Thermal bath systems and thermally-conductive particulate thermal bath media and methods

a technology of thermal bath and thermal bath media, applied in the field of thermal instrument bath, can solve the problems of compromising laboratory supplies and equipment, compromising sterile operations, and compromising laboratory personnel, and achieve the effects of constant temperature, optimal shape and size, and maintenance and contamination control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

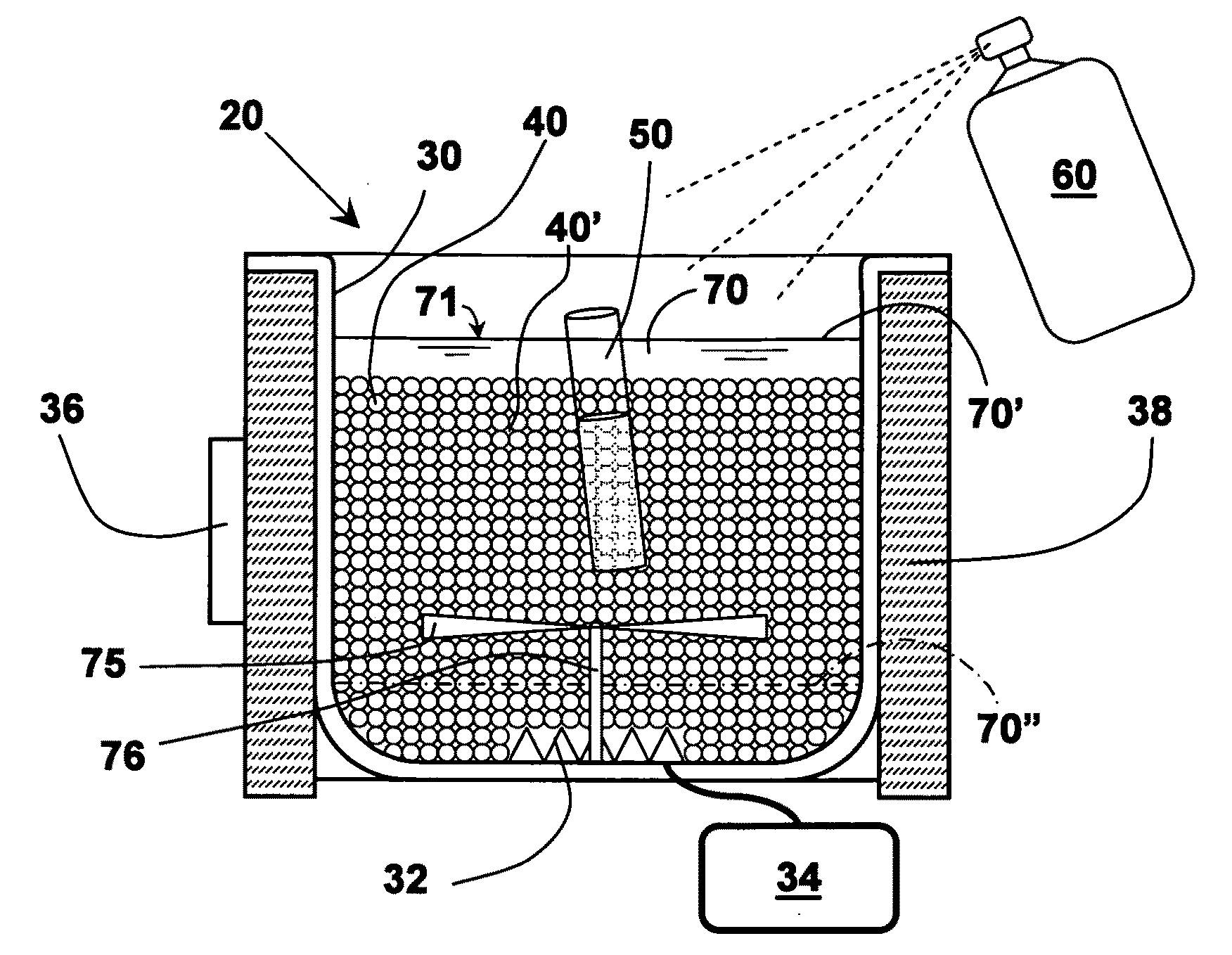

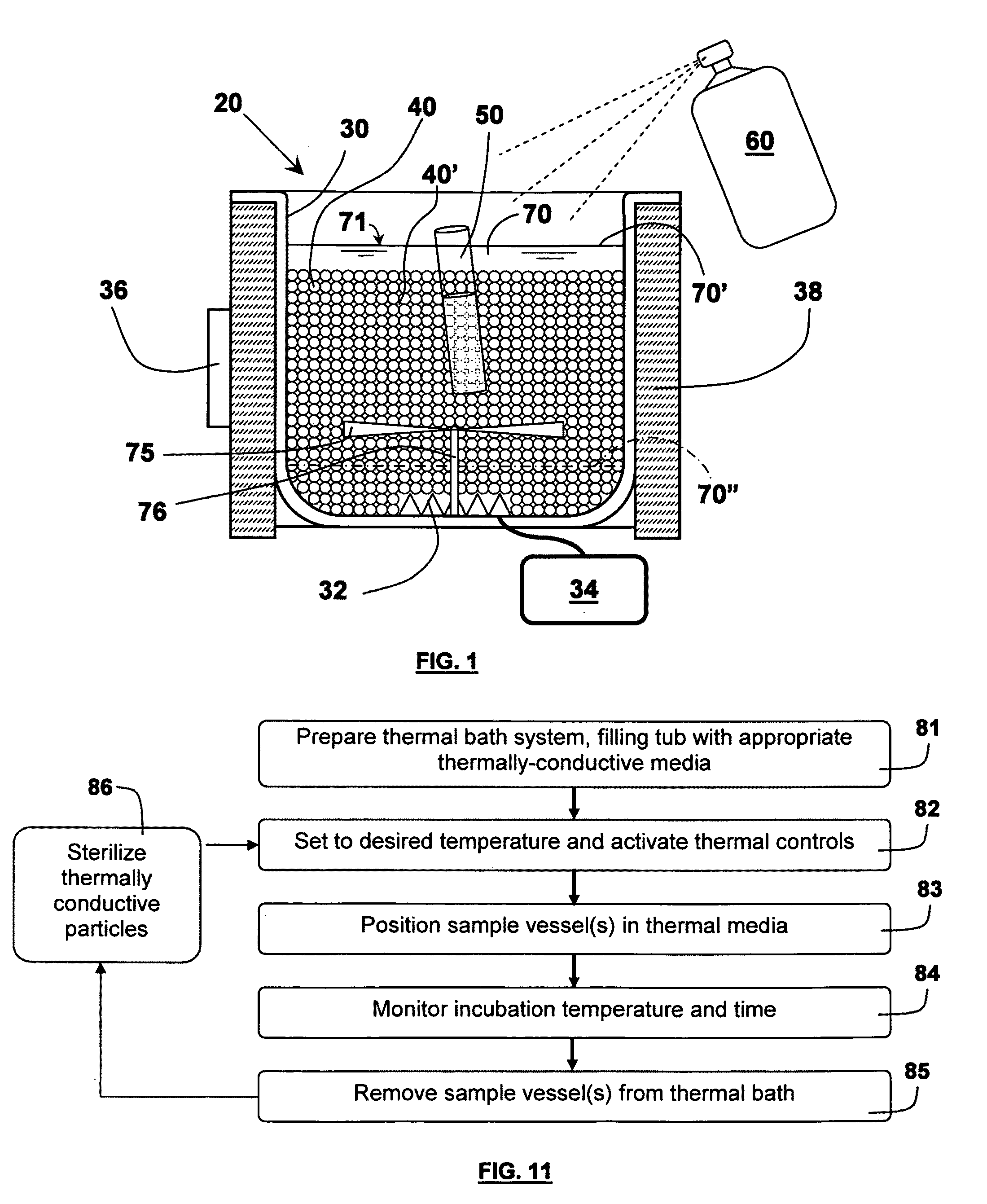

[0025]Referring now to preferred embodiments in more detail, FIG. 1 shows a partially-cross-sectional schematic representation of a thermal bath system (20) according to the teachings of the present invention. On the basic level, laboratory thermal bath system (20) comprises many components similar to those of conventional laboratory thermal bath systems—namely a tub (30), a thermal source (32), power source (34), a temperature control unit (36), and thermal insulation (38). Conventional laboratory thermal baths such as water baths and dry blocks are well-established laboratory instruments for heating or cooling objects, vessels, or samples contained therein, and their uses have become standard practices in the laboratory. Hence, as will be evident to those of ordinary skill in the art, various alternative embodiments of the certain aspects of the present invention can be implemented by use and / or modification of virtually any conventional laboratory thermal bath systems and their c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| thermally-conductive | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com