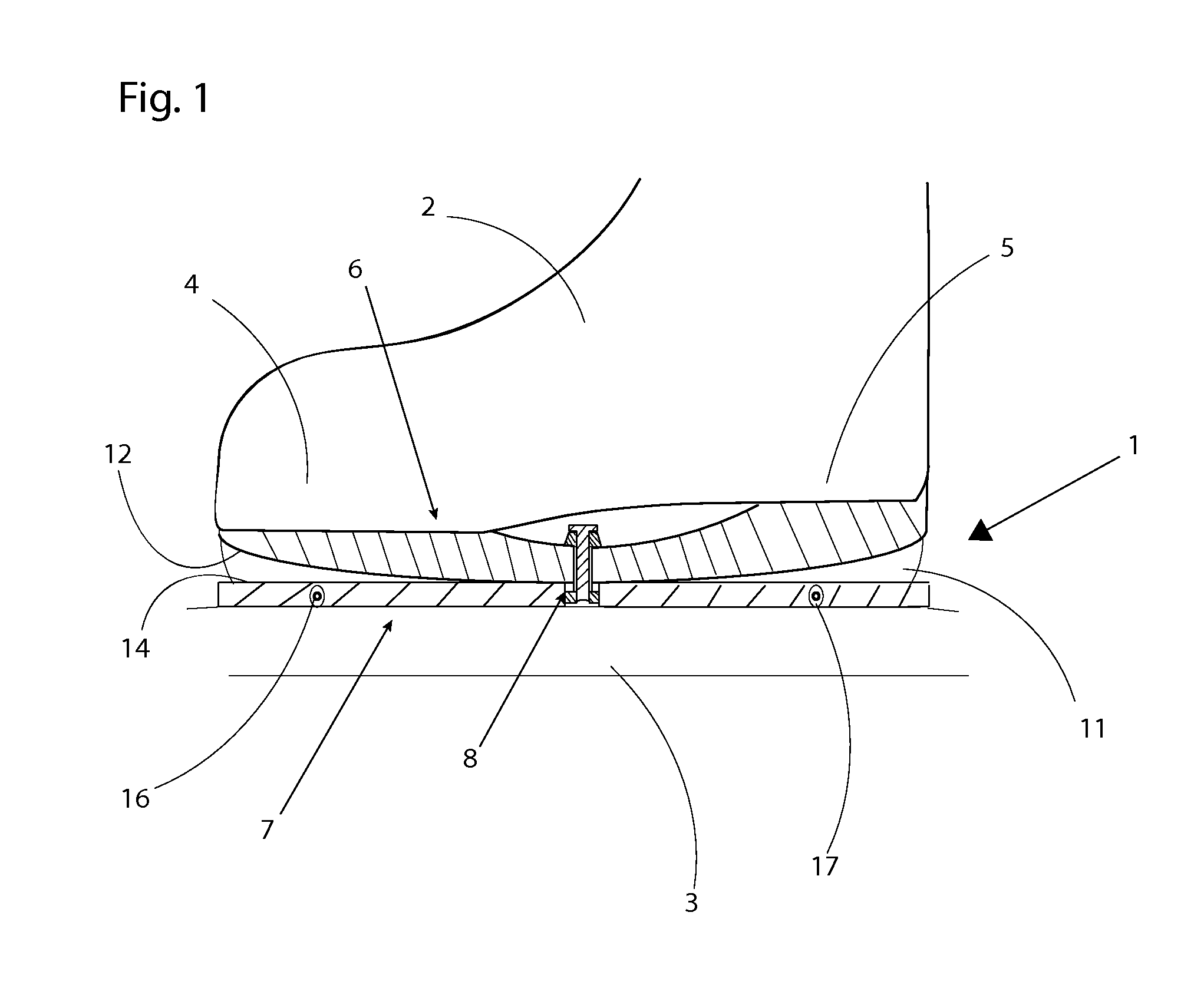

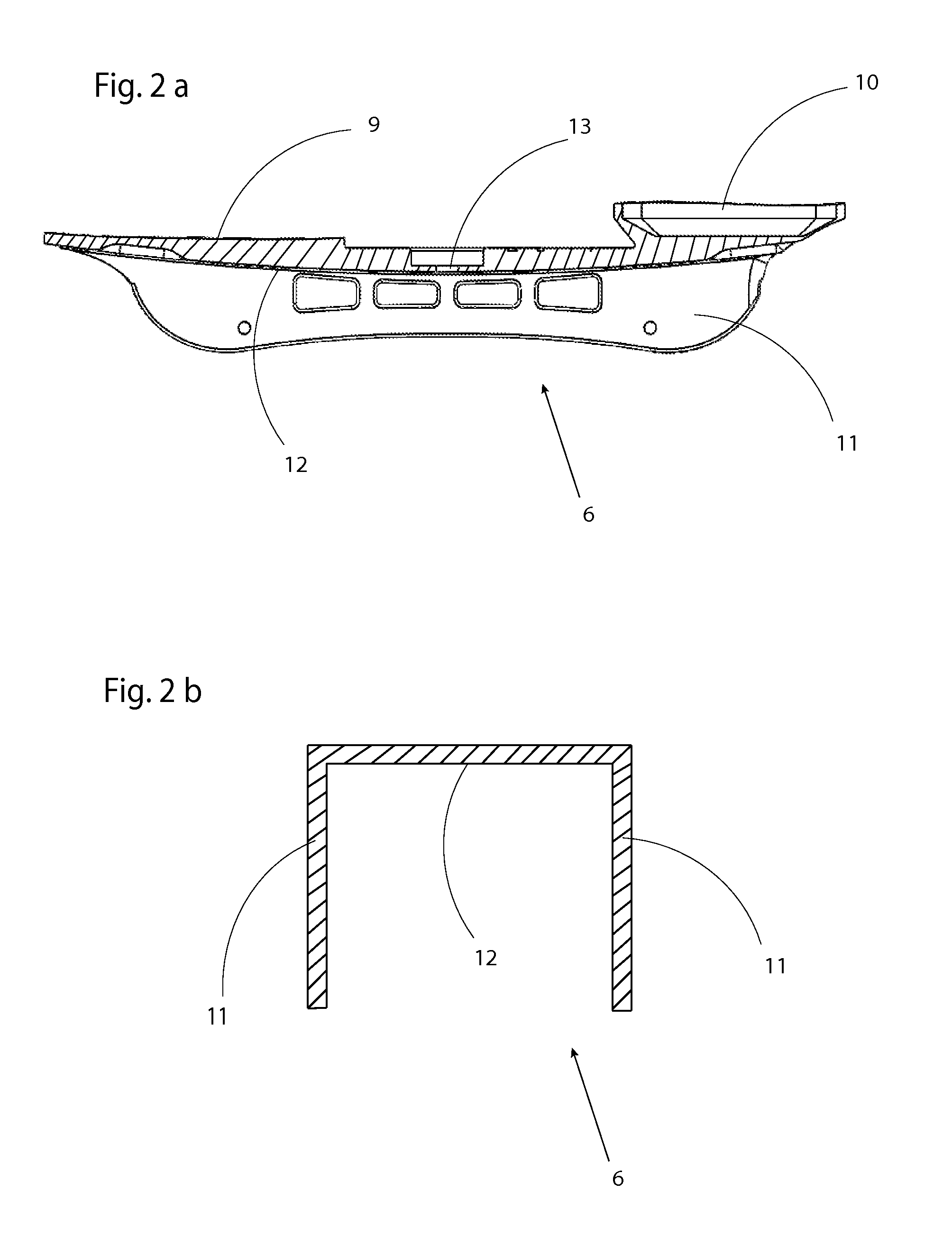

Ski or skate binding

A binding for a vehicle, such as a skate for skating on ice or a ski. The binding has an upper chassis section and a lower chassis section, which are interconnected by means of coupling means. The upper chassis section and the lower chassis section are arranged to be rollable relative to each other in the vehicle's longitudinal direction. The binding includes a first and a second contact surface at least one of the first and the second contact surface being curved. Thereby a stepless rolling motion between the upper chassis and the lower chassis is provided for, allowing the chassis to rock both backwards and forwards in relation to each other.

Owner:FLOW MOTION TECH AB

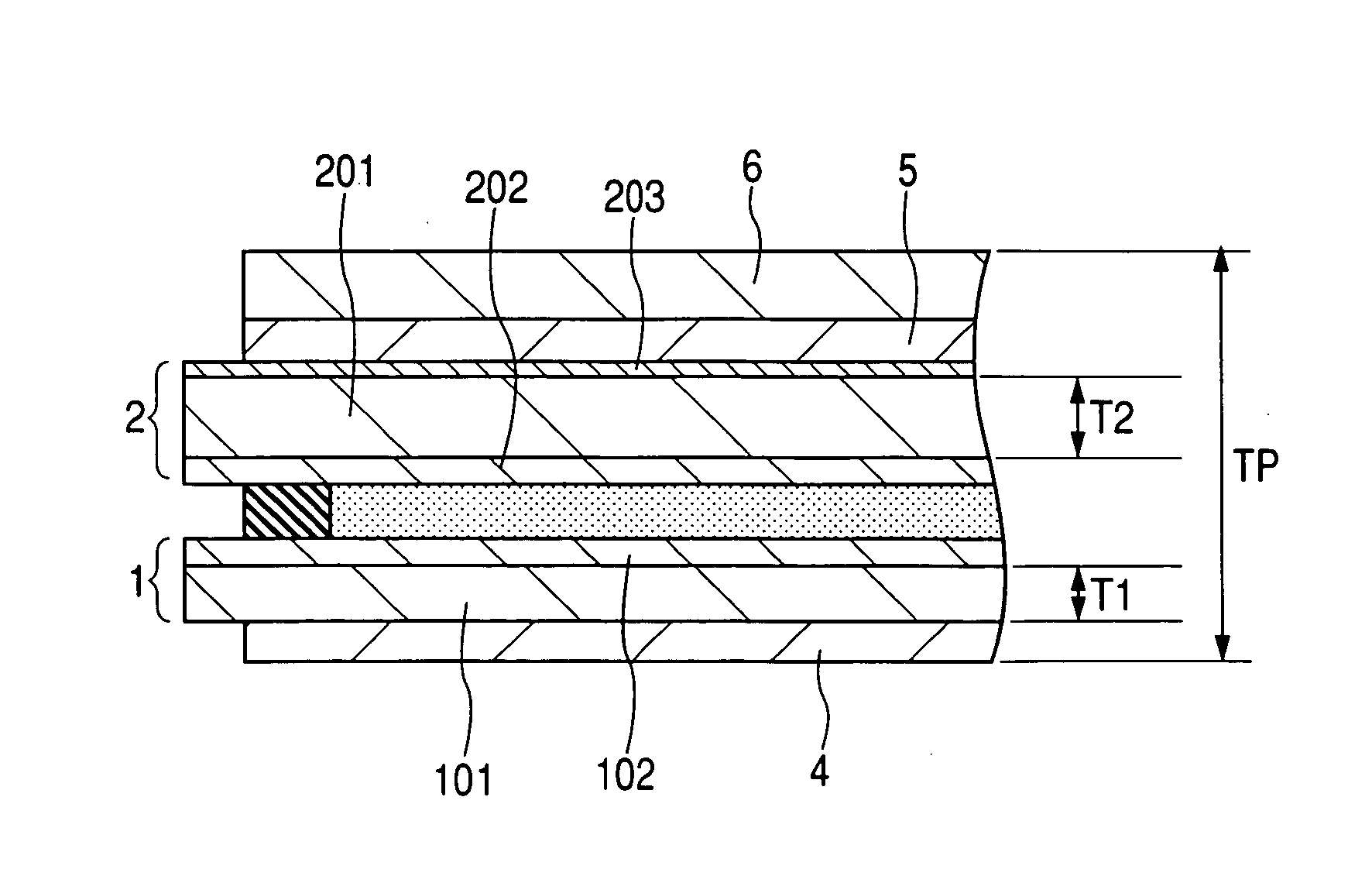

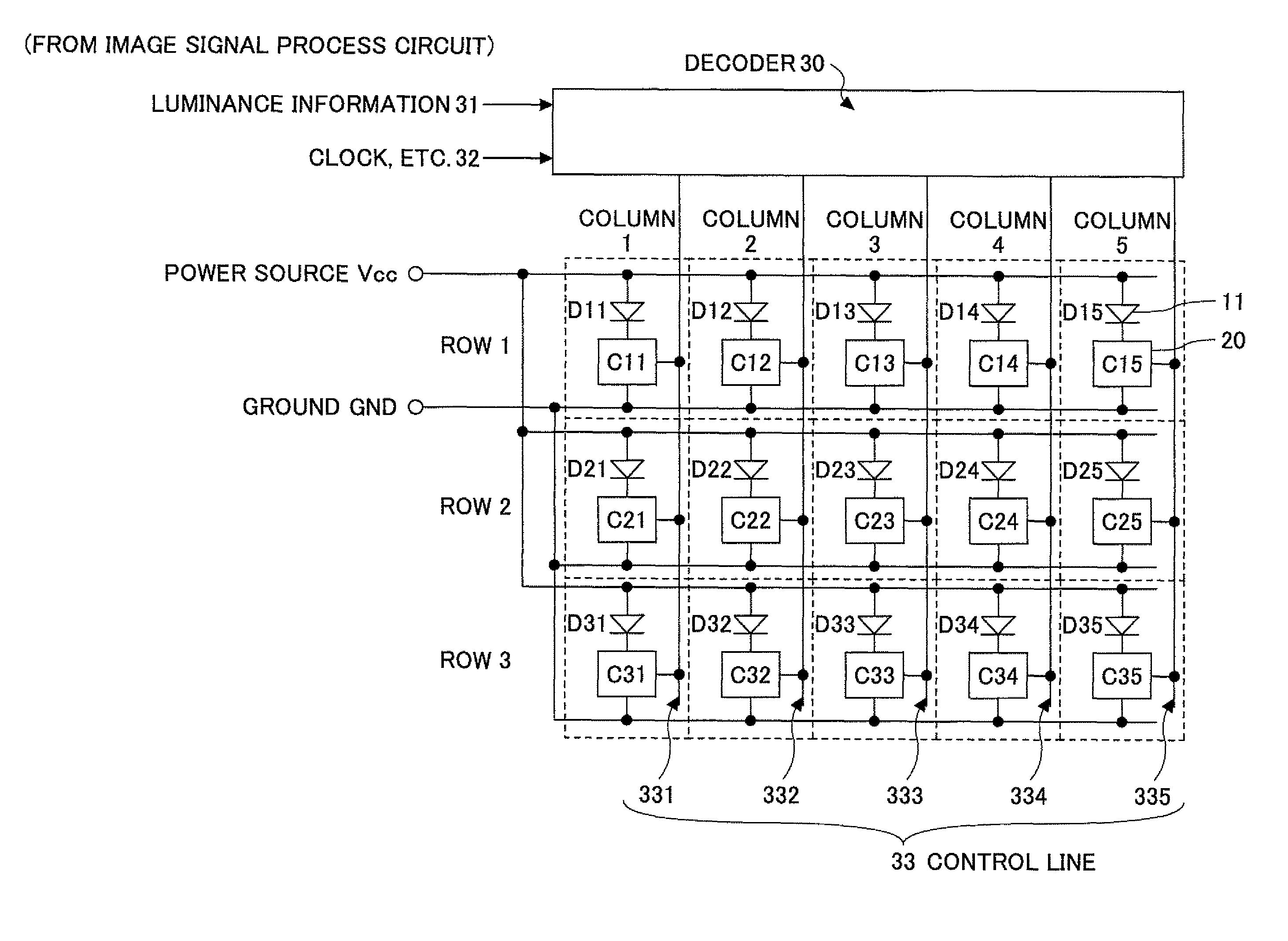

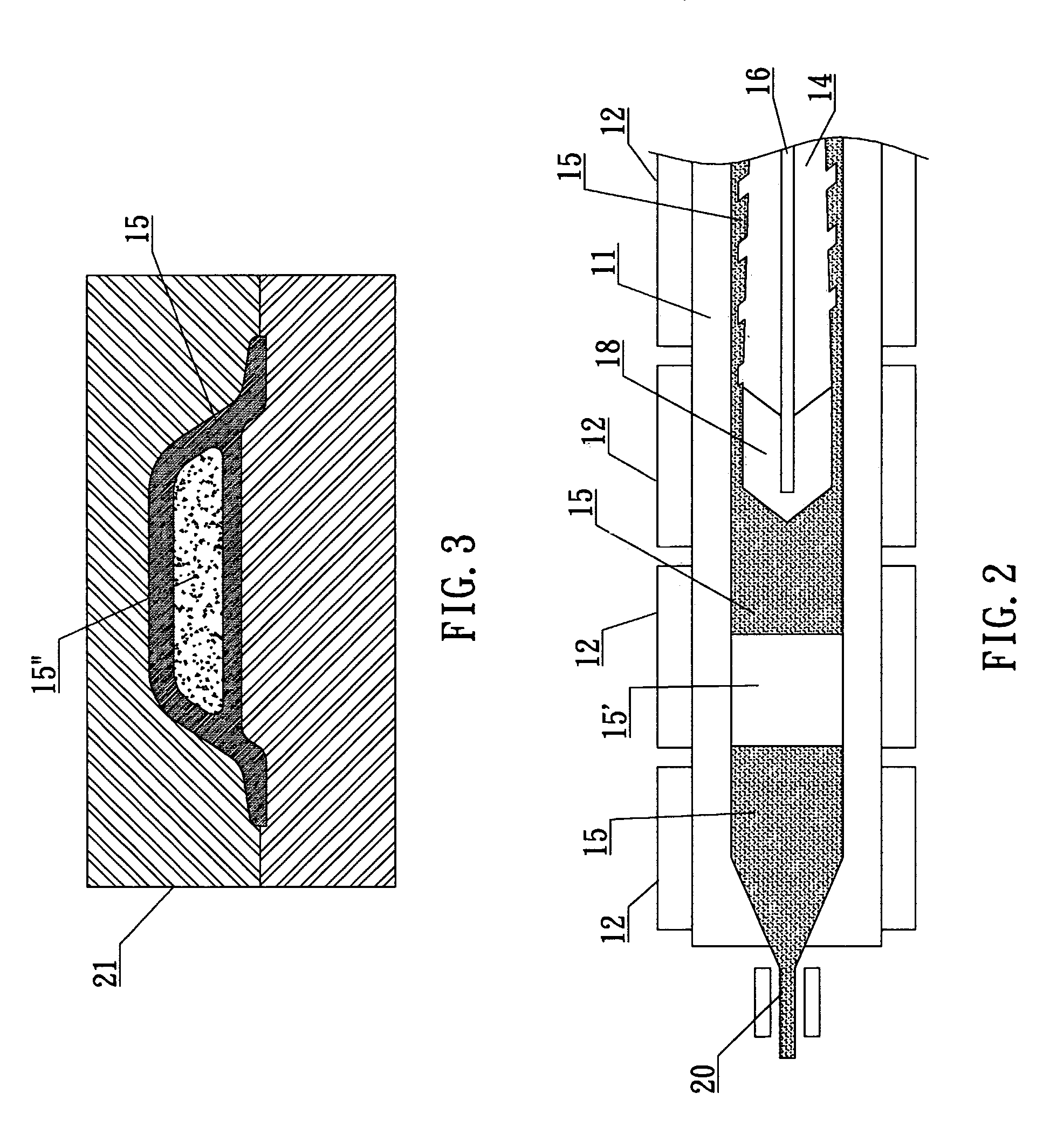

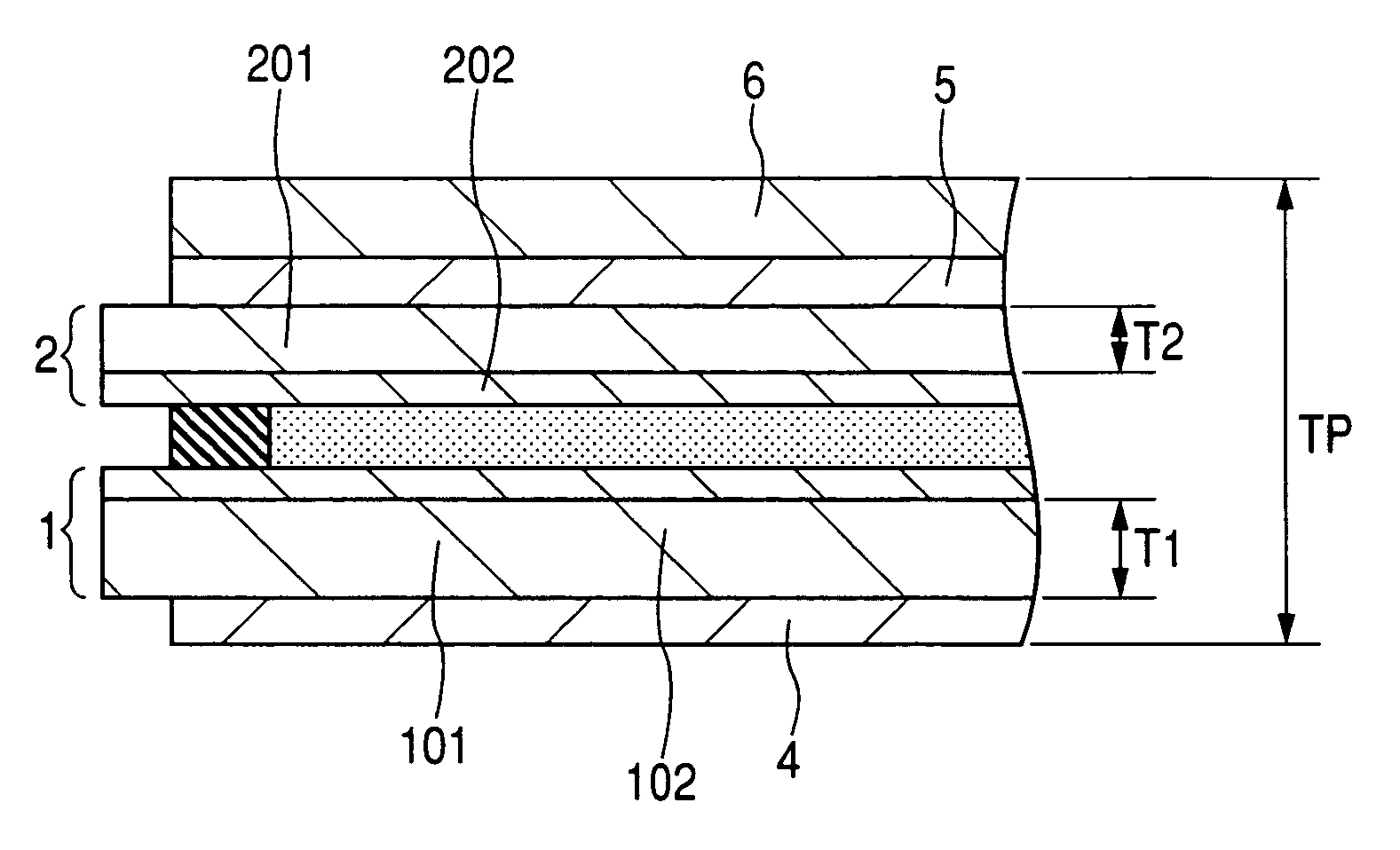

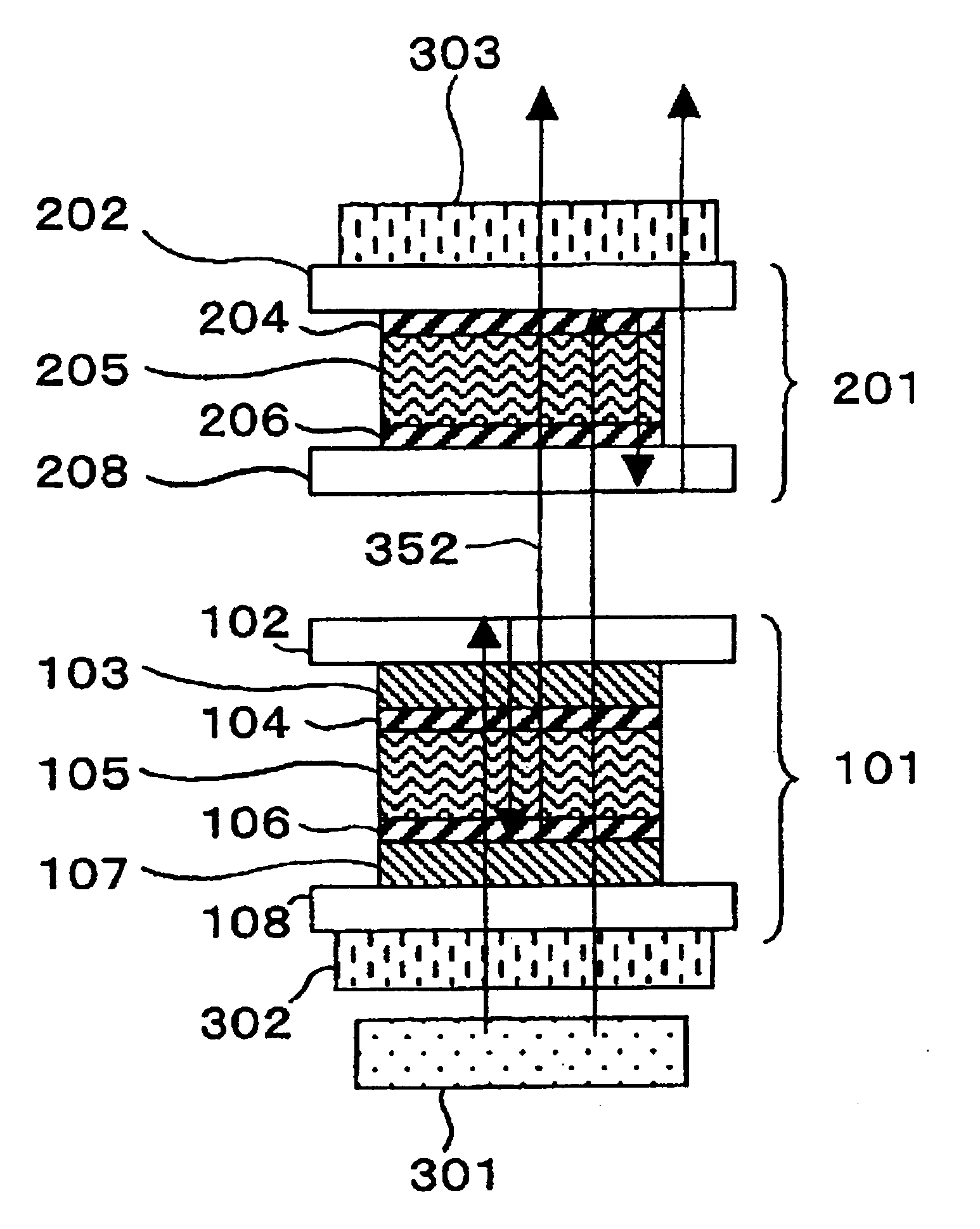

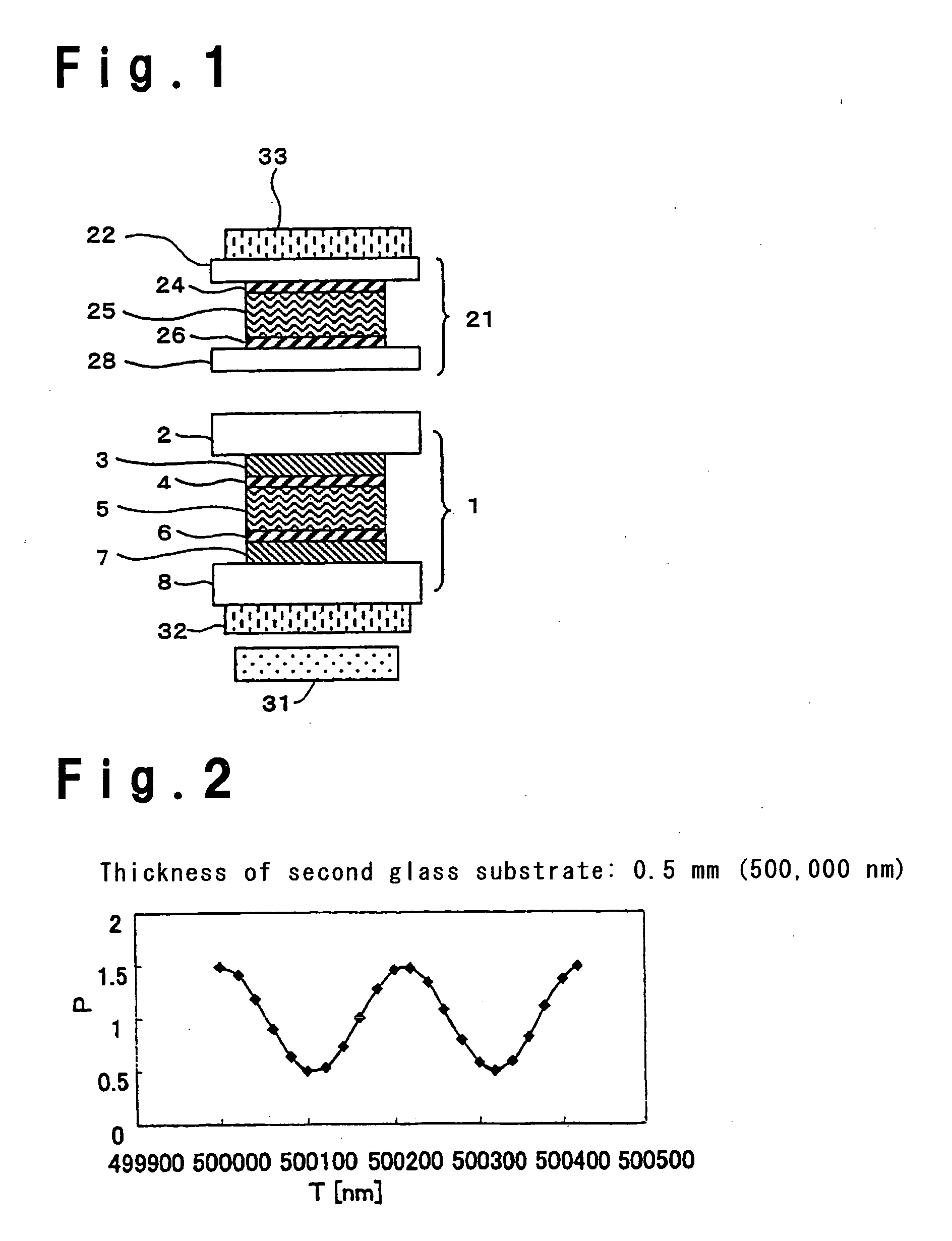

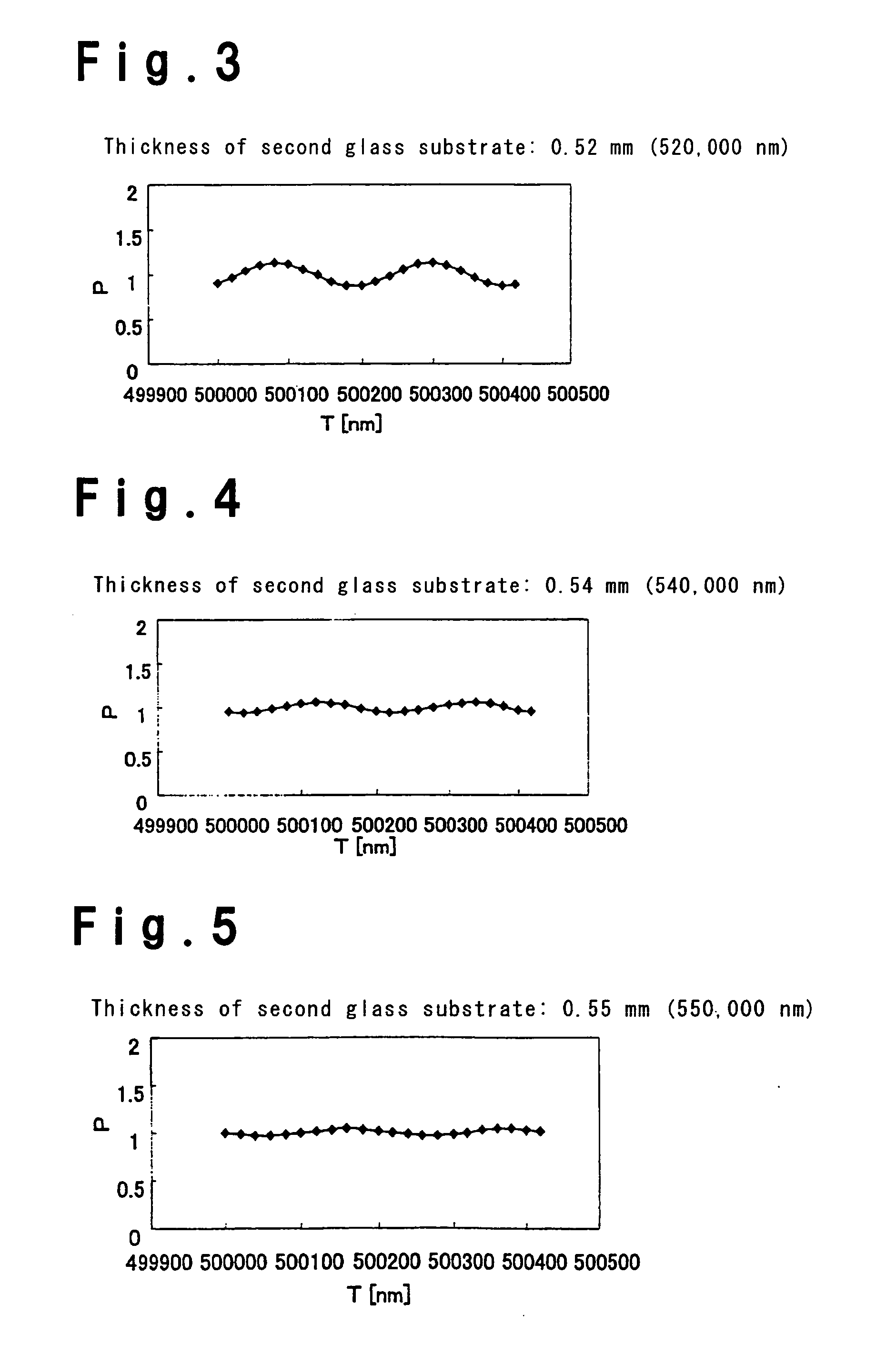

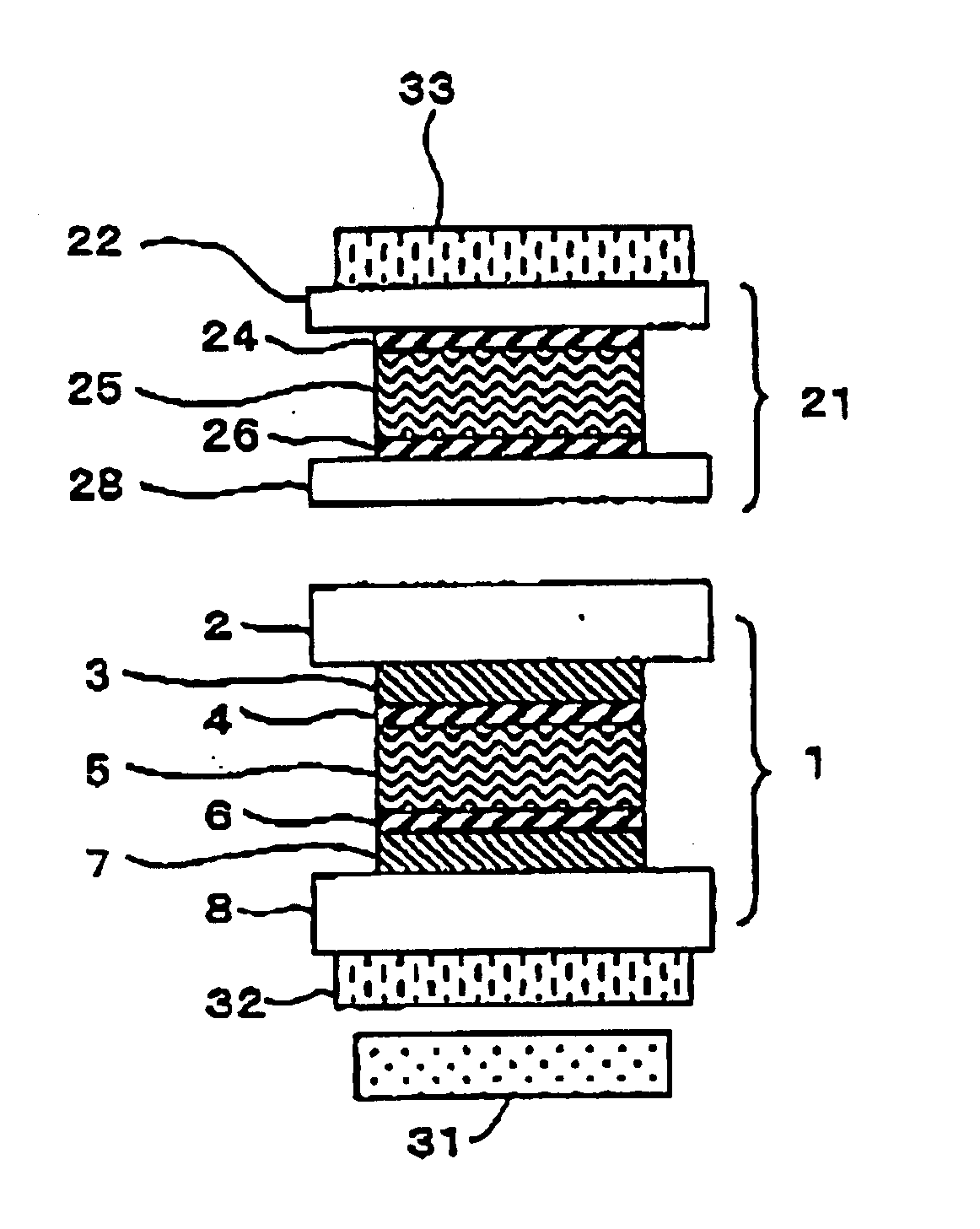

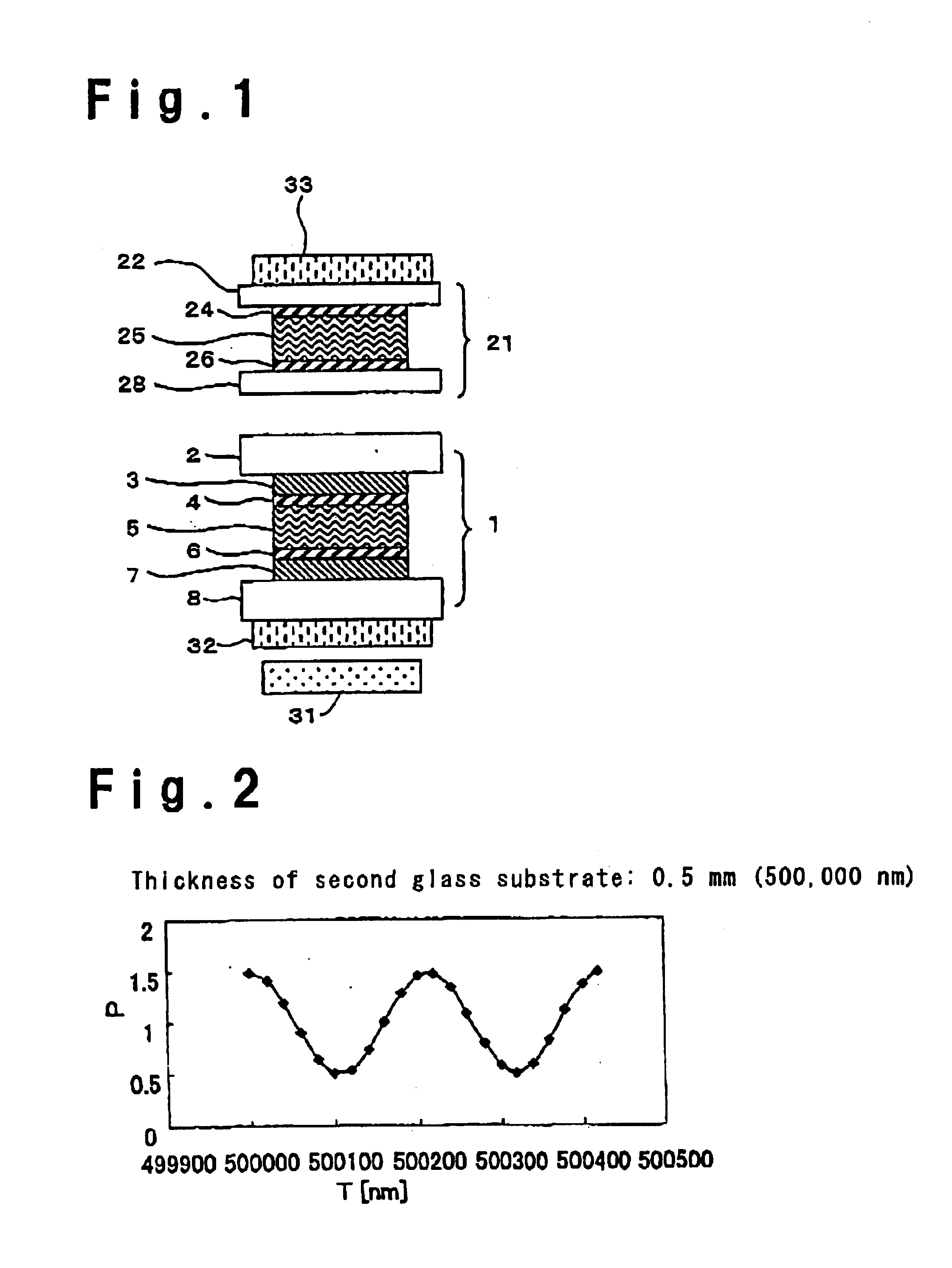

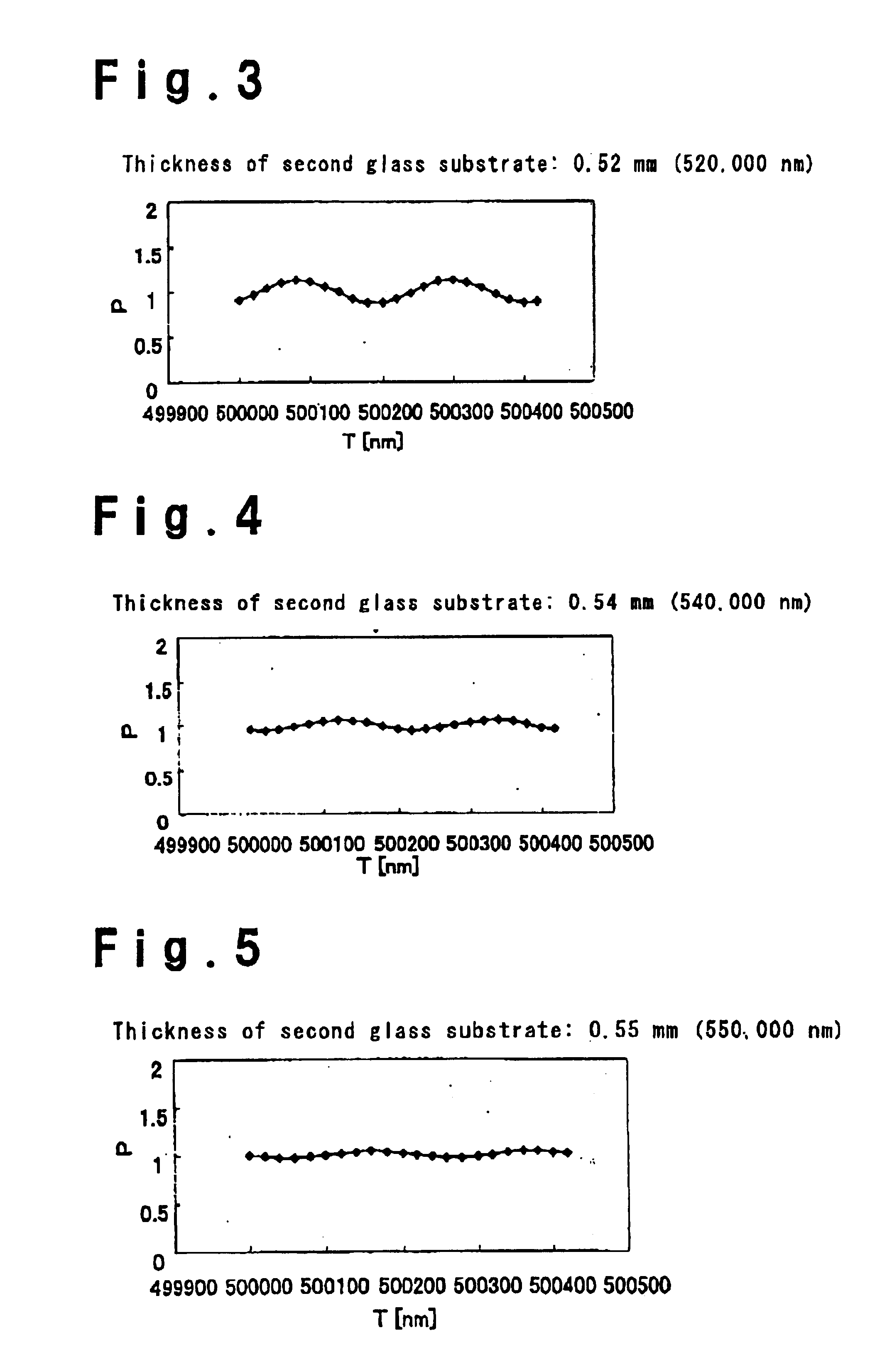

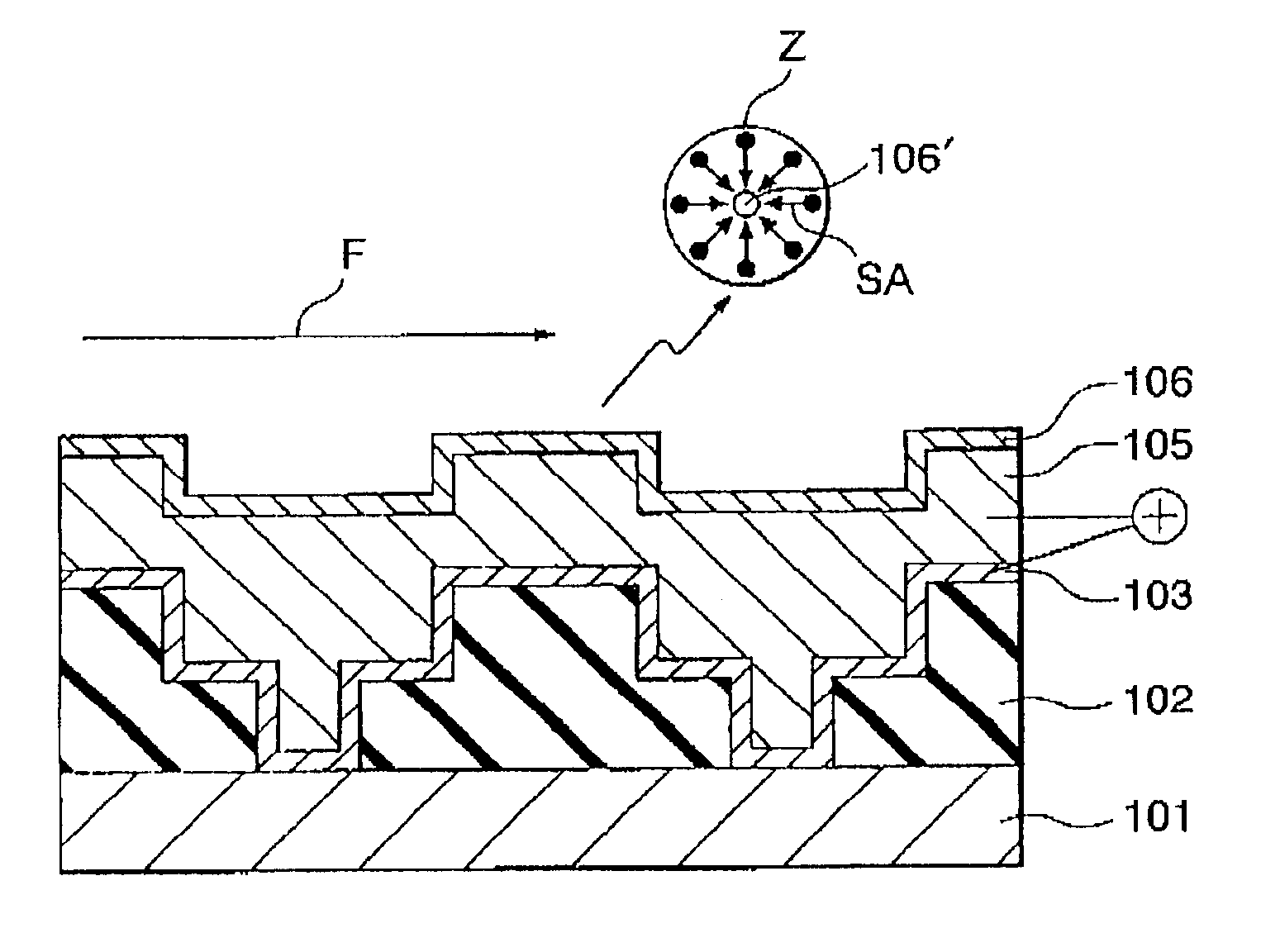

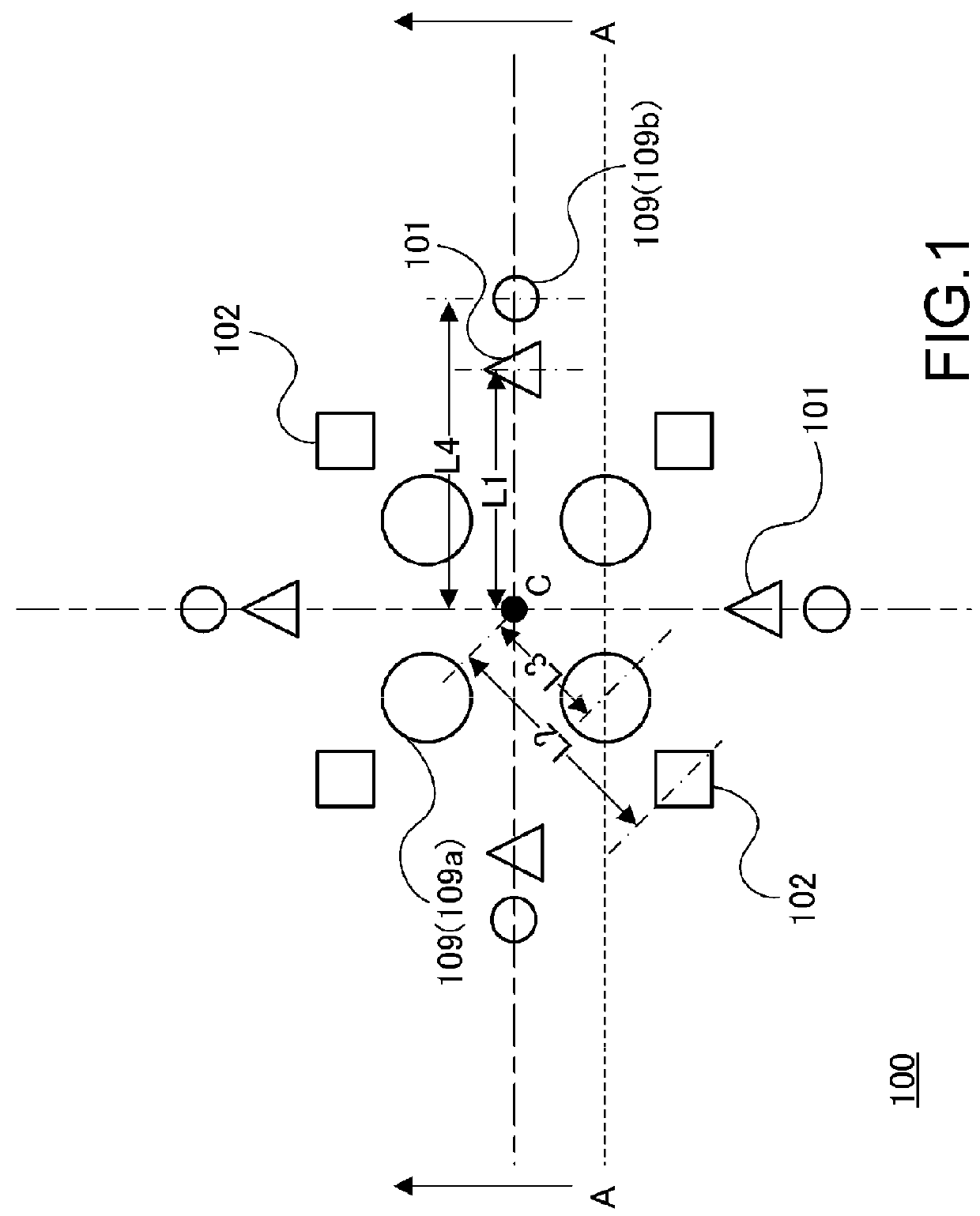

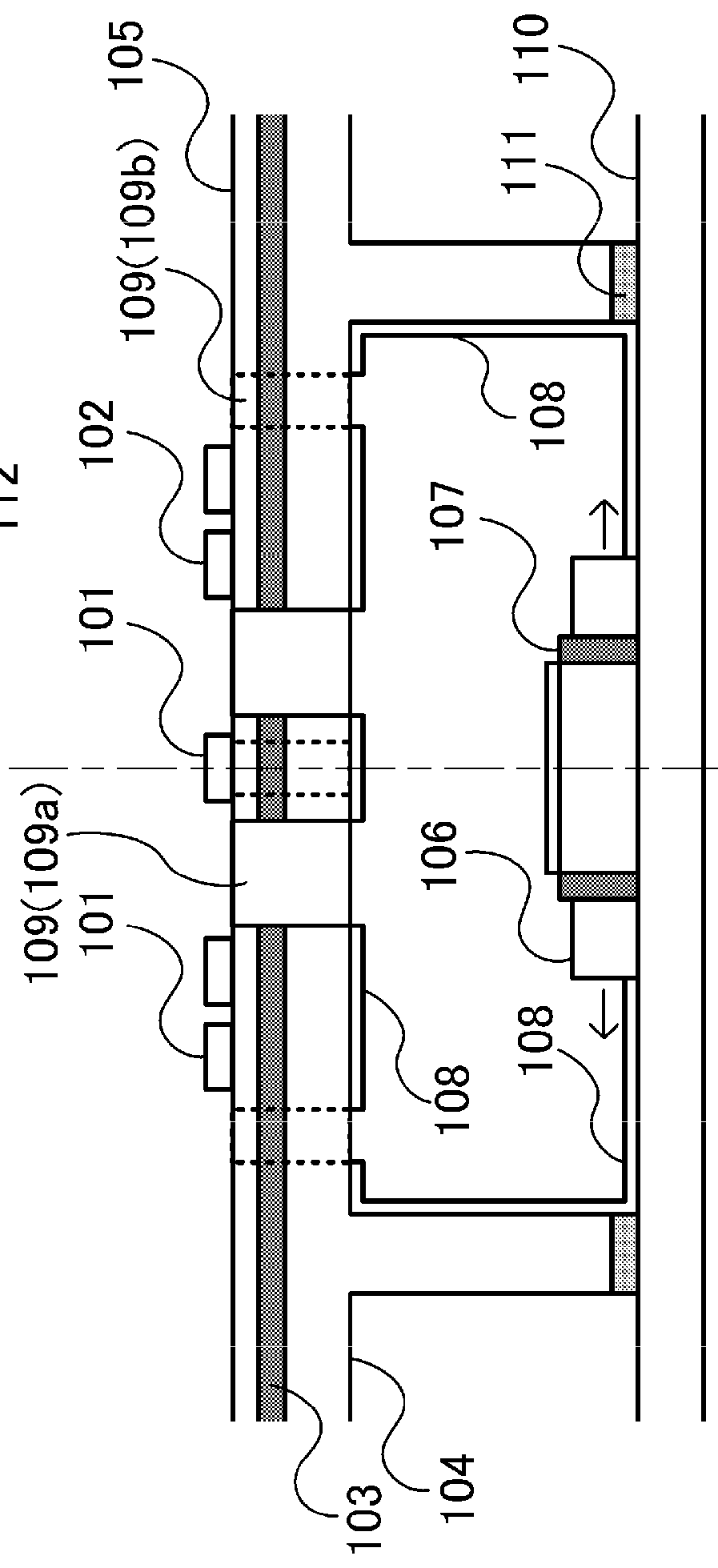

Liquid crystal display device and inspection method for a transparent substrate

InactiveUS20050140853A1Unevenness easilyNice appearanceOptical measurementsPhase-affecting property measurementsLiquid-crystal displayDisplay device

A liquid display device of D-STN mode capable of suppressing a line-shaped ununiformity of brightness in displaying a dark appearance is presented. A displaying cell 1 and a compensation cell 21 are formed so that there is a difference of thickness of at least 0.05 mm between the thickness of a glass substrate 2 at a front side of the displaying cell 1 and the thickness of a glass substrate at a rear side of the compensation cell 21. The displaying cell 1 and the compensation cell 21 are arranged between a first polarizing plate 32 and a second polarizing plate 33. A backlight 31 is of a type emitting light whose half value width with respect to the peak luminance is at least 5 nm.

Owner:OPTREX CORP +1

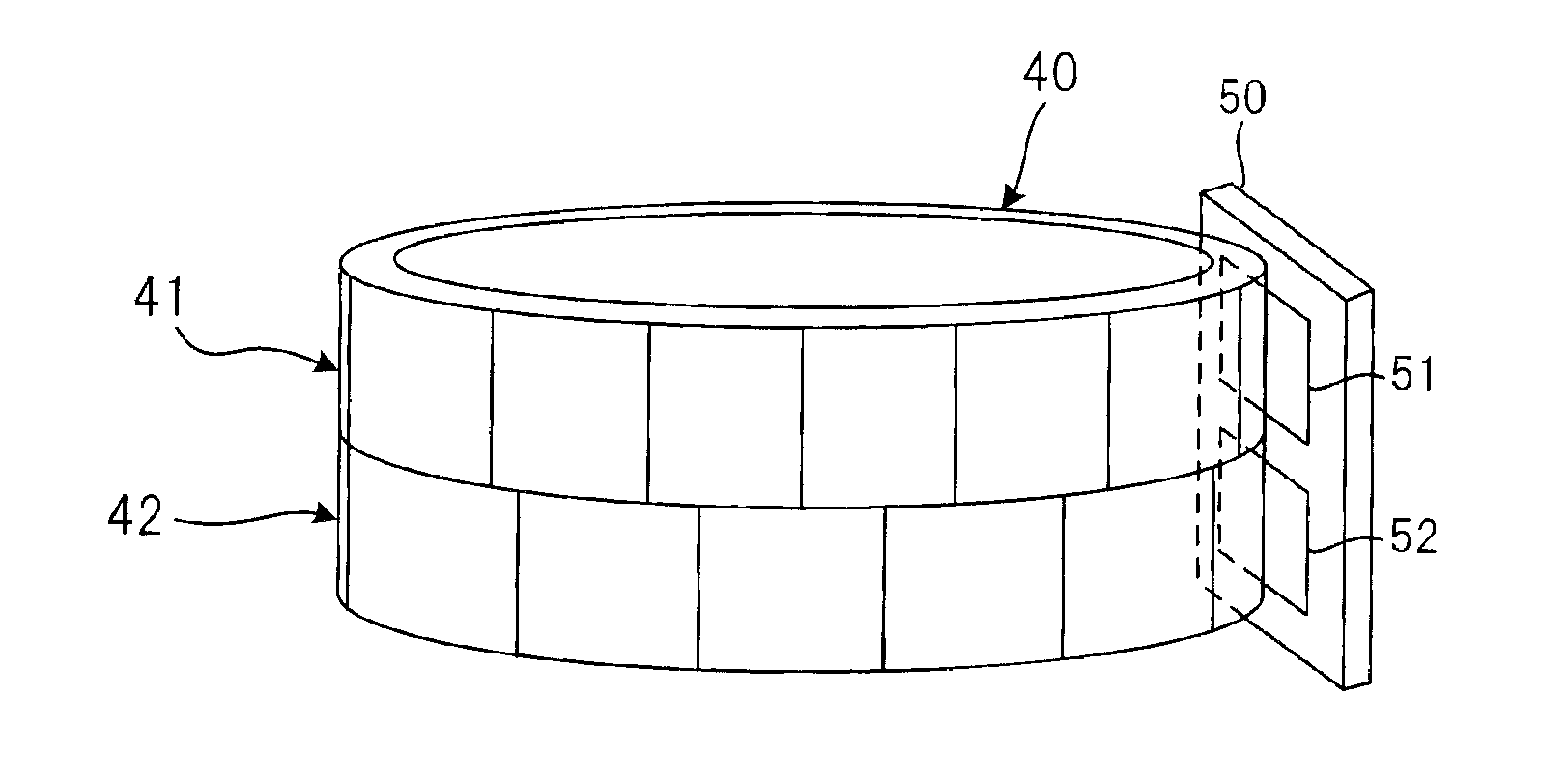

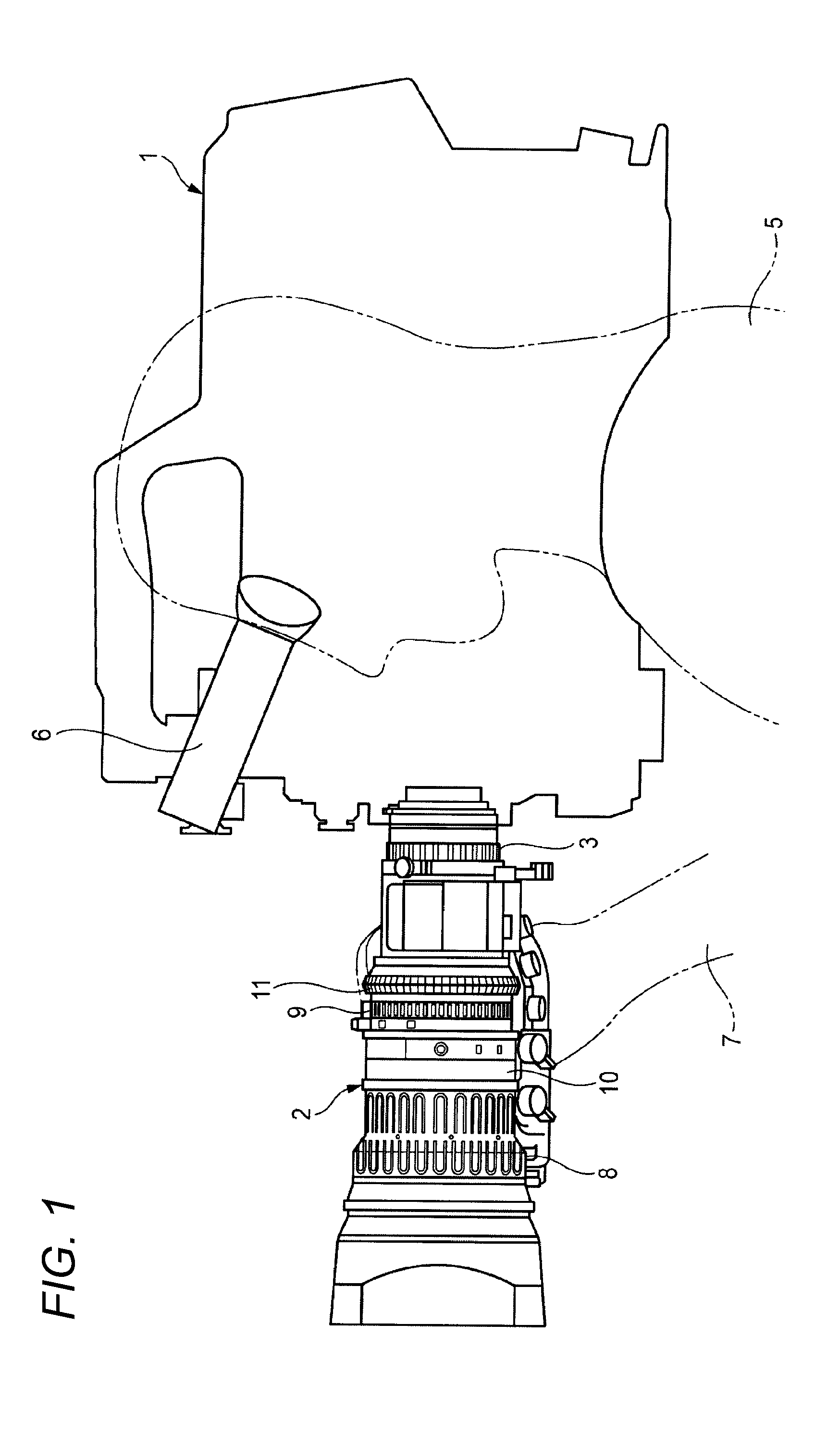

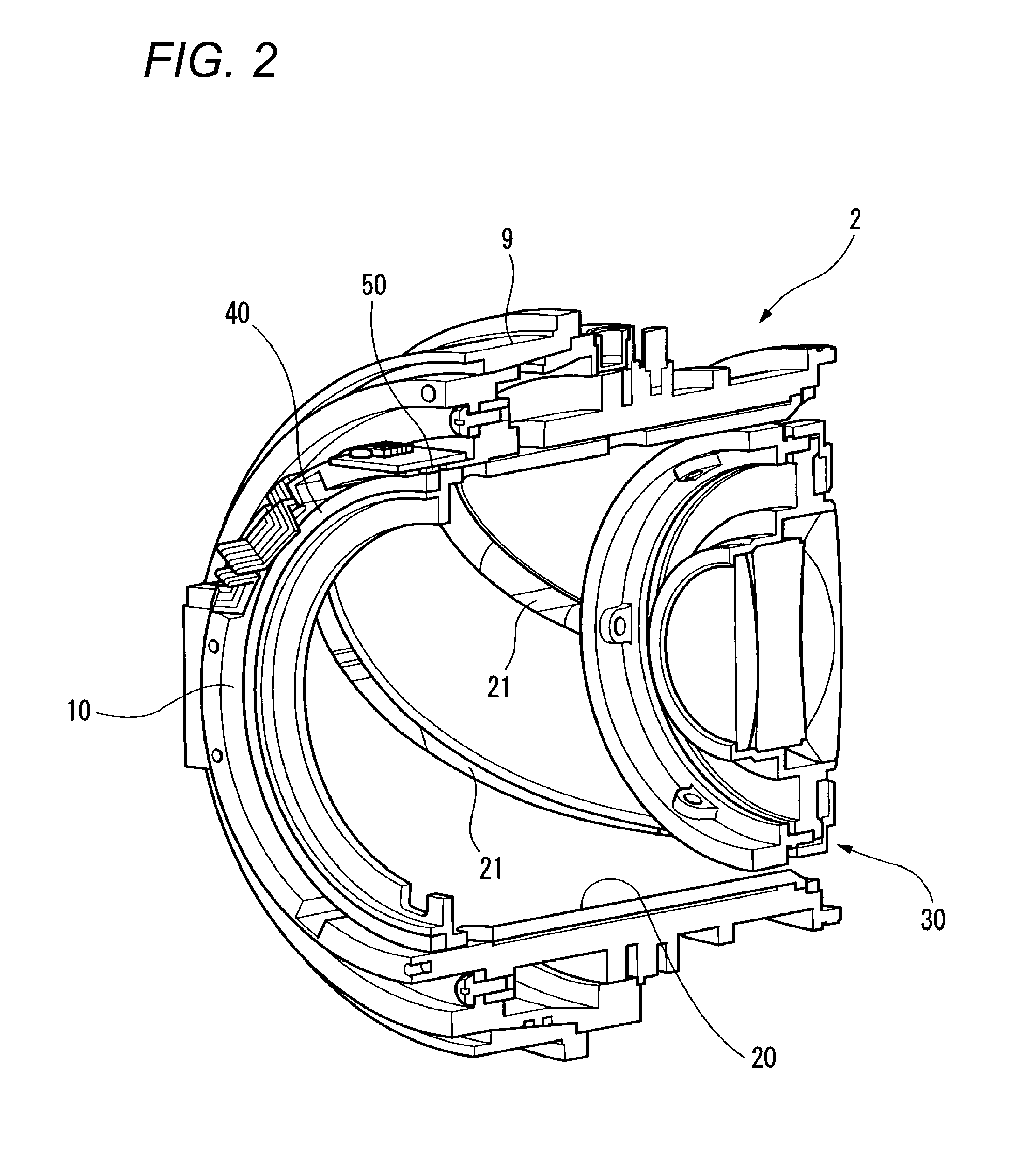

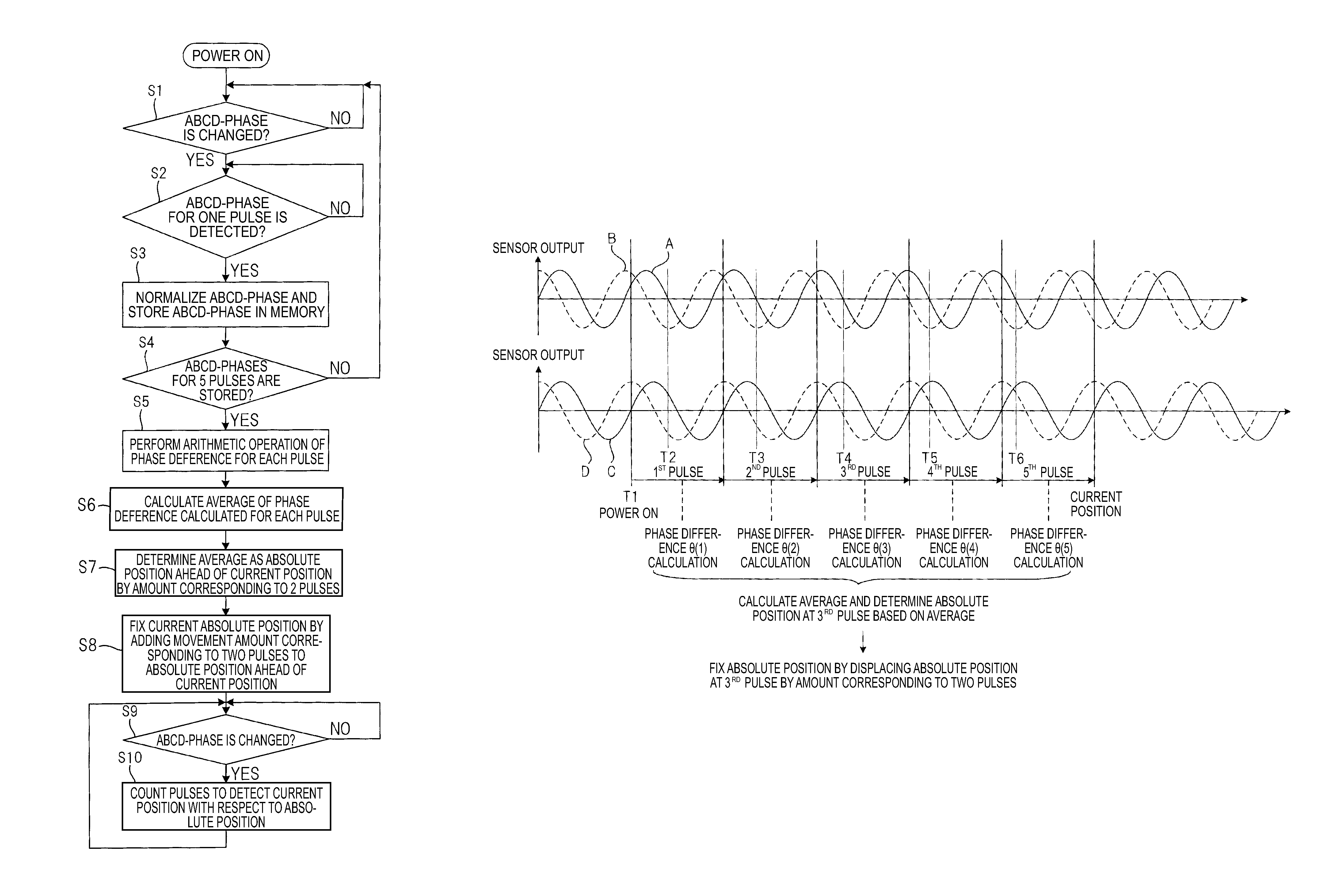

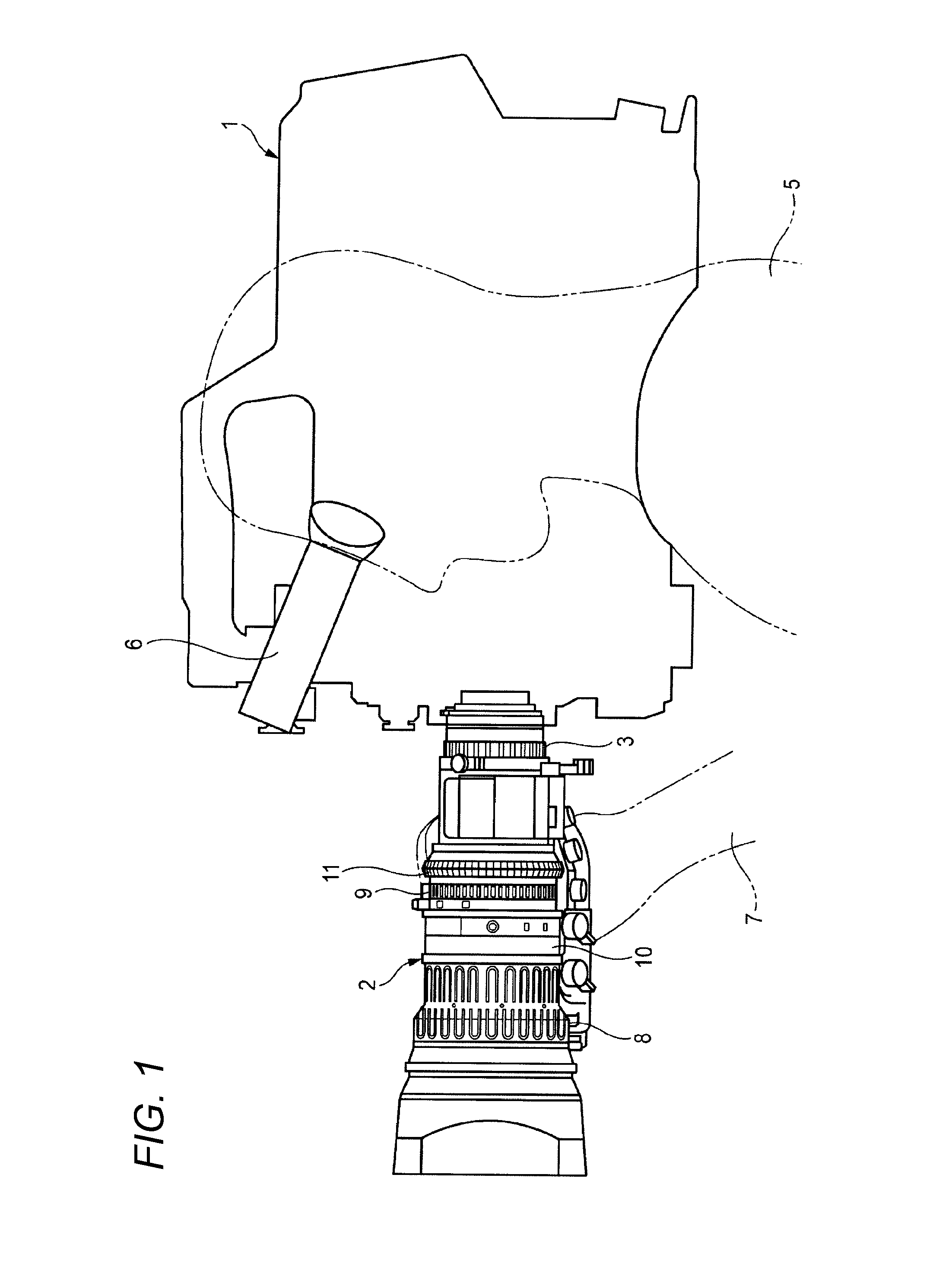

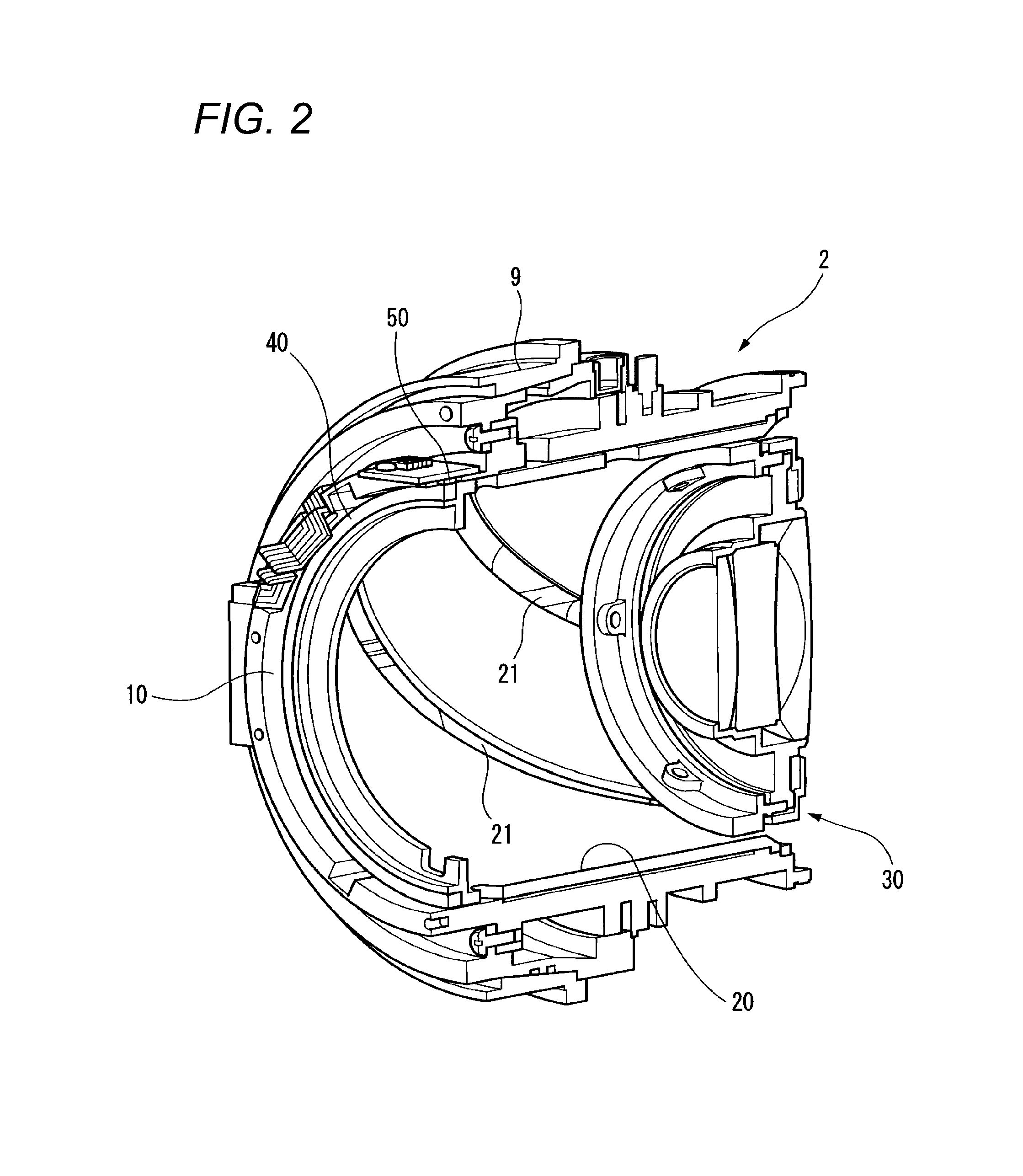

Lens device and position detection method of movable optical element

ActiveUS20140340560A1Low costSimple configurationTelevision system detailsRecord information storageLocation detectionPhase difference

A lens device includes a movable optical element, a rotary member; first and second magnetic recording scales fixedly disposed on an outer periphery of the rotary member to extend along a peripheral direction of the rotary member; a signal detecting unit which detects first to fourth signals; and a position detecting unit which detects a position of the movable optical element based on the detected signals, in which the position detecting unit includes: a phase difference calculating unit which calculates a phase difference between the first signal and the third signal, based on the detected first to fourth signals for one cycle; a phase average calculating unit which calculates an average of the phase differences respectively calculated for n cycles; and an absolute position detecting unit which detects an absolute position of the movable optical element based on the calculated average.

Owner:FUJIFILM CORP

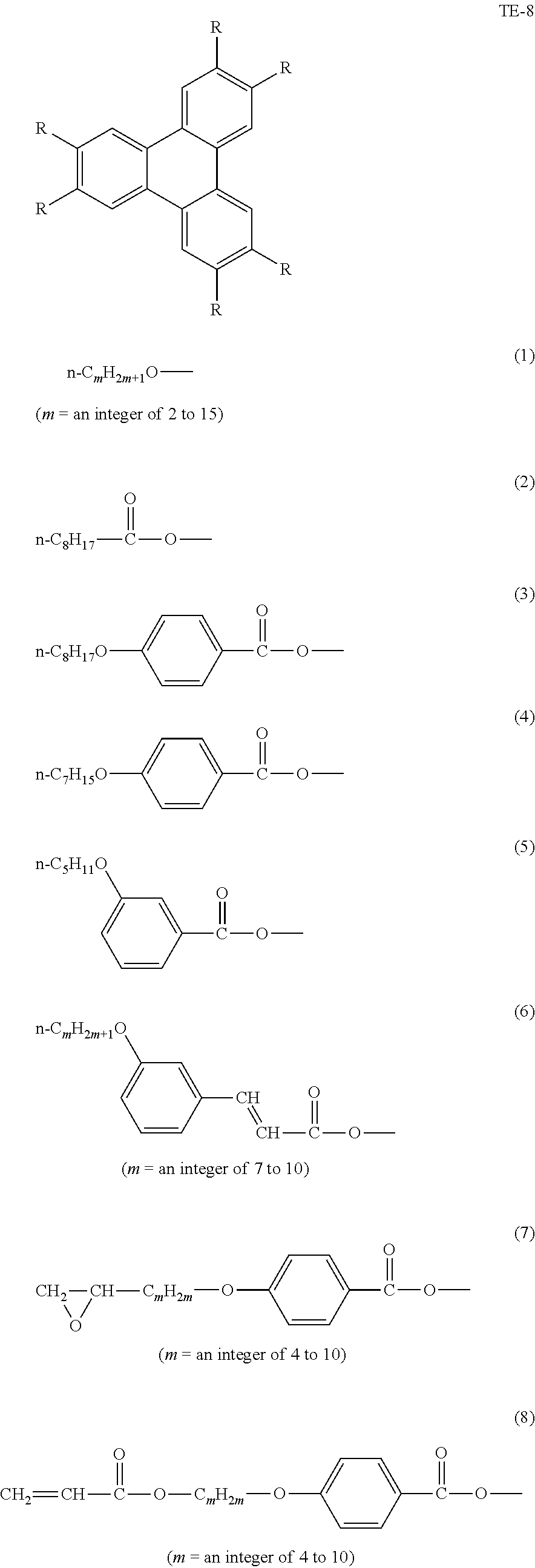

Optical film and liquid crystal display device

InactiveUS20120092594A1Wide viewing angleGood outdoor visibilityPolarising elementsNon-linear opticsCelluloseLiquid-crystal display

An optical film contains a cellulose acylate film, and at least two layers of an optically anisotropic layer A and an optically anisotropic layer B, wherein the cellulose acylate film satisfies the specific formulae, Re(548) of the optically anisotropic layer A is from 80 to 190 nm and the slow axis of the optically anisotropic layer A is at 45°±10° with respect to the film conveying direction, and the optically anisotropic layer B satisfies the specific formulae.

Owner:FUJIFILM CORP

Highly heat conductive insulating member, method of manufacturing the same and electromagnetic device

ActiveUS7524557B2Easy to manufactureImprove thermal conductivityPlastic/resin/waxes insulatorsSynthetic resin layered productsResin matrixMaterials science

The present invention provides a solution to the above-described drawbacks, and more specifically, as the tape-like or sheet-like insulation member, the resin matrix in which the first particles having a heat conductivity of 1 W / mK or higher and 300 W / mK or lower, that are diffused in the resin matrix, and the second particles having a heat conductivity of 0.5 W / mK or higher and 300 W / mK or lower, are diffused, is employed.

Owner:KK TOSHIBA

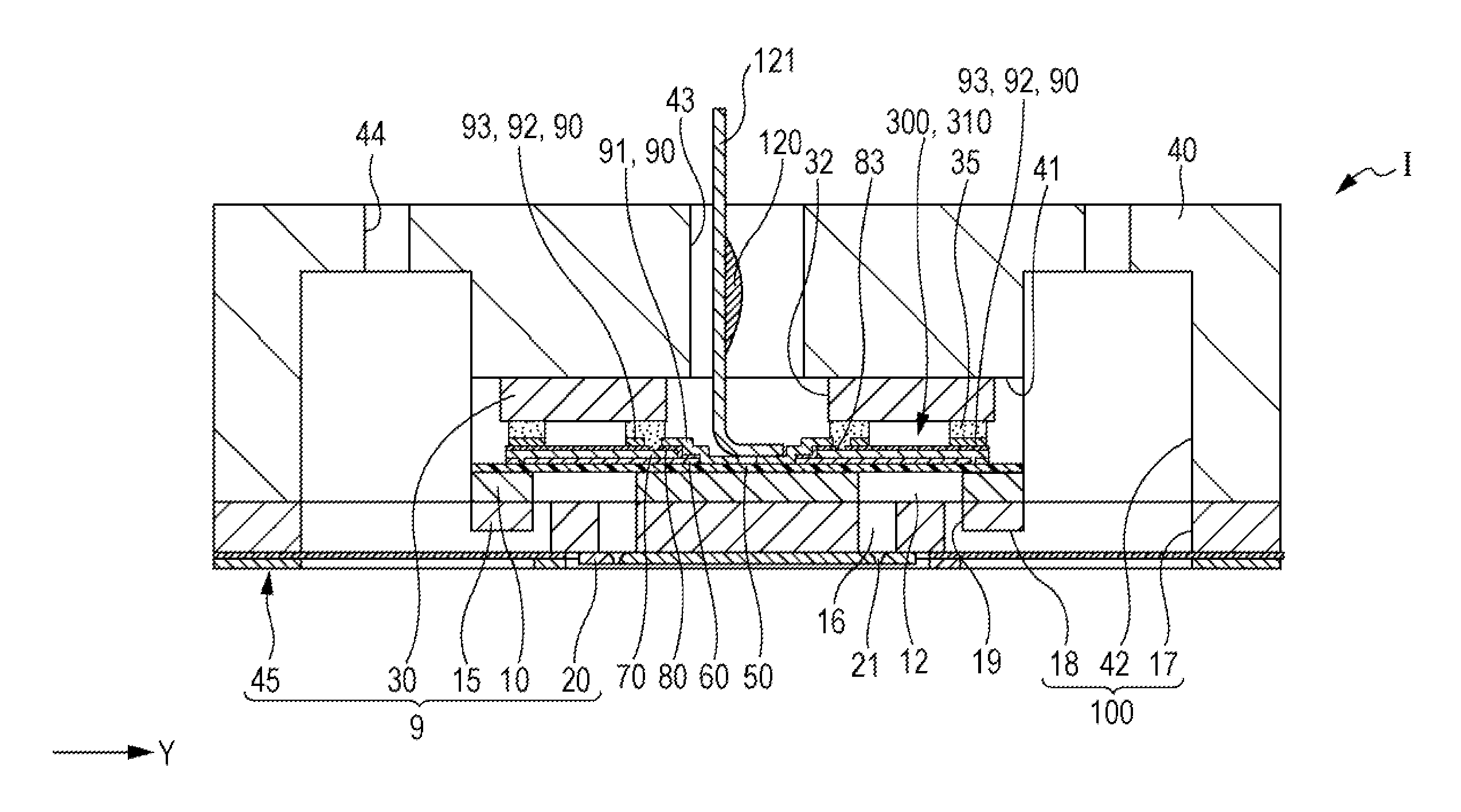

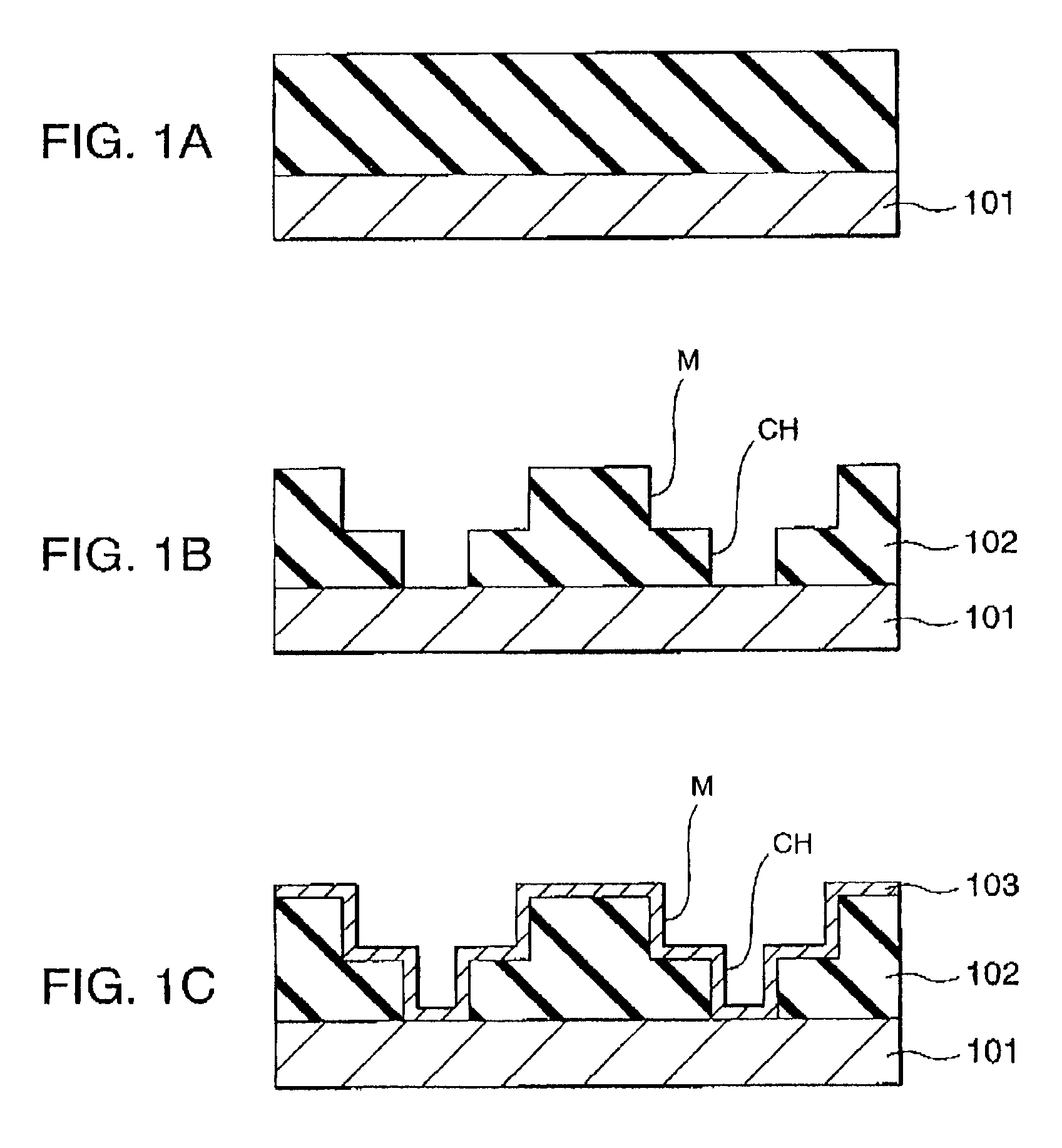

Methods of manufacturing piezoelectric element, liquid ejecting head, and ultrasonic transducer

ActiveUS20150052715A1Reduce harmWell formedPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostrictive transducersUltrasonic sensorTransducer

Owner:SEIKO EPSON CORP

Liquid crystal display device and inspection method for a transparent substrate

ActiveUS6906763B2Good dark appearanceUnevenness easilyOptical measurementsPhase-affecting property measurementsLiquid-crystal displayDisplay device

A liquid display device of D-STN mode capable of suppressing a line-shaped ununiformity of brightness in displaying a dark appearance is presented. A displaying cell 1 and a compensation cell 21 are formed so that there is a difference of thickness of at least 0.05 mm between the thickness of a glass substrate 2 at a front side of the displaying cell 1 and the thickness of a glass substrate at a rear side of the compensation cell 21. The displaying cell 1 and the compensation cell 21 are arranged between a first polarizing plate 32 and a second polarizing plate 33. A backlight 31 is of a type emitting light whose half value width with respect to the peak luminance is at least 5 nm.

Owner:OPTREX CORP +1

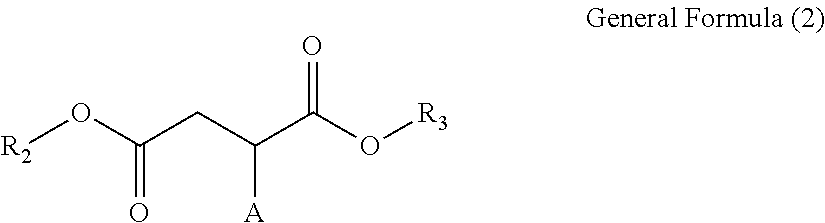

Ink set and image forming method

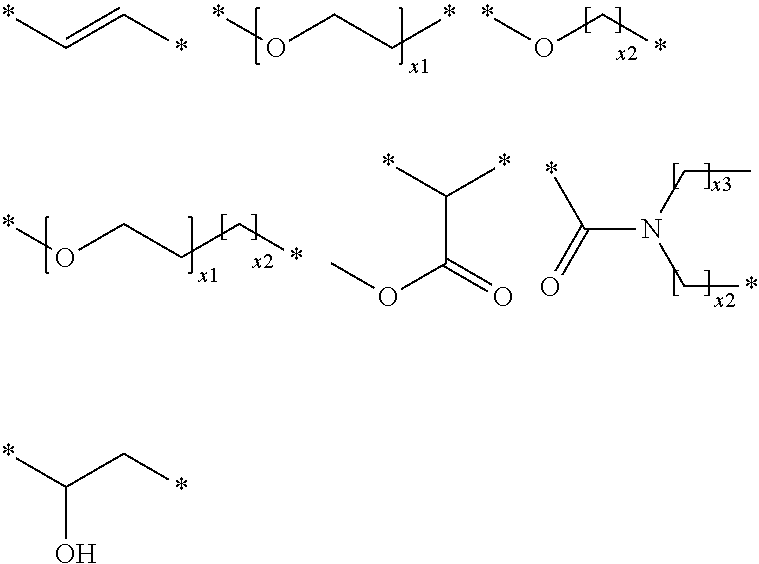

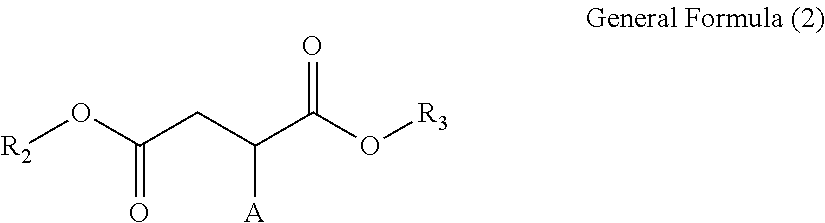

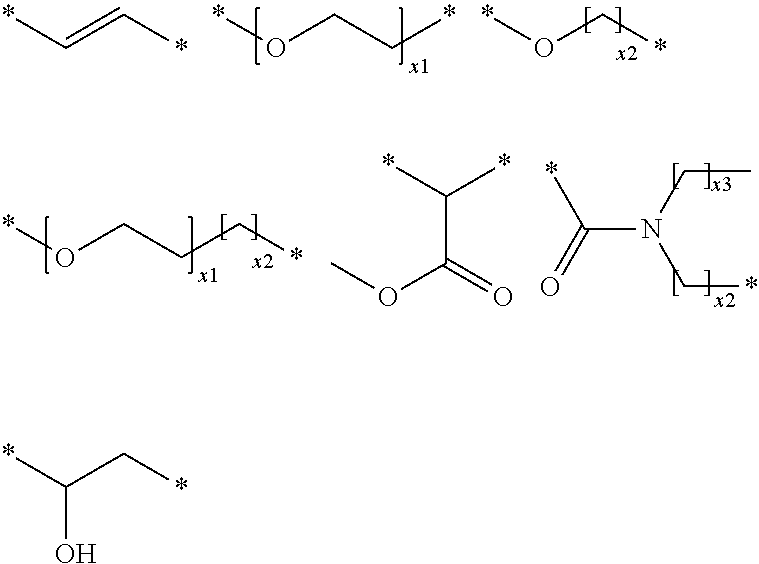

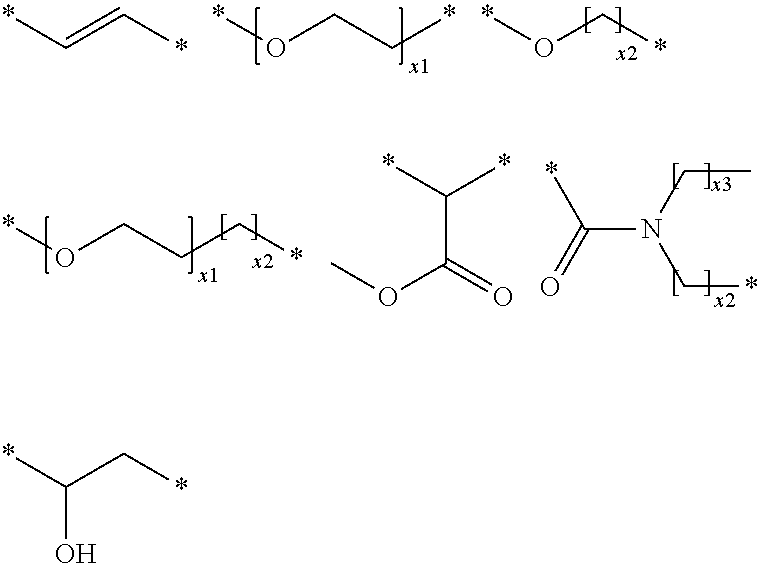

ActiveUS9951239B2High water repelling propertyLow wettabilityDuplicating/marking methodsInksPolymer chemistryColoring agents

An ink set including an ink composition including resin particles, a colorant, and water, and a treatment solution including an anionic surfactant, water, and a compound configured to aggregate at least one of the colorant or the resin particles in the ink composition, in which the ratio of the content of the anionic surfactant with respect to the content of the compound configured to aggregate at least one of the colorant or the resin particles is 0.001 to 0.600 in terms of mass. An image forming method in which the ink set is used.

Owner:FUJIFILM CORP

Highly heat conductive insulating member, method of manufacturing the same and electromagnetic device

InactiveUS20090197102A1Easy to manufactureImprove thermal conductivityPlastic/resin/waxes insulatorsNatural mineral layered productsResin matrixMaterials science

The present invention provides a solution to the above-described drawbacks, and more specifically, as the tape-like or sheet-like insulation member, the resin matrix in which the first particles having a heat conductivity of 1 W / mK or higher and 300 W / mK or lower, that are diffused in the resin matrix, and the second particles having a heat conductivity of 0.5 W / mK or higher and 300 W / mK or lower, are diffused, is employed.

Owner:OKAMOTO TETABUSHI +9

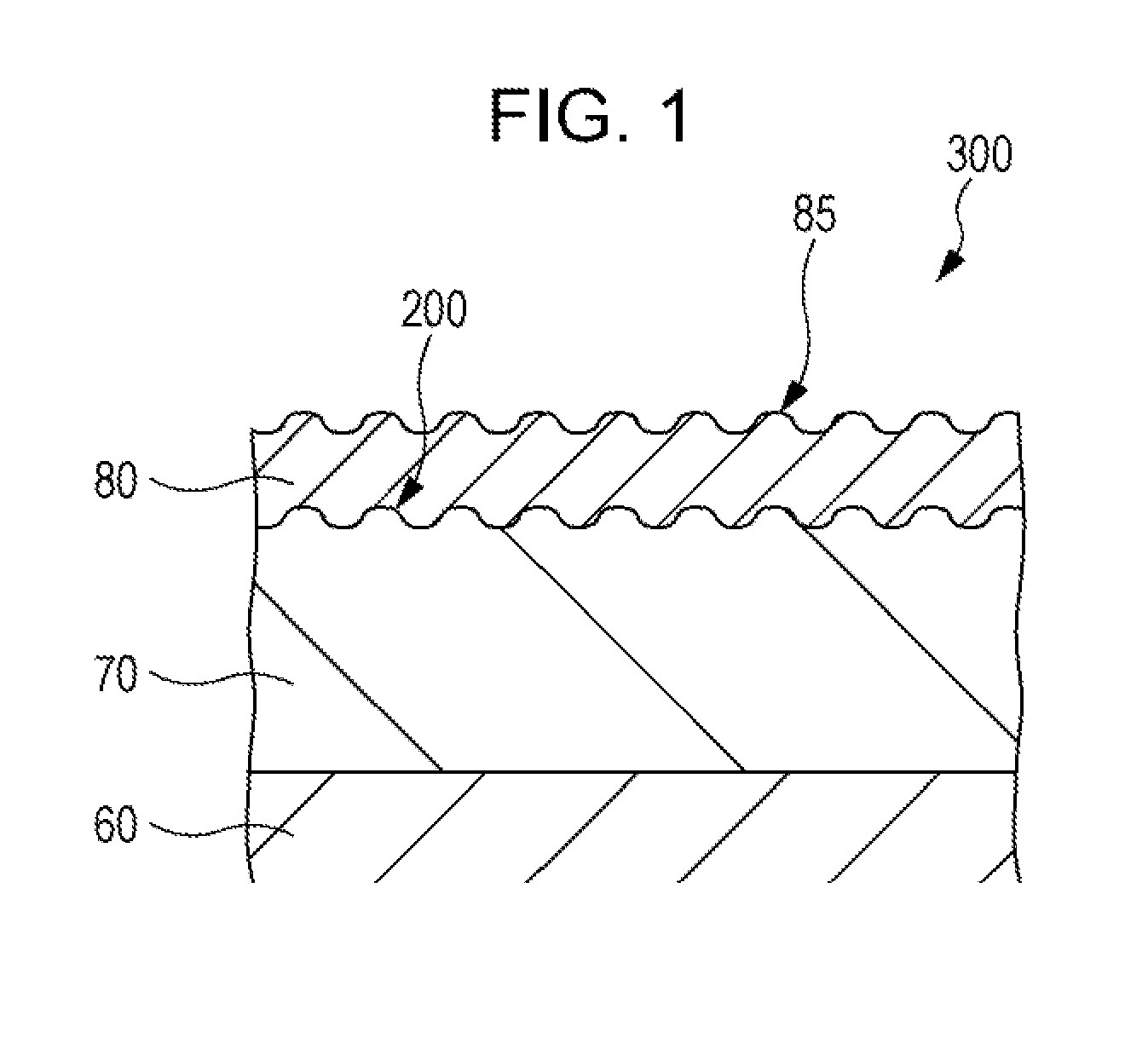

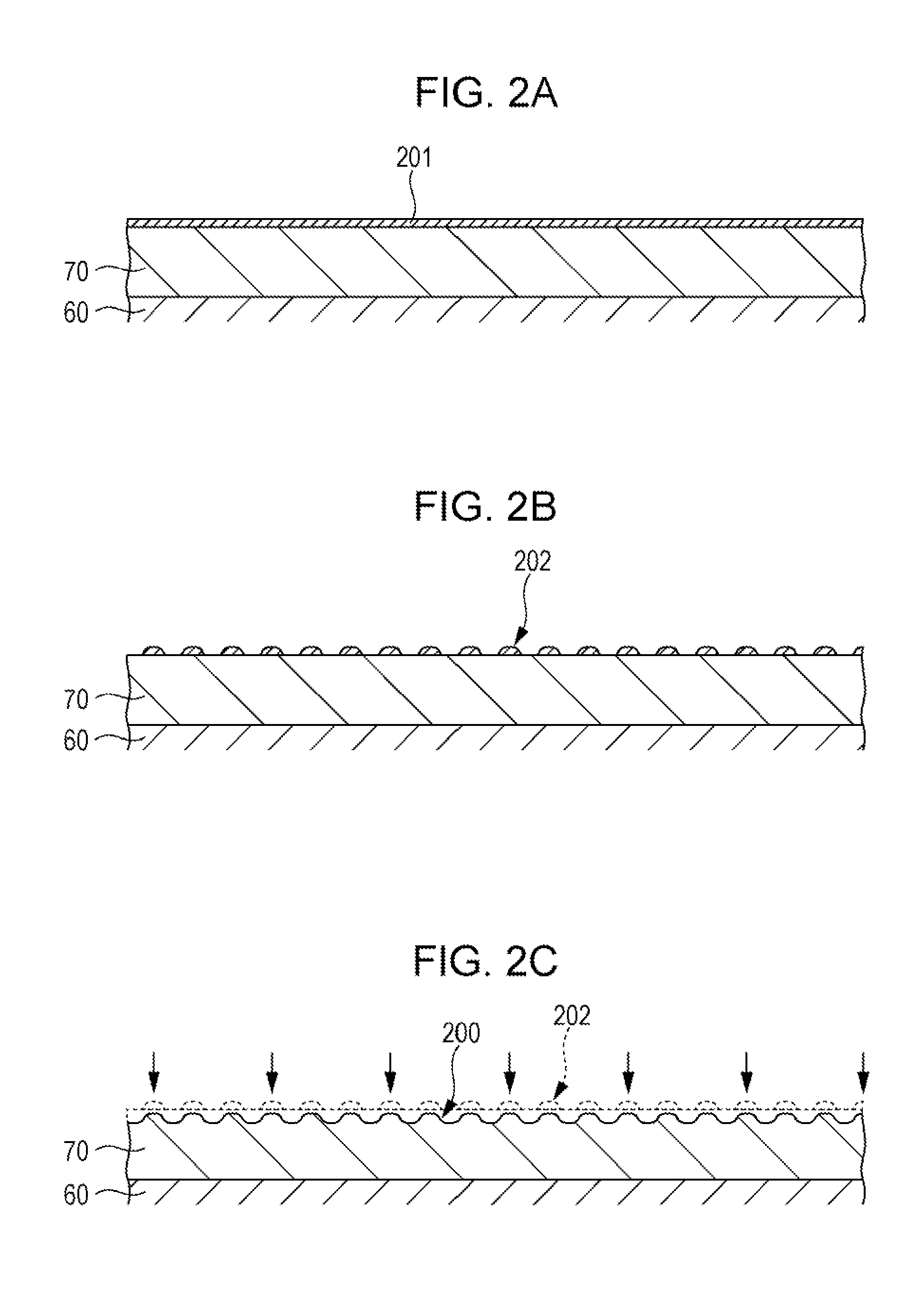

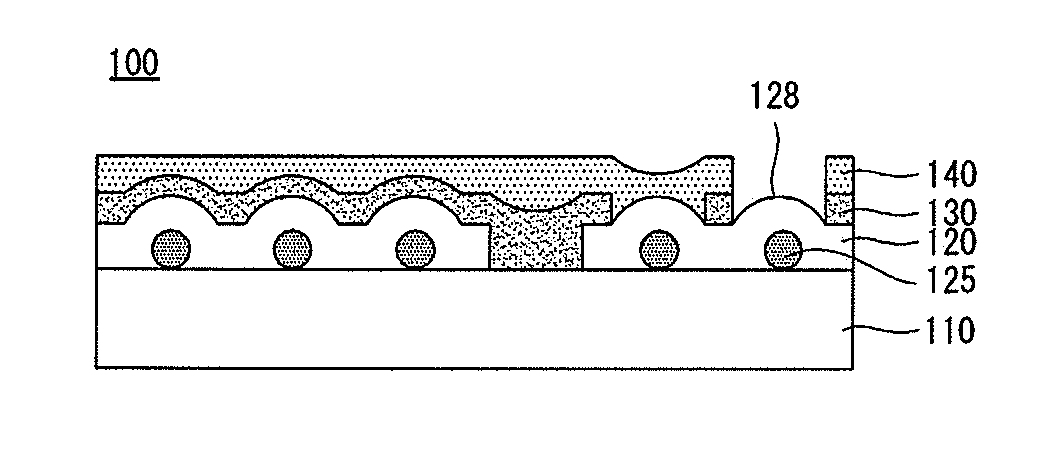

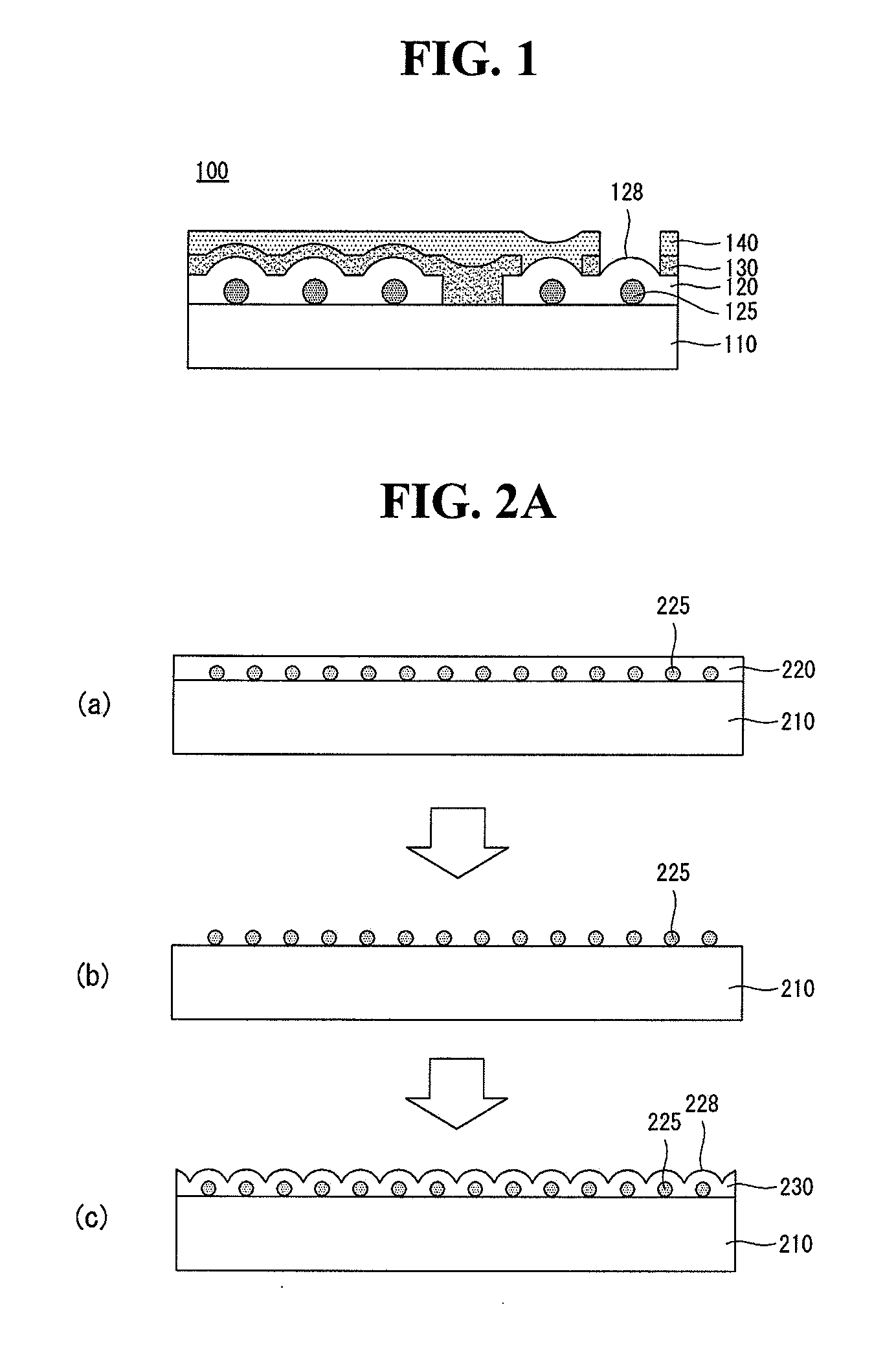

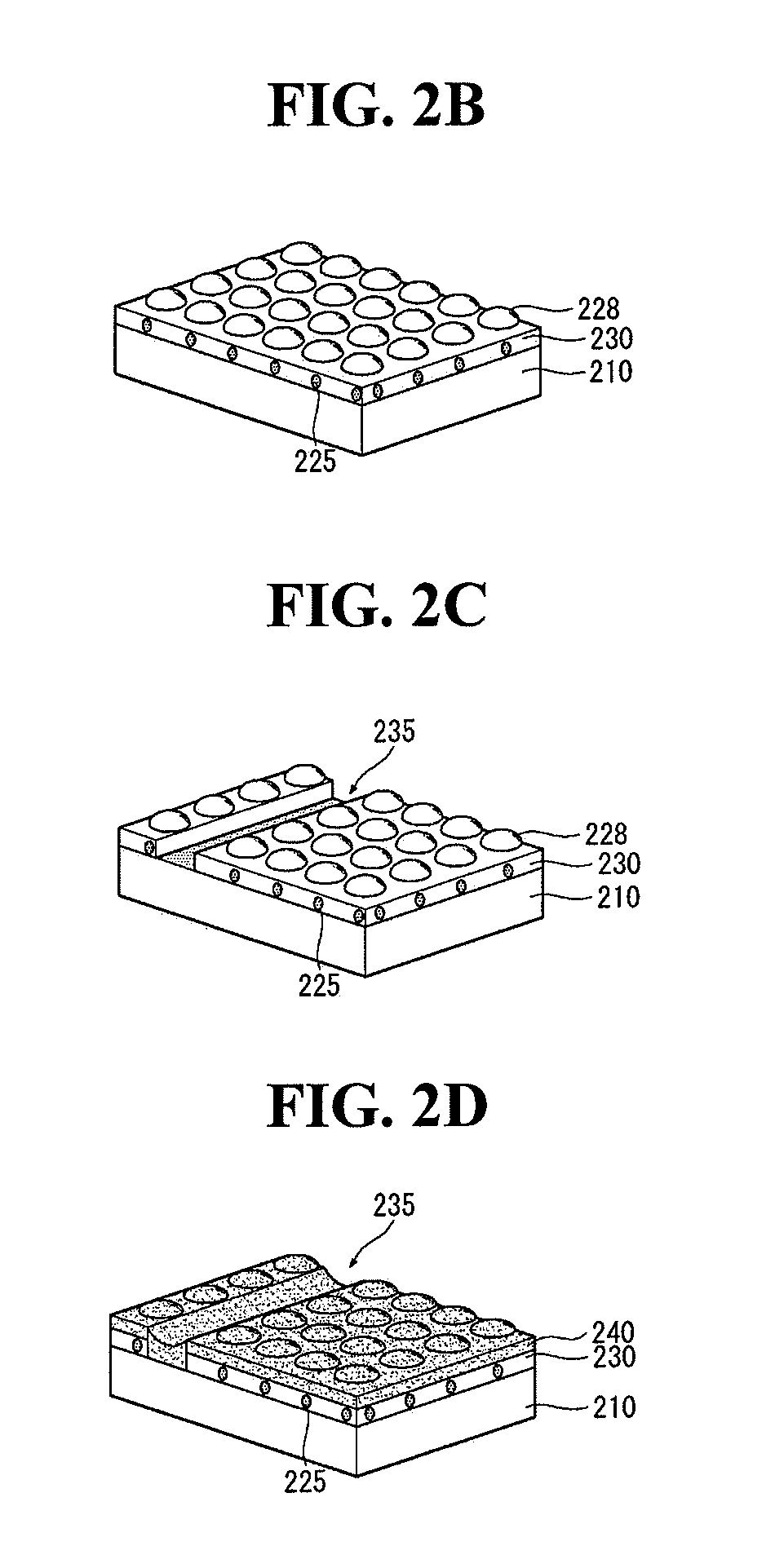

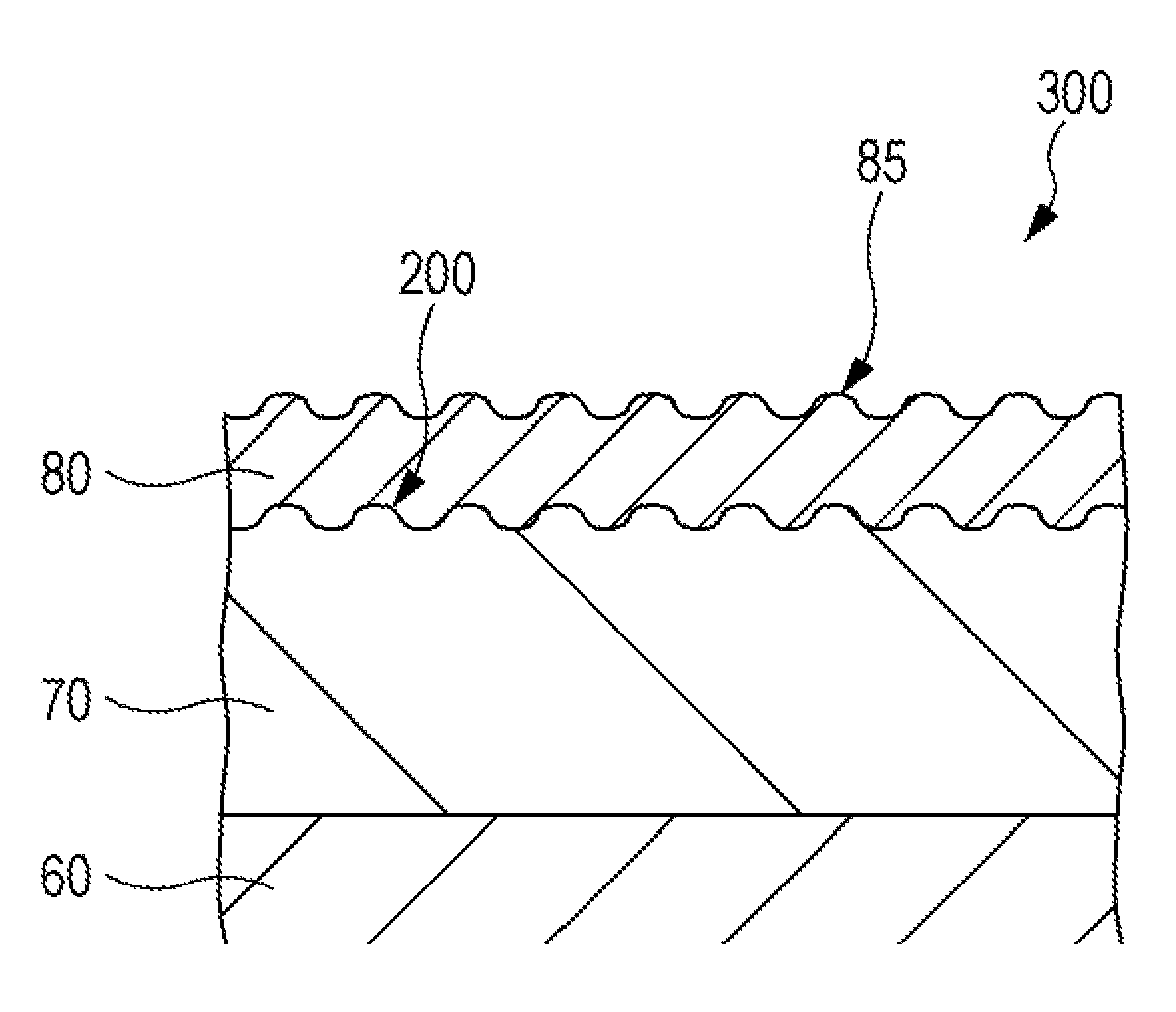

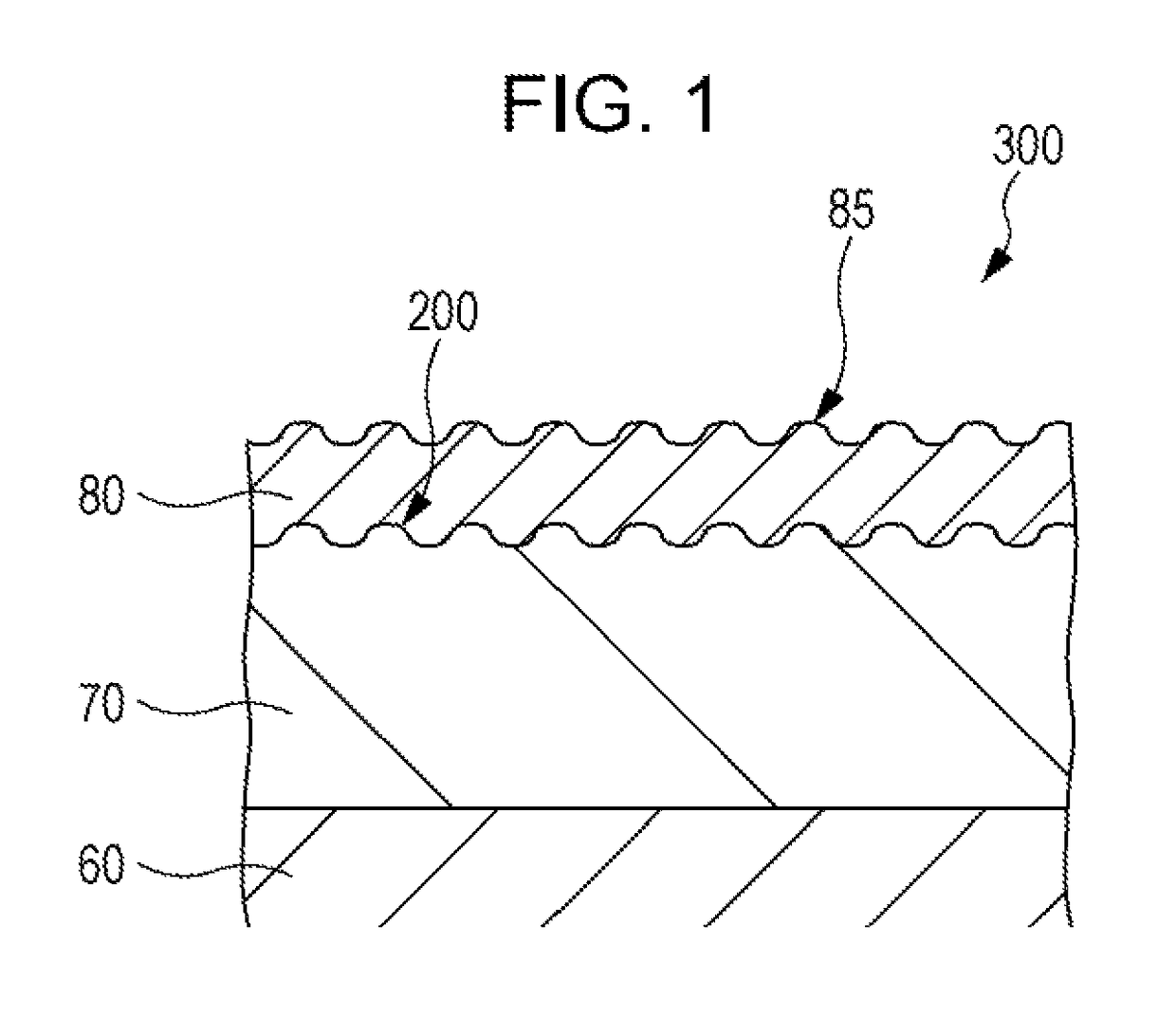

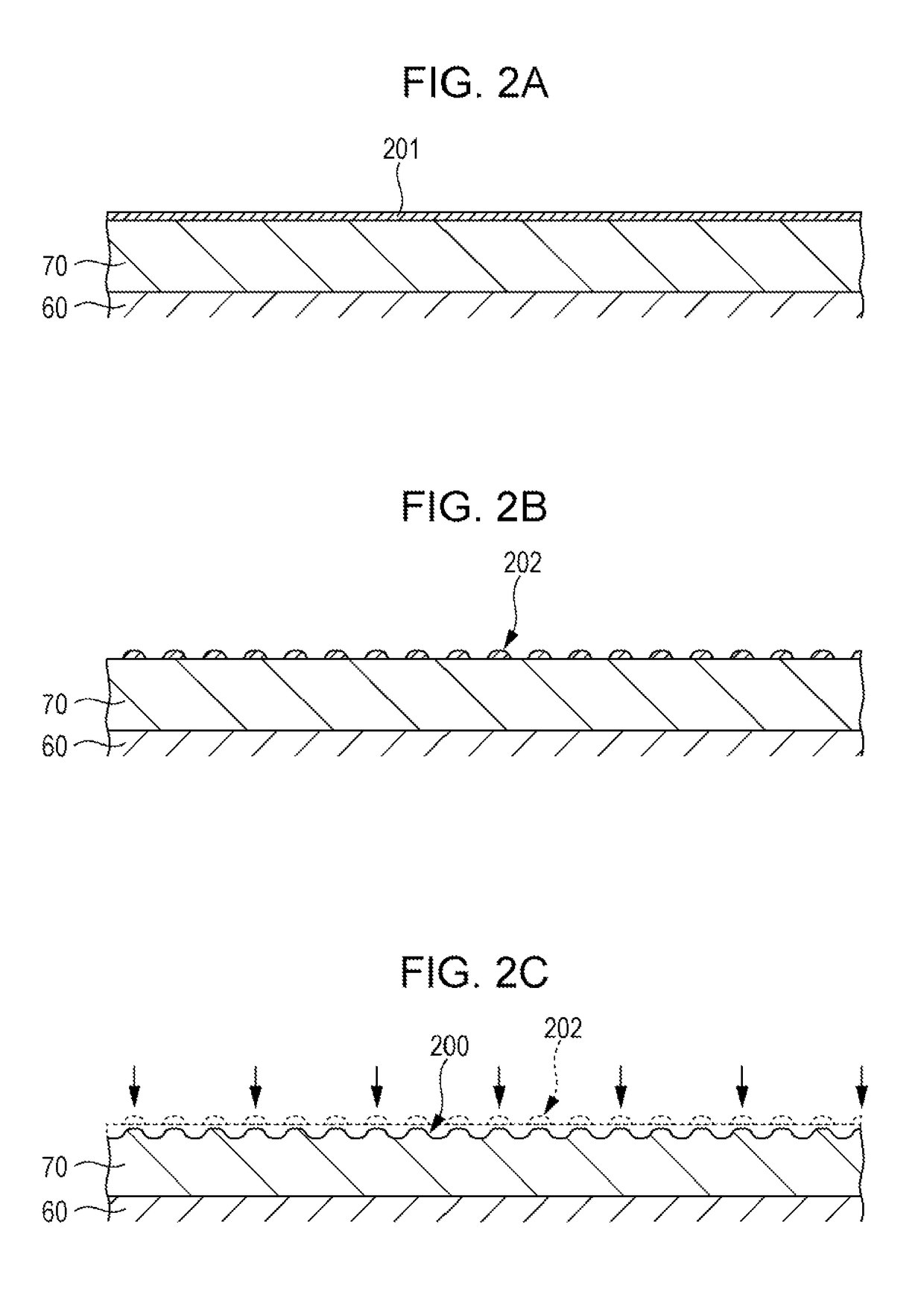

Thin film solar cell and manufacturing method for the same

InactiveUS20100206368A1Unevenness easilyShorten production timeFinal product manufactureSemiconductor/solid-state device manufacturingAbsorption layerThin film solar cell

Thin film solar cell and a manufacturing method for the same are disclosed. Thin film solar cell according to one embodiment of this document comprises a substrate, a first electrode positioned on the substrate including a plurality of conductive particles and having unevenness on the surface thereof, an absorption layer positioned on the first electrode, and a second electrode positioned on the absorption layer.

Owner:LG DISPLAY CO LTD

Polishing method and polishing apparatus

InactiveUS6855634B2Efficient polishingDamage suppressionSemiconductor/solid-state device manufacturingLapping machinesShear stressEngineering

A polishing method able to easily flatten unevenness formed on the surface of a film to be polished and able to efficiently polish the film flat while suppressing damage to an interlayer insulating film below the film, comprising, when polishing an object having a film such as an interconnection layer formed burying interconnection grooves formed in an insulating film of a substrate, supplying a polishing solution over the surface to be polished at least substantially parallel to the surface to preferentially remove by polishing the projecting portions of the film and flatten the surface by the shear stress of the processing solution or arranging a cathode member facing the surface and supplying an electrolytic solution containing a chelating agent between the surface and cathode member while supplying voltage between the film and the cathode member to preferentially remove by polishing the projecting portions of the film and flatten the surface by the shear stress of the electrolytic solution, and a polishing apparatus using the same.

Owner:SONY CORP

Liquid Crystal Display and Display

ActiveUS20090213306A1Easy to displayUnevenness easilyNon-linear opticsLiquid-crystal displayDisplay device

A liquid crystal display includes a liquid crystal display panel having a first substrate, a second substrate disposed on an observer side with respect to the first substrate and opposed to the first substrate, a liquid crystal held between the first substrate and the second substrate, an upper polarizing plate disposed on the observer side with respect to the second substrate, and a resin film disposed on the observer side with respect to the upper polarizing plate and affixed in contact with the upper polarizing plate. The resin film is higher in surface hardness than the upper polarizing plate and has a surface hardness of at least 3H in terms of surface pencil hardness. Each of the first and second substrates have a thickness of no greater than 0.5 mm, and a total thickness of the liquid crystal display panel is no greater than 2 mm.

Owner:PANASONIC INTELLECTUAL PROPERTY CORP OF AMERICA +1

Adhesive resin composition for semiconductor, adhesive film for semiconductor, and dicing die bonding film

ActiveUS20190043748A1Easily burry unevennessImprove reliabilityAdhesive processesNon-macromolecular adhesive additivesEpoxyEquivalent weight

The present invention relates to an adhesive resin composition for a semiconductor, including: a (meth)acrylate-based resin including a (meth)acrylate-based repeating unit containing an epoxy-based functional group and a (meth)acrylate-based repeating unit containing an aromatic functional group, the (meth)acrylate-based resin having a hydroxyl equivalent weight of 0.15 eq / kg or less; a curing agent including a phenol resin having a softening point of 100° C. or higher; and an epoxy resin, wherein the content of a (meth)acrylate-based functional group containing an aromatic functional group in the (meth)acrylate-based resin is 2 to 40% by weight, an adhesive film for a semiconductor including the above adhesive resin composition for a semiconductor, a dicing die bonding film including an adhesive layer including the adhesive film for a semiconductor, and a method for dicing a semiconductor wafer using the dicing die bonding film.

Owner:LG CHEM LTD

Light source device

A light source device comprises a plurality of kinds of light sources having different directivity characteristics and including a first light source and a second light source having a directivity characteristic wider than a directivity characteristic of the first light source; and a diffusing structure section for radiating light emitted by the first light source after diffusing the light, wherein a position of a center of a first brightness distribution of light radiated from the diffusing structure section in a case when the first light source emits light is a position corresponding to a position of a center of a second brightness distribution in a case when the second light source emits light.

Owner:CANON KK

Adhesive resin composition for semiconductor, adhesive film for semiconductor, and dicing die bonding film

ActiveUS10510579B2Improve reliabilityImprove efficiencyAdhesive processesNon-macromolecular adhesive additivesEpoxyEquivalent weight

The present invention relates to an adhesive resin composition for a semiconductor, including: a (meth)acrylate-based resin including a (meth)acrylate-based repeating unit containing an epoxy-based functional group and a (meth)acrylate-based repeating unit containing an aromatic functional group, the (meth)acrylate-based resin having a hydroxyl equivalent weight of 0.15 eq / kg or less; a curing agent including a phenol resin having a softening point of 100° C. or higher; and an epoxy resin, wherein the content of a (meth)acrylate-based functional group containing an aromatic functional group in the (meth)acrylate-based resin is 2 to 40% by weight, an adhesive film for a semiconductor including the above adhesive resin composition for a semiconductor, a dicing die bonding film including an adhesive layer including the adhesive film for a semiconductor, and a method for dicing a semiconductor wafer using the dicing die bonding film.

Owner:LG CHEM LTD

Methods of manufacturing piezoelectric element, liquid ejecting head, and ultrasonic transducer

ActiveUS9682560B2Reduce harmWell formedPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostrictive transducersLiquid jetUltrasonic sensor

A method of manufacturing a piezoelectric element includes a first electrode, a piezoelectric layer, and a second electrode, in which unevenness on one surface of the piezoelectric layer is formed by forming an oxidizable metal layer on the one surface of the piezoelectric layer; aggregating the metal layer by thermal oxidation; and performing isotropic etching on the metal layer aggregated on the one surface of the piezoelectric layer.

Owner:SEIKO EPSON CORP

Optical film and liquid crystal display device

InactiveUS8477275B2Wide viewing angleImprove visibilityNon-linear opticsOptical elementsCelluloseLiquid-crystal display

An optical film contains a cellulose acylate film, and at least two layers of an optically anisotropic layer A and an optically anisotropic layer B, wherein the cellulose acylate film satisfies the specific formulae, Re(548) of the optically anisotropic layer A is from 80 to 190 nm and the slow axis of the optically anisotropic layer A is at 45°±10° with respect to the film conveying direction, and the optically anisotropic layer B satisfies the specific formulae.

Owner:FUJIFILM CORP

Lens device and position detection method of movable optical element

ActiveUS8942553B2Unevenness easilyCause the unevenness of the magnetic signalTelevision system detailsRecord information storagePhase differenceEngineering

A lens device includes a movable optical element, a rotary member; first and second magnetic recording scales fixedly disposed on an outer periphery of the rotary member to extend along a peripheral direction of the rotary member; a signal detecting unit which detects first to fourth signals; and a position detecting unit which detects a position of the movable optical element based on the detected signals, in which the position detecting unit includes: a phase difference calculating unit which calculates a phase difference between the first signal and the third signal, based on the detected first to fourth signals for one cycle; a phase average calculating unit which calculates an average of the phase differences respectively calculated for n cycles; and an absolute position detecting unit which detects an absolute position of the movable optical element based on the calculated average.

Owner:FUJIFILM CORP

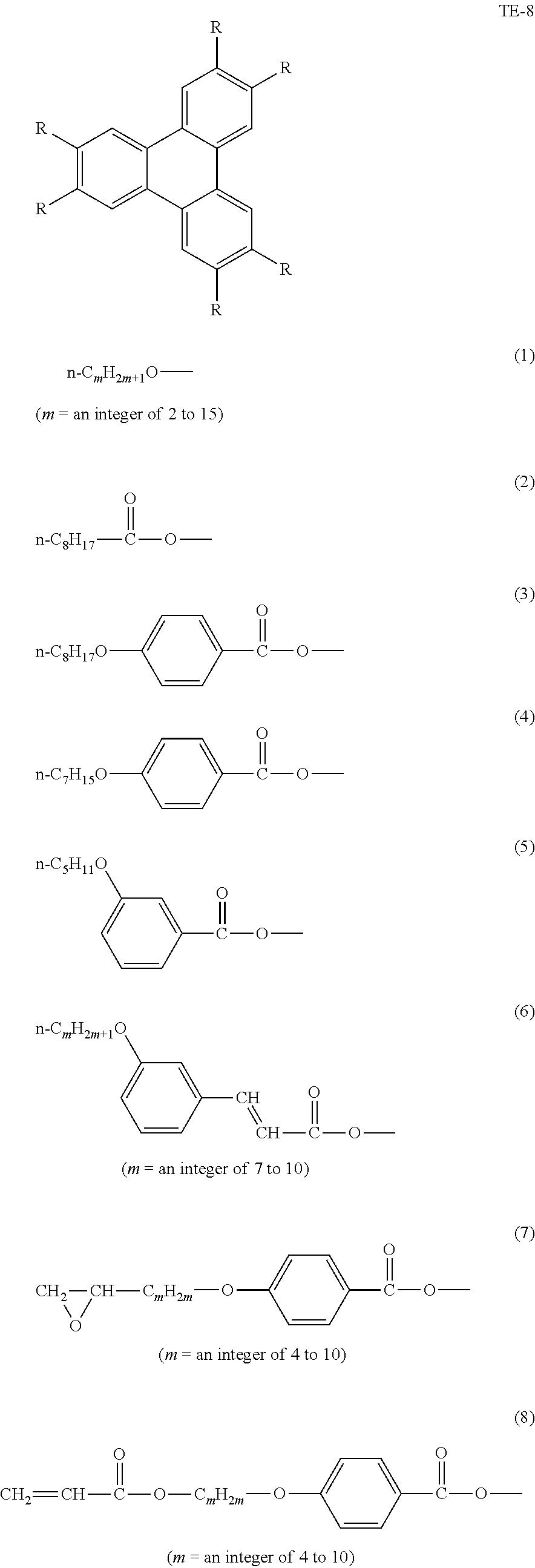

Ink set and image recording method

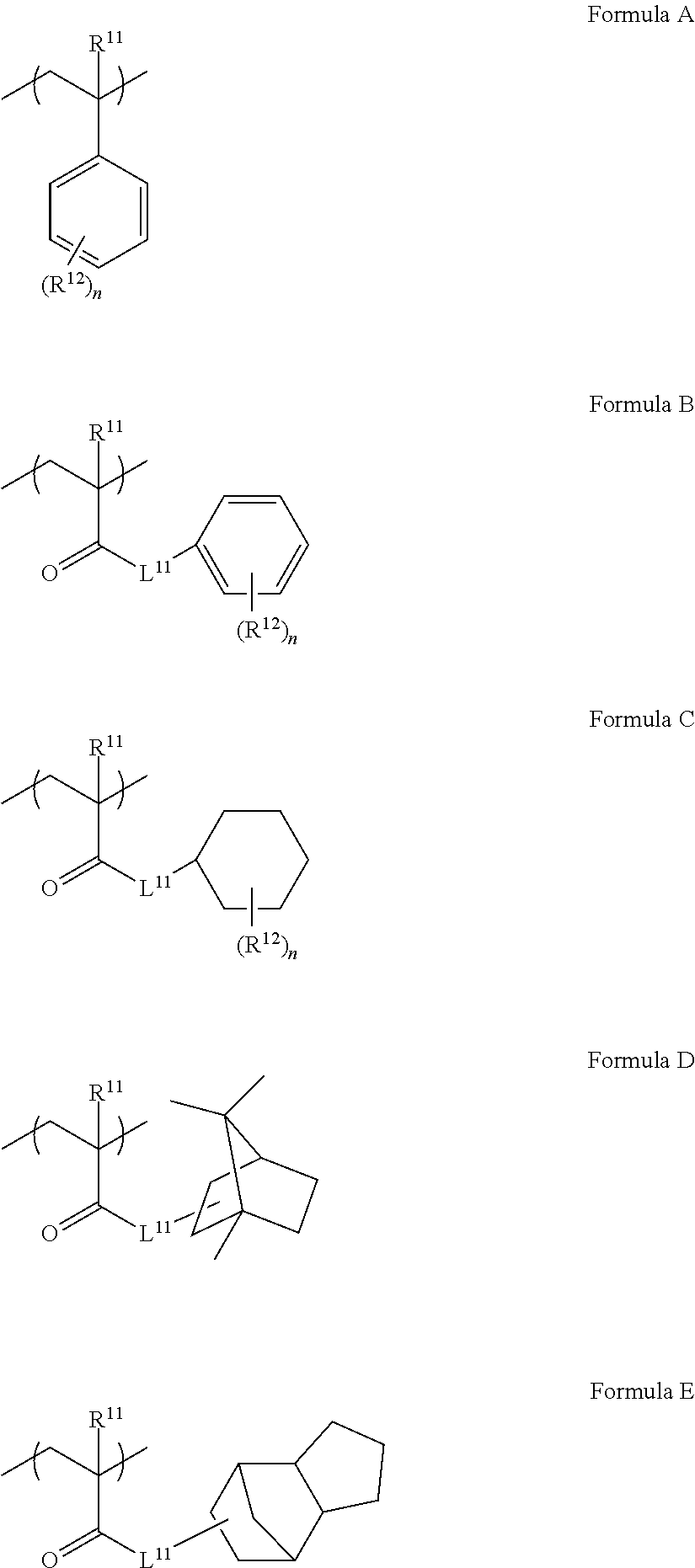

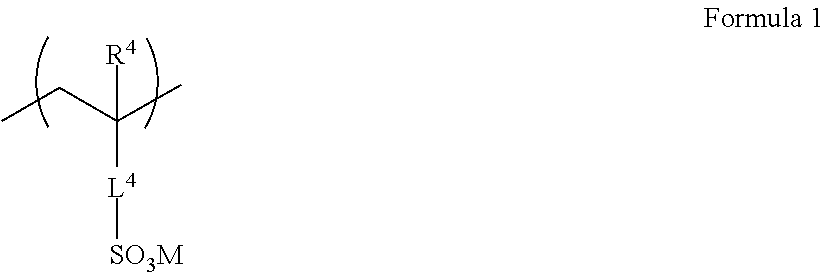

ActiveUS20190010349A1Improve surface wettabilitySuppressing swellingDuplicating/marking methodsInksWater insolubleImage recording

Provided are an ink set including: an ink composition which contains a colorant and water, and a treatment liquid which contains water-insoluble resin particles having a constitutional unit derived from a first monomer that contains at least one group selected from a sulfo group and a salt of the sulfo group and a constitutional unit derived from a second monomer that has at least one structure selected from an aromatic ring structure and an alicyclic structure, a compound that causes the colorant in the ink composition to aggregate, and water; and an image recording method.

Owner:FUJIFILM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com